Professional Documents

Culture Documents

Pipeline Economics

Uploaded by

ObaidUrRehmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipeline Economics

Uploaded by

ObaidUrRehmanCopyright:

Available Formats

Alternative design proposals may be considered where:

• Watercare’s standardised design is not suitable

• Watercare’s Health and Safety in design minimum standards are achieved

• The design features do not involve extraordinary operational, maintenance or renewal obligations

• The alternative design is able to demonstrate that the required performance outcomes are met

Acceptance of an alternative design in concept does not conclude approval of any design criteria, construction

technique or material selection. Specific approval must be sought during the design process.

9. Pipeline economics

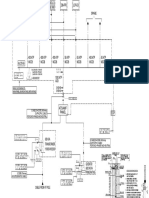

1. Capital cost: The capital outlay to design, fabricate, install and commission the pipeline. Components include

the pipe, balancing tanks, valve, fittings, meter stations, chambers, cathodic protection, control systems,

consents, design, construction, commissioning and management of the project.

Typical capital cost spread for straight pipeline construction is:

• Consents and legal agreements = 4%

• Design = 6%

• Material = 45%

• Labour = 40 %

• Incidental = 5%

For straight length pipelines the capital cost can be expressed as:

Pipeline capital cost = Pipe diameter(mm) x (Average total construction cost per mm-diameter-km) x

Length(km)

Detailed breakdown is required for some specific pipeline scenarios in instances such as control chambers,

balancing tanks, bridge or stream crossings and rail crossings.

The capital cost spread for detailed components typically is:

• Consents and legal agreements = 5%

• Design = 20%

• Material = 25%

• Labour = 48 %

• Incidental = 2%

The detailed cost is added to the pipeline cost as a lump sum to obtain the total capital cost:

Capital cost = Pipeline capital cost + Detailed costs

2. Operation and maintenance cost: The operational cost for energy consumption, utility cost such as

telecommunication, lease costs, routine inspections (staff, vehicles and other resources) and component

replacements or renewals. This cost is typically estimated based on operational history of similar systems.

3. Depreciation cost: The loss of value of the pipeline assets over time. The typical useful life expectancy of

various material types is listed in the Watercare Material Supply standard.

Annual Depreciation = (initial cost – salvage value) / useful life in years

Ver.1.1 This is an electronic ESF document that

is uncontrolled when copied or printed Page 25 of 70

You might also like

- Maintaining Structural Integrity Against Corrosion 12.1 Corrosion Protection SystemsDocument1 pageMaintaining Structural Integrity Against Corrosion 12.1 Corrosion Protection SystemsObaidUrRehmanNo ratings yet

- 2.3 Pressure, Flow and Level Control Valves: Section 2.7.5Document1 page2.3 Pressure, Flow and Level Control Valves: Section 2.7.5ObaidUrRehmanNo ratings yet

- 3.1.2 National and International StandardsDocument1 page3.1.2 National and International StandardsObaidUrRehmanNo ratings yet

- Maintaining Structural Integrity Against Corrosion 12.1 Corrosion Protection SystemsDocument1 pageMaintaining Structural Integrity Against Corrosion 12.1 Corrosion Protection SystemsObaidUrRehmanNo ratings yet

- 3.3 Reservoir Access and PlatformsDocument1 page3.3 Reservoir Access and PlatformsObaidUrRehmanNo ratings yet

- 2.2 Imposed LoadingsDocument1 page2.2 Imposed LoadingsObaidUrRehmanNo ratings yet

- Safety and Hazard Mitigation 7.1 Safety in Design Guidelines 7.2 Safety in Facilities Design GuidelinesDocument1 pageSafety and Hazard Mitigation 7.1 Safety in Design Guidelines 7.2 Safety in Facilities Design GuidelinesObaidUrRehmanNo ratings yet

- Pages From GSM Based Flow metering-IFLM 2Document1 pagePages From GSM Based Flow metering-IFLM 2ObaidUrRehmanNo ratings yet

- Bid Format RequirementsDocument1 pageBid Format RequirementsObaidUrRehmanNo ratings yet

- Pages From Applsci-09-02703 4Document1 pagePages From Applsci-09-02703 4ObaidUrRehmanNo ratings yet

- Pages From Book3Document1 pagePages From Book3ObaidUrRehmanNo ratings yet

- Pages From GSM Based Flow metering-IFLMDocument1 pagePages From GSM Based Flow metering-IFLMObaidUrRehmanNo ratings yet

- P/Ha L/P/D L/S M M M MDD MM NB Nominal Bore O&M PDF Pe PPB PVC RCRRJ Sec Scada SN Sop Uo/DoDocument1 pageP/Ha L/P/D L/S M M M MDD MM NB Nominal Bore O&M PDF Pe PPB PVC RCRRJ Sec Scada SN Sop Uo/DoObaidUrRehmanNo ratings yet

- Pages From GSM Based Flow metering-IFLM-3Document1 pagePages From GSM Based Flow metering-IFLM-3ObaidUrRehmanNo ratings yet

- PrincipleDocument1 pagePrincipleObaidUrRehmanNo ratings yet

- Relationship between manure total solids and density for dairy farms with anaerobic digestionDocument1 pageRelationship between manure total solids and density for dairy farms with anaerobic digestionObaidUrRehmanNo ratings yet

- Pages From BookDocument1 pagePages From BookObaidUrRehmanNo ratings yet

- Pages From CombineDocument1 pagePages From CombineObaidUrRehmanNo ratings yet

- QwedDocument1 pageQwedObaidUrRehmanNo ratings yet

- Pages From Book2Document1 pagePages From Book2ObaidUrRehmanNo ratings yet

- Qwerd QasdeDocument2 pagesQwerd QasdeObaidUrRehmanNo ratings yet

- Useful KeltDocument1 pageUseful KeltObaidUrRehmanNo ratings yet

- AL Atic: Air Release Valve SpecificationDocument1 pageAL Atic: Air Release Valve SpecificationObaidUrRehmanNo ratings yet

- Graph ModelDocument1 pageGraph ModelObaidUrRehmanNo ratings yet

- 38.1 Surge Computation: Surges - Moving (Travelling Fronts)Document5 pages38.1 Surge Computation: Surges - Moving (Travelling Fronts)rajesh005No ratings yet

- Laboratory Models-A Scale Model Can Be Built To Reproduce TransientsDocument2 pagesLaboratory Models-A Scale Model Can Be Built To Reproduce TransientsObaidUrRehmanNo ratings yet

- C. System Installation.: D. BackfillingDocument1 pageC. System Installation.: D. BackfillingObaidUrRehmanNo ratings yet

- Pages From Sewerage Manual 2 EurocodesDocument1 pagePages From Sewerage Manual 2 EurocodesObaidUrRehmanNo ratings yet

- Pages From 11822699 - 07Document1 pagePages From 11822699 - 07ObaidUrRehmanNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- MICS6 Water Quality Testing Questionnaire 20180604Document6 pagesMICS6 Water Quality Testing Questionnaire 20180604KaalNo ratings yet

- Structural and Non-Structural Measures for Disaster ManagementDocument23 pagesStructural and Non-Structural Measures for Disaster ManagementAnanyaNo ratings yet

- Progress Test 2 Level 9 - Google FormsDocument48 pagesProgress Test 2 Level 9 - Google FormsJosé Suárez100% (1)

- Global Warming Lesson PlanDocument10 pagesGlobal Warming Lesson PlanMisty MamintaNo ratings yet

- Exploringthe Challengeand Scopeof Solid Waste Management AComparative Analysisof Bangladeshand TurkeyDocument8 pagesExploringthe Challengeand Scopeof Solid Waste Management AComparative Analysisof Bangladeshand TurkeySumaiya Tazreen 2012653030No ratings yet

- Waste Management: Alireza Ashori, Amir NourbakhshDocument5 pagesWaste Management: Alireza Ashori, Amir NourbakhshKenza SADOUKINo ratings yet

- Chapter 8 McqsDocument4 pagesChapter 8 McqsKAINAT MUSHTAQNo ratings yet

- BenguerilDocument22 pagesBenguerilJuan Ignacio de PabloNo ratings yet

- Ecotech Pricelist PPR (Tech Global)Document10 pagesEcotech Pricelist PPR (Tech Global)Jonathan BaoNo ratings yet

- Group 7 Plumbing EstimateDocument1 pageGroup 7 Plumbing EstimateLorenz BerroyaNo ratings yet

- GHG-EW 3-INF.2 - Factsheet On Emission Cap-And-Trade System (Norway)Document8 pagesGHG-EW 3-INF.2 - Factsheet On Emission Cap-And-Trade System (Norway)John KokarakisNo ratings yet

- EWMS 1 - Rev 2 - Temp Jetty and BridgeDocument17 pagesEWMS 1 - Rev 2 - Temp Jetty and BridgeCatalin OanceaNo ratings yet

- Safety of Ship's Crew, Cargo, and Marine EnvironmentDocument2 pagesSafety of Ship's Crew, Cargo, and Marine EnvironmentVICTORNo ratings yet

- LGU CAMALANIUGAN Position PaperDocument6 pagesLGU CAMALANIUGAN Position PaperJhoanna Marie Manuel-AbelNo ratings yet

- Kota Super Thermal Power Station: Practical Training SeminarDocument14 pagesKota Super Thermal Power Station: Practical Training Seminarnitinyadav25No ratings yet

- Ford Motor Company Pestel & Environment AnalysisDocument3 pagesFord Motor Company Pestel & Environment AnalysisCHARALABOS LABROUNo ratings yet

- The World's Most Pointless Animals or Are TheyDocument82 pagesThe World's Most Pointless Animals or Are TheyMrigasiraNo ratings yet

- Solid Waste Management GuideDocument37 pagesSolid Waste Management GuideMahmoud I. Mahmoud100% (1)

- Carbon Neutral Buildings RoadmapDocument188 pagesCarbon Neutral Buildings RoadmapJishnu Medhi100% (1)

- Invasive Alien Species in The PhilippinesDocument2 pagesInvasive Alien Species in The PhilippinesEna Farillas100% (1)

- Sishen Iron Ore Mine Ea and Empr Audit 2022Document373 pagesSishen Iron Ore Mine Ea and Empr Audit 2022vidhya sagarNo ratings yet

- Balachaur DNIT Volume II-1Document172 pagesBalachaur DNIT Volume II-1Navjyot SinghNo ratings yet

- Light Bulb Standards PRODocument8 pagesLight Bulb Standards PROcalebprofittNo ratings yet

- PNS BAFS 183 2020 Organic Soil AmendmentsDocument14 pagesPNS BAFS 183 2020 Organic Soil Amendmentsjeffrey sarolNo ratings yet

- Big Data Improves Weather Forecasting AccuracyDocument13 pagesBig Data Improves Weather Forecasting Accuracyspoorthi sNo ratings yet

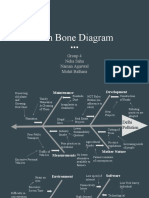

- Fish Bone Diagram: Group 4 Neha Saha Naman Agarwal Mohit BalharaDocument3 pagesFish Bone Diagram: Group 4 Neha Saha Naman Agarwal Mohit BalharaMohitNo ratings yet

- Medical HandwashingDocument3 pagesMedical HandwashingEly TalledoNo ratings yet

- Sandhya Dasegowda,+5Document18 pagesSandhya Dasegowda,+5nayanchandan093No ratings yet

- Forestry Dissertation TopicsDocument5 pagesForestry Dissertation TopicsINeedHelpWritingAPaperUK100% (1)

- A New Global Dataset of Bioclimatic Indicators: Data DescriptorDocument12 pagesA New Global Dataset of Bioclimatic Indicators: Data DescriptorSamir FellousNo ratings yet