Professional Documents

Culture Documents

An Experimental Study of Air-Entraining Vortices

Uploaded by

Bharath kumarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

An Experimental Study of Air-Entraining Vortices

Uploaded by

Bharath kumarCopyright:

Available Formats

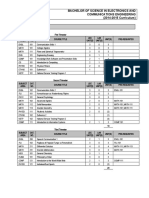

106

AN EXPERIMENTAL STUDY OF AIR-ENTRAINING VORTICES

IN PUMP SUMPS

By D. F. Denny, B.Sc. (Eng.), Ph.D. (Associate Member)*

The factors affecting the formation of air-entraining vortices in sumps are enumerated,

and their relative importance assessed from experimentswith a number of different sumps.

It is established that vortices are caused by rotation of the mass of water within the sump

arising primarily from the entry conditions. Their severity, measured in terms of the

minimum safe submergence to avoid air entrainment was also found to depend greatly

on the velocity in the suction inlet; air entrainment rarely occurred below a velocity of

2 ft. per sec., and above 15 or 20 ft. per sec. the severity of the vortices did not increase

substantially.

The shape and disposition of the suction inlet only slightly affected the vortices,

but sump boundaries were found to reduce appreciably the tendency for vortex formation

when closer than 8 diameters to the suction pipe: with the walls very close to the pipe,

vortices did not occur. Small sumps may thus be more satisfactory than spacious ones.

Tests with scale models of existing or proposed pump installations are described, and

for one sump, where vortices formed within the working range, it is demonstrated that

suitably placed boundary walls would be considerablymore effective in preventing vortices

than modifications to the suction inlets.

Measurements of the quantity of air drawn into the pump through a vortex showed that

air entrainment of this type could seriously impair pump performance. Severe vortices

could lead to depriming of pumps operating with suction lift.

INTRODUCTION contradictory. It is well known that air-entraining vortices

IT IS GENERALLY ACCEPTED that the performance of a pump can be avoided by allowing sufficient submergence of the

can be greatly affected by the design of sump from which inlet below the water surface, but reliable means of esti-

it draws water. For instance Stepanoff (1948)t and Fraser mating minimum safe submergence do not yet exist.

(1953) both quote instances in which pumps overloaded or Stepanoff (1948) claimed that a submergence of 5 feet on the

ran roughly because of faulty sump design. suction bell edge was sficient, but that with low velocities

There are two aspects to this problem. Firstly, swirl in in the inlet (2-3 ft. per sec.) a submergence of half a dia-

the sump leads to rotation of the water in the suction pipe, meter was safe. Richardson (1941) also recommended a

which may impair the performance of the pump, and this is submergence based on inlet velocities.

particularly important with axial-flow pumps and high- More recently, Iversen (1953) has published results of

specific-speed centrifugal pumps. Secondly, severe swirl model experiments showing the effect of sump boundaries

sometimesleads to a fully-developed vortex having a hollow and bottom clearances on minimum safe submergence of

core through which air is drawn into the suction-inlet. the inlet, but these investigations did not include the in-

Apart from the effect of the air itself, which tends to lower fluence of inlet velocities or of sump shape.

the delivery of the pump, such vortices are unstable and give Regarding the cause of vortices, Addison (1948) men-

rise to unsteady swirl flows in .the pipe, and to fluctuating tions that swirl round comers or obstructions may set up

loads on the pump bearings. This paper is confined in scope vortex-forming conditions. Stepanoff (1948), on the other

to consideration of the factors affecting air entrainment hand, states that all vortices originate in the impeller, which

through vortices, and its effect on pump performance. is certainly not always true as pre-rotation does not travel

Published information on the subject is somewhat far upstream at normal pump deliveries. Iversen (1953)

The M S . of this paper was received at the Institution on 18th M a y

seems nearer the truth when he says ‘while this effect (pre-

1955. Far a report of the meeting, in Lona’on, on 4th November rotation of the fluid entering the suction-bell as a result of

1955, at which this paper was presented, seep. 126. impeller action) is undoubtedly present, the major influence

* Research Engineer, British Hydromechanics Research Association, stems ...

from the sump design and the flow pattern in the

Harlow, Essex.

t A n alphabetical list of references is given in the Appendix. sump’.

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 12, 2016

AIR-ENTRAINING VORTICES I N PUMP SUMPS 107

In 1950 a programme of research on this subject was by small waves. Flow of air through the core was inaudible

started at the British HydromechanicsResearch Association except with very high water velocities.

(B.H.R.A.). This paper is based on the results of that work When the mouth of the pipe was less deeply submerged

which included a study both of experimental models and the vortex formed much closer to the pipe and tended to be

of full-scale pump installations. less stable (Fig. 23b). It rarelyremained in the same position

for long, usually revolving slowly round the pipe and then

Notation disappearing; during this time another vortex would have

formed at the original point and that one would begin to

C Clearance between suction-inlet and sump floor. entrain air as soon as the previous one had disappeared.

d Internal diameter of suction pipe. Only rarely did two vortices entrain air simultaneously.

h Depth of water in sump.

1 Length of approach channel to sump.

Q Total flow through sump.

S Submergence of suction-inlet (depth of water covering

the inlet).

V Velocity of water in suction pipe.

W Width of approach channel to sump.

X Clearance between suction pipe and sump wall, mea-

sured from the centre-line of the pipe.

EXPERIMENTAL A P P A R A T U S

Several model sumps ranging in width from 3 to 8 feet were

used in these experiments. In each, the water was with-

drawn through the suction-inlet by a pump, the flow rate

4'

being measured by weir or orifice plate, and then returned

to the sump through suitable straightening guides and

screens. In method of construction the models varied con-

siderably as shown in Fig. 21, Plate 1. The suction pipes

were usually flexible and of sufficient length (some were

4Q pipe-diameters) to exclude any effects of pre-rotation

due to the impeller; they ranged in diameter from 4 inch to

30 inches. Suitable bellmouths or conical inlets were fitted Fig. 22. Stages in Development of an

as necessary. The quantity of air entering the suction Air-entraining Vortex

through the vortex was measured after separation from the

water and reduction to atmospheric volume. With very small submergences the vortex frequently

Sumps in practice are more often designed from con- became concentric with the pipe as shown in Fig. 23c, when

siderations of site layout than of hydraulics, and thus tend the drawdown around the periphery of the pipe allowed

to take very diverse forms. For this reason a preliminary air to enter the inlet. Air entrainment of this type was

study of very simple layouts seemed necessary, and, accord- always accompanied by considerable noise.

ingly, the first experiments were made with a vertical suc- It soon became apparent that there was no precise

tion pipe mounted above the centre of a sump 8 feet square boundary between vortex-forming and vortex-free con-

(Fig. 21a). ditions. In the critical region, development of an air core

seemed to be largely a matter of time and chance. Instead,

EXPERIMENTAL R E S U L T S therefore, of adjusting either water level or flow until it was

estimated that the vortex did or did not entrain air, the

Description of Air-entraining Vortices method adopted was to plot on a graph, relating water-depth

When the suction-inlet was well covered with water the to flow, a large number of both vortex-forming and vortex-

vortex appeared first as a small dimple in the free surface, free conditions. The criterion used was whether under

Fig. 22a, which gradually deepened to form a cone-shaped steady conditions any air from the free surface of the water

hole; air bubbles broke away from time to time and were in the sump entered the suction pipe, either continuously or

swept into the bellmouth (Fig. 224. With steady flows this intermittently, through the agency of the vortex. This pro-

condition appeared to be quite stable and often persisted cedure resulted in a diagram such as that shown in Fig. 24.

for long periods. At high velocities the air-core lengthened Between these points a line enveloping the vortex region

to reach the suction-inlet and allowed continuous passage could be drawn, and usually 30 or 40 points were sufficient

of air up the pipe (Fig. 22e). Such a vortex was located some to locate such an envelope with reasonable accuracy. This

distance from the pipe, as shown in Fig. 23a, Plate 2; it was method of recording often disclosed small vortex-free

very stable and soon reformed if disturbed; its core rotated pockets within the main vortex region, but these generally

at great speed and the internal free surface was corrugated occurred haphazardly and did not appear to be important.

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 12, 2016

108 D. F. DENNY

10

the rate of air flow. It is thus possible for the pump delivery

to fluctuate slowly between wide limits, the vortex con-

tinually changing in severity as a result.

8 Examination of the flow in the suction pipe showed that

the water was spirallingowing to the swirl in the sump, even

k! in the absence of air entrainment, and that the angle of the

$6 spiral increased with increased severity of the vortex. In

I

Y

0. some instances the circumferential velocity of the water at

&

z the wall of the pipe exceeded the axial velocity. This aspect

s4 is of considerable importance, and will be dealt with at

9

Y greater length in a later paper.

2 Effect of Swirl in the Sump

With the suction pipe fixed in the centre of the sump,

I I In experiments were made with different amounts of swirl, this

0 1.5 50 75 - being produced by forcing the water to enter the sump

WATER DEPTH-INCHES

through only part of its width, Results for a 4-inch bell-

Fig. 24. Typical Plot of Vortex Data mouthed pipe are shown in Fig. 26 where the envelopes of

Variation of critical water depth with flow, for 8-inch bellmouthed

suction pipe in an 8-foot sump.

W-FEET 8

c/d = 0.9.

o Existence of air-entraining vortices.

0 Absence of vortices.

The proportion of air in the water entering the suction

pipe increased with decrease of submergence, from zero at

the critical depth to as much as 10 or 15 per cent (true

volume ratio) with very small submergences, .although in

the transition from the local vortex to the concentric vortex

the air flow temporarily diminished considerably. Typical

air-flow measurementsare given in Fig. 25. The significance

of these quantities can be judged from the fact that 1 per

cent of free air may reduce the efficiency of a centrifugal

pump by between 5 and 15 per cent (Denny 1953, Siebrecht

1930). Most low or medium specific-speed centrifugal

pumps operating under suction lift conditions will deprime

with less than 10 per cent of air entering the suction.

Appreciable decrease in pump delivery due to air in the

suction usually reduces the severity of the vortex and also

1

10 15 0

SUBMERGENCE s/d

Fig. 26. Effect of Swirl on the Relation between Critical

Submergence and Suction Velocity

cld=l.

air-entraining conditions are plotted; test points have been

omitted. The swirl resulting in most severe vortices oc-

curred when the water entered through approximately half

the width of the sump, and under these conditions a sub-

mergence exceeding 15 pipe-diameters was necessary to

2 3 4 prevent air entrainment at high flows. With water entering

SUBMERGENCE s/d over the whole width of the sump, however, a submergence

Fig. 25. Variatiun of Air-water Ratio with Submergence of 33 diameters was sufficient. Thus a fourfold change in

---- 5 ft. per sec.

critical submergence was effected by simple changes in

15 ft. per sec. width of the idowing stream of water.

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 12, 2016

AIR-ENTRAINING VORTICES IN PUMP SUMPS Plate 1

[I.Mech.E., 19561

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 12, 2016

Plate 2 D. F. DENNY

FQ. 23. Vortex Configurations with Different Submergences

[l.Mech.E., 19561

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 12, 2016

AIR-ENTRAINING VORTICES IN PUMP SUMPS 109

Although there is no doubt that these vortices originated

in the swirl within the sump, the swirl merely initiated a

local free vortex of suffcient strength to form a deep depres-

sion in the water surface, and a strong downward flow

towards the suction inlet in the neighbourhood of the dimple

was also necessary before the vortex could develop fully and

entrain air. In other words, the swirl did not have to be

strong enough to form, of its own accord, a vortex depres-

sion extending to the depth of the inlet. Many dimples

often occurred simultaneouslyin the sump but only the one

near a strong downward current ever developed into a full

vortex.

Effect of Shape of Suction Inlet

With a I+-inch suction pipe in the centre of a 2-foot sump,

limiting air-entraining conditions were determined for

various shapes of inlet.

Bellmouths and Conical Inlets. Bellmouths having a bell-

radius of less than d/2 were found to have no effect on vortex

formation. This appeared to be due to a somewhat for- i

tuitous cancelling out of two effects, namely, the reduced 0

0 0.5 0

inlet velocity and the tendency of the bell-skirt to hold the WATER DEPTH-FEET.

vortices away from the pipe wall. At the other extreme,

slightly conical inlets with an included angle of less than Fk. 28. Effect of Radial Suction Inlet on Relation

30 deg. behaved similarly to a pipe of the same diameter as between Critical Depth and Flow

the base of the cone. Large-radius bellmouths and obtuse- Suction pipe located centrally in 2-foot square sump.

angled cones gave results as illustrated in Fig. 27. W=8 inches. c=2.25 inches.

Radial Inlets. Three radial inlets, two fitted with per-

forated plates around the periphery, and all having a real

flow area equivalent to a 3-inch diameter pipe were com-

pared in the same sump. The radial inlet C, gave almost the

same results as the straight pipe (Fig. 28), but the strainers

both produced less severe vortices, owing to the fact that

the holes around the periphery prevented the air-core of the

INLET DETAILS

SUBMERGENCE r / d

0 0.5 1.0

WATER DEPTH-FEET Fig.29. Effect of Horizontal and Inverted Suction Inlets on

Fig.27. Effect of Conical and Bellmouthed Suction Inlets Relation between Critical Submergence and Suction

on Relation between Critical Depth and Flow Velocity

Suction pipe located centrally in 2-foot square sump. Sump 2 feet square.

W=8 inches. c-2.9 inches. W=19 inches. d=1-2 inches.

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 12, 2016

110 D. F. DENNY

vortex from entering the pipe. Near the critical conditions

there often existed a strong vortex whose air-core ended

abruptly at the strainer perforations. In practice it would

be unwise to rely on this effect without knowing the maxi-

mum size of hole that can ‘filter out’ the air.

Horizontal and Inverted Inlets. A straight pipe 1.2 inches

in diameter was tested with its inlet in different planes and

facing in different directions. Fig. 29 shows that the differ-

ences in vortex-forming tendency were mostly slight. The

inverted inlet behaved differently only at low velocities,

where vortices formed rather more easily than with the

conventional pipe arrangement. With the upstream-facing

inlet the vortices were disturbed by the presence of the pipe

in the place where they usually formed and so tended to be

less severe. The downstream-facing inlet, on the other

hand, substantially facilitated vortex formation by in-

tensrfying the downward currents responsible for entraining

air from the free surface. 0 5 10

Subsequent experiments with other sump arrangements BOTTOM CLEARANCE c / d

suggested that the actual direction of the horizontal pipe

inlet was not so important as the direction relative to the Fig. 31. Relation between Bottom Clearance and (i) Critical

vortex zone in the sump, since vortices tended to form more Water Depth, (ii) Critical Submergence, from Data

readily with the inlet facing the area where vortices were Given in Fig. 30

prone to form and less easily when facing away from this V=10 ft. per sec.

area.

Effect of Sump Boundaries Wall Clearance. When the suction pipe was moved

about the sump it was found that the strength of the vortices

Bottom Clearance. Experiments were made in the 8-foot varied greatly from place to place. For several sump ar-

sump with & of the inlet width obstructed and with the rangements the whole area was mapped by moving the

4-inch pipe mounted centrally at different distances from suction pipe into different positions, the critical depth of

the sump floor. The envelopes of air-entraining conditions water for a given velocity being recorded at each position.

for bottom clearances varying from 1.75 to 11.5 pipe dia- From these results contours of equal critical depth were

meters are shown in Fig. 30a. It is clear that as the bell- drawn as in Figs. 32 and 33.

mouth is raised from the floor the critical submergence The vortices assumed various positions relative to the

decreases, although as Fig. 31 shows, the actual water depth suction pipe, but in each case they were strongest with the

increases considerably. Further experiments were then pipe near the centre of the sump and weakest with the pipe

carried out with a $-inch pipe in a 2-foot sump of the same

near the walls; the small sumps were better than the large

shape, and precisely similar results were obtained (Fig. 30b). ones.

Changes in bottom clearance seem to modify the value of s Another aspect of the same effect is to be found in the

in a given ratio which does not vary with velocity. relative improvement in vortex conditions as the suction

BOTTOM CLEARANCE c / d BOTTOM CLEARANCE c/d

pipe in a particular sump is increased in size, and Fig. 34

shows the results for pipes ranging in diameter from 0-55

inch to 3.0 inches in a sump 12 inches square.

Results from all the experiments, using both different

pipes and different sumps, correlate as shown in Fig. 35.

With the sump wall close to the suction pipe the critical

submergence seems to be approximately proportional to the

distance separating them, but substantially independent of

wall clearance when this exceeds 8 or 10 pipe diameters.

This wall effect was found to take the same form at ali

SUBMERGENCE s/d SUBMERGENCE s/d

velocities and to be common to all sump arrangements;

Fig. 36 shows that the effect of varying the swirl in the sump

u 4-inch pipe in %foot square b Q-inch pipe in 2-foot is merely to multiply the submergence by a constant

sump. sump.

value.

W = 16 inches. W=4 inches.

The above correlations all refer to sump arrangements in

Fig. 30. Eflect of Bottom Clearance on Relation between which the suction pipe was equidistant from two adjacent

Critical Submergeme and Suction Velocity walls. A single wall in close proximity to the pipe usually,

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 12, 2016

AIR-ENTRAINING VORTICES IN PUMP SUMPS 111

U W= 19 inches. b W= 12 inches.

Fk. 32. Contours of Equal Critical Water Depth in Inches for a 11-inch Suction P+e in a 2-foot Square Sump

c/d= 1. V = 13.5 ft. per sec.

1b W = 12 inches.

U W=24 inches. C W=6 inchcs.

F*. 33. Contours of Equal Critical Water Depth in inches for a If-inch Suction Pipe in Di-erent Sumps

c/d=l.

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 12, 2016

112 D. P. DENNY

but not always, had as much effect, as can be seen from 15,

I W-INCHES\

Figs. 32 and 33. When the suction inlet was merely a hole

in the wall, similar results to those for a vertical pipe close

to the wall were obtained.

3 10

z

Y

5

f

3

5 5

t

CL

u

OO 5 10

WALL CLEARANCE x / d

Fig.36. Effect of Swirl on Relation between Wall

Clearance and Critical Submergence

cld= 1.0. d=l+ inches. Y = 15 ft. per sec.

Scale Effects

It is apparent from the results already given that the

relation between critical submergence, expressed in terms

of pipe diameter, and inlet velocity is substantially the same

for different sizes of model, and that sumps exhibit similar

vortex characteristics when velocities are approximately the

same in each. This surprising result has no obvious theo-

retical justification, and for this reason great care is being

taken to establish the scale relationship for different sizes of

sump. In the laboratory large-scale ratios are difficult to

achieve, but within a range of 8 to 1 it has been verified that

sumps having equal flow velocities exhibit comparable con-

ditions so far as air-entraining vortices are concerned.

Results of a particular test in which flow measurements in

two similar sumps were made as accurately as possible are

given in Fig. 37. It can be seen that at high velocities the

same velocity corresponds to an equal critical submergence;

with small submergences the velocity ratio seems to be of

the order 1.1 to 1 and since this difference is much greater

than the error of measurement, some scale effect is

apparent.

Scale effects for higher scale ratios can be obtained only

from full-scale installations, and difficulties of accurate flow

measurement on site have prevented conclusive tests. Such

measurements as have been taken at least do not conflict

with the 'same velocity' hypothesis.

"0 5 10 I5

WALL CLEARANCE s / d

Experiments with Models of Large Pump

Fig. 35. Effect of Wall Clearance on Critical Submergence Installations

for Pipes of Various Sizes Situated Centrally Within Small-scale models of several existing or proposed pump in-

Similar Sumps stallations have been constructed and tested for air entrain-

c/d=l. Y=135 ft. per sec. ment. These have proved valuable for showing whether the

design of sump was satisfactory, and for indicating modifi-

Sumps 2 feet and 8 feet.

0 sump 1 foot. cations to improve flow conditions, although the scale was

+ Sump 6 inches. probably too small to provide completely accurate data

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 12, 2016

AIR-ENTRAINING VORTICES IN PUMP SUMPS 113

SUCTION

SCREENS PIPE I I I

I n I

WATER DEPTH IN PROTOTYPE-INCHES

10 15 20 25 30 35

a Scale 1/20.

b I I I I

22: ' 3 4 5

WATER DEPTH fi IN MODEL-INCHES

6 7

FQ. 37. Determination of Scale Effect between 115 Scale c/d= I

Model Sump and Prototype 5 10

SUBMERGENCE s/d

Dimensions in inches. b Scale 1/20.

Prototype Model

d 9.0 1.8

x 14.5 2.9

C 12-3 2.45

W 48 9.6

1 250 49

about critical submergences. Some of these pump instal-

lations are illustrated together with the results of model

tests.

Pumps Arranged Perpendicular to the Flow. The simplest

form of multi-pump sump of this type is shown in Fig. 38a

where the sump is of equal width to the approach channel.

The critical submergence was found to be greatly dependent

0 I 2

on the actual size of sump, but did not exceed 2 pipe dia- SUBMERGENCE s/d

meters when the sump width was less than 10 diameters.

With the approach channel narrower than the sump, so that

the flow suffered sudden expansion on entry to the sump,

vortices formed much more readily. For instance, when the

channel was half the width of the sump, as in Fig. 38b, c Scale 1/30.

critical submergence was doubled. Breakaway at the sudden

enlargement, leading to counter-swirls in the two dead areas, Fig. 38. Characteristics of Various Sumps Obtained from

was responsible for the increased severity of the vortices. Model Tests

Another form of twin-pump sump, part of the cooling- Equal flow in each sump unless otherwise stated.

water system of a power station, is shown in Fig. 38c. In

spite of the large swirl caused by oblique entry of the water vortices occurred within the operating range when pump

to the sump, vortices were not severe, mainly because the No. 1 was running either alone or together with No. 3,

sump was very narrow. It is interesting that although vortices although not under other conditions (Fig. 39b, c). These

formed first at pump B when both pumps were in operation, results were in accordance with observations of vortex con-

pump A alone required a higher submergence to prevent ditions made at the pumping station, and thus show that

vortices. full-scale conditions may be reproduced even in very small

Fig. 39a shows the layout of an existing triple-pump land- models.

drainage installation, of which an accurate 1/32-scale model Regarding the characteristics of the sump, No. 3 pump

was made. A study of the vortex conditions showed that did not produce such strong vortices as No. 1 pump,

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 12, 2016

114 D. P. DENNY

owing, no doubt, to the raised platform close to the inlet vent vortices at the outer pumps, the rear wall being needed

of No. 3, which served to fill in the dead water region at the to improve the performance of the centre pump.

end of the sump. The positions in which the vortices A well-designed triple-pump sump for a chemical plant

occurred are shown in Fig. 39a; each pump had its own is shown in Fig. 41. Model tests indicated that the ex-

vortex region which was unaffected by whether or not other pansion was not gradual enough to entirely avoid separation

pumps were in operation. Various schemes for improving and air entrainment, but the critical submergence was low

the flow in this sump were tried, including re-siting the and did not under any conditions exceed twice the diameter

boundary walls and fitting different inlets to the pumps. of the centre suction-inlet. There are unfortunately no full-

The most effective modification consisted of placing scale data available to compare with these model results.

boundary walls within 13 diameters of each suction pipe,

for with this arrangement the submergence of the pump Pumps Arranged in Line with the Flow. A frequent

inlets could fall to half the operating minimum before form of in-line sump is illustrated in Fig. 42. Swirl

vortices occurred (Fig. 40). The side walls served to pre- was very slight and vortices therefore not severe; for

DETAILS OF MODIFICATION

A B C D

----

E

Ir L

RAISED

I

PLATFORM (2 VORTEX REGION WATER DEPTH-FEET

Fig. 40. Effect on Vortex Characteristics of Modifications

to Sump in Fig.39

b C

Fig. 39. Dimensions and Characteristics of Tr@e-pump Fig. 41. Characteristics of Another Design of Tr$le-pump

Lad-drainage Sump, 1/32 Scale Model Sump, obtained from Tests with a 1/30 Scale Model

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 12, 2016

AIR-ENTRAINING VORTICES IN PUMP SUMPS I15

instance with the arrangement shown, the critical sub- CONCLUSIONS

mergence in the model did not exceed 14 pipe-diameters. The importance of sump design is apparent from the fact

Vortices were less prone to occur near the upstream inlet that air entering the suction-inlet through a vortex can

because flow past this inlet swept away any vortex dimples seriously reduce both output and efficiency of the pump,

in the vicinity. and can even lead to depriming. Such vortices are the

direct result of unsatisfactory sump layout.

The experiments have shown that although the mechan-

isms of vortex formation and air entrainment are complex,

they do show regular and repeatable behaviour. The largest

f‘;

single factor is the flow pattern within the sump, which is

in turn governed by the entry conditions. Vortices are most

severe when the swirl in the sump is considerable or when

the pipe is located at the centre of the swirl but, at the other

extreme, vortices can stiU form with imperceptible swirl in

the sump.

Although results from sumps of different sizes agree well

enough on a basis of equal velocities at scale distances, there

appears to be no theoretical confirmation of such a relation.

According to Froude’s laws, which generally apply to free

Mfl

I A

- #, -

6’

surface models when gravity forces are predominant,

similarity should occur when the velocity scale is propor-

tional to the square root of the linear scale; so it is clear that

in this case effects of other forces are by no means negligible.

The present results tend to accord with the experience of

I other investigators. For instance Iversen (1953) showed

SUBMERGENCE f/d

that model velocities based on the Froude number were far

Fig. 42. Characteristics of a Straight ‘In-line’ Sump too low to give comparable conditions and concluded that

Obtained from a 1/32 Scale Model the velocity scale should be less than the square root of the

linear scale. Stepanoff (1953) has also advocated operating

models at speeds in excess of the Froude number, while

The conditions in this type of sump became much more Fraser (1953) stated that ‘satisfactory results have been

severe when the water entered obliquely, as in Fig. 43, obtained if the model is designed with the same flow

because separation of the flow from the inner wall set up a velocities as in the prototype’.

large swirl. In this particular sump the flow patterns were It may well be that, while the velocity required to form a

such that no air-entrainment occurred when both pumps dimple in the water surface follows Froude’s laws, the local

were passing equal quantities of water. velocity required to drag air from the tail of the vortex is

unaffected by the scale of the phenomenon within the range

of sizes investigated. This would follow if, as seems likely

from visual observations, there is a minimum stable dia-

meter of vortex filament, owing to the effects of surface

tension.

In many other ways the vortex flow and sink flow appear

to be separate effects, each making varying contributions to

the conveyance of air from the free surface to the suction

inlet. At low %owsthe strength of the swirl seems to be of

little importance, for under a wide range of conditions the

entrainment of air was determined only by the velocity of

water entering the pipe. At high flows, however, the

strength of the swirl played a much larger part in deter-

mining the critical submergence, and the inlet velocity

became of minor importance. It is therefore surprising that

2 4 6 under these conditions the submergence should be so

SUBMERGENCE s/d

greatly affected by the diameter of the pipe for, except very

near to the suction-inlet, the flow patterns should be

identical for the same total flow. However, attempts to

correlate the results on a basis of quantity flow proved fiuit-

Fig. 43. Characteristics of an Angled ‘In-line’ Sump less, and there is no doubt that greater submergence of the

Obtained from a 1/10 Scale Model inlet is necessary when water at a low velocity enters a large

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 12, 2016

116 D. P. DENNY

pipe than when the same quantity of water at high velocity and towards the suction inlets should be the aim; enlarge-

enters a small pipe. This is not easily explained. ments, if necessary at all, should be carried out very

The critical submergence of the inlet approaches a maxi- gradually. Only in this way can air entrainment be pre-

mum when the velocity exceeds 15 ft. per sec. whilst vented when the submergence over the inlet is small. Ex-

below approximately 2 ft. per sec. air entrainment rarely perience has shown, however, that without model tests it is

occurred even with very small submergences. Provided very difficult to predict with any certainty the behaviour of

inlet velocities remain the same, the inlet itself seems to a particular sump.

have very little effect and can be regarded as one of the

minor factors in vortex formation. The direction in which ACKNOWLEDGEMENTS

a horizontal inlet faces has appreciable effect, and vortices Acknowledgements are due to the many members of the

form more easily with the inlet facing the potential vortex British Hydromechanics Research Association who have

region than away from it. As the inlet is raised from the shown interest in this work and offered valuable advice, to

sump floor the critical submergence diminishes, although at colleagues for their practical assistance, and to the Council

the same time the total depth of water continues to increase; of the Association for permission to publish the material

thus usually the most satisfactory arrangement will have the contained in this paper.

pipe as close to the floor as is consistent with uniform flow

into the inlet. Iversen’s experiments on pump efficiency

APPENDIX

suggest a clearance of 4 2 as optimum.

Boundary walls help to delay air entrainment when closer REFERENCES

than 8 diameters to the suction pipe, and within this distance ADDISON, H. 1948 ‘Centrifugaland Other Rotodynamic Pumps’.

the submergence required is approximately proportional to (Chapman and Hall, London.)

the separation of the wall from the pipe. There is ample DENNY,D. F. 1953 British Hydromechanics Research Assoc.

Research Report R.R. 465, ‘Experiments with Air in Centri-

evidence that air entrainment is least likely when the sump fugal Pumps’.

is as small as possible, and this rule apparently has no ex- FRASER, W. H. 1953 Trans. A.S.M.E., vol. 75, No. 4, p. 643,

ceptions. If a sump has of necessity to be large, the suction ‘Hydraulic Problems Encountered in Intake Structures of

inlet should be close to the rear wall, or preferably in a corner Vertical Wet-Pit Pumps and Methods Leading to Their

between adjacent walls. A minimum separation of d/2 Solution’.

IVERSEN,H. W. 1953 Trans. A.S.M.E., vol. 75, No. 4, p. 635,

between the wall and the outside of the pipe seems desirable, ‘Studies of Submergence Requirements of High-Specific-

to allow water to flow freely all round the inlet (Iversen Speed Pumps’.

1953). RICHARDSON, C. A. 1941 Water Works and Sewerage Reference

Asymmetrical layouts and sudden changes in the width and Data, Part 1, Water Supply, p. 25, ‘Submergence and

Spacing of Suction Bells’.

or direction of the flow channel cause large swirls in the SIEBRECHT, W. 1930 Z.V.D.I., vol. 74, No. 3, p. 87, ‘Beitrag zur

sump which increase the likelihood of vortices. The not Regelung der KreiseIpumpen und Untersuchungen Ueber die

infrequent practice of constructing the sump to the dimen- Theoretische und Wirkliche Foerderhoehe’.

sions demanded by the machinery in the pump-house leads STEPANOFF, A. J. 1948 ‘Centrifugal and Axial-flow Pumps,

to sumps that are larger than desirable, and frequently to Theory, Design and Application’. (Chapman and Hall,

London, p. 963.)

sudden enlargements in the flow channel which are a 1953 Contribution to Discussion on Iversen (1953) Trans.

potential source of vortices. Uniform flow into the sump A.S.M.E., vol. 75, No. 4, p. 639.

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 12, 2016

117

Discussion

Professor C. M. WHITE(London), opening the discussion, of a vortex. In the vortex itself the water was without rota-

said that in both papers he had found much which was tion, and the core contained nothing more than air.

difficult to reconcile with his own observation, To find how vortices originated and under what con-

Dr. Denny had given the speed at which the water entered ditions, possibly some sort of calculation in connexion with

the submerged pipe, and had shown how it depended on what was going on at the intake at the bottom of the pipe

the submergence; i.e. how the depth to which the vortex could be made. Presumablyin an inlet which was submerged

extended depended on the speed in the pipe. Certainly the 9 feet a velocity of 24 ft. per sec. would be generated in the

curves thus obtained by comparing the submergence and vortex itself, a velocity of 24 ft. per sec. of whirl against the

velocity were all much alike, but he himself wondered air core. That offered a tempting but an erroneous line of

whether that was good evidence that the depth to which thought, so also would be to reason from the size of

the vortex extended was dependent on the velocity. core, the maximum differences of speed which could be

That was no superficial question, but one which con- tolerated in the sump.

cerned the very fundamentals of design. It concerned also He would agree with Dr. Denny that the flow pattern

the methods used for scaling up results from models. For within the sump was the chief factor, and had also observed

such evidence it was unnecessaryto look beyond Dr. Denny’s that unless the pump drew surface water, a vortex did not

own experiments. For example, Fig. 32 presented a great form. That was very near to the real truth of the matter,

deal of valuable information concerning the good and the and he would add that a surface of discontinuity, a plane

bad places in a model of a sump, and incidentally did so cutting into the water, must also exist for generation of a

in a remarkably clear and simple manner. However, when vortex, Therefore to cure vortices it was necessary first to

using the method of the paper, the values were scaled up to locate those surfaces of discontinuity and, having found

represent an 18-inch suction pipe, drawing from a %foot them, displace them to positions where they could do no

sump, Fig. 32 would predict a variation from place to place harm.

of no less than 20 feet in the minimum cover required to

avoid a vortex at 13.5 ft. per sec., whereas Fig. 34 similarly Mr. G . A. WAUCHOPE (Member) said that he would discuss

scaled up would require a variation of only 2 feet in the both papers together, because in many ways they were com-

minimum cover necessary to safeguard velocities from 5 to plementary. The problems of what depth of sump and what

25 ft. per sec., a range of speed surely wide enough to include submergencemust be provided to ensure that pumps applied

almost every practical case. That seemed good evidence for to pipes or the suction pipe would work satisfactorily, and

the view that the depth required was nearly independent what might be done with the shape of the sump were

of the speed in the suction pipe, and supported Dr. frequently met.

Markland and Professor Pope’s cautious phrase about Both papers would help to solve those problems, but

regarding velocity as the criterion The inlet velocity was a there were many variables which could not easily be

convenient measure of what was taking place, but was not analysed and reduced to a common and easily resolved

the variable in question, not the cause itself. formula. Therefore in many cases it would s t i l l be necessary

Also in regard to velocity, he himself had observed vortices to make a model of the sump inro which the suction pipe

extending deeply downwards, possibly for several feet, in was going to be placed.

slack water in the Thames Estuary, at a place where the He had had experience of failure after thinking every-

current was less than 2 ft. per sec. Those vortices were far thing was satisfactory. An example was a fairly large vertical-

away from any solid boundaries. Again, in storage reservoirs spindle suspended pump which had been drawing from a

in which the water was drawn off well below the surface, sump in which the tide had varied over the range usual in

vortices would sometimes extend very far down from the Great Britain. When the trials of that pump had been carried

surface, despite a low velocity at the outlet. out the shape of the characteristic curve of the pump had

In both papers the cause of vortices was said to be initial been found to be rather abnormal. The measurement of the

swirl, but one of the quickest ways to stop a vortex was to quantity had been carried out in two ways :with a weir, and

put an irregular swirl on the water; a stir with the hand with Pitot tubes. The shape of the curve had seemed

would stop the vortex, but it was very difficult to start one reasonable from the Pitot tube readings, but checks from

in that way. Swirl was not always necessary for the initiation the weir had thrown doubt on it. The answer had been that

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 12, 2016

118 DISCUSSION

at a certain period of the tide, and degree of submergence, swirl. Dr. Denny had mentioned the direction of rotation

a Iarge proportion of air had been drawn into the pump, not being affected by the earth's rotation. Although that

which had given a high velocity by the Pitot tube reading, was a minor matter, it must be remembered that the effect

whereas by the time the water had come to the weir the air of the earth's rotation depended on the latitude at which

had been dissipated and was not recorded by the weir. observations were made. When a vortex was formed by

Another point was that when the tide had been high all water escaping downwards from a reservoir through an

had been well, but as it had gone down, a point had been orifice, the direction of rotation in a high northerly latitude

reached at which vortices had formed, and air had been was the reverse of what it would have been in a correspond-

drawn into the suction of the pump. As it had gone down ing southern latitude.

still farther, however, the irregularities had been such that Regarding the size of the vortices in relation to the size

there had been a considerable degree of turbulence, so that of the pipe, especially so far as scale effects were concerned,

the vortices had been broken up as soon as they had formed. he would like to ask the authors whether in any of the

The reason for that was that when the tide had been very experiments on pipes of different scales it had ever been

low the flow conditions had been very bad, and, being a found that the physical shape of the vortices could be

high-specific-speed pump, its performance had not been brought to scale too; that is, whether the sump, suction

very good. At the present time, with the limited knowledge pipe, and vortex could all be completely to scale.

available, undoubtedly a model should be made, and from He had noticed a slight divergence between the two

the advice given in the two papers trouble might be avoided. papers regarding the effect of the eddies formed downstream

He had known instances where it would be perfectly of the suction pipe. Some very interesting slides had been

simple, to be on the safe side, to make the velocity in the shown of the eddies immediately behind the suction pipe,

model suction pipe the same as that in the full-size suction which by Dr. Markland and Professor Pope had been given

pipe, and other components to linear scale; but he had found the credit, or the blame, for the entrainment of air. On the

that the shape of the sump and the entrance to it was such other hand, Dr. Denny had stated that if the velocity was

that the velocities under those conditions were too high, increased, improved results were obtained. In Fig. 42 the

and the Froude number should be used and the flow into author had shown two pumps, one behind the other, in a

the sump arranged to be of the order of the square root of sump, and the water first flowed past the first suction pipe

the scale, instead of directly proportional. Thus in making a and then into the second, whereby the first was subjected

model compromise was necessary, and that difficulty had to bigger velocities in a horizontal direction than it would

not been altogether solved, but he strongly advised the have been if it were working alone. Dr. Denny pointed out

use of a model. that the performance of that pump was improved, but he

Very often other things dictated the shape of the suction himself suggested that improvement had been obtained

sump, and also the position of the suction pipe. The authors because the flow of water, as it were, washed the vortices

had suggested a fairing round the suction pipe. He would away so quickly that they could not penetrate into the first

like them to consider that further, and to advise on its merits suction pipe. He would like the author to clarify that.

because such a procedure might prove inexpensive in con-

struction.

Vortices might accelerate corrosion. He knew of an

instance, working with rather warm and slightly corrosive

sea-water, where severe impingement corrosion had taken

place, that had been aggravated if not caused entirely by

the presence of air bubbles which had entered the suction

by way of vortices.

Air entrainment could be very awkward in high-specific-

speed pumps, and velocities might have a bad effect on

the performance, but there were many instances where a

suction sump was closed by a roof and filled with water, so

that there was no question of entrainment of air; neverthe- Fig. 44. Suction Sump with Submerged Roof

less vortices might form and detract fiom the efficient work-

ing of the pump. He asked whether the authors would In regard to practical applications, Dr. Markland and

comment on that. Reliability of these results depended on Professor Pope had shown various kinds of fairings,

repeated testing as there were borderline cases. shrouds, and so on, and he would be very interested to hear

the authors' opinions on their practicability. A horizontal

Mr. H.ADDISON,O.B.E., M.Sc. (Member), M.I.C.E., attachment did not appear to have been experimented with.

said that his first question concerned the sense of direction Such an attachment might be in the form of a floating

of the vortices. Dr. Denny did not appear to have men- platform surrounding the suction pipe, floating on the

tioned that sense, and in Dr. Markland and Professor Pope's surface of the water. Another modification which was used,

paper the sense had been random, but when there was a he believed, in Holland, was of the form shown in Fig. 44.

swirl the eddies had had the same sense of rotation as the That ensured that there was no free water surface near the

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 12, 2016

A SMALL PUMP SUCTION WELL AND VORTICES 119

suction pipe. Nevertheless, he had been told that, although often could not wait while a model was being made, and it

the air could not enter, there was a swirl in the pipe which was important that ultimately it should be possible to design

might impair the performance of the pump. an installation without having recourse to making a model.

An interesting point in the paper by Dr. Markland and

Professor Pope concerned the effect of a screen put in front Mr. G. W. HESLETT (Associate Member) said that his

of the suction pipe, which when removed, had made comments would relate in particular to Dr. Denny’s paper,

the performance very much worse. In practice the equiva- where he had stated that in the experimental apparatus

lent of that was the weed screen used with low-head which had been employed, the suction pipes were of sufIi-

drainage pumps, and he would like to know whether the cient length to exclude any effects of prerotation due to the

weed screen would also have a stabilizing effect, first, when impeller, but it would appear that on that account the use-

it was clear and, secondly, when it was blocked with weeds. fulness of the experiments and the extent to which the

If the weeds accumulated on the screen in an irregular way general conclusions could be applied to the practical design

there might be a swirl which would impair the pump of a pump sump, were somewhat limited. The effect of the

performance. flow pattern created within the suction pipe and bellmouth

Professor White had spoken about vortices on the out- by the impeller, on the flow pattern external to the pipe,

lets from reservoirs where the vortex might be 100 feet including vortex formation, would vary considerably, with

deep. He wondered whether those vortices would be worth the majority of pumping installations where that pheno-

further study. In particular, in low-head turbines where the menon created problems, it was necessary to treat the sump

water passed between piers with grooves, large vortices were and pump design characteristics as a whole if a satisfactory

formed as the water passed the grooves. He questioned solution was to be reached.

whether they would be sufficiently serious to influence the That point had already been covered by suggesting that

performance of the turbine; possibly the total flow would sump design could and would in fact sometimes affect the

be too large for that. efficiency of the pump, and other investigators had already

He inquired whether the scope of the papers could be noted and recorded that.

extended to cover any kind of outlet drawing water from a His own first-hand observation of many types of installa-

sump, and whether rules could be proposed for minimum tion had shown that the problem of avoiding vortex forma-

submergence. tion was intensified, and in some cases only existed, where

high specific-speed units were employed, and that with

Mr. R. A. SMITH,M.A. (Associate Member), said that similar design treatment of the sump alone for high and

the authors of both papers had given useful information on low specific-speed units, quite different results could be

how to design a sump and take-off pipe in such a way that produced.

air-entraining vortices did not form, but the normal reaction It was of particular interest that under the test conditions

of anyone faced with the problem of stopping such a vortex it had been possible to establish a relationship between the

was to try to devise some sort of baffle, and fit it to the entry critical submergence, and suction velocity and bottom

of the suction pipe. The baf€le might have the form of a clearance, whereas previous field experience with actual

cross inside the pipe, or a disk underneath or above the installations had shown that there was very considerable

pipe, or some sort of combination of b d e s , and often trial difficulty in doing that. On one installation, a land drainage

and error was necessary before the vortex was stopped; but plant, with two vertical-spindle medium specific-speed units

some such method was a simple way of stopping the vortex with a specific speed of 7,000 and a rectangular sump, severe

and did not involve any large modifications to the installa- vortex formation had occurred intermittently at maximum

tion. In neither paper had there been any mention of baffles, depth of submergence, and had disappeared and reappeared

and he would like to ask the authors whether they intended at various diminishing levels, finally disappearing com-

to do any work on that subject in the future, or whether they pletely when a minimum level with submergence level to

considered that care in the design in the first place was pipe diameter of 1-5 was reached. Under those conditions

always to be preferred to some form of baffling. the pump discharge, and the velocity within the suction

He was interested in the finding of Dr. Markland and pipe and bellmouth varied with the levels in the total head.

Professor Pope that by deliberately putting swirl on to the Observations had subsequently been made on that

water in the sump they could stop the formation of a installation over a period of several hours on three occasions,

vortex, although it might be thought at first sight that that the suction pump and flow conditions each time being

would have made it more likely to form. He wondered controlled to cover the same range of levels and outputs. The

whether it would be possible to do that with the same effect results had varied to the extent that throughout one test,

in the case of a circular sump with a central uptake and the extending over approximately 6 hours, no vortices having an

water coming in through a form of tangential inlet. air core had appeared, despite the apparent similarity of the

Dr. Denny had recommended that a model should always conditions. It had been considered that probably the

be made for a sump for any important installation, although explanation lay in the variations of the small degree of

he did not appear to be certain whether the experiment turbulence induced in the sump due to the interference of

should be done with the same velocity, or the same Froude solid matter on the screen, although the actual difference in

number. Designers, however, were usually in a hurry and the head during the tests had been hardly noticeable.

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 12, 2016

120 DISCUSSION

That and similar experiences supported the conclusion frequent vortex formation in the sump. A degree of

reached by the author that there was no precise boundary turbulence had existed in the sump and had increased as

between vortex-forming and vortex-free conditions, and the level diminished, but at all times was of an acceptable

that over a wide zone the formation of an air core was largely order. It was probable that that was a major factor con-

a matter of time and chance, in so far as the formation and tributing to what was, for all practical conditions, entirely

dispersionof vortices might result from minor and secondary satisfactory operation. He thought that that supported the

influences. He thought that that point had been sufficiently view which had already been expressed, that an initial

emphasized. disturbance or a purposely-created disturbance might be

He had recently been associated with aerodynamicexperi- extremely valuable in destroying, or even preventing, vortex

mental work to determinethe most favourable design of bell- formation.

mouth and suction guide apparatus for a suction system of He was of the opinion that the relationship between sump

extremely large pumping units dealing with 270 cusecs and pump sizes opened up a field of considerable possi-

each, which were being installed in an existing sump. The bilities in the civil engineering design of a pumping station,

combination of an internal and external guide, disposed at because a single- or multi-cell construction could be

various positions in the suction pipes relative to the main adopted eliminating the need for a large suction sump, the

stream flow, had been found to be necessary and had shown intake to each pump sump or cell from the main stream

the most favourable flow pattern. There was no uniformity being through a circular pipe. Where desired those intake

about it. The influence of each succeeding suction pipe on pipes could be brought out to a shallow fore-bed, where

the others was quite definite. screens could be accommodated. The ultimate development

The point concerning the benefits associated with small of that principle was the elimination of the free-surface

sumps confirmed the result of experimental work already area type of sump, which should substantially diminish, if

camed out to determine the probable flow conditions in not entirely preclude, vortex formation.

what, by generally accepted standards, were sumps of

extremely small dimensions when related to the pump and Mr. J. R. D. FRANCIS, Assoc.1.C.E. (London), said that

suction-system sizes. That work had been undertaken with all the authors were in agreement that models should be

particular reference to land drainage installations, and tested at the same height and speed as the full-scale job,

covered the use of a cylindrical sump having a sump but Dr. Denny had gone a stage beyond and had pointed

diameterlinlet bellmouth ratio of 1.6 or less. The tests had to the slight mystery of why scaling the Froude law seemed

been full scale, and employed a vertical-spindle medium to be inadequate. If, as it seemed from both papers, vortices

specific-speed pump with a specific speed of about 7,000, were caused by eddies being shed by something, surely the

rated for a nominal output of 45 cusecs. The water had criterion should theoretically be the Reynolds criterion. In

been allowed to enter the main sump through a radial other words, the mystery was why should the scaling laws

approach having a diametric ratio with the sump of 0.8, not be the Reynolds law.

and in an extreme case was allowed to enter also over the

top of the sump, the pump performance and flow conditions Mr. F. H. TOWLER (Member) (Chairman) said that he

in the sump having been observed over a wide range of hoped someone would contribute to this subject, using

levels. oil and trying the effect of various viscosities on the forma-

Through the complete range the pump had run com- tion of vortices, which was so easy with oil, because it was

pletely satisfactorily, and with only minor and very in- only necessary to alter the temperature.

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 12, 2016

121

Communications

Mr. G. H. JONES, B.Sc. (Associate Member), A.M.I.E.E., vortices were readily formed, even with considerable cover

wrote suggesting that air-entraining vortices in pump over the bellmouth. They had moved the bellmouth close

sumps could normally be eliminated by using a rather large to the back wall of the sump, and had found that vortices

bellmouth at entry, and fitting over the mouth a grid were not so easily formed, nor were they so large. The back

similar to those used for open drains. Such an arrangement of the sump had then been wrapped round the bellmouth,

was shown in Fig. 45. and carried tangentially to the side walls as indicated in

Fig. 46.

. I .

- FLOW

.

Fig. 46. Suction Sump to Ensure Freedom from Vortices

As a result it had been found that vortices had not

formed, even with the bellmouth submerged to a very small

depth.

Mr. LESLIE YOUNG(East Kilbride) wrote that the problem

of efficient sump design had not hitherto received the

attention it deserved. Badly laid out sumps and intakes

were very common, and failure of the installations to per-

form satisfactorily was often blamed on the pumps,

F9. 45. Bellmouth Entry with Grid although in fact they had not been given a chance to work

efficiently. The two papers were therefore very welcome, but

it should be pointed out that while air entrainment was an

Mr.W. RIGBY( M d m ) wrote congratulating the authors extreme condition, easily recognized, and attributed to bad

on their carefid study of the problem which had become sump design, serious effects on pump operation could and

intense on the introduction of the vertical-spindle axial-flow did arise owing to unsatisfactory sumps, without air entrain-

pump. With that type of pump it was often necessary to ment having taken place.

increase the water velocity from zero to 15 or 20 ft. per sec., Some experiments on the formation of air-entraining

within the range of a relatively short bellmouth, con- vortices had been carried out by the Mechanical Engineer-

sequently, the acceleration was very great. To prevent the ing Research Laboratory in connexion with the design of a

formation of vortices, recommendationshad been made that large water sump for the new hydraulic machinery labora-

the water should cover the bellmouth by 5 or 6 feet, but tory. A model to Q scale had been constructed, having a

that increased the cost of the civil engineering work. length of 9 feet and a width of 1 ft. 104 in. A circulating

Ten years earlier his company had carried out a con- pump had taken water from one end through a pipe of

siderablenumber of experiments to try to reduce that cover, 23 inches nominal bore mounted vertically, and returned

and to eliminate some of the trouble which they occasionally it to the other end. A distributor on the discharge pipe, and

experienced with vertical-spindle axial-flow pumps. They a screen, had produced uniform flow conditions over the

had found that in the normal rectangular suction sump greater part of the length of the sump.

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 12, 2016

122 COMMUNICATIONS

The arrangement had thus been very similar to that used

by Dr. Markland and Professor Pope for their experiments I2O

on rectangular sumps. Investigation had been confined to 100

determining the effect of the rear wall position relative to *

the intake pipe on the formation of air-entraining vortices. ‘0

The intake pipe had had no bellmouth, and had been X

d W

situated 5 inches above the floor of the sump. After some m

y1

z:

preliminary trials, it had been decided to use as the critical 3

Z

submergence the depth at which a stable vortex, as distinct

from an intermittent one, was formed. The scatter on results

z

obtained using any other criterion had been too great for Ld

practical use. ;40

Analysis of the results for various positions of the rear -t

wall had shown that they could be correlated to a reasonable 4

approximation by an empirical equation of the form 20

77 / L - \ + l

R, =-

(9’

A

(ac)’-

;t

xi04 . . (1)

0

D/d

where R, was the Reynolds number of the flow in the intake

pipe, D the distance from the rear wall to the centre-line Fig. 48. Effect of Rear Wall Position in a Rectangular

of the intake pipe, d the intake pipe diameter, and S, the Sump

critical depth of submergence. Z = l l + inches.

K had been found to be a constant whose value was 27.4;

n was not a constant but varied with D/d, its value being lower critical submergences than theirs, the agreement

given by seemed fairly good.

Fig. 48 showed the relation between R,, D/d, and S,/d

n = 0.39+045(:) given by the empirical equation (1). The curves for

S,/d = 2 and S,/d = 3 at D/d less than 2 should be regarded

Fig. 47 showed the M.E.R.L. results for D = 12 inches with caution, as they were outside the range of the experi-

compared with Dr. Markland and Professor Pope’s results mental results.

for an almost similar system given in Fig. 11. Bearing in Experience of the formation of air-entraining vortices

mind the fact that the ‘stable vortex’ criterion would give had been very similar to that of Dr. Markland and Professor

Pope. In the early stages of formation, two symmetrical

vortices had been observed, one subsequently developing

and the other dying away. A vortex had shown great per-

sistence once formed, and had readily reformed after being

broken up by hand.

He would like to have some points in Dr. Denny’s paper

I I Y-I~CHES 1 clarified. Firstly, it had been stated in the conclusions:‘there

is no doubt that a greater submergence of the inlet is neces-

sary when water at a low velocity enters a large pipe than

when the same quantity of water at a high velocity enters a

small pipe’. That did not appear to be borne out by the

results quoted. In Fig. 37, which presented results for two

geometrically similar systems with a 511 difference in scale,

the ‘water depth’ scales could be reduced to dimensionless

form by dividing by the appropriate pipe diameter, With

two pipes of diameter d and 2d respectively, such that

1-8<d, and 9>2d, it was fair to have assumed that results

for those hypothetical pipes would be covered by those

curves. If the larger of the two pipes had been running at a

I I

suction velocity of 3-5ft. per sec., and considering the worst

0 I 2 3

hy-FEET case as shown by the prototype curve in Fig. 37, the required

Fig. 47. Critical Submergence in a Rectangular Sump water depth would be 20/9 x 2d inches. The submergence

would be (20/9)-(12.3/9) x 2d, or 1-71dinches.

D = 12 inches. For equal discharge, the smaller pipe would run with a

2 = 12 inches (M. and P.).

2 = I l t inches (M.E.R.L.). suction velocity of 14 ft. per sec. From Fig. 37, the required

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 12, 2016

A SMALL PUMP SUCTION WELL AND VORTICES 123

water depth would be 31/9 x d inches and the submergence contour lines of Figs. 32 and 33. It appeared that there was

(31/9)-(12*3/9)xd or 2.08d inches. Thus the smaller pipe one position in a rectangular sump which was worse than

required a greater submergence than the larger for a similar any other for vortex formation. M.E.R.L. experiments

discharge. confirmed that finding (Fig. 48) and it was worth noting that

The same result was obtained by considering Fig. 34, and improvement in conditions for a rectangular sump might

from it was found that a suction velocity of 20 fi. per sec. result from moving the intake in the direction of flow. The

in a pipe of 0.92 inch diameter gave a critical submergence distance to be moved, however, might be greater than if the

of 3.13 inches, while a velocity of 7.5 ft. per sec. in a pipe of movement were made towards the walls.

1.5 inches diameter (corresponding to the same discharge) Those observations suggested that vorticity generated at

gave a critical submergenceof 2.4 inches. The systems were the boundary walls might be a factor in vortex formation,

not quite geometrically similar in that case. as well as vorticity generated at the intake itself. In the

Since it was unlikely in practice to use a velocity ratio M.E.R.L. model it had been found that eddies tended to

much greater than 4/1 for two pipes carrying equal quantities form in the rear corners of the sump when the intake was

of water, he considered that the author’s statement should placed so as to touch the rear wall. Although those did not

be qualified. seem to have resulted in vortex formation, it had been

Secondly, there seemed to have been some discrepancy decided to round offthe corners with a generous curve. That

between the results shown in Figs. 34 and 35. From Fig. 34 had been completely successful in eliminating eddies.

for a 3-inch pipe with a suction velocity of 13.5 ft. per sec. It might be of interest to mention that the full-size sump

S/d was 0.3. From Fig. 35 under the same conditions designed as a result of the experiments with the M.E.R.L.

(x/d = 2) S/d was 1.6. Similarly Fig. 34 gave S/d as 1.8 for model had been in operation and had proved very satis-

a 1.5-inch pipe under the same conditions for which Fig. 35 factory. Two service pumps were placed symmetricallywith

gave S/d as 4. the lip of their intake bellmouths about 2 inches from the

From the results quoted to illustrate the effect of wall rear wall. The submergencewas 6 feet, which was calculated

proximity on vortex formation it appeared that the distance to have been considerably greater than that necessary to

of the intakes from both sides and rear of the model sumps avoid vortex formation. They were operating quite satis-

had been varied in the same proportion for most of the factorily in their design conditions. There was no tendency

experiments. Dr. Markland and Professor Pope had found for vortices to form with the pumps running together, or

that decreasing the width of their model, maintaining the singly. It was possible in that system to measure the flow

rear clearance constant, had given greater critical sub- accurately, and they hoped to determine the critical sub-

mergences, and he would be interested to know if Dr. Denny mergences as soon as it was convenient. The pumps were

had any results which showed the same effect. One very each rated to deliver 6,000 gal. per min. at a head of

interesting feature of his experiments was shown in the 80 feet.

Authors’ Replies

Dr. E. MARKLAND and Professor J. A. POPEwrote, in reply suction pipe in a cylindrical sump, was conducive to the

to the discussion and communications, that Professor White formation of air-entraining vortices.

had raised many most interesting points in his discussion. In view of Professor White’s comments on the effect of

As to whether inlet velocity was the appropriate variable erratic disturbances in the flow, it was interesting to learn

against which to measure critical submergence, it might of Mr. Wauchope’s experience of a practical case in which

only be said that, for a given arrangement of sump and turbulence in the sump had been found to break up air-

suction pipe, the critical submergence did not vary with entraining vortices when the water level fell very low, and

inlet velocity, or inlet velocity head, in a fairly systematic flow conditions were particularly bad. It was most valuable

way. Other than that, there was no justification for using it; to hear that his experience indicated scale velocities in

the critical submergence at a given inlet velocity could vary models to be roughly in accord with the Froude criterion.

very much as the geometry of the system was changed, as Mr. Francis had asked why the Reynolds criterion was not

was shown both by Dr. Denny’s results and their own. the important one. Their own view was that there was

They agreed that irregular swirl put on the water normally unlikely to be any simple law which might be applied

stopped a vortex from forming. Air-entraining vortices took infallibly to all cases. The overall flow pattern in the sump

some time in establishing themselves and, so long as the was likely to depend principally on Reynolds number, but

flowpattern in the sump was broken up in a random fashion, the depression of the surface of a vortex depended on the

incipient vortices had not the steady conditions required for Froude number. Dynamic similarity could not then be

their growth. But swirl occurring in the natural and steady achieved for both the main ffow in the sump and for the

flow pattern in the sump, provided it was not centred on the motion of the vortex, in a model using water, so that no

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 12, 2016

124 AUTHORS’ REPLIES

model could completely reproduce the behaviour of its the floor of the sump up into the suction pipe had been

prototype, and only experience could decide the most disappointing; it had produced no diminution in vortex

appropriate velocity to use The importance of reproducing formation, vortex filaments merely passing through one of

in the model the details of the sump, including the entry, the quadrants of the cross up into the suction pipe. Mr.

should be emphasized. Smith had also referred to the possibility of a cylindrical

The effect of a fairinground the suction pipe was primarily sump with a tangential inlet, and such a sump 12 inches in

investigated to provide confirmation of the effect of the diameter with an entrance 2 inches wide had been made.

suction pipe itself in a rectangular sump in which every An extremely strong swirl had been formed, which had

attempt had been made to remove swirl; it had not been produced a differenceof water levels between the wall of the

thought of at first as a practical means of preventing vortex sump and the suction pipe of as much as 8 inches at

formation. The extremelybeneficialeffect which it had in the maximum discharge, so that very severe deviation of the

model shouldbe emphasized; even when circulating flow was flow from the axial direction would have been produced in

engendered in the sump by placing a vane projecting from the suction pipe. Unfortunately, no systematic tests had

one side, air-entraining vortices were not produced. If been made in which the degree of swirl had been controlled,

Mr. Wauchope had the opportunity of trying the effect of bur it would seem quite feasible to control the swirl,

fairing the suction pipe of a larger installation, they would possibly by having a combination of tangential slot and

be most interested to hear of it. radial inlet through an annular gap around the whole of

In reply to Mr. Addison’s question regarding the effect the bottom of the cylinder.

of the earth’s rotation on the direction of rotation of the Mr. Rigby’s communication was extremely valuable, and

vortices, it was considered that the direction of any swirl the design of a vortex-free sump which he showed repre-

which existed in a sump was fixed by irregularities at the sented perhaps the ultimate development of the concept of

inlet or in the sump itself and, on that scale, the earth’s having the rear wall as close as possible to the suction pipe.

rotation would have no appreciable effect. Only where a The advantage of having a uniform entry condition aver the

large mass of more or less stationarywater was involved was whole of the suction pipe cross-section, which a bellmouth

the sense of any vortex which might form likely to be ideally produced, might be sacrified to some extent if the

determined by the earth’s rotation. Mr. Addison quite water were accelerated too much before it was turned

rightly remarked that many devices other than those men- upwards into the pipe.

tioned in the paper might be effective in suppressing air- They were most gratified that Mr. Young had obtained

entraining vortices. A floating platform or other device similar results to their own on similar apparatus, and that

which ensured that no free water surface occurred near the he had ventured to put them in the form of an empirical

suction pipe might be used, and their results with bell- equation. That was a step that they had not taken because

mouths of two different sizes supported Mr. Jones’s of the wide difference in results which they had obtained

suggestion that a large bellmouth could be helpful. But it with a given sump layout between conditions of no swirl,

should be borne in mind that the swirl in the sump which and swirl which was perceptible bur too small to

might occur, whether or not they were fitted, would pass measure.

into the suction pipe, where large deviationsof the flow might

be produced. As mentioned in the paper, angles of deviation

as large as 35 deg. had been measured in a plain suction Dr. D. F, DENNY wrote, in reply to the discussion and

pipe and as much as 19 deg. in the suction pipe fitted with a communications, that it was evident from the discussion

coaxial boss of 1-10inches diameter; the effect of variations that, although much was known about the influence of the

as large as that would be noticed in the performance of a relevant factors on the formation of vortices, the mechanism