Professional Documents

Culture Documents

3.2 Notes

3.2 Notes

Uploaded by

jacob thangam0 ratings0% found this document useful (0 votes)

4 views26 pagesOriginal Title

3.2 notes

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views26 pages3.2 Notes

3.2 Notes

Uploaded by

jacob thangamCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 26

Senior Welding Inspector

General Theory (Situations) - QP-S1

‘You are an SWI who has taken over from an SWI who has been on site for a few months.

It becomes obvious that there is a complete lack of morale amongst your inspectors but

they do not approach you to discuss any grievance. What would be your approach to the

situation?

‘You are an SWI responsible for a team of welding inspectors who have been on-site for

{wo months. “A welding inspector who has been on site for only one week informs you

that the contractor has approached him with an offer of money in return for “turning a

blind eye" when certain welding work is being performed. Discuss your possible course

of action,

You are the SWI working on behalf of a client on project to build an offshore platform.

You discover that one of the welding inspectors, supplied from a different agency, who

has been on the site for one week, does not hold a valid welding inspector approval.

State the actions that you would take.

You are the SWI on a pipeline project. The radiographic interpreter informs you that he

believes that the same weld has been radiographed with different weld numbers on a

snumber of occasions and the radiographs have been submitted. What action do you take?

‘You are the SWI who is required to visita factory where a number of pressure vessels

have just been manufactured and inspected by your inspection team. The client requires

the vessels to be signed off by you What questions do you ask, what information do

you require and what random checks (if any) do you make before signing off?

You visit a fabrication company as an SWI on behalf of a client and you discover in a

welder's electrode quiver a number of incorrect electrodes among the correct ones which

are very different to those specified for the item being welded. The welder states that he

only uses the correct electrodes. State your course of action.

Fracture Surface Assessment Report Form

vel

af. pieceno5

The win features of the ounce Sagat

ame on feller do He Weel

— v wv ‘

- , ee potone, ov Susutaly OPE NT, votives

o B

C2 Chesson marly +

np = metadlorgea Seqeigations .

ska faochue amt imitated Lon point #

Gin a brittle. momen +o the rok de

Ta ae pig 9 Seley oie de dan

a pouttle a sel eneeel ee a

7p? ea . ak .

doves fs daberh Gems) - polosad antes

Feilon occssed 4m ind

oe ward ayo 0 metol Y

D’

Name: Dota Sanlay

Date: o5-(2-2006

/

Signature: Aaa of 4 4

/

/

wes

/ ' ..

‘ KE eg 3

Sah 2

M y

b ;

did Samp. keb- 3

7 The appesisanCe af Ika fon

“ 4 » Stestted ak

mito cto oy cot f Letline &

ape fle daa te TS pnt ob

foal of Steps in te Gomdine og the matewel

ak pani’ -g The Seton a

ae et Aan hoon nis at ponte

Abs Sen at paint taka Couey

»

6)

#)

Fracture Surface Assessment Report Form

Fracts, wmtated ot doe ab Ke Lilet were

Mot ewidewed amy jprerenge at defects “im Perwmk- matosal

Posmenty mmede of fortune 4 aude

Secovdny medeof foitire in Bottle

Name:

Date:

Signature:

Feilane ocomed im hem ty toe qty board ond

Pook materot ay

Alan © : =. doe of te wold f

ST ae th Te yh hanged

Deca. Sambar

©2- 12-2006

235tay_

Fraction Inhaled feom Toe of te Gut wady

tet eniclanted das pretence a drmny deLeckes lon Rerant—

moecoh,

Fobpwe To te Besnnouny onde hf os han

Decehe Losckuoe ae the Sacontoy mode hd tang

Sen Ye toe werd ancl paront

Foden mg eated dsvomn — vratenah

cas ocuned dee te fobgon cuidonee rowing.

dasha forackine . _-

en

rae) <= ny

phen

~

Fracture Surface Assessment Report Form

pj —r shear Laps,

5 > Bought cortaline Stourctine

CP NOLO

(eg > wed

The foacline Gabiabed ak poss (C bhin 4a

Teton The panmony anode eidiune 4 raliges Spacion

daa ke We Gertnta ay bes Ones oxen e

- aA:

Loackine, inte fh ofesnania oS PB

bsayhh yet nn

a bpa ak pa A.

Tee data ocosted Sn pron metal

Lam He toe of Be ean

Name: Decl. Somban no dekecdy an tke parent rockers

Date: 0.3) (2/2006 Ret

nwo

Signature: A3¢{00q

Senior Welding Inspector

General Theory (Situations) - QP-S1

You are an SWI who has taken over from an SWI who has been on site for a few months

It becomes obvious that there is a complete lack of morale amongst your inspectors but

they do not approach you to discuss any grievance. What would be your approach to the

situation?

You are an SW! responsible for a team of welding inspectors who have been on-site for

{wo months. A welding inspector who has been on site for only one week informs you

that the contractor has approached him with an offer of money in return for “turning a

blind eye" when certain welding work is being performed, Discuss your possible course

of action.

You are the SW1 working on behalf of a client on project to build an offshore platform.

‘You discover that one of the welding inspectors, supplied from a different agency, who

has been on the site for one week, does not hold a valid welding inspector approval

State the actions that you would take

‘You are the SWI on a pipeline project. ‘The radiographic interpreter informs you that he

believes that the same weld has been radiographed with different weld numbers on a

number of occasions and the radiographs have been submitted. What action do you take?

You are the SWI who is required to visit a factory where a number of pressure vessels

hhave just been manufactured and inspected by your inspection team, The clieit requires

the vessels to be signed off by you What questions do you ask, what information do

you require and what random checks (if any) do you make before signing off?

You visit a fabrication company as an SWI on behalf of a client and you discover in a

welder's electrode quiver a number of incorrect electrodes among the correct ones which

axe very different to those specified for the item being welded. The welder states that he

only uses the correct electrodes. State your course of action.

snesca

aa

ei

soma

#8

{ Bane eb SIM

way G

Dies acy Supa

/

SA: “Ss! Symbol 4 nk Meron on Bancts Ade rot

a, wand

Ls:

Tarosmeck Syorbl Ler Sprbedih washing on bere ide Wud AL opund Sh va

4c Siymatenced wad Anewd be heum egucd (oy Ung thy vv cpa ae Prick. ney

LoD: Rake werd Mace eevee ake mh, — Sir Ka

Se: Merrrored 2% “im 3 Pltay % Showul be hou yp”

VF: Fo mm wed Length con aot be Antted a} Chonnek Homye caide ZA ony

Q@: 12mm

40mm

thasc Tacky gel parnbia ‘eg plate. Heck hy, Bx ony (om

Met Real Hackney Comm wh Poet, wa Gy Augie bho be

Bi Vmm encet Made and 24 ann onal

I! a HY GOmm .

Ne red te theres Dotted Sedna rs ARO wad

aAkstoomd and LD Aypnetox cout,

MaIA INO

SoU aUpp I IAM LAIOOF

ssouy URL] PH

oi (0 woystsoy) 7 # astoaaxg Bupnesg

—— —> Buruyeay OL SIM

Doed sedernce on oniftes| , (onm gy Gough om ayeow Ade

estentetion ab fe Lit wed Sywib rah Cored

Pemm Gallet leg dng fate om wade)

Sage re) poteat pevakrotion courk . tot thewd Pametzon aS’

cet gum on dhe wade Cin ede hte Bw) Bw phe

Preckcall, im 200 Pf PRE

Debel sakronee. Lene omitted. Sagte Tt rove wud Bocca

Pendrvreten for wen ciymemre eon wk Fru | tab werd om

“Jowed walk LO mm) Bie TR te bonded Forel,

Fred Ward carte mm ie An rde Caradr of BRA) 7

SS3c eh Aege (VI mh Bum, Gooencl Asratt Co

MIG, nardoy pom:

Cox mm Length owed spamag

lomm 4EUek an aromade 5 wade

um ov thgeodd bu

onal } wm Gl 2) wud’

u 63? weds te be -Rhappe

Spang EX 2

* path 6S mom oy and

“e]youd xeauog

“WUIDp PIOM Ydee UseMyeq eoUR;sS{p EYL

“WIUSZ PleMm Ydee Jo y:BuE] oy

“SPIEM ye]

WeH!UWJe3U! ‘sseUyd]43 JeOsYy WG ‘easy

“S3dIS HLOG G3013aM 2%

“sseooud Bulpiem WWW

“Aiyjoows pepuelq eq 07 seo,

“PIeM 39114 4yBue] 6a; wg ‘snonuguos y

"SIS MOMNY G307aM ‘+

See SEE—EEEEeoeeees

L

3Sldeaxs ‘SATSM IAT id €SSzz2 Na Sa

3. WELDED ARROW SIDE.

Three, 10mm leg length, Intermittent fillet welds.

The length of each weld 40mm.

The distance between each weld 30mm.

WELDED OTHER SIDE.

Three, 5mm throat thickness, intermittent fillet welds.

The length of each weld 50mm.

The distance between each weld 25mm.

Welds to be staggered.

4. WELDED ARROW SIDE.

Four, 7mm throat thickness, intermittent fillet welds.

The length of each weld 25mm.

The distance between each weld 50mm.

WELDED OTHER SIDE.

Two, 8mm leg length, intermittent fillet welds.

The length of each weld 50mm

The distance between each weld 30mm.

Welds to be staggered.

Welding process MAG.

“sseooid Buipjem QYW

“ej youd pjem je} 4

“PIE WNg / e[buIs

"3GIS Y3HLO G307aM ‘Z

“sseooud Bulpjem OL,

e]yord pyem 3214

? “dias Bupjoeq yueueweg

7\ “PIeEM HNg 88, e/BuIg

_— “"30IS MOWNY G3073M “+

@ ASIDYNSXS “SO TAM LING “€SSzz Na Sa

3. WELDED ARROW SIDE.

Single Vee butt weld.

Depth of penetration 10mm.

WELDED OTHER SIDE.

Backing/sealing run.

Plate thickness 15mm.

=

|. WELDED ARROW SIDE.

Single J bevel butt weld.

Depth of penetration 12mm.

8mm leg length fillet weld superimposed.

Plate thickness 15mm.

WELDED OTHER SIDE.

12mm leg length fillet weld.

Fracture Surface Assessment Report Form

Time allowed: 1 hour for two samples.

Instructions:

1. Sketch the fracture surface.

2. Indicate fracture initiation points (if known).

. Show any weld/parent material defects present.

w

4, Identify primary mode of failure.

5. Identify secondary mode of failure.

6. State whether failure occurred in the weld, parent material or

both.

7. Write a conclusion to summarise, provide reasons for/evidence

to support your findings.

8, Sign and date your report.

Assessment

Presentation: 6 marks,

Sketch: 8 marks.

Identification of primary mode of failure: 20 marks,

Identification of secondary mode of. failure: 16 marks,

Total marks possible from one sample: 50 marks

SENIOR WELDING INSPECTOR

AMERICAN WELDING SOCIETY

STANDARD WELDING SYMBOLS*

elding Symbols and Tele Locate

secaton | rust S501

m8 Pane

sloniscmce | "| ore

mian\

OY te Sea se, AN

TwI

fl

‘THE WELDING INSTITUTE

Certification Scheme for Welding and Inspection Personnel

Phase 6: Senior Welding Inspectors and Welding Inspectors

Codes, Standards and Specifications

The following is a list of Codes/Standards and Specifications to which

candidates for the above examinations may use. They may be selected by the

candidate or the candidate's employer.

) The candidate is required to have a good working knowledge of his/her chosen

Code/Standard or Specification. In addition, they should also be aware and in

possession of any such specifications that may be cross referenced by their

main application Code/Standard, relating to Materials, Consumables, Welding

procedure/Welder qualifications, destructive and non destructive testing etc.

The candidate should ensure that the selected code, Standard/Specification is

up to date, and wherever possible contains the latest amendments.

The use of any document not listed, may be permitted by contacting the

Approvals Examiner responsible. In certain circumstances a copy for

scrutinising may be requested before permission is given.

To be accepted for examination, candidates for Welding Inspector must have

had at least three years experience related to the duties required, under

qualified supervision.

Candidates need to be in satisfactory physical condition and the person

completing the application form will be required to signify that the candidate's

health and eyesight are adequate to enable him to carry out his duties.

WELDING TECHNOLOGY

Issue 0191

TwI

CT

British

BS 1113

BS 2633

BS 2654

BS 2971

BS 3351

BS 4515

BS 4677

BS 5500

BS 6235

THE WELDING INSTITUTE

Specification for design and manufacture of Water-tube

steam Generating Plant (including superheaters, reheaters

and steel tube economies).

Specification for Class 1 arc welding of ferritic steel pipework

for carrying fluids.

Specification for manufacture of vertical steel welded storage

tanks with butt-welded shells for the petroleum industry.

Specification for Class Il arc welding of carbon steel

pipework for carrying fluids.

Specification for piping systems for petroleum refineries and

petro-chemical plants.

Specification for process of welding of steel pipelines on land

and offshore.

Specification for arc welding of austenitic stainless steel pipe

work for carrying fluids.

Specification for unfired fusion welded pressure vessel,

Code of practice for fixed offshore structures.

WELDING TECHNOLOGY

Issue 0191

CSWIP SENIOR WELDING INSPECTOR

TECHNOLOGY PAPER 5 FROM 7 QUESTIONS

MANDATORY QUESTION: “SIGNING OFF OF A PRODUCT" +

SUPERVISORY PART

1 HR 15 MINUTES

ENGINEERING DRAWINGS: SCRUTINY OF WELD SYMBOLS

1HR.

FRACTURE ASSESSMENT REPORTING ON TWO FRACTURES AND THEIR

PROBABLE CAUSE(S) OF FAILURE

1 HR.

NDT REPORTS: 3 NDT REPORTS FOR SCRUTINY

1 HR.

ALSO REQUIRED:

RADIOGRAPHIC INTERPRETER

PRACTICAL AND THEORY

TWI

aT

American

ANSI/ASME 831-3:

API 1104:

ASME VIII division 1:

ANSI/AWS DI:

ABS

THE WELDING INSTITUTE

Chemical plant and petroleum refinery piping.

Standard for welding pipelines and related facilities

(16th Edition).

Boiler and Pressure vessel code.

Structural Welding Code (Steel)

Rules for Building and Classing Steel vessels

(American Bureau of Shipping). @

In addition the following are permissible:

AESS 6021:

Parts 1 and 2

NF 0081/1&2:

Fusion welded fabrication in Austenitic Stainless steel.

NF Standard, Fabrication of stainless steel

British Engineering Standard BGC/PS/P2 1981. Specification for field welding

of steel pipelines and installations.

MOD/NAVY

Det Norske Veritas:

WELDING TECHNOLOGY

Issue 0191

DGS-NAS3 Acceptable standard for welds

DGS - GS - 3003 General Welding Specification

Rules for the design, construction and Inspection of @

offshore structures.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Taxi ReceiptDocument17 pagesTaxi ReceiptPraveen KumarNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Valve Assurance FrameworkDocument15 pagesValve Assurance FrameworkPraveen KumarNo ratings yet

- Retail Invoice / Bill: Your Total Savings: Rs.23.39Document1 pageRetail Invoice / Bill: Your Total Savings: Rs.23.39Praveen KumarNo ratings yet

- 003 - PTS - Pipeline Welding - Rev 0Document38 pages003 - PTS - Pipeline Welding - Rev 0Praveen KumarNo ratings yet

- Original For Recipient Duplicate For Transporter Triplicate For SupplierDocument1 pageOriginal For Recipient Duplicate For Transporter Triplicate For SupplierPraveen KumarNo ratings yet

- UHB Problem PDFDocument1 pageUHB Problem PDFPraveen KumarNo ratings yet

- Rev - SoR For River Crossing Pune GA - 20.05.2020Document5 pagesRev - SoR For River Crossing Pune GA - 20.05.2020Praveen KumarNo ratings yet

- Fixed Asset Register As On 31.3.20Document14 pagesFixed Asset Register As On 31.3.20Praveen KumarNo ratings yet

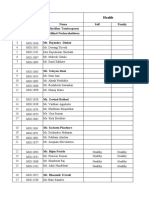

- Employee Details - HealthDocument10 pagesEmployee Details - HealthPraveen KumarNo ratings yet

- Updated Catch-Up Plan For Steel Laying (20-21)Document7 pagesUpdated Catch-Up Plan For Steel Laying (20-21)Praveen KumarNo ratings yet

- Work From Anywhere Using Teams - SOPDocument53 pagesWork From Anywhere Using Teams - SOPPraveen Kumar100% (1)

- Onlinejyotish NewbornDocument7 pagesOnlinejyotish NewbornPraveen KumarNo ratings yet

- ASME IX 2019 Key Changes PDFDocument4 pagesASME IX 2019 Key Changes PDFPraveen KumarNo ratings yet

- Approval Note - JategaonDocument1 pageApproval Note - JategaonPraveen KumarNo ratings yet