Professional Documents

Culture Documents

Nunchuck Grips: Case Study

Uploaded by

mubarakOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nunchuck Grips: Case Study

Uploaded by

mubarakCopyright:

Available Formats

Case Study

Nunchuck Grips

Nunchuck Grips LLC doesn’t actually sell

nunchucks as the name implies. They make

outdoor recreational products that allow you to

protect yourself very quickly when needed.

Their products are very unique, and serve a

useful purpose of providing concealed self-

protection devices that you can quickly access

should you encounter danger.

You can carry a knife concealed in your bicycle

handlebar. Or pepper spray in the handle of

your umbrella or trekking pole.

Nunchuck Grips are storage systems with a patent pending quick-release feature - simply pinch

the tabs together and pull out to gain access to the accessory. The mechanism has up to 5

parts that must fit together with extremely tight tolerances.

Mike Yin, founder of Nunchuck Grips, approached a handful of local plastic injection molders,

but they took way too long to quote, or were not able to do the molding for him because the

molds required multiple slides and interchangeable inserts. So he came to ICOMold.

“ICOMold was able to tackle the project and de-

liver,” said Yin. “What I liked most was the ability

to review the details of the molded parts (gates,

parting lines, ejector marks, etc.), with the tooling

engineers.”

“Being a Mechanical Engineer myself with nearly

15 years experience,” continued Yin, “I found it

refreshing to work with a company with such a

phenomenal online quoting tool. It allowed us to

experiment with different materials, quantities, and

mold configurations to see the cost impact in real

time.”

Perhaps the most flattering compliment Mike gave us was when he said, “I see ICOMold as

more of a team member, not just a molder.”

We enjoyed working with Mike on this project and wish him much success selling his unique

products. To learn more about Nunchuck Grips, visit their website at www.NunchuckGrips.com.

© 2016 ICOMold. All Rights Reserved.

You might also like

- Trek Case Study PDFDocument2 pagesTrek Case Study PDFsapiencecorpNo ratings yet

- Pen Production Factory Simulation Laboratory Report Template Format 1Document4 pagesPen Production Factory Simulation Laboratory Report Template Format 1api-253978194No ratings yet

- Lathe Machine OperationDocument15 pagesLathe Machine OperationSimon DeracoNo ratings yet

- Paper Prototyping: The Fast and Easy Way to Design and Refine User InterfacesFrom EverandPaper Prototyping: The Fast and Easy Way to Design and Refine User InterfacesRating: 4 out of 5 stars4/5 (33)

- Open Innovation: PHD, Stanford University Professor, Ucsd Rady School of MGMT Kxzhu@Ucsd - EduDocument50 pagesOpen Innovation: PHD, Stanford University Professor, Ucsd Rady School of MGMT Kxzhu@Ucsd - Edujshen5No ratings yet

- UX/UI ToolkitDocument22 pagesUX/UI Toolkitbasil100% (4)

- IDEO ProductDocument40 pagesIDEO ProductMaithili JoshiNo ratings yet

- Design Modeling and Simulation of Block Moulding Machine: Management ApproachDocument12 pagesDesign Modeling and Simulation of Block Moulding Machine: Management ApproachLinda zubyNo ratings yet

- Smart Things: Ubiquitous Computing User Experience DesignFrom EverandSmart Things: Ubiquitous Computing User Experience DesignRating: 3.5 out of 5 stars3.5/5 (2)

- Methodology Chapter 3 RobinosDocument2 pagesMethodology Chapter 3 RobinosKeith Tanaka MagakaNo ratings yet

- Intrapreneur and ManagerDocument24 pagesIntrapreneur and ManagerYatik ParmarNo ratings yet

- Buidling A Culture of Experimentation Case StudyDocument10 pagesBuidling A Culture of Experimentation Case StudyAmit KumarNo ratings yet

- Production Engineering - Jig And Tool DesignFrom EverandProduction Engineering - Jig And Tool DesignRating: 3.5 out of 5 stars3.5/5 (3)

- Testingexperience02 09Document104 pagesTestingexperience02 09Jesper AndersenNo ratings yet

- 4 Mini Case Studies EDDocument18 pages4 Mini Case Studies EDSenthil KumarNo ratings yet

- Replacing Usability TestingDocument4 pagesReplacing Usability Testingapi-113773120No ratings yet

- Top5 Reasons White Paper v2Document7 pagesTop5 Reasons White Paper v2gilcasertaNo ratings yet

- Project Deliverable I: Final Report: CGT 163: Graphical Communication & Spatial AnalysisDocument13 pagesProject Deliverable I: Final Report: CGT 163: Graphical Communication & Spatial AnalysisWadha AlmishwatNo ratings yet

- UX Studio-Product Managers Guide To Ux Design PDFDocument34 pagesUX Studio-Product Managers Guide To Ux Design PDFChisomOji100% (1)

- Applications of Virtual RealityDocument222 pagesApplications of Virtual RealitysakthivelNo ratings yet

- Bridging UX and Web Development: Better Results through Team IntegrationFrom EverandBridging UX and Web Development: Better Results through Team IntegrationNo ratings yet

- What Surface Can Do?Document26 pagesWhat Surface Can Do?Bipin SunnyNo ratings yet

- Emotional Engineering Volume 4Document243 pagesEmotional Engineering Volume 4Akaash DudwaniNo ratings yet

- The Power of Injection MoldingDocument17 pagesThe Power of Injection Moldingsawy23725No ratings yet

- Prob With Doc On InstallDocument2 pagesProb With Doc On Installsenthur123No ratings yet

- Inventor ReportDocument7 pagesInventor Report2cekal50% (2)

- Last Project 4Document14 pagesLast Project 4Simon DeracoNo ratings yet

- Glass Cleaning Robot: Guide-Dr. Swet Chandan Presented by (Group-22)Document29 pagesGlass Cleaning Robot: Guide-Dr. Swet Chandan Presented by (Group-22)MRITYUNJOY GUPTANo ratings yet

- ANS Promo Version Opt1 14mgDocument42 pagesANS Promo Version Opt1 14mgrelayoneNo ratings yet

- Presented By: Rosemary Josekutty ThomasDocument23 pagesPresented By: Rosemary Josekutty ThomasRosemary J Thomas100% (3)

- Senior Project ReflectionDocument2 pagesSenior Project Reflectionapi-735723488No ratings yet

- Construction Technologies Post Covid-19Document4 pagesConstruction Technologies Post Covid-19VEERKUMAR GNDECNo ratings yet

- Creating the Intangible Enterprise: The Critical Skills Required to Thrive in an AI-Driven WorldFrom EverandCreating the Intangible Enterprise: The Critical Skills Required to Thrive in an AI-Driven WorldNo ratings yet

- Designing For and Against The Manufactured Normalcy Field - Ideas For DozensDocument9 pagesDesigning For and Against The Manufactured Normalcy Field - Ideas For Dozensnur coskunNo ratings yet

- Poka-Yoke Designs Make Assemblies Mistakeproof: Cad/CamDocument4 pagesPoka-Yoke Designs Make Assemblies Mistakeproof: Cad/CamvikaspalNo ratings yet

- Poka-Yoke Designs Make Assemblies Mistakeproof: Cad/CamDocument4 pagesPoka-Yoke Designs Make Assemblies Mistakeproof: Cad/CamamondacaNo ratings yet

- MetalForming Magazine - 2020 12Document2 pagesMetalForming Magazine - 2020 12waqar mansoorNo ratings yet

- Entrepreneurship AssignmentDocument3 pagesEntrepreneurship AssignmentFarrukhAhmedKhanNo ratings yet

- Review and EvaluationDocument2 pagesReview and EvaluationMichael MaxwellNo ratings yet

- Paper Prototypes Still Our FavoriteDocument4 pagesPaper Prototypes Still Our FavoriteFederico CórdobaNo ratings yet

- Ágil What Is AgileDocument94 pagesÁgil What Is AgileCoolNo ratings yet

- PortfolioDocument9 pagesPortfolioapi-290279144No ratings yet

- ThatlazymachinistDocument66 pagesThatlazymachinistchellaliNo ratings yet

- Top Five Reasons: To Integrate 3D Printing Into Your Product Development LifecycleDocument5 pagesTop Five Reasons: To Integrate 3D Printing Into Your Product Development LifecycleARUNarrNo ratings yet

- Webinar UX UI Design Wireframes and PrototypesDocument34 pagesWebinar UX UI Design Wireframes and PrototypesRohite Sofyan100% (1)

- "Surface Computing": Noida Institute of Engineering and Technology Greater NoidaDocument25 pages"Surface Computing": Noida Institute of Engineering and Technology Greater NoidaPraveen SinghNo ratings yet

- Group 1 IdeoDocument22 pagesGroup 1 IdeokaranbhayaNo ratings yet

- CAD Case StudiesDocument3 pagesCAD Case Studiesmax molenaar100% (2)

- Internship SummaryDocument1 pageInternship Summaryapi-243953764No ratings yet

- ITE Combine LessonsDocument108 pagesITE Combine LessonsKAYLA DE TORRESNo ratings yet

- The Design and Need For Jigs and Fixtures in Manufacturing: August 2015Document8 pagesThe Design and Need For Jigs and Fixtures in Manufacturing: August 2015ashok_abclNo ratings yet

- CE Logitech CS A4 IlDocument2 pagesCE Logitech CS A4 Ilabak_jolpaanNo ratings yet

- Basics - Sheet - Metal - Possibilities GJ PDFDocument13 pagesBasics - Sheet - Metal - Possibilities GJ PDFNaukowyDrpNo ratings yet

- FULLTEXT01Document109 pagesFULLTEXT01raisul dianaNo ratings yet

- Making Something Out of Nothing: Identify The ProblemDocument12 pagesMaking Something Out of Nothing: Identify The Problemapi-238872104No ratings yet

- ECE3080 Lecture 4 Eng Soc ExpDocument25 pagesECE3080 Lecture 4 Eng Soc ExpVocem LuxNo ratings yet

- Emotional Engineering Volume 5Document198 pagesEmotional Engineering Volume 5hernansanabria100% (1)

- English Transcription SamplesDocument6 pagesEnglish Transcription SampleshchaghomiNo ratings yet

- Coordinating User Interfaces for ConsistencyFrom EverandCoordinating User Interfaces for ConsistencyRating: 5 out of 5 stars5/5 (2)

- Slingbaron: Why Not Just Bang It On Your Knee? Noooo!Document3 pagesSlingbaron: Why Not Just Bang It On Your Knee? Noooo!mubarakNo ratings yet

- Smart Manufacturing in Plastic Injection Molding: by Denny ScherDocument1 pageSmart Manufacturing in Plastic Injection Molding: by Denny SchermubarakNo ratings yet

- Interaction Between A Surface Acoustic Wave and Adsorbed AtomsDocument10 pagesInteraction Between A Surface Acoustic Wave and Adsorbed AtomsmubarakNo ratings yet

- ICOMolds Online Quotation System Is A Disruptive InteractionDocument1 pageICOMolds Online Quotation System Is A Disruptive InteractionmubarakNo ratings yet

- Materials and Design: Babur Ozcelik, Ibrahim SonatDocument9 pagesMaterials and Design: Babur Ozcelik, Ibrahim SonatmubarakNo ratings yet

- 3516B 1600 KW 2000 kVA PDFDocument6 pages3516B 1600 KW 2000 kVA PDFmubarakNo ratings yet

- السعدء2Document6 pagesالسعدء2mubarakNo ratings yet

- 一、example 2: unit:inchesDocument14 pages一、example 2: unit:inchesmubarakNo ratings yet

- O I E B (6HN01162) J 16, 2016: Rder Nvoice With Ngineering Reakdown UNEDocument3 pagesO I E B (6HN01162) J 16, 2016: Rder Nvoice With Ngineering Reakdown UNEmubarakNo ratings yet

- Robot Technology: Ch.7 Trajectory Planning of RobotsDocument53 pagesRobot Technology: Ch.7 Trajectory Planning of RobotsmubarakNo ratings yet

- Introduction To Mobile Robotics: A Lecture For Undergraduate Students Who Major in Automation EngineeringDocument53 pagesIntroduction To Mobile Robotics: A Lecture For Undergraduate Students Who Major in Automation EngineeringmubarakNo ratings yet

- About Differentia Transformation-4.17Document12 pagesAbout Differentia Transformation-4.17mubarakNo ratings yet

- 一、example 3: unit:mmDocument17 pages一、example 3: unit:mmmubarakNo ratings yet

- 一、example 1: unit:mmDocument7 pages一、example 1: unit:mmmubarakNo ratings yet

- Multiscale Modeling and Simulation of Polymer Blends in Injection Molding A ReviewDocument26 pagesMultiscale Modeling and Simulation of Polymer Blends in Injection Molding A ReviewmubarakNo ratings yet

- MT 199 Malaysia 100.000 EuroDocument1 pageMT 199 Malaysia 100.000 Eurorasool mehrjooNo ratings yet

- M&a DamodaramDocument37 pagesM&a DamodaramYash SonkarNo ratings yet

- The Cost ProductionDocument17 pagesThe Cost ProductionKhizzyia Paula Gil ManiscanNo ratings yet

- 8.social CommerceDocument21 pages8.social CommerceMounika ReddyNo ratings yet

- Week 7 - Self-Study QuestionsDocument9 pagesWeek 7 - Self-Study QuestionsNguyen Trung Kien ( Swinburne HN)No ratings yet

- Paper I & 11 Answer All Questions: (E) Explain The Use of Correlation and Regression Studies in Busainess?Document5 pagesPaper I & 11 Answer All Questions: (E) Explain The Use of Correlation and Regression Studies in Busainess?Suthaharan PerampalamNo ratings yet

- Deed of Absolute SaleDocument2 pagesDeed of Absolute SalePrincess Dungca FloresNo ratings yet

- Uchechukwu Anthony Onuesi 0773429880 20210926073744Document10 pagesUchechukwu Anthony Onuesi 0773429880 20210926073744Onuesi AnthonyNo ratings yet

- LPJ Proposal Sisterhood - OctoberDocument14 pagesLPJ Proposal Sisterhood - OctoberGoldy ThariqNo ratings yet

- ProjectDocument5 pagesProjectGunavardhanareddy ChinnaNo ratings yet

- Enterpreneurship and ManagmentDocument28 pagesEnterpreneurship and ManagmentSAYEENo ratings yet

- Chargeback GuideDocument608 pagesChargeback GuideMrleiokNo ratings yet

- Dry CleanersDocument12 pagesDry CleanersDarshan ChinnuNo ratings yet

- DSGO 2019 Official NotesDocument75 pagesDSGO 2019 Official NoteslvnvenkatNo ratings yet

- Summary of Current Regional Daily Minimum Wage RatesDocument1 pageSummary of Current Regional Daily Minimum Wage RatesjepoyNo ratings yet

- Explanatory Leaflet For Form EUTR1ADocument16 pagesExplanatory Leaflet For Form EUTR1AFernanda MoraisNo ratings yet

- Assignment - Value Stream Map - Narrative - Coffee Beans Ver1.3Document3 pagesAssignment - Value Stream Map - Narrative - Coffee Beans Ver1.3Sakthi VelNo ratings yet

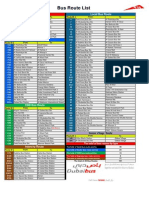

- Dubai Bus Route PDFDocument1 pageDubai Bus Route PDFneedzin100% (1)

- 2go Itinerary MR Alex TarimanDocument1 page2go Itinerary MR Alex TarimanMaica Jarie RiguaNo ratings yet

- The Chartered Institute of Personnel and DevelopmentDocument10 pagesThe Chartered Institute of Personnel and DevelopmentMaruf IslamNo ratings yet

- Zee InvoiceDocument1 pageZee InvoiceRajkumar WadhwaniNo ratings yet

- This Study Resource Was: Contributor: Atty. Mendoza, B. Date Contributed: March 2011Document7 pagesThis Study Resource Was: Contributor: Atty. Mendoza, B. Date Contributed: March 2011Nah HamzaNo ratings yet

- Blueprint Training Presentation:: Maintenance Work OrdersDocument24 pagesBlueprint Training Presentation:: Maintenance Work OrdersUrea3 MaintenanceNo ratings yet

- 5 AFM - 004 - Distribution - and - Retention - Policy - NotesDocument3 pages5 AFM - 004 - Distribution - and - Retention - Policy - NotesDerickNo ratings yet

- Novaliches FileDocument33 pagesNovaliches FileAngel CabreraNo ratings yet

- Inter TradeDocument15 pagesInter Tradesatya_somani_1No ratings yet

- MEGHNATH REGMI CV AccountantDocument5 pagesMEGHNATH REGMI CV AccountantPrakash RegmiNo ratings yet

- Direct Costs vs. Indirect Costs: Understanding EachDocument3 pagesDirect Costs vs. Indirect Costs: Understanding EachNeoRa Ndivo RamsNo ratings yet

- NEFT Mandate FormDocument2 pagesNEFT Mandate FormSupriya KandukuriNo ratings yet

- Solution Manual For Governmental and Nonprofit Accounting 10th Edition by FreemanDocument7 pagesSolution Manual For Governmental and Nonprofit Accounting 10th Edition by FreemanEarl Thibeau100% (33)