Professional Documents

Culture Documents

XX ZIEHL ABEGG Operating Instructions ZAdyn4C MRL

XX ZIEHL ABEGG Operating Instructions ZAdyn4C MRL

Uploaded by

Mohamed SaadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

XX ZIEHL ABEGG Operating Instructions ZAdyn4C MRL

XX ZIEHL ABEGG Operating Instructions ZAdyn4C MRL

Uploaded by

Mohamed SaadCopyright:

Available Formats

ZA dyn4C MRL

Frequency inverter

Original operating instructions

Store for future use!

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

Original operating instructions

ZAdyn4C MRL

Content

1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Validity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Structure of the operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Target group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Exclusion of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 Mechanical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.1 General notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.1.1 Switch cabinet installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.1.2 Wall installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.1.3 Fixation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.1.3.1 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.2 Dimensions / minimum clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1 EMC-compatible installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1.1 ZAdyn4C MRL AI . . . . . . . . . . . . . . . ........... . . . . . . . . . . . . . . . . . . . . . 8

5.1.1.1 Motor cable . . . . . . . . . . ........... . . . . . . . . . . . . . . . . . . . . . 8

5.1.2 ZAdyn4C MRL Bx . . . . . . . . . . . . . . ........... . . . . . . . . . . . . . . . . . . . . . 9

5.1.2.1 Power cable / motor cable / control cables . . . . . . . . . . . . . . . . . . . . . 9

5.2 Device set-up / Terminal positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.3 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.3.1 ZAdyn4C MRL AI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.3.2 ZAdyn4C MRL Bx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.4 Strain relief by cable ties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.5 Protective ground connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.6 Mains connection (X1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.6.1 Network form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.6.2 Cable cross section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.6.3 Mains fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.6.4 Type of cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.6.5 Connection ZAdyn4C MRL AI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.6.6 Connection ZAdyn4C MRL Bx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.7 Motor connection (X3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.7.1 Cable cross section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.7.2 Type of cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.7.3 Cable length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.7.4 Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.7.5 Electronic short-circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.8 Motor temperature monitoring (X-MT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.9 Brake resistor (X 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.9.1 ZAdyn4C MRL BE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.10 Digital inputs (X-IN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.10.1 Connection with external power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.10.2 Connection with internal power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.10.3 Terminal assignment X-IN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.11 Digital outputs (X-OUT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.11.1 Digital outputs X-OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.11.1.1 Connection X-OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.11.2 Terminal assignment X-OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.12 DCP / CAN interface (X-DCP, X-CAN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

2/44

Original operating instructions

ZAdyn4C MRL

5.12.1 DCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.13 Interface operation without contactors (X-SC) ............................... 23

5.13.1 Terminal assignment X-SC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.13.2 Technical data X-SC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.13.3 Connection X-SC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.14 Encoder connection synchronous motors (X-ENC15) . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.14.1 Technical data X-ENC15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.14.2 Pin assignment X-ENC15 for absolute value encoder with EnDat, SSI, ERN1387 and

HIPERFACE interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.15 Artificial encoder (X-ENCO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.15.1 Connection X-ENCO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.16 External 24 V power supply (X-EXT) ..................................... 26

5.16.1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.16.2 Connection X-EXT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.17 Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.17.1 Brake release monitoring (X-BR) . . . . . . . . . . . ... . . . . . . . . . . . . . . . . . . . . . . 26

5.17.2 Connection X-BR . . . . . . . . . . . . . . . . . . . . . . ... . . . . . . . . . . . . . . . . . . . . . . 27

5.17.3 Triggering of the brakes . . . . . . . . . . . . . . . . . ... . . . . . . . . . . . . . . . . . . . . . . 27

5.17.3.1 Technical data brake contactors . . . ... . . . . . . . . . . . . . . . . . . . . . . 27

5.17.3.2 Emergency power suply . . . . . . . . . ... . . . . . . . . . . . . . . . . . . . . . . 28

5.17.3.3 ZAdyn4C MRL AI . . . . . . . . . . . . . ... . . . . . . . . . . . . . . . . . . . . . . 28

5.17.3.4 ZAdyn4C MRL BI and ZAdyn4C MRL BE . . . . . . . . . . . . . . . . . . . . . . 29

5.18 External monitoring functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.18.1 Brake contactors (ZAdyn4C MRL AI, ZAdyn4C MRL BI and ZAdyn4C MRL BE) . . . 29

5.18.1.1 Technical data auxiliary contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.18.1.2 Assignment connection terminal X400 (ZAdyn4C MRL AI) . . . . . . . . . . 30

5.18.1.3 Assignment connection terminal X-K (ZAdyn4C MRL Bx) . . . . . . . . . . . 30

5.18.1.4 Fault and speed monitoring frequency inverter (only ZAdyn4C MRL AI) . 30

5.19 Circuit suggestion for ZAdyn4CS MRL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6 Device switch Q1 (only for ZAdyn4C MRL AI, optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.1 Mechanical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.2 Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.1 Testing the "Safe Torque Off (STO)" safety function . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8 Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8.1 Technical data ZAdyn4C MRL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8.1.1 ZAdyn4C 011 - 032 MRL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8.2 EC/EU declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

3/44

Original operating instructions

ZAdyn4C MRL General information

1 General information

Compliance with the following instructions is mandatory to ensure the functionality and safety of the

product. If the following instructions given especially but not limited for general safety, transport,

storage, mounting, operating conditions, start-up, maintenance, repair, cleaning and disposal / recy-

cling are not observed, the product may not operate safely and may cause a hazard to the life and

limb of users and third parties.

Deviations from the following requirements may therefore lead both to the loss of the statutory material

defect liability rights and to the liability of the buyer for the product that has become unsafe due to the

deviation from the specifications.

1.1 Validity

This instruction manual applies to:

frequency inverter from the series:ZAdyn4C MRL

from software version 4.42

1.2 Structure of the operating instructions

These Operating Instructions are a Quick Start Guide with additional information. They are

only valid in connection with the following Operating Instructions.

• R-TBA12_01 (ZAdyn4C)

Please notice and follow the below described informations:

• Safety instructions

• Product overview

• Mechanical installation

• Electrical Installation

• Service & Maintenance

• Transport

• Storage duration:

• Disposal & recycling

Before installation and start-up, read this manual carefully to ensure correct use!

1.3 Target group

The operating instructions address persons entrusted with planning, installation, commissioning and

maintenance and servicing and who have the corresponding qualifications and skills for their job.

1.4 Exclusion of liability

It has been established that the content of these operating instructions is concurrent with the

frequency inverter hardware and software described.

It is still possible that non-compliances exist; no guarantee is assumed for complete conformity. The

contents of this manual are put through periodic reviews. Necessary modifications are incorporated

into the next version.

ZIEHL-ABEGG SEis not liable for damage due to misuse, incorrect use, improper use or as a

consequence of unauthorized repairs or modifications.

2 Safety instructions

The safety instructions described in chapter 2 of the operating instructions R-TBA12_01

(ZAdyn4C) must be observed!

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

4/44

Original operating instructions

ZAdyn4C MRL Product overview

3 Product overview

3.1 Application

The ZAdyn4C MRL is a field-oriented frequency inverter for speed control of three-phase motors

developed for use in elevator machines.

They are based on the ZAdyn4C, whereby a brake control, a device switch, a brake resistance (except

ZAdyn4C MRL BE) and room for additional components (only ZAdyn4C MRL AI) have been addition-

ally integrated.

The inverter is equipped with a microprocessing control. This drives the motor based on time and

travel-dependent programs, which can be selected through the superordinate elevator controls. The

use of IGBT modules and a pulse width modulation in which the clock frequencies can be modified

enable low-noise motor operation. The user interface specifically matched to elevator technology,

interfaces and software enable simple installation and commissioning of the device.

The frequency inverter is designed for elevator installations for passenger and freight transport with a

high demand on travel comfort and positioning accuracy.

The frequency inverter has been developed for operating synchronous motors.

4 Mechanical installation

4.1 General notes

The ZAdyn4C MRL frequency inverter is a closed compact device that is designed for mounting on

the machine frame carrier. Wall mounting is also possible but adequate cooling must be ensured in

this case (see chapter "Wall mounting").

Danger!

The following points must be complied with during the mechanical installation to avoid causing a defect

in the device due to assembly errors or environmental influences:

Before installation

• Remove the device from the packing and check for any possible shipping damage

• Carry out installation only on a clean, level and stable foundation

• Assemble the device outside of the traffic area

During installation

• Mount the device in a torsion free conditions

• Installation position: vertical; no lying installation

• Mount the device in a torsion free conditions

• Avoid that drilling chips, screws and other foreign bodies reach the interior of the device

• Maintain the stated minimum clearances to ensure unobstructed cooling- air feed as well as

unobstructed outgoing air discharge (see fig. "Minimum clearances")

Ambient conditions

• Prevent humidity

• Avoid aggressive and conductive materials in the environment

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

5/44

Original operating instructions

ZAdyn4C MRL Mechanical installation

4.1.1 Switch cabinet installation

Attention!

CAUTION! The device is designed for installation on the machine carrier in the lift shaft. An adequate cooling must

be ensured for assembly in the switch cabinet. The power loss of the device (see chapter "Technical

Data") must be taken into account here.

The specified installation position and the minimum distances must be observed when assembling in

the switch cabinet.

4.1.2 Wall installation

Attention!

CAUTION! The minimum distances and the installation position must be observed for wall mounting (see chapter

"Dimensions / minimum distances").

4.1.3 Fixation

The ZAdyn4C MRL has a fastening variant which matches the special installation situation of the

device.

4.1.3.1 Procedure

" Fix the fastening plate (6) to the machine carrier with 4 fastening screws (2).

" for ZAdyn4C MRL AI: Feed the cables through the opening (5) in the centre of the fastening plate.

" Push the housing (1) of the ZAdyn4C MRL into the hooks (4) of the fastening plate (6).

" Screw together both parts with 2 fastening screws (3).

4

5

6

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

6/44

Original operating instructions

ZAdyn4C MRL Mechanical installation

4.2 Dimensions / minimum clearances

Dimensions / minimum distances ZAdyn4C MRL in mm

Dimensions / minimum distances ZAdyn4C MRL in mm

ZD4C10M0

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

7/44

Original operating instructions

ZAdyn4C MRL Electrical installation

5 Electrical installation

The safety instructions described in chapter "Electrical installation" of the operating instruc-

tions R-TBA12_01 (ZAdyn4C) must be observed!

5.1 EMC-compatible installation

When correctly installed (see below), the device corresponds to the following standards:

• EN 12015 Electromagnetic compatibility – product series standard for lifts, escalators, moving

pavements – spurious emission

• EN 12016 Electromagnetic compatibility – product series standard for lifts, escalators, moving

pavements – interference immunity

The following points must be observed if the above mentioned standards are to be adhered to:

• Use only shielded cables for motor and brake chopper or brake resister connections.

• Max. motor line length is 25 m

• Wind unshielded cables of brake resistor type BR11-A around the toroidal core provided (see

figure)

• If an interruption in the shield is necessary, the shield must then be continued with as low an HF

impedance as possible

• Use only shielded control cables

• The shielding of control cables (inputs and outputs, rotary encoder cable, etc.) must be connected

to earth potential on the inverter side

• The shielding of control cables (inputs and outputs, rotary encoder cable, etc.) must be connected

to earth potential on the inverter side

• Use shielded lines in the switching cabinet also

• Do not twist shielding for connections; use a suitable shield connection system

• Run the control cables and the encoder cables separate from the power cables

• Provide connected inductances (brakes, motor contactors) with suppressors

• Feed the voltage supply of the motor contactors through the mains filter of the elevator control

Toroidal core BR11-A

5.1.1 ZAdyn4C MRL AI

5.1.1.1 Motor cable

Cable length

The maximum line length is 25 m.

When lines over > 25 m are used, compliance with DIN EN 12015 (electromagnetic compatibility –

electrical interference) and DIN EN 12016 (electromagnetic compatibility – noise immunity) is no

longer guaranteed.

Contacting the shielding of the motor line on the ZAdyn4C MRL AI

On the ZAdyn4C MRL AI, the shielding of the motor line must be connected with earth potential with

the clip provided (see fig.).

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

8/44

Original operating instructions

ZAdyn4C MRL Electrical installation

1 2

Remove the sheath 1 Cable tie for strain relief

2 Clip

Contacting the shielding on the motor

Connect the shielding on the motor side to the PE junction that is located directly on the motor

housing.

For prefabricated motor lines from ZIEHL-ABEGG SE, the shielding connection is provided with a ring

cable eye for the corresponding thread size.

When using non-prefabricated lines, implement the shielding connection by using a suitable shielding

connection system.

5.1.2 ZAdyn4C MRL Bx

5.1.2.1 Power cable / motor cable / control cables

Contacting of the power cable to the ZAdyn4C MRL Bx

The shield of the power cable must be connected to earth potential at the bolt for the earth connection

on the ZAdyn4C MRL Bx.

1

2

3

1.3 Cable tie for strain relief

2 Bolt for the earth connection

Contacting the shielding of the motor line on the ZAdyn4C MRL Bx

Cable length

The maximum line length is 25 m.

When lines over > 25 m are used, compliance with DIN EN 12015 (electromagnetic compatibility –

electrical interference) and DIN EN 12016 (electromagnetic compatibility – noise immunity) is no

longer guaranteed.

On the ZAdyn4C MRL Bx, the shielding of the motor line must be connected with earth potential with

the clip provided (see fig.).

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

9/44

Original operating instructions

ZAdyn4C MRL Electrical installation

1

2

Remove the sheath 1 Cable tie for strain relief

2 Clip

Contacting the shielding on the motor

Connect the shielding on the motor side to the PE junction that is located directly on the motor

housing.

For prefabricated motor lines from ZIEHL-ABEGG SE, the shielding connection is provided with a ring

cable eye for the corresponding thread size.

When using non-prefabricated lines, implement the shielding connection by using a suitable shielding

connection system.

Control cables

The shields of the control cables (digital inputs and outputs) must be connected to earth potential on

the inverter side. Earthing clips are provided in the ZAdyn4C MRL Bx for this (see fig.).

Shielding digital inputs line

1 Earthing clip

2 Strain relief by cable ties

Shielding digital outputs line

1 Strain relief by cable ties

2 Earthing clip

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

10/44

Original operating instructions

ZAdyn4C MRL Electrical installation

5.2 Device set-up / Terminal positions

1 2 3 4 5 6

Device set-up ZAdyn4C MRL AI

1 K7.1 brake contactor

2 K141 manual brake release

3 K140 manual brake release

4 K1 coupling relay for STO activation

5 Coupling relay for STO activation

6 Brake resistor

7 K0 main contactor

8 K7 brake contactor

1 2 3 4 5

Device set-up ZAdyn4C MRL Bx

1 Brake resistance (only for ZAdyn4C MRL BI)

2 K3 brake contactor

3 K4 brake contactor

4 K1 coupling relay for STO activation

5 Coupling relay for STO activation

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

11/44

Original operating instructions

ZAdyn4C MRL Electrical installation

3

7

6

Terminal positions ZAdyn4C MRL AI

1 X400 manual brake release, monitoring brake contactors, X-OUT O41-O44

2 X300 supply brake, remote switch-off, emergency feed brake release, X-OUT O11-O14

3 X600 connection device switch

4 X2 motor

5 X-70 feeding of UPS, supply of UPS

6 X-SC activation of STO relays safety circuit

7 X3 brakes

2 7

6

Terminal positions ZAdyn4C MRL Bx

1 X-BA brakes

2 X-SC activation of STO relays safety circuit

3 X-K2 connection button for emergency mode and two-circuit test

4 X-K1 monitoring of brake contactors

5 Switch Q1, mains connection

6 X3 motor

7 X2 Brake resistance (only for ZAdyn4C MRL BE)

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

12/44

Original operating instructions

ZAdyn4C MRL Electrical installation

5.3 Wiring

The device is fitted with openings and recesses to feed the different cables into the ZAdyn4C MRL.

The figures below show their arrangement and position.

5.3.1 ZAdyn4C MRL AI

1 1

Wiring Wiring

1 Cable brakes, 1 Motor cable

cable X-DCP,

cable X-CAN,

cable X-MON,

cable X-ENC15,

cable X-ENC8,

cable X-SC,

cable X300,

cable X400

1

Wiring

1 Power line

2 Cable X600

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

13/44

Original operating instructions

ZAdyn4C MRL Electrical installation

5.3.2 ZAdyn4C MRL Bx

1

Wiring

1 Cable brakes, cable brake resistance, cable motor temper-

2 ature monitoring, cables X-ENC15, X-ENC8, X-MON

Wiring

1 Cables X-IN, X-OUT, cable protective earth connection

2 Power line

5.4 Strain relief by cable ties

A cable tie must be attached to all lines for strain relief (see fig.).

1 1

2

Strain relief by cable tie on the ZAdyn4C MRL AI

1.2 Strain relief by cable ties

Strain relief by cable tie on the ZAdyn4C MRL Bx

1.2 Strain relief by cable ties

5.5 Protective ground connection

In accordance with the defined networks in DIN EN 60990 the device has a leakage current > 3.5 mA

and must therefore be permanently connected. In accordance with EN 50178 item 5.2.11 and 5.3.2.1,

the PE conductor connection must have a cross-section of at least 10 mm². In the case of PE

conductors < 10 mm², an additional PE conductor must be connected. The cross-section must

correspond at least to the cross-section of the PE conductor on the connecting lead. M6 threaded

bolts are available on the ZAdyn4C MRL for connecting the PE conductors (see fig.).

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

14/44

Original operating instructions

ZAdyn4C MRL Electrical installation

Protective earth connection ZAdyn4C MRL AI

Protective earth connection ZAdyn4C MRL Bx

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

15/44

Original operating instructions

ZAdyn4C MRL Electrical installation

5.6 Mains connection (X1)

Danger!

Before connecting to the mains, check if the technical data on the rating plate of the ZAdyn4C MRL

correspond to the required connection values.

5.6.1 Network form

The mains filter and ZAdyn4C MRL are designed for use in an earthed power supply system.

Permissible mains forms are:

• TN network

• TT network

Information

The mains filter and ZAdyn4C MRL are unsuitable for use in the IT network!

5.6.2 Cable cross section

The line cross-section must be specified dependent on the motor’s rated current and the ambient

conditions (e.g. temperature, wiring method) in accordance with DIN VDE 0100.

5.6.3 Mains fuse

The fuse protection is implemented in accordance with the line cross-section used.

5.6.4 Type of cable

Both rigid and flexible lines can be utilized. The use of wire-end sleeves is recommended for flexible

lines.

The mains line does not have to be shielded.

5.6.5 Connection ZAdyn4C MRL AI

The power cable is connected to the main contactor of the ZAdyn4C MRL AI. The mains connection is

designed with screw contact terminals.

ZAdyn4C MRL AI

K0

L1 2

1 L2 4

L3 6

PE

Mains connection ZAdyn4C MRL AI

1 Mains 3~ 400V/PE/50Hz

5.6.6 Connection ZAdyn4C MRL Bx

The power cable is connected to the device switch of the ZAdyn4C MRL Bx.

ZAdyn4C MRL Bx

Q1

L1 2

1 L2 4

L3 6

PE

Mains connection ZAdyn4C MRL Bx

1 Mains 3~ 400V/PE/50Hz

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

16/44

Original operating instructions

ZAdyn4C MRL Electrical installation

5.7 Motor connection (X3)

5.7.1 Cable cross section

The line cross-section must be specified dependent on the motor´s current and the ambient conditions

(e.g. temperature, wiring method) in accordance with DIN VDE 0298-4.

5.7.2 Type of cable

Always use shielded cables for the motor connections! Both rigid and flexible lines can be installed.

The use of wire-end sleeves is recommended for flexible lines.

Rated voltage U0 / U: 450 / 750 VAC

5.7.3 Cable length

The maximum line length is 25 m. With a motor power line > 25 m compliance with DIN EN 12015

(electromagnetic compatibility – spurious emission and DIN EN 12016 (electromagnetic compatibility

– interference immunity) can no longer be guaranteed.

5.7.4 Connection

Danger!

Always switch off the mains voltage when connecting the motor line. The STO function (operation

without contactors) does not electrically isolate the output stage of the inverter from the motor line

terminal!

The motor connection is designed with spring contact terminals. To avoid damage to the connection

terminals and to ensure a safe contact, a suitable screwdriver must be inserted into the terminals as

far as it will go to fully open them when connecting cables.

Danger!

When operating the motor with a rotary encoder, the line to the motor must be connected on the motor

and inverter side phase-correct: U -> U / V -> V / W -> W.

Never swap the connection; not even if the rotary direction of the motor is false!! If the motor phases

are swapped, motor control is generally not possible. This can lead to jerky movements or uncontrolled

acceleration of the motor.

X3

U

U

M

V

V 3~

W

W

P1 P2

Synchronous motor connection

5.7.5 Electronic short-circuit

If emergency evacuation is performed by opening the brakes, the motor windings are short-circuited

by a self-activating electronic short-circuit to prevent uncontrolled acceleration of the lift. The short-

circuit generates a speed-dependent brake torque which is sufficient in most cases to limit the lift

speed to a safe value.

Information

• The electronic short-circuit is also active when there is no operating voltage on the ZAdyn4C.

• Please contact Ziehl-Abegg if you want to switch off the electronic short-circuit.

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

17/44

Original operating instructions

ZAdyn4C MRL Electrical installation

CAUTION! When operating synchronous motors from other manufacturers, make sure that they can be operated

with the electronic short-circuit and that manual emergency evacuation with short-circuited motor

windings is permissible.

5.8 Motor temperature monitoring (X-MT)

Information

The X-MT terminal is a standard part of the ZAdyn4C MRL frequency inverter.

Information

The detection of over temperature of the motor doesn't cause a drive interruption. The current drive

will be completed.

If an over temperature of the motor will be detected at stop, there is no further drive possible.

The temperature monitoring is carried out according to IEC 61800-5-1:2003-02 (switching point at

3500 Ω)

The following sensor types can be used:

• PTC thermistor (PTC according to DIN 44082)

• Temperature sensor KTY84-130

• Thermal circuit breaker

The used sensor has to be parametrized in the menueMonitoring/P1P2!

Monitor

-" P1P2

|

PTC

|

-" PTC

Motor temp. monitor

U V W PE

M

3~

X-MT

P1 (P1) P1

P2 (P2) P2

Temperature monitoring connection

() terminal designation of connector

Information

If the temperature monitor is not used, it must be switched off (monitors/P1P2=Off)). Short-circuiting

of the inputs P1 and P2 is detected as an error by the ZAdyn4C MRL.

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

18/44

Original operating instructions

ZAdyn4C MRL Electrical installation

5.9 Brake resistor (X 2)

Information

The brake resistance is already integrated into the ZAdyn4C MRL AI and the ZAdyn4C MRL BI.

5.9.1 ZAdyn4C MRL BE

Attention!

CAUTION! An existing temperature monitor absolutely must be connected to the ZAdyn4C MRL AI!

The device can burn out in case of a fault!

Attention!

CAUTION! If the connection of a brake resistor (type BRxx) to the +DC and -DC terminals is faulty, it will emit a

continuous power output and the device will become overheated. If a temperature monitor is not

connected, the device will burn out!

Attention!

CAUTION! The brake resistor or brake chopper used must be configured in the menu Encoder & BC/BC_TYP.

Encoder & BC

-" BC_TYP

|

BR25

|

-" BR25

BR/BC - Typ

Cable length

The maximum line length is 5 m.

When lines over >5 m are used, compliance with DIN EN 12015 (electromagnetic compatibility –

electrical interference) and DIN EN 12016 (electromagnetic compatibility – noise immunity) is no

longer guaranteed.

If the11pre-fabricated5cable is not long enough in the brake resistor of the BR11-A type, this can be

extended up to a length of 5 m.

A shielded, self-extinguising cable is required for this.

Brake-Resistor connection

Information

The brake resistor of the BR11-A type has no temperature monitor.

X2 X2

BR ZAdyn4C MRL

ZAdyn4C MRL

BR

+DC +DC

+DC +DC

R -DC

R -DC

TB1 R

R

1 X-MON

TB2

X-MON

BC

BC +24V

+24V

BR11-A connection Installation position BR17 / BR25 / BR50 / BR100

1 Max. contact load: 5 A / 250 VAC

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

19/44

Original operating instructions

ZAdyn4C MRL Electrical installation

5.10 Digital inputs (X-IN)

5.10.1 Connection with external power supply

+24V GND

+24V

_IN

I01 I02 I03 I04 I05 I06 I07 I08 _IN

GND

X-IN (1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11) (12) (13)

1* 2* 3* 4* 5* 6* 7* 8* 9* 10*

1* 2* 3* 4* 5* 6* 7* 8* 9* 10*

1

0V

+24V

Connection of digital input with external power supply

1 Modulation

() terminal designation of connector

* Wire number of the pre-assembled connecting lead X-I

Information

When using the external power supply the bridges between the terminals +24V / +24V_IN and

GND / GND_IN the pre-assembled control cable X-I are not required. These must be removed!

5.10.2 Connection with internal power supply

+24V GND

X-IN +24V

_IN

I01 I02 I03 I04 I05 I06 I07 I08 _IN

GND

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11) (12) (13)

1* 2* 3* 4* 5* 6* 7* 8* 9* 10*

1* 2* 3* 4* 5* 6* 7* 8* 9*

Connection of digital input with internal power supply

1 Modulation

() terminal designation of connector

* Wire number of the pre-assembled connecting lead X-I

Information

When using the internal power supply a bridge must be inserted between the terminals

+24V / +24V_IN and between GND / GND_IN. These bridges are already integrated into the pre-

assembled X-I cable.

The cable GND_IN (wire no.10) is not required. This must be removed from the connection

terminal both on the converter side and the control side and insulated.

Attention!

CAUTION! The internal 24 V power supply is provided solely for the digital inputs. Switching consumer load with

this voltage is prohibited!

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

20/44

Original operating instructions

ZAdyn4C MRL Electrical installation

5.10.3 Terminal assignment X-IN

You can configure the inputs I1 … I8 assignments. The configuration can be implemented by:

• Presetting the used control system (assignment corresponding to the control requirements)

• Free configuration

Implement configuration of the digital inputs in the Control system\CONFIG menu.

The input assignments dependent on the configuration:

Inputs

Configuration

I01 I02 I03 I04 I05 I06 I07 I08

RV2

00:Free RF* V1* V2* V3* VZ* RV1 UP* Free*

DOWN*

RV2

01:ZA_IO RF V1 V2 V3 VZ RV1 UP Free*

DOWN

RV2

03:BP_IO RF V1 V2 V3 VZ RV1 UP Free*

DOWN

RV2

08:KN_IO RF V1 V2 V3 VZ RV1 UP Free*

DOWN

RV2

11:NL_IO RF V1 V2 V3 VZ RV1 UP Free*

DOWN

RV2

13:SS_IO RF V1 V2 V3 VZ RV1 UP V4*

DOWN

15:ZA_BIN RF DIR BIN0 BIN1 BIN2 Free* Free* Free*

RV2

16:WL_IO RF V1 V2 V3 VZ RV1 UP Free*

DOWN

RV2

21:ST_IO RF V1 V2 V3 VZ RV1 UP Free*

DOWN

RV2

24:CSILVA RF BIN0 BIN1 BIN2 Free* RV1 UP Free*

DOWN

RV1 RV2

25:S+S SBIN2 SBIN1 SBIN0 Free* Free* RF

UP DOWN

27:MAS_BIN RF DIR MBIN0 MBIN1 MBIN2 BR1 BR2 Free*

RV2

30:KS_IO RF V1 V4 V2 VZ RV1 UP V3*

DOWN

RF+ PA-

31:KL_IO V4 V1 V2 V3 VZ RF+RV1

RV2 RA2

RV2

32: S_SMART RF V1 LZ V3 V5 RV1 UP Free*

DOWN

* The function of the inputs can be changed

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

21/44

Original operating instructions

ZAdyn4C MRL Electrical installation

5.11 Digital outputs (X-OUT)

5.11.1 Digital outputs X-OUT

The connection terminal X-OUT is equipped with 5 digital outputs as zero potential relay contacts with

normally open function. The functions of the outputs are pre-parameterised but can be assigned other

functions by changing the parameters.

5.11.1.1 Connection X-OUT

X-OUT O11 O14 O21 O24 O31 O34 O41 O44 O51 O54

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10)

1* 2* 3* 4* 5* 6* 7* 8* 9* 10*

Connection of the digital outputs X-OUT

1 Modulation

() terminal designation of connector

* Wire number of the pre-assembled connecting lead X-O

5.11.2 Terminal assignment X-OUT

The output assignments can be configured. The configuration can be implemented by:

• Presetting the used control system (assignment corresponding to the control requirements)

• Free configuration

Implement configuration of the digital outputs in the Control system\CONFIG menu.

Please refer to the "Parameter list/Control menu" chapter for a description of the individual parameters

The output assignments dependent on the configuration:

Configura- Outputs

tion O11 - O14 O21 - O24 O31 -O34 O41 - O44 O51--54

00:Free Err* MB_Brake* MotContact* V < V_G1* STO-Info*

01:ZA_IO Fault MB_Brake MotContact V < V_G1 STO-Info

03:BP_IO Fault MB_Brake MotContact V < V_G1 STO-Info

08:KN_IO Fault MB_Brake MotContact V < V_G1 STO-Info

11:NL_IO Fault MB_Brake MotContact V < V_G1 STO-Info

13:SS_IO Fault MB_Brake MotContact V < V_G1 STO-Info

15:ZA_BIN Fault MB_Brake MotContact V < V_G1 STO-Info

16:WL_IO Fault MB_Brake MotContact V < V_G1 STO-Info

21:ST_IO Fault MB_Brake MotContact V < V_G1 STO-Info

24:CSILVA Fault MB_Brake MotContact V < V_G1 STO-Info

25:S+S MotContact MB_Brake V=O Fault STO-Info

27:MAS_BIN Fault MB_Brake MotContact Off* STO-Info

30:KS_IO Fault MB_Brake MotContact V < V_G1 STO-Info

31:KL_IO Error MB_Brake MotContact EVAC.DIR STO-Info

32:

Fault MB_Brake MotContact SD STO-Info

S_SMART

* The function of the outputs can be changed

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

22/44

Original operating instructions

ZAdyn4C MRL Electrical installation

5.12 DCP / CAN interface (X-DCP, X-CAN)

Alternatively to the conventional wiring it is possible to activate the ZAdyn4C MRL by DCP or

CANopenLift (see chapter "Serial communication").

Information

The X-DCP and X-CAN terminals are standard parts of the ZAdyn4C MRL.

5.12.1 DCP

Information

• Use a shielded cable for the connection. The shielding must be grounded on the inverter side.

• Make the connection between ZAdyn4C MRL and the control without additional terminal points.

• The maximum line length is 50 m.

X-DCP

(4)

0VD (3) GND

DB (2) DATA - (B)

DA (1) DATA + (A)

DCP connection

() terminal designation of connector

5.13 Interface operation without contactors (X-SC)

The safety circuit must be evaluated for the "Safe Torque Off (STO)" function of the ZAdyn4C MRL.

Relays K1 and K2 are activated depending on the safety circuit. The safety circuit is connected by

cable L-SL-...-HX-BM/SBM-SC to terminal X-SC of the ZAdyn4C MRL.

ZIEHL-ABEGG SE offers the pre-assembled cable L-SL-...-HX-BM/SBM-SC.

See the chapter "Safe Torque Off (STO) function" in the ZAdyn4C operating instructions for further

information about the STO function.

5.13.1 Terminal assignment X-SC

no. Name Function

3 NS N-conductor

2 LS2 Phase safety circuit, activation K2

1 LS1 Phase safety circuit, activation K1

5.13.2 Technical data X-SC

Rated voltage 110 VAC 230 VAC

Operating voltage 94...138 VAC 184...264 VAC

Hold voltage 66 VAC 138 VAC

Drop voltage 44 VAC 72 VAC

Opening time 6 ms

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

23/44

Original operating instructions

ZAdyn4C MRL Electrical installation

5.13.3 Connection X-SC

X-SC 1

NS 3*

3

6A

K2 LS2 2*

2

2

6A

K1 LS1 1*

1

Connection X-SC

1 Modulation

2 Safety circuit

* Wire designation of the pre-assembled cable L-SL-...-HX-BM/SBM-SC

5.14 Encoder connection synchronous motors (X-ENC15)

Information

At the X-ENC 15 connection, both incremental encoders for asynchronous motors and absolute

encoders for synchronous motors can be connected.

Attention!

CAUTION! The pin assignment of the SUB-D-socket X-ENC15 is not standardised. When using encoders

from other manufacturers, make sure that these have the same contact assignment and an

interface with identical specification.

Attention!

CAUTION! Before the encoder is plugged on/connected, the encoder type and resolution used must be

configured in the menus "Encoder & BC/ENC_TYP" and "Encoder & BC/ENC_INC " .

Encoder & BC Encoder & BC

-" ENC_Typ TTL rect.

|

-" ENC_INC 2048

|

|

-" TTL rect. |

-" 2048

Encoder type Encoder resolution

5.14.1 Technical data X-ENC15

Encoder types Absolute value encoder with EnDat or SSI interface

Absolute value encoder type ERN1387

Encoder resolution 512 ... 4096 pulse / revolution

Input resistor 120 Ω

Cut-off frequency 200 kHz

Sine differential signal (at 2.5 V off- 0,6 Vss ... 1,2 Vss (typ. 1Vss)

set against GND)

Connection cable Shielded twisted pair cable

Max. cable length 25 m

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

24/44

Original operating instructions

ZAdyn4C MRL Electrical installation

5.14.2 Pin assignment X-ENC15 for absolute value encoder with EnDat, SSI, ERN1387 and HIPER-

FACE interface

1 DATA Data line for communication with the absolute encoder

2 /DATA Data line inverse

3 /D Analog track D inverse

4 +5 V_E +5/8V voltage supply

(With missing encoder the power supply is switched off)

5 DGND Ground power supply absolute encoder

6 /C Analog track C inverse

7 B Analog track B

8 C Analog track C for transmitting position

9 /CLK Clock signal invers

10 CLK Clock signal for serial transfer

11 D Analog track D for transmitting position

12 A Analog track A

13 /A Analog track A inverse

14 /B Analog track B inverse

15 DGND Ground power supply absolute encoder

Housing Shielding

5.15 Artificial encoder (X-ENCO)

The encoder simulation transforms the signals of the encoder mounted on the motor into differential

signals according to ANSI standard RS422 um and transmits them to the control. The resolution of the

encoder simulations is identical with the resolution of the encoder.

Information

The X-ENCO connection is not a connection for the impulse encoder but an output for transission of

data to the control. The impulse encoder is connected to connections X-ENC8 or X-ENC15.

Information

As a result of the connection of an external 24 V voltage source to terminal X-EXT, the encoder

simulation is active even when the ZAdyn4C MRL is switched off.

5.15.1 Connection X-ENCO

1

X-ENCO

X (14)

/X (13)

Y (12)

/Y (11)

GND (10)

(9)

Artificial encoder connection

1 Signals depending on the rotating direction of the motor (with view to the power take-off side)

() terminal designation of connector

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

25/44

Original operating instructions

ZAdyn4C MRL Electrical installation

5.16 External 24 V power supply (X-EXT)

By applying an external 24 V power supply to terminal X-EXT, the following functions are active even

when the ZAdyn4C is switched off:

• Communication between control and ZAdyn4C MRL

• Artificial encoder

• ZETAPAD (parameter changes are possible)

• USB interface of the ZApad

5.16.1 Technical data

Voltage range 23 ... 26 V

5.16.2 Connection X-EXT

X-EXT

24V

(1)

_EX +24V

GND 0V

1

(2)

_EX

Connection external power supply

1 external power supply

() terminal designation of connector

5.17 Brakes

5.17.1 Brake release monitoring (X-BR)

Information

The brake release monitoring serves as monitoring for redundancy and the operation status of the

brakes.

It is recommended to connect the brake air monitor to the ZAdyn4C MRL for optimum starting and

stopping.

The monitoring conforms chapter 9.10 of EN81-1:2010 for brakes as protection for the upside traveling

elevator car against overspeed.

With activated lock function the brake release monitoring fulfills the requirements for self monitoring

according to chapter 9.11.3 of EN81-1:2010 for brake elements for protection against unintendend

movement of the car.

Monitoring voltage +24 VDC / 12 mA

Contact type Normally open contact (NO) or nor-

mally closed contact (NC)

Number of inputs 4

Clamping range max. 1,5 mm²

The contactor monitoring can be activated/deactivated in the menu Monitoring.

Monitoring

-" BR

|

1*NC

|

-" 3*NC

Brake control (BR1..BR4)

The lock function of the ZAdyn4C is engaged by activating the “LOCKBR=On” parameter in the menu

Monitoring.

Monitoring

-" LOCKBR

|

Off

|

-" On

Lock inverter

Activation of the parameter ensures that the ZAdyn4C locks upon detection of a faulty brake circuit.

The ZAdyn4C lock can only be released by setting the “Monitors / UNLOCK = On” parameter.

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

26/44

Original operating instructions

ZAdyn4C MRL Electrical installation

5.17.2 Connection X-BR

X-MON 1

+24V

_B

(13)

BR1 (12)

BR2 (11)

BR3 (10)

BR4 (9)

Brake release monitor connection

1 Monitoring contacts

() terminal designation of connector

Attention!

CAUTION! The internal 24 V power supply is provided solely for the brake release monitoring. Switching

consumer load with this voltage is prohibited!

5.17.3 Triggering of the brakes

The integrated brake contactors are activated by the frequency inverter. The power supply of the

brake contactors takes place on terminal X-300 (ZAdyn4C MRL AI) respectively X-K (ZAdyn4C MRL

BI und ZAdyn4C MRL BE).

The signal to activate the brake contactors is switched by the digital output 021-024.

Information

To reduce noises when switching-off the brake, during normal operation the brake is switched on the

alternating current side. The brakes are switched-off more slowly and thus quietly through the rectifier.

To ensure instantaneous brake application in emergencies, during inspection drives and return rides,

a second contactor, which disconnects the brake on the direct current side, is used.

Warning!

The power supply of the brake contactors has to be integrated in the safety circuit of the lift. If the

safety circuit will be interrupted, also the power supply of the brake contactors has to be interrupted!

Attention!

CAUTION! Brakes, which are connected to the direct current side, must be protected against excess voltage from

the switching actions by using corresponding varistors! The varistor should be connected as close as

possible to the brake (e.g. in the terminal box of the drive).

Due to the high operating current, master contactors must be used to switch the brakes!

5.17.3.1 Technical data brake contactors

K3/K7* K4/K71* K140/K141*

(ac side) (dc side) (manual brake release)

Operating voltage 88...121 VAC 220...240 VAC 92...127 VAC 184...253 VAC 20,4...26,4 VDC

Power consumption ≤5W ≤5W max. 8 W max. 8 W max. 3,5 W

Opening time 40 ms 40 ms 19 ms 19 ms -

* only with ZAdyn4C MRL AI

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

27/44

Original operating instructions

ZAdyn4C MRL Electrical installation

5.17.3.2 Emergency power suply

Information

If no voltage is available for opening the brake due to a fault in the power supply, an external power

supply can be connected directly to terminal X-300 (ZAdyn4C MRL AI) respectively X-K (ZAdyn4C

MRL BI und ZAdyn4C MRL BE) 5 for manual opening of the brakes.

This ensures fast rescue of trapped passengers in the event of a fault.

5.17.3.3 ZAdyn4C MRL AI

Activation for brakes without overexcitation

X3 22 21 4 3 2 1

K140 K7.1 K7.1

21 22

K1 A2 K2 A2 K7.1 A2 K7 A2

K141

4 13 14

A1 A1 A1 A1

K140

14 13

3 K141

4 (O21)

B U X-OUT

V7 + 5 (O24)

2 ~ ~

9 -

1

A U

24

Q1

23

43 44 4

K140 K141 K3

44 43 3

K140 A2 K141 A2

2

K3 A1 A1

1

F1 (3,15A)

X300 10 11 12 X300 8 9 4 5 X70 3 2 1 X-SC 1 2 3 X400 2 3 4

A+ B+ A/B- L L L N L L N

8 7 6 5 4 2

Activation for brakes ZAdyn4C MRL AI without overexcitation

1 Modulation

2 Manual brake release

3 End safety circuit

4 Input UPS

5 Power supply for the brakes with normal operation

6 Power supply for the brakes with evacuation

7 Power supply for the brakes with brake test

8 Emergency feed brake airing

9 Brake A/B

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

28/44

Original operating instructions

ZAdyn4C MRL Electrical installation

5.17.3.4 ZAdyn4C MRL BI and ZAdyn4C MRL BE

Activation for brakes without overexcitation

X-BA 1 2

K4

K1 A2 K2 A2 K4 A2 K3 A2

4 A1 A1 A1 A1

V7 +

4 3

3 ~ ~ 4 (O21)

K4

B U - X-OUT

5 (O24)

2

7

6 5

1

K4

A U

13 21

6 K4 14 K4 22

K3

5

1 21

3 K3 2 K3 22

K3

4

X-K2 5 6 7 8 9 10 X-K1 1 2 3 4 X-SC 1 2 3

L L L N L L N

5 3 2

6 4

Activation for brakes ZAdyn4C MRL BI and ZAdyn4C MRL BE without overexcitation

1 Modulation

2 Safety circuit

3 Monitoring brake contactors

4 Power supply brakes

5 Emergency operation two-circuit test

6 Manual release of brake A/B

7 Brake A/B

5.18 External monitoring functions

5.18.1 Brake contactors (ZAdyn4C MRL AI, ZAdyn4C MRL BI and ZAdyn4C MRL BE)

5.18.1.1 Technical data auxiliary contacts

Contact type 1x normally closed

contact (NC)

1x normally open

contact (NO)

Min. switching capacity 5 mA / 17 VDC

Max. switching capacity 6 A / 230 VAC

4 A / 24 VDC

Clamping range max. 4,0 mm²

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

29/44

Original operating instructions

ZAdyn4C MRL Electrical installation

5.18.1.2 Assignment connection terminal X400 (ZAdyn4C MRL AI)

22

K7.1

21

21

K7

22

6T3 22

K7 K141

5L3 21

13 21

K7.1 K140

14 22

X400 1 5 6 7 8

1 2

Connecting diagram contactor monitoring ZAdyn4C MRL AI

1 Monitoring brake contactors

K7 Brake contactor AC-side

K7.1 Brake contactor DC-side

2 Monitoring the standstill

K140 Contactor for manual brake release brake A

K141 Contactor for manual brake release brake B

K7 Brake contactor AC-side

K7.1 Brake contactor DC-side

5.18.1.3 Assignment connection terminal X-K (ZAdyn4C MRL Bx)

13 21

K4

K4

14 22

1 21

K3 K3

2 22

1 2 3 4

X-K1

Connecting diagram contactor monitoring ZAdyn4C MRL Bx - integrated brake contactor

K3 Brake contactor AC-side

K4 Brake contactor DC-side

5.18.1.4 Fault and speed monitoring frequency inverter (only ZAdyn4C MRL AI)

2 (O14) 8 (O44)

X-OUT X-OUT

1 (O11) 7 (O41)

X300 18 17 X400 8 9

Connecting diagram fault monitoring Connecting diagram speed monitoring

X-OUT Output "Fault" X-OUT Output "V < V_G1"

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

30/44

Original operating instructions

ZAdyn4C MRL Electrical installation

5.19 Circuit suggestion for ZAdyn4CS MRL

Circuit suggestion for ZAdyn4C MRL AI

ZD4C10K1

Index 03, 11.06.18

ZD4C10K1

1 Monitoring brake contactors

2 Power supply brakes

3 Power supply by UPS

4 Power supply by UPS

5 Remote

6 Power supply brake for brake test

7 Power supply brake for evacuation

8 Emergency feed brake airing

9 Manual brake release

10 Control STO-relay, end safety circuit

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

31/44

Original operating instructions

ZAdyn4C MRL Electrical installation

Circuit suggestion ZAdyn4C MRL Bx with integrated brake activation with bridge rectifiers

ZD4C10K2

Index 03, 11.06.18

ZD4C10K2

1 Control STO-relay, end safety circuit

2 Monitoring brake contactors

3 Power supply brake

4 Pushbutton fort two-circuit test/emergency operation

5 Manual brake release

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

32/44

Original operating instructions

ZAdyn4C MRL Electrical installation

Circuit suggestion ZAdyn4C MRL Bx without integrated brake activation

ZD4C10K3

Index 03, 11.06.18

ZD4C10K3

1 Control STO-relay, end safety circuit

2 Voltage supply Fan 230 VAC *

* In the ZAdyn4C MRL without integrated brake activation, the power supply of the brake is not connected to the ZAdyn.

Therefore, a separate power supply of the fan is necessary. Connect the power supply to the connection terminals X4/1 and

X4/3.

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

33/44

Original operating instructions

ZAdyn4C MRL Electrical installation

Circuit suggestion ZAdyn4C MRL Bx with integrated brake activation with fast acting rectifiers

ZD4C10K6

Index 03, 01.02.19

ZD4C10K6

1 Control STO-relay, end safety circuit

2 Monitoring brake contactors

3 Power supply brake

4 Pushbutton fort two-circuit test/emergency operation

5 Manual brake release

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

34/44

Original operating instructions

ZAdyn4C MRL Device switch Q1 (only for ZAdyn4C MRL AI, optional)

6 Device switch Q1 (only for ZAdyn4C MRL AI, optional)

6.1 Mechanical installation

" Remove the cover of the metal housing of the ZAdyn4C MRL. Loosen the four screws (1) on the

front to do so.

" Remove the cover of the device switch Q1. Loosen the two screws to do so.

" Screw the device switch (4) onto the mounting surface (2) of the fastening plate with 2 fastening

screws (3).

2 3 4

" Perform the electrical installation of the device switch (see chapter "Device switch Q1/Electrical

installation").

" Refit and screw on the cover of the device switch.

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

35/44

Original operating instructions

ZAdyn4C MRL Start-up

6.2 Electrical installation

ZAdyn4C MRL AI

Q1

K0

L3 6 5 6

1 L2 4 3 4

L1 2 1 2

PE PE

2 X600

14 2

13 1

23 3

24 4

Device switch connection

1 Mains 3~ 400V/PE/50Hz

2 auxiliary contacts

7 Start-up

7.1 Testing the "Safe Torque Off (STO)" safety function

In the course of start-up and maintenance, the "Safe Torque Off (STO)" function must be tested as a

safety function test.

Danger!

To prevent unintentional movement of the lift car, the fuse for the brakes supply must be removed for

tests which are conducted with the drive at a standstill. In the MRL devices, the contactors for the

brakes are activated by the STO coupling relay supply; the brakes could open unintentionally.

The procedure for testing the "Safe Torque Off (STO)" function is described in the chapter "Testing the

"Safe Torque Off (STO)" function" of the ZAdyn4C operating instructions.

In the ZAdyn4C MRL the relay contacts of the coupling relay for STO activation are not accessible

because the control unit is usually installed in the lift shaft. The coupling relays used for activation are

activated separately. The described tests must be performed by suitable activation of the relays.

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

36/44

Original operating instructions

ZAdyn4C MRL Enclosure

8 Enclosure

8.1 Technical data ZAdyn4C MRL

8.1.1 ZAdyn4C 011 - 032 MRL

ZAdyn

4CS011- 4CS013- 4CS017 4CS023- 4CS032-

MRL-AI/BI/ MRL-AI/BI/ -MRL-AI/BI/ MRL-AI/BI/ MRL-AI/BI/

BE BE BE BE BE

Electrical data

Mains connection voltage [V] 3~180 ... 440 absolut

Mains frequency [Hz] 50 / 60 (±1,5 Hz)

Typ. motor output (400 V) [kW] 4.6 5.5 7.5 11 14

Duty cycle at rated current and clock frequency [%] 60

8 kHz

Rated current for 60% duty ratio and clock [A] 11 13 17 23 32

frequency 8 kHz fix

Nominal current for 60% switch-on duration and [A] 9 11 15 20 27

switching frequency 12 kHz fix1)

Nominal current for 60% switch-on duration and [A] 8 10 13 17 23

switching frequency 16 kHz fix1)

Max. operating current (for max. 3 s) [A] 20 24 31 42 58

Power loss at rated current, clock frequency [W] 193 204 242 309 424

8 kHz and duty ratio of 60 %

Power loss at rated current, clock frequency [W] 298 326 373 475 612

16 kHz and duty ratio of 60%

Heat dissipation standstill 4CS [W] max. 12

Heat dissipation stand-by 1 4CS [W] max. 12

Heat dissipation stand-by 2 4CS [W] max. 12

Switching frequency [kHz] 4 ... 16

Brake contactor power loss [W] max. 12

Motor frequency [Hz] max. 200

2

Max. terminal cross-section line/motor/brake [mm ] 16

chopper/brake resistor

Min. cable cross-section [mm2] 11 11 11 11 14

Brake-Chopper / Brake-Resistor

Min. cable cross-section [mm2] 11 11 11 11 14

Motor

Ambient conditions

The user must ensure that the specified ambient conditions are observed.

Protection rating IP20

Ambient temperature for operation [°C] 0 ... 45, from 40 °C power reduction by1.66% per 1 k temperature

increase

Relative humidity [%] 90 / condensation prohibited

Installation height [m über bis 2000, ab 1000 m Leistungsreduzierung um 1% pro 100 m

NN]

Storage and shipping temperature [°C]

Degree of soiling (in acc. with DIN EN 61800-5- 2

1)

Physical data

Weight ZAdyn4CS MRL AI [kg] 23.9 24.7 25,1 26.2 28.5

Weight ZAdyn4CS MRL BI [kg] 23.1 23.9 24.3 25.4 27.7

Weight ZAdyn4CS MRL BE [kg] 20.9 21.7 22.1 23.2 25.5

Dimensions h x w x d [mm] 429 x 300 x 191

1)

with a variable switching frequency (power component/M_PWM=AUTO menu), there is no reduction in power

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

37/44

Original operating instructions

ZAdyn4C MRL Enclosure

8.2 EC/EU declaration of conformity - Translation -

(english)

A-KON16_06-GB

1741 Index 003

Manufacturer: ZIEHL-ABEGG SE

Heinz-Ziehl-Straße

74653 Künzelsau

Germany

The manufacturer shall bear sole responsibility for issuing this EC/EU declaration of

conformity.

Product description: Control devices ZAdyn/ZETADYN for elevator machines

Frequency inverters with a safe torque off (STO) function according to

the Machinery directive 2006/42/EC, Annex IV, Nr. 21.

Type: ZAdyn4CA...

ZAdyn4CS...

ZETADYN 4CA...

ZETADYN 4CS...

ZAdynpro...

(The type details contain further additions concerning the version, e.g. ZAdyn4CA 018

HY)

Serial number from

30284129/0001

The above mentioned products of this declaration fulfil all relevant provisions of the following Directives of

the Union:

Machinery directive 2006/42/EC

EMC Directive 2014/30/EU

Because of the accordance with the Machinery directive, the protection targets of the Low voltage directive

2014/35/EU are also fulfilled.

The following harmonised standards have been used:

EN 61800-5-1:2007 Adjustable speed electrical power drive systems - Part 5-1:

Safety requirements -

Electrical, thermal and energy

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

38/44

Original operating instructions

ZAdyn4C MRL Enclosure

IEC 61800-5-2:2016 Adjustable speed electrical power drive systems – Part 5-2:

Safety requirements –

Functional

EN 62061:2005 + Safety of machinery -

A1:2013 Functional safety of safety-related electrical, electronic and programmable electronic

control systems

EN ISO 13849-1:2008 + Safety of machinery -

AC:2009 Safety-related parts of control systems -

Part 1: General principles for design

EN ISO 13849-2:2012 Safety of machinery -

Safety-related parts of control systems -

Part 2: Validation

EN 61800-3:2004 + Adjustable speed electrical power drive systems -

A1:2012 Part 3: EMC requirements and specific test methods

EN 12015:2014 Electromagnetic compatibility-

Productfamily standard for lifts, escalators and moving walks - Emission

EN 12016:2013 Electromagnetic compatibility-

Productfamily standard for lifts, escalators and moving walks - Immunity

The EG type-examination procedures referred to in the enclosure IX of the Machinery directive 2006/42/EC was

carried out by TÜV Rheinland and certified by the type-examination certificate 01/205/5288.01/17

The identification number / address of the notified body is:

NB 0035

TÜV Rheinland Industrie Service GmbH

Am Grauen Stein

51105 Köln

Germany

This declaration relates exclusively to the product in the state in which it was placed on the market, and excludes

components which are added and/or operations carried out subsequently by the final user.

The authorised representative for the assembly of the technical file is:

Mr. Roland Hoppenstedt (see above for address).

Künzelsau, 10.10.2017

(place and date of issue )

ZIEHL-ABEGG SE ZIEHL-ABEGG SE

Werner Bundscherer Roland Hoppenstedt

Director Drive Division Technical Director Drive Division

(name, function) (name, function)

(signature) (signature)

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

39/44

Original operating instructions

ZAdyn4C MRL Enclosure

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

40/44

Original operating instructions

ZAdyn4C MRL Enclosure

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

41/44

Original operating instructions

ZAdyn4C MRL Enclosure

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

42/44

Original operating instructions

ZAdyn4C MRL Enclosure

R-TBA14_01-GB 1845 Part.-No. 00163419-GB

43/44

© by Ziehl-Abegg - - - 00163419-GB - 1845 - - - Subject to technical modifications

Customer Service

phone +49 7940 16-308

fax +49 7940 16-249

drives-service@ziehl-abegg.com

Headquarters

ZIEHL-ABEGG SE

Heinz-Ziehl-Straße · 74653 Künzelsau

Germany

phone +49 7940 16-0 · fax +49 7940 16-249

drives@ziehl-abegg.de www.ziehl-abegg.com

You might also like

- MR LTC Type RMV-II-TL7002.05Document48 pagesMR LTC Type RMV-II-TL7002.05Yudis MercadoNo ratings yet

- Trio Strartup PDFDocument77 pagesTrio Strartup PDFMuhammad AhmadNo ratings yet

- Surescan SR Power Converter: Fault Investigation ManualDocument107 pagesSurescan SR Power Converter: Fault Investigation Manualfauzy syaeful100% (1)

- Ziehlabegg Motor SM200. 40C PDFDocument60 pagesZiehlabegg Motor SM200. 40C PDFalper sungurNo ratings yet

- XXXX Zadyn4ca Hydrulic SeriesDocument28 pagesXXXX Zadyn4ca Hydrulic SeriesMohamed SaadNo ratings yet

- Technical Dossier: Installation - Assembly - Start-Up Use - Maintenance - RepairDocument45 pagesTechnical Dossier: Installation - Assembly - Start-Up Use - Maintenance - Repairtuner12No ratings yet

- ZIEHL-ABEGG HDSD ZAdynpro Part1Document60 pagesZIEHL-ABEGG HDSD ZAdynpro Part1Phạm MạnhNo ratings yet

- MC Propeller Flow Meters: Installation, Operation and Maintenance ManualDocument30 pagesMC Propeller Flow Meters: Installation, Operation and Maintenance ManualEquitec CalibrationNo ratings yet

- MTL 4500 - 4600 ManualDocument72 pagesMTL 4500 - 4600 ManualAjayNo ratings yet

- Xtreme Installation ManualDocument80 pagesXtreme Installation ManualMihai CindeaNo ratings yet

- Zatop Sm160 30b 40b InglesDocument68 pagesZatop Sm160 30b 40b InglesElieser DiazNo ratings yet

- Itron Delta RPD Meters - LubricantDocument5 pagesItron Delta RPD Meters - Lubricantravirebba9695No ratings yet

- Redundant Fieldbus Power System For Foxboro EVO Control SystemsDocument20 pagesRedundant Fieldbus Power System For Foxboro EVO Control SystemsAsif KhanNo ratings yet

- Diris A 40 Installation and Operating Manual 2018-01-545802b enDocument58 pagesDiris A 40 Installation and Operating Manual 2018-01-545802b entholgasenelNo ratings yet

- Operating Instruction ZETADYN 4CDocument204 pagesOperating Instruction ZETADYN 4CMohamed SaadNo ratings yet

- Hipace300 ManualDocument44 pagesHipace300 ManualFellipo CamposNo ratings yet

- GFD MgeDocument72 pagesGFD MgeMárton HNo ratings yet

- EK F200K DLT7621 19 aEN 005Document18 pagesEK F200K DLT7621 19 aEN 005Dio MaseraNo ratings yet

- LED Assembly (Simulation) InfoDocument22 pagesLED Assembly (Simulation) Infofangs997No ratings yet

- Newport NK180 Owners ManualDocument47 pagesNewport NK180 Owners Manualricardo.leandichoNo ratings yet

- FDC7000ServiceManual PDFDocument366 pagesFDC7000ServiceManual PDFRene Samos100% (1)

- Operating Instructions g500-B Bevel Gearboxes ATEX g500 Gearboxes ENDocument44 pagesOperating Instructions g500-B Bevel Gearboxes ATEX g500 Gearboxes ENbensho348No ratings yet

- 080 - HE ManualDocument53 pages080 - HE ManualThe LamNo ratings yet

- AC50 1 68501 Part1 - enDocument420 pagesAC50 1 68501 Part1 - enM Refai100% (1)

- RevA TruckMountArrowBdsOwnersManualDocument52 pagesRevA TruckMountArrowBdsOwnersManualgino sasNo ratings yet

- Ecblue: Ec-Centrifugal Fans With Top EfficiencyDocument42 pagesEcblue: Ec-Centrifugal Fans With Top EfficiencyCiprian BalcanNo ratings yet

- Ecblue: Ec Centrifugal Housing FansDocument42 pagesEcblue: Ec Centrifugal Housing Fansjose luisNo ratings yet

- Eicedriver™: Asic & Power IcsDocument28 pagesEicedriver™: Asic & Power Icsy2k_yah7758No ratings yet

- Suricata Readthedocs Io en Suricata 5.0.3 PDFDocument358 pagesSuricata Readthedocs Io en Suricata 5.0.3 PDFEnrique Herrera NoyaNo ratings yet

- Service: Marine Generator SetsDocument116 pagesService: Marine Generator SetsWilly Alexander RamirezNo ratings yet

- TOEZ-S616-10.2 VS-616 G2 Instructions (460V 0.4K To 18.5K)Document53 pagesTOEZ-S616-10.2 VS-616 G2 Instructions (460V 0.4K To 18.5K)UsamaTariqNo ratings yet

- Vs1Sp AC V/HZ and Sensorless Vector Control: Installation & Operating ManualDocument196 pagesVs1Sp AC V/HZ and Sensorless Vector Control: Installation & Operating ManualAndres NovilloNo ratings yet

- 2 Finger 85 141105Document81 pages2 Finger 85 141105Pham LongNo ratings yet

- 2ED20I12F2Document28 pages2ED20I12F2ALVARO LEALNo ratings yet

- Centrifugation - Operating Manual - Centrifuge 58XX Family PDFDocument126 pagesCentrifugation - Operating Manual - Centrifuge 58XX Family PDFMisael CrespínNo ratings yet

- 0460 671 161 GBDocument44 pages0460 671 161 GBDavid MangionNo ratings yet

- Fleck 9000 SXTDocument108 pagesFleck 9000 SXTFernando HinostrozaNo ratings yet

- Wiring E1102000143GB03Document122 pagesWiring E1102000143GB03Gilberto100% (2)

- Netconvis@ZasetDocument67 pagesNetconvis@ZasetJarosław SkarbekNo ratings yet

- 307.1143.3.6# 02 Manuale Agrovector 40.8 - 40.9 IngDocument179 pages307.1143.3.6# 02 Manuale Agrovector 40.8 - 40.9 IngHugues DescharmesNo ratings yet

- # Delta StringDocument108 pages# Delta StringV'nay KuMarNo ratings yet

- Ex Motor Manual 3gzf500730-47 Rev G 06-2019 en FR de It PT Es TR LQPDocument254 pagesEx Motor Manual 3gzf500730-47 Rev G 06-2019 en FR de It PT Es TR LQPChrist Rodney MAKANANo ratings yet

- Powerware 9395 Integrated Battery Cabinet (Model IBC-L) Installation ManualDocument52 pagesPowerware 9395 Integrated Battery Cabinet (Model IBC-L) Installation ManualalexNo ratings yet

- Low Voltage Motors Installation, Operation, Maintenance and Safety ManualDocument32 pagesLow Voltage Motors Installation, Operation, Maintenance and Safety ManualTowfiqur RahmanNo ratings yet

- EK EtamaticV DLT2004 22 aEN 022 1Document30 pagesEK EtamaticV DLT2004 22 aEN 022 1Deilan HarjantoNo ratings yet

- Kempact R A Om enDocument40 pagesKempact R A Om enAmir ZorlakNo ratings yet

- Operating Instruction Fcontrol FXDMDocument97 pagesOperating Instruction Fcontrol FXDMGrascia RoloNo ratings yet

- Ba880 VLR60-251 enDocument34 pagesBa880 VLR60-251 enluislisinNo ratings yet

- Operating Instructions For Actuators Type AB: OM-ENGLISH-AB-V2.05-2017.06.28Document21 pagesOperating Instructions For Actuators Type AB: OM-ENGLISH-AB-V2.05-2017.06.28Nikhil AggarwalNo ratings yet

- SuricataDocument358 pagesSuricatanamelessNo ratings yet

- Pfeiffer ASM 340 Operating InstructionsDocument77 pagesPfeiffer ASM 340 Operating InstructionsPérsio Mozart PintoNo ratings yet

- 121762oen 01Document71 pages121762oen 01210719872010No ratings yet

- Centrifugation - Operating Manual - Centrifuge 5804 5804 R - Centrifuge 5810 5810 RDocument130 pagesCentrifugation - Operating Manual - Centrifuge 5804 5804 R - Centrifuge 5810 5810 Ralwan noval maulanaNo ratings yet

- Cat EMCP 4.4 Supervisory Control Panel A&i (LEBE0040-00)Document136 pagesCat EMCP 4.4 Supervisory Control Panel A&i (LEBE0040-00)marvinNo ratings yet

- Installation and Operating Manual: IOMMASGPXX00-GB - 00Document64 pagesInstallation and Operating Manual: IOMMASGPXX00-GB - 00Khách Sạn Hoàng PhốNo ratings yet

- Lenze AC MotorDocument56 pagesLenze AC MotorHarley AnanaNo ratings yet

- 34830H61 - Rev C - Thermo Scientific Revco Laboratory Refrigerators A and D Voltages - Installation and Operation ManualDocument19 pages34830H61 - Rev C - Thermo Scientific Revco Laboratory Refrigerators A and D Voltages - Installation and Operation ManualCalixto GrajalesNo ratings yet

- Danfoss IOM APP 1.5 3.5 L User ManualDocument70 pagesDanfoss IOM APP 1.5 3.5 L User ManualSaravanan MNo ratings yet

- Elmo Rletschle V-VC 202 User ManualDocument32 pagesElmo Rletschle V-VC 202 User ManualFirdhaus JaniNo ratings yet

- HPV1000 JVOP App - Note - 28 PM Guide R1Document8 pagesHPV1000 JVOP App - Note - 28 PM Guide R1m.alfarez87gmail.comNo ratings yet

- HPV1000 JVOP App - Note - 30 Pre Torque Setup Guide R1Document4 pagesHPV1000 JVOP App - Note - 30 Pre Torque Setup Guide R1m.alfarez87gmail.comNo ratings yet

- HPV1000-App - Note - 33b - L1000A DCP Closed Loop Guide R1.1Document10 pagesHPV1000-App - Note - 33b - L1000A DCP Closed Loop Guide R1.1m.alfarez87gmail.comNo ratings yet

- ZIEHL ABEGG Operating Instructions ZAdyn4C EnglishDocument224 pagesZIEHL ABEGG Operating Instructions ZAdyn4C Englishm.alfarez87gmail.com100% (1)

- Addendum For L1000A Technical Manual: Yaskawa Europe GMBH 1Document89 pagesAddendum For L1000A Technical Manual: Yaskawa Europe GMBH 1m.alfarez87gmail.comNo ratings yet

- Low Harmonics Regenerative Matrix Converter: Certified For ISO9001 and ISO14001Document48 pagesLow Harmonics Regenerative Matrix Converter: Certified For ISO9001 and ISO14001m.alfarez87gmail.comNo ratings yet

- Bone McqsDocument4 pagesBone McqsAwan1994100% (2)

- A8t PD-TemperKote850Document2 pagesA8t PD-TemperKote850Janet BastidaNo ratings yet

- Boysen Epoxy Primer: Description Technical DataDocument2 pagesBoysen Epoxy Primer: Description Technical DataRaymond R Rosales100% (4)

- Down SyndromeDocument4 pagesDown Syndromeapi-165286810No ratings yet

- 39-Article Text-131-1-10-20191111Document9 pages39-Article Text-131-1-10-20191111berlian gurningNo ratings yet

- Royal Mega Organic Food ParkDocument25 pagesRoyal Mega Organic Food ParkCHARAK RAYNo ratings yet

- Thermal ComfortDocument18 pagesThermal ComfortIlham AndiNo ratings yet

- Technical Manual FOR H1252B DC Printer: S.P. Radio A/S Aalborg DenmarkDocument48 pagesTechnical Manual FOR H1252B DC Printer: S.P. Radio A/S Aalborg DenmarkDharan NarayananNo ratings yet

- KJT - CatalogDocument15 pagesKJT - CatalogGurdip Singh ChawlaNo ratings yet

- Community Development ProjectDocument15 pagesCommunity Development Projectabhi4you.lukNo ratings yet

- Current Developments in Marine Microbiology High-Pressure Biotechnology and The Genetic Engineering of PiezophilesDocument8 pagesCurrent Developments in Marine Microbiology High-Pressure Biotechnology and The Genetic Engineering of PiezophileskiaNo ratings yet

- The Anxiety Sensitivity Index:: Construct Validity and Factor Analytic StructureDocument5 pagesThe Anxiety Sensitivity Index:: Construct Validity and Factor Analytic StructureTomás ArriazaNo ratings yet

- Schreiber Engineering: Model No. 400 ACDocument4 pagesSchreiber Engineering: Model No. 400 ACcarlo jose cortez montano0% (1)

- Answering Cause and Effect Questions in The Reading TestDocument3 pagesAnswering Cause and Effect Questions in The Reading TestChahat GuptaNo ratings yet

- DIASSDocument7 pagesDIASSJam Dela CruzNo ratings yet

- Njqs Core Audit Module - Rev1.6cDocument14 pagesNjqs Core Audit Module - Rev1.6cNene UmohNo ratings yet

- Chapter 10Document9 pagesChapter 10Patrick Earl T. PintacNo ratings yet

- Lesson 0: Bach CentreDocument8 pagesLesson 0: Bach CentrewasuvetiNo ratings yet

- Cyclo GestDocument2 pagesCyclo GestirfanascribdNo ratings yet

- Report On Strategic Analysis of Oceania Dairy Limited - The Competitive AdvantagesDocument17 pagesReport On Strategic Analysis of Oceania Dairy Limited - The Competitive AdvantagesYu Hong LINNo ratings yet

- SRP (390 405) BMD HV - 182 - en - 2021V2.0Document2 pagesSRP (390 405) BMD HV - 182 - en - 2021V2.0Kholis MursyidNo ratings yet

- GLEN 2018 Resources Reserves ReportDocument67 pagesGLEN 2018 Resources Reserves ReportMauricio Cherman GonzálezNo ratings yet

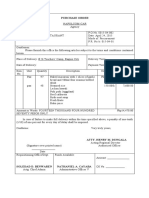

- PO-Purchase Order CATERINGDocument9 pagesPO-Purchase Order CATERINGNarz SabangNo ratings yet

- 3.2 The - Lay - ReportsDocument237 pages3.2 The - Lay - Reportsdavidescu5costin33% (3)

- Especificaciones Motor CatDocument5 pagesEspecificaciones Motor CatWalter TaucherNo ratings yet

- Benefits of Coconut OilDocument4 pagesBenefits of Coconut Oilsrinivasan9No ratings yet