Professional Documents

Culture Documents

Chapter 20-52-00, 201 Chapter 20-53-00, 201: Table 601. Tools/Equipment and Recommended Materials

Uploaded by

ianmcnultywork83Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 20-52-00, 201 Chapter 20-53-00, 201: Table 601. Tools/Equipment and Recommended Materials

Uploaded by

ianmcnultywork83Copyright:

Available Formats

Model 390 Premier Maintenance Manual (Rev B2)

56-00-00 (Rev B1)

WINDOWS - INSPECTION/CHECK

1. Information

Refer to Chapter 20-52-00, 201 for information on tools and equipment referenced in Table 601. Refer to Chapter 20-53-00, 201 for

information on recommended materials referenced in Table 601.

Table 601. Tools/Equipment and Recommended Materials

RECOMMENDED

ITEM TOOLS AND EQUIPMENT ITEM

MATERIALS

050 Surface Seal ® Master Kit

ASTM Glass Scratch Visual

210 Comparison Standard Set

(ASTM F 428-7)

2. Front and Side Windshield Inspection

The front and side windshield surface seal coating will be damaged if they are cleaned with solvents or abrasive material. If the

surface seal is damaged, it will need to be completely removed and a new coating applied. The requirements for evaluation,

cleaning, removal and re-coating of the front and side windshields is contained in the Surface Seal Maintenance, Assessment,

Application Procedures for Aircraft and Specialty Glass-Faced Windshields (Part number DSS 4042) which is obtained as part of

the Surface Seal ® Master Kit (050, Table 601).

Inspect the front and side windshields for delamination, bubbles, discoloration, scratches and all other evidence of damage. Refer to

Table 602 for damage types and recommended action. A preflight inspection should be conducted by the pilot to disclose any

possible condition that could warrant further inspection as noted below. These windows are life-limited (Ref. Airworthiness

Limitations Manual).

Table 602. Front and Side Windshield Damage

Damage Type Damage Limits Recommended Action

Delamination - the disbonding of Up to two inches from the edge of the

interlayer material from a glass ply. A daylight opening around the entire

delaminated area can be either periphery with four inches penetration

transparent (clear) or translucent (milky allowed in the corners. Localized areas of

If delamination and/or crackling exceed the

white) if moisture ingression has occurred. delamination are allowed to exceed the

stated limits, replace the windshield.

continuous peripheral limit as long as pilot

Crackling - the degradation of urethane visibility is not impaired. Delamination in

due to exposure to moisture and has an the area of the heating system is not

appearance similar to dry mud. allowed.

Windshield structural integrity is not

Bubbles - trapped air within the interlayer, affected by the presence of bubbles. Windshield should be replaced if vision is

impaired by bubbles or window heating

normally spherical in shape. Check the window heating resistance is

resistance is outside of acceptable limits.

within acceptable limits.

Discoloration - dark brown or black areas Discoloration on or near the bus bar is

Windshield should be replaced when

on the windshield. Subtle color changes allowed, but the window heating resistance

window heating resistance is outside of

are not the result of an electrical check must be performed every 200 hours

acceptable limits (Ref. 30-40-00, 101).

discrepancy. to verify it is within acceptable limits.

Moisture present at the windshield bus bar Windshield should be replaced at the next

Moisture

area. scheduled servicing.

If vision is not impaired the windshield

Windshield structural integrity is not should be replaced at the next

Scratches - Outer Ply affected but could impact on the service maintenance opportunity. If vision is

life of the component. impaired then the windshield should be

replaced.

Copyright © Textron Aviation Inc. Page 1 of 3

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Tue Dec 07 12:37:17 CST 2021

You might also like

- 753-826 - Cheyenne Service Manual - Pa-31t Cheyenne - Cheyenne II, Pa-31t1 Cheyenne I - Ia, Pa-31t2 Cheyenne II XLDocument8 pages753-826 - Cheyenne Service Manual - Pa-31t Cheyenne - Cheyenne II, Pa-31t1 Cheyenne I - Ia, Pa-31t2 Cheyenne II XLGustavo HofstatterNo ratings yet

- Paul Wade - The Ultimate Isometrics Manual - Building Maximum Strength and Conditioning With Static Training-Dragon Door Publications (2020) - 120-146Document27 pagesPaul Wade - The Ultimate Isometrics Manual - Building Maximum Strength and Conditioning With Static Training-Dragon Door Publications (2020) - 120-146usman azharNo ratings yet

- Check Windshield For DamageDocument2 pagesCheck Windshield For Damagex7c56d5zy8No ratings yet

- 2750 514-23 en Rev BDocument4 pages2750 514-23 en Rev BGuitART TVNo ratings yet

- Windshield - Inspection/Check Aircraft Maintenance Manual: PAGE PRINTED ON 4-14-2017Document24 pagesWindshield - Inspection/Check Aircraft Maintenance Manual: PAGE PRINTED ON 4-14-2017Adhitya RamadhanNo ratings yet

- grg10 2Document4 pagesgrg10 2jrkennedy262No ratings yet

- Inspeccion de Mantenimiento Por Vida Limite.Document11 pagesInspeccion de Mantenimiento Por Vida Limite.francisco ybarra blancoNo ratings yet

- Quality Criteria en PDFDocument16 pagesQuality Criteria en PDFNapassorn KeeratibunharnNo ratings yet

- Astm C1376 03Document1 pageAstm C1376 03MOHAMMADNo ratings yet

- 14.body (Interior and Exterior)Document118 pages14.body (Interior and Exterior)robin machadoNo ratings yet

- Time Limits/Maintenance Checks Time Limits Inspection/Check: Maintenance Manual (Rev G12) 05-10-00 (Rev Apr 1/15)Document6 pagesTime Limits/Maintenance Checks Time Limits Inspection/Check: Maintenance Manual (Rev G12) 05-10-00 (Rev Apr 1/15)Nathaniel LuraNo ratings yet

- Astm C1376-2003Document3 pagesAstm C1376-2003y2kareinNo ratings yet

- PM-965-041C Bell 204 - 205 - 210 - 212 - 412 WSPS MM and IplDocument30 pagesPM-965-041C Bell 204 - 205 - 210 - 212 - 412 WSPS MM and IplLuis Antonio HermozaNo ratings yet

- FCCU Expansion Joint On-Site Inspection ServiceDocument4 pagesFCCU Expansion Joint On-Site Inspection ServiceliNo ratings yet

- 03 Iris1Document12 pages03 Iris1AndiosoNo ratings yet

- Inst - 1002 RLG ObDocument10 pagesInst - 1002 RLG ObviksursNo ratings yet

- 04-ComSpec Property Inspection Report - SampleDocument11 pages04-ComSpec Property Inspection Report - SamplesafinditNo ratings yet

- ML B 90 Bkasr158Document5 pagesML B 90 Bkasr158mario2No ratings yet

- Alu 80 C Technical Datasheet Installation Advice: 7 YearsDocument1 pageAlu 80 C Technical Datasheet Installation Advice: 7 YearsredineziriNo ratings yet

- QY360 Blasting Wheel Operation ManualDocument15 pagesQY360 Blasting Wheel Operation ManualDecho KrachevNo ratings yet

- VersiFlex FRS PVC Membrane TDBDocument2 pagesVersiFlex FRS PVC Membrane TDBRafael Ramirez CasateNo ratings yet

- Window Systems 061506 RevisedDocument2 pagesWindow Systems 061506 RevisedDavid SandovalNo ratings yet

- Renderoc SP40: Constructive SolutionsDocument2 pagesRenderoc SP40: Constructive SolutionsChandan MirajkarNo ratings yet

- V4500 Bypass Mulitslide Installation Instructions BypassDocument17 pagesV4500 Bypass Mulitslide Installation Instructions BypassJames ReiterNo ratings yet

- Corro-Coat PE Series 50: Technical Data SheetDocument3 pagesCorro-Coat PE Series 50: Technical Data SheetBiju_PottayilNo ratings yet

- 121 UkDocument4 pages121 UkAhmed IbrahimNo ratings yet

- Astm D2563 - 94 (R2002)Document24 pagesAstm D2563 - 94 (R2002)Jaechang LeeNo ratings yet

- Time Limits/Maintenance Checks Time Limits Inspection/CheckDocument7 pagesTime Limits/Maintenance Checks Time Limits Inspection/CheckWalter TorenaNo ratings yet

- ASTM D2563 Visual Inspection GRP Laminates PDFDocument24 pagesASTM D2563 Visual Inspection GRP Laminates PDFbiondimi100% (1)

- Technical Specification For Dow Corning 789Document2 pagesTechnical Specification For Dow Corning 789Akash SharmaNo ratings yet

- 86 Aluminium Repair PrecautionsDocument13 pages86 Aluminium Repair PrecautionsAdrianNo ratings yet

- Dow Corning 991 Product InfoDocument4 pagesDow Corning 991 Product InfocurlyjockeyNo ratings yet

- Flat Glass: Standard Specification ForDocument8 pagesFlat Glass: Standard Specification ForMohd parvez100% (1)

- 15 - DTA Guidelines For Repairs and AltertaionsDocument55 pages15 - DTA Guidelines For Repairs and AltertaionsskullmacNo ratings yet

- ASTM D2563 Defectos VisualesDocument24 pagesASTM D2563 Defectos VisualesCristian VegaNo ratings yet

- Repair and Re-Cover Roofing Guide: 1.877.MAMMOUTHDocument28 pagesRepair and Re-Cover Roofing Guide: 1.877.MAMMOUTHmichelNo ratings yet

- 611 Wipers and WashersDocument8 pages611 Wipers and Washersخليل مقبوعNo ratings yet

- PDS - AFTEK Flex-Pro PU Sealant PDFDocument4 pagesPDS - AFTEK Flex-Pro PU Sealant PDFLexyNo ratings yet

- Flex-Pro Pu: Technical Data SheetDocument4 pagesFlex-Pro Pu: Technical Data SheetKenneth CabacunganNo ratings yet

- 1910 - Handy Adhesion PDFDocument3 pages1910 - Handy Adhesion PDFMohamed NouzerNo ratings yet

- Dow Corning 732 Multi-Purpose Sealant: Product InformationDocument2 pagesDow Corning 732 Multi-Purpose Sealant: Product InformationProject Sales CorpNo ratings yet

- PU523 TDS - TremcoDocument2 pagesPU523 TDS - TremcoZerina MoralesNo ratings yet

- World-Leading Skylights and Roof Windows: Product Information and Price List 1st April 2020Document16 pagesWorld-Leading Skylights and Roof Windows: Product Information and Price List 1st April 2020Toni Rose Peliño CaNo ratings yet

- Tds - Jotun - Guard Classic EtDocument3 pagesTds - Jotun - Guard Classic Etvijh van niemannNo ratings yet

- Sikalastic - 614: Single Component, Polyurethane, Liquid Waterproofing MembraneDocument7 pagesSikalastic - 614: Single Component, Polyurethane, Liquid Waterproofing MembraneANDRE AURELLIONo ratings yet

- TL 52038 enDocument12 pagesTL 52038 enCindy Rivera100% (1)

- SF6 Leak Detector TIF XP-1A ManualDocument20 pagesSF6 Leak Detector TIF XP-1A ManualwubinhappydayNo ratings yet

- SDI 133 Guideline For Specifying Steel Doors and Frames For BlastDocument8 pagesSDI 133 Guideline For Specifying Steel Doors and Frames For BlastAngusNo ratings yet

- Xpower VRF SeriesDocument11 pagesXpower VRF SeriesMelissa MendozaNo ratings yet

- Dow Corning 791Document3 pagesDow Corning 791Trung Nguyễn Ngọc100% (1)

- Causes and Solutions For Cracking in Grouts: Technical BulletinDocument2 pagesCauses and Solutions For Cracking in Grouts: Technical BulletinCarlos AlvaNo ratings yet

- Classifying Visual Defects in Glass-Reinforced Plastic Laminate PartsDocument24 pagesClassifying Visual Defects in Glass-Reinforced Plastic Laminate Partsbassl.elkingNo ratings yet

- Inspection of Transparent Parts by Prism: Standard Practice ForDocument6 pagesInspection of Transparent Parts by Prism: Standard Practice ForJuanNo ratings yet

- iKOTE AC 40 (DEC-2023) V1.3Document2 pagesiKOTE AC 40 (DEC-2023) V1.3nguyen hoang AnhNo ratings yet

- Astm D4060 14Document5 pagesAstm D4060 14hadi ebrahimfathNo ratings yet

- Damper Shutter Accessories Product Guide 1Document26 pagesDamper Shutter Accessories Product Guide 1Omar KhaterNo ratings yet

- Asme D2563 PDFDocument18 pagesAsme D2563 PDFMohd Idris MohiuddinNo ratings yet

- Silicon Dow Corning Ficha TecnicaDocument2 pagesSilicon Dow Corning Ficha TecnicadanieldayettddNo ratings yet

- Overall Aspects of Non-Traditional Glasses: Synthesis, Properties and ApplicationsFrom EverandOverall Aspects of Non-Traditional Glasses: Synthesis, Properties and ApplicationsNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- 900-00003-001 BU EFD1k-5c SW2 X Instl ManualDocument423 pages900-00003-001 BU EFD1k-5c SW2 X Instl ManualSilas AntoniolliNo ratings yet

- 71-00-00 Oil ConsuptionDocument2 pages71-00-00 Oil Consuptionianmcnultywork83No ratings yet

- Cessna 1962 Cessna 210B Owners ManualDocument42 pagesCessna 1962 Cessna 210B Owners Manualianmcnultywork83No ratings yet

- JPI Installation ManualDocument52 pagesJPI Installation Manualianmcnultywork83No ratings yet

- An Eastern Orthodox Understanding of The Dangers of Modernity and TechnologyDocument10 pagesAn Eastern Orthodox Understanding of The Dangers of Modernity and TechnologyTimothy ZelinskiNo ratings yet

- Eapp Melc 12Document31 pagesEapp Melc 12Christian Joseph HerreraNo ratings yet

- Flow of FoodDocument2 pagesFlow of FoodGenevaNo ratings yet

- European Construction Sector Observatory: Country Profile MaltaDocument40 pagesEuropean Construction Sector Observatory: Country Profile MaltaRainbootNo ratings yet

- Electrical Engineering Lab Vica AnDocument6 pagesElectrical Engineering Lab Vica Anabdulnaveed50% (2)

- Green Dot ExtractDocument25 pagesGreen Dot ExtractAllen & UnwinNo ratings yet

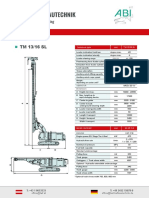

- ABI TM 13 16 SL - EngDocument1 pageABI TM 13 16 SL - EngJuan Carlos Benitez MartinezNo ratings yet

- 1500 Series: Pull Force Range: 10-12 Lbs (44-53 N) Hold Force Range: 19-28 Lbs (85-125 N)Document2 pages1500 Series: Pull Force Range: 10-12 Lbs (44-53 N) Hold Force Range: 19-28 Lbs (85-125 N)Mario FloresNo ratings yet

- KundaliniDocument3 pagesKundaliniAlfred IDunnoNo ratings yet

- Sainik School Balachadi: Name-Class - Roll No - Subject - House - Assigned byDocument10 pagesSainik School Balachadi: Name-Class - Roll No - Subject - House - Assigned byPagalNo ratings yet

- BÀI TẬP LESSON 7. CÂU BỊ ĐỘNG 1Document4 pagesBÀI TẬP LESSON 7. CÂU BỊ ĐỘNG 1Yến Vy TrầnNo ratings yet

- Angel C. Delos Santos: Personal DataDocument8 pagesAngel C. Delos Santos: Personal DataAngel Cascayan Delos SantosNo ratings yet

- Caradol sc48 08Document2 pagesCaradol sc48 08GİZEM DEMİRNo ratings yet

- Past Simple Vs Past ContinuousDocument3 pagesPast Simple Vs Past ContinuousNatalia SalinasNo ratings yet

- Getting Started With Citrix NetScalerDocument252 pagesGetting Started With Citrix NetScalersudharaghavanNo ratings yet

- RPH Week 31Document8 pagesRPH Week 31bbwowoNo ratings yet

- Ti05001 PDFDocument1 pageTi05001 PDFanggieNo ratings yet

- 105 2Document17 pages105 2Diego TobrNo ratings yet

- William Hallett - BiographyDocument2 pagesWilliam Hallett - Biographyapi-215611511No ratings yet

- Measurement and Scaling Techniques1Document42 pagesMeasurement and Scaling Techniques1Ankush ChaudharyNo ratings yet

- Strategic Marketing: The University of Lahore (Islamabad Campus)Document3 pagesStrategic Marketing: The University of Lahore (Islamabad Campus)Sumaira IrshadNo ratings yet

- Power System TransientsDocument11 pagesPower System TransientsKhairul AshrafNo ratings yet

- All India Civil Services Coaching Centre, Chennai - 28Document4 pagesAll India Civil Services Coaching Centre, Chennai - 28prakashNo ratings yet

- Play ClawDocument2 pagesPlay ClawFrenda SeivelunNo ratings yet

- Duo Interpretation Class PresentationDocument31 pagesDuo Interpretation Class PresentationPlanetSparkNo ratings yet

- Principles of Supply Chain Management A Balanced Approach 4th Edition Wisner Solutions ManualDocument36 pagesPrinciples of Supply Chain Management A Balanced Approach 4th Edition Wisner Solutions Manualoutlying.pedantry.85yc100% (28)

- Lightning Protection Measures NewDocument9 pagesLightning Protection Measures NewjithishNo ratings yet

- SAFE RC Design ForDocument425 pagesSAFE RC Design ForMarlon Braggian Burgos FloresNo ratings yet

- DAA UNIT 1 - FinalDocument38 pagesDAA UNIT 1 - FinalkarthickamsecNo ratings yet