Professional Documents

Culture Documents

Uttam Sugarcane Mills Catalogue

Uttam Sugarcane Mills Catalogue

Uploaded by

Tung Bui Thanh0 ratings0% found this document useful (0 votes)

15 views4 pagesOriginal Title

4. Uttam Sugarcane Mills Catalogue

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views4 pagesUttam Sugarcane Mills Catalogue

Uttam Sugarcane Mills Catalogue

Uploaded by

Tung Bui ThanhCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

Low Energy

High Efficiency

Milling Technology

Uttam Group made its foray into sugar machinery manufacture in 1962. The Group, today is one of

the largest and most diversified sugar engineering and manufacturing organisations. Group owns 4 (four)

Rene meme CMC tem crea ema Mca tan St Mem aceite a

Ene U RT Uae CRO Rel ee a neko res

(oe eee Cur ur eon ecean te ons

be! T) rs

ADVANTAGES OF UTTAM MILLS &

MILLING PLANTS

eee uma Ue Men ne

Deuce ce ere eT)

workshops owned by the Uttam Group. 100%

Peetu an Cee es

CNet me Rag cen)

quick job finishing.

rep ees UE)

Mee ok eee ol

CANE MILLING TECHNOLOGY FROM See es

A. GONINAN OF AUSTRALIA

Low Energy, High Efficiency Milling Technology from

one of the leading sugar engineering companies in

Uttam Cane Preparation System uses

state-of-art designed Shredders to achieve

Re at)

the world.

Drees ae eeu haar

Goninan has designed, manufactured and installed Cea

Ru soa Sn MT ES eMC nM acetone

ao

Uttam is the only Company in India having access to

Goninan design to manufacture Mills upto 55” x 110” eT MMe RSS ESR sl lel

Pre o AU AU CMA RC Re ete lit WS Tee eo

DE oo RRM Een Ny

Highly responsive to Control Systems for

gee Ete es

Complete range of Mills from: 20°x 40” up to 55°x 110”

ENT) aol meee eel oy

een ee ia uccumecc nN

Remon heme ae

Seuss uneuieeus

eye UNM R ie US Rear)

Planetary Gear unit directly attached with

motor on each roller at required differential

Peer h Oke muE rca ese

Cre CIn

Perea uae Rano

pee Mae cu kee uke t

on-crop & off-crop.

SPECIAL FEATURES OF UTTAM MILLS

RECs Meg ores

even at much wider settings for higher crush rate

DUR

Uttam Mills have inbuilt provisions for installation of

Sime ea CRS orcs

ae Reda cee ee oe CMS

Pee Coca Rcus mn ea

ene

Mee en eS ec Re Meer un

Geom ucts

Ona rene a ane)

DCM ene eget Cun Cs

ee Roma Rn

manpower.

Renee eo RU Re olny

(SOUR ne Weer a oc)

og

ee Mea Ce ts ence unary

Eiken)

Dee eM AOE eeu cacy

Pea cma OMe esceu Mesa ce)

eens

CECE eee Reece Rees

with tie bolts which impart rigidity to the complete

GMa aca mene| oss

BT ee ee eeu Rt aoc

Pe eee cs cen geod

Pe Rm rm Koa conc

SS eee rele oR esa oe

Pee ume ose RRR)

Pome eon i area ace ToR ey

Headstock.

Floating type Top Roller Scraper assembly is

eee

DUT tele ol mC eeu ele Ey

PUR R Utd Te NC

Ceo aca Tac con

which provides better juice drainage and best

Milling results.

Preece ae Matec Ron

elegans surety erate

Seog)

INCREASE MILLING CAPACITY UP TO

35% IN EXISTING MILLING TANDEMS

|- AUTTAM SPECIALITY

Uttam’s engineers have developed expertise in

increasing milling capacities by upto 35% through the

addition of Special Heavy Duty - Grooved Roller

Pressure Feeder (GRPF) and Heavy Duty - Toothed

Roller Pressure Feeder (TRPF) to existing Mills. Adding

to your profits even with low investments.

Uttam supplies Hybrid PLC Control System/ DCS

‘System with Advanced Control Logarithms. The Control

ecules

‘@ Auto Cane Feed Control

© Mill Speed Control

Cec M circa)

MILL CONTROL SYSTEM

:

ORM eal

© imbibition Control

eRe RN aus

OR es nS Cu

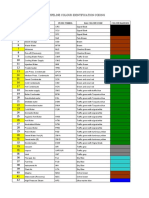

UTTAM MILL RANGE

NOMINAL MILL SIZE lel Nar

mm eo mm eu

300 x 375L_O12x 15L

EEE

380 x 500L_15 x 20L

Eee

460 x 600L_O18x 24

Eras

(2500 x 650L_20 x 25.5L.

CE eee

G45 x 90L__9570x750L_ 022.5 x 29.5.

CERNE tere

EEE

1230 x 60L,

PEE

36 x 721,

EES

240 x 80L,

55x 110L_700x

UT TAM

MILLING SYSTEM

PROVEN PERFORMANCE OF UTTAM MILL

ee Seen rer Preity DSCL Sug:

Pe) cry reed Pret

Rac) ao ova ova ad

eae ea oe pe) 13.88

Imbibition (%) Fiber Ee Os En Ea

eek kanal cE 1.69 1.52 1.55

Moisture % Bagasse aa rr 49.60 49.83

‘Source: Season Ending Repor (Form RT8(C}] of above factories

00% CNC BASED MILLS MANUFACTURING

Caren eouganize

UTTAM SUCROTECH | %010A-201301, UP. India| integrated Management

ca L

Tel.: +91-120-4726400 Pesdanirisri

Oro key encase

Rootes)

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Sugar Industry ReportDocument47 pagesSugar Industry ReportTung Bui ThanhNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- 2016 Tascon OverviewCrystallizationinColombianSugarMillsDocument16 pages2016 Tascon OverviewCrystallizationinColombianSugarMillsTung Bui ThanhNo ratings yet

- 2018-Felt Bag - R00Document2 pages2018-Felt Bag - R00Tung Bui ThanhNo ratings yet

- A. Raw Sugar Affination and Melting-SkillDocument1 pageA. Raw Sugar Affination and Melting-SkillTung Bui ThanhNo ratings yet

- UntitledDocument2 pagesUntitledTung Bui ThanhNo ratings yet

- Effect of Calcium On TurbidityDocument5 pagesEffect of Calcium On TurbidityTung Bui ThanhNo ratings yet

- Carbondioxide in Water EquilibriumDocument7 pagesCarbondioxide in Water EquilibriumTung Bui ThanhNo ratings yet

- Condenser ManualDocument4 pagesCondenser ManualTung Bui ThanhNo ratings yet

- Condenser DRGDocument1 pageCondenser DRGTung Bui ThanhNo ratings yet

- Pipeline Colour Identification CodingDocument2 pagesPipeline Colour Identification CodingTung Bui ThanhNo ratings yet

- Molasses Conditioning: Additional Heating SurfaceDocument1 pageMolasses Conditioning: Additional Heating SurfaceTung Bui ThanhNo ratings yet

- A MK 1800 TCD Pump InquiryDocument4 pagesA MK 1800 TCD Pump InquiryTung Bui ThanhNo ratings yet

- VR505ADocument3 pagesVR505ATung Bui ThanhNo ratings yet

- Fdocuments - in Sugar Cane CrusherDocument25 pagesFdocuments - in Sugar Cane CrusherTung Bui ThanhNo ratings yet

- VIVI Trash Plate Heel Session - 2. - KP - Singh - 210318044122 - 2Document55 pagesVIVI Trash Plate Heel Session - 2. - KP - Singh - 210318044122 - 2Tung Bui ThanhNo ratings yet

- DG Series Boiler Water Suppl Y PumpDocument40 pagesDG Series Boiler Water Suppl Y PumpTung Bui ThanhNo ratings yet

- GB T5656Document50 pagesGB T5656Tung Bui ThanhNo ratings yet

- Tinh May EpDocument10 pagesTinh May EpTung Bui ThanhNo ratings yet

- Mill Training CourseDocument27 pagesMill Training CourseTung Bui ThanhNo ratings yet