Professional Documents

Culture Documents

I Ma Tech (Italy) Brochure

Uploaded by

sahiljain_146Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

I Ma Tech (Italy) Brochure

Uploaded by

sahiljain_146Copyright:

Available Formats

HONEYCOMB ALUMINUM 5052

Product details

Description

The honeycomb aluminum aeronautical grade is produced by thin aluminum strip

of 5000. The protection is applied on the tape against corrosion of atmospheric

agents. There are several sections of cells and density. The honeycomb is produced

by bonding aluminum sheets that damage all'esagno expanded form.

The honeycomb can be provided in blocks, unexpanded strips and expanded

sheets. The thickness is chosen by the customer. The material can be perforated for

communicating all the cells between them (for vacuum application and space).

Some cells can be expanded in OX shape (rectangular) to allow the curvature in

one direction.

Features

- High resistance to compression and shear / Weight reduction

- Corrosion resistant and fire / recyclable material

Applications

It is used in various aero fields (airplanes, helicopters, radar), automotive (racing

cars), RF shelding to ensuring a long life and resistance to moisture and

temperature.

Dimensions

The standard size is mm1220x2440. General tolerances - 50 / + 100 mm - On

request special sizes. The thickness is chosen by the customer: minimum 1.5 mm

up to 500 mm depending on the type of cell. Tolerance standard +/- 0.12 mm or

+/- 0.05mm with extracost.

Designation

The full description of the honeycomb provides:

Alloy: description of the type of aluminum alloy used (5052 and 5056)

Density: the weight of material expressed in pounds per cubif feet or kg/m3

Cell: distance between two sides of the hexagon (mm or fraction of an inch)

Foil Nom: thickness of the wall that makes up the hexagon (mm or inches) -

P or N : material can be supplied perforated or non perforated

Tolerances + / - 10%

Pag.1/2

I.MA.TEC. IMPIANTI MATERIALI & TECNOLOGIA srl

20019 SETTIMO MIL.SE - VIA A. Einstein 16/18 - Tel. 02 33 510140 – Fax 02 32 84036

e-mail info@imatec.it - www.imatec.it

HONEYCOMB ALUMINUM 5052

Product details

Mechanical properties

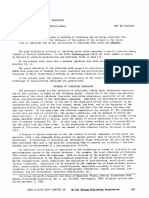

5052 Alloy Hexagonal Aluminum Honeycomb – Specification Grade

Both CR-PAA and CR III corrosion-resistant coating

Compressiv Plate

Honeycomb Nominal e Stabilized Crush Shear

Bare L Direction W Direction

Designation Density Strengt

Cell Size – Alloy – Foil Gauge pcf Strengt Strengt Modulu h psi Strengt Modulu Strengt Modulu

h psi h psi s ksi h psi s ksi h psi s ksi

typ min typ min typ typ typ min typ typ min typ

1/16 – 5052 – .0007 6.5 950 740 1000 780 275 505x 560 440 90.0 350 270 40.0

1/16 – 5052 – .001 9.2 1500 1170 1550 1200 420 750x 850 660 150.0 520 400 53.0

1/16 – 5052 – .0015 12.4 2430 1900 2650 2000 650 1200x 1150 900 210.0 715 560 65.0

1/8 – 5052 – .0007 3.1 285 200 300 215 75 130 210 155 45.0 130 90 22.0

1/8 – 5052 – .001 4.5 550 375 570 405 150 260 340 285 70.0 220 168 31.0

1/8 – 5052 – .0015 6.1 980 650 1020 680 240 450 560 455 98.0 340 272 41.0

1/8 – 5052 – .002 8.1 1500 1000 1560 1100 350 750 800 670 135.0 470 400 54.0

1/8 – 5052 – .0025 10.0 2100p 1575p 2250p 1685p 500x 1050x 980p 735p 175.0p 550p 415p 65.0p

1/8 – 5052 – .003 12.0 2700 2100 2900 2200 900 1350x 1940I1250I 210.0x 1430I 1000I 78.0

x

5/32 – 5052 – .0007 2.6 220 150 240 160 55 90 165 120 37.0 100 70 19.0

5/32 – 5052 – .001 3.8 395 285 410 300 110 185 270 215 56.0 165 125 26.4

5/32 – 5052 – .0015 5.3 690 490 720 535 195 340 420 370 84.0 270 215 36.0

5/32 – 5052 – .002 6.9 1080 770 1130 800 285 575 590 540 114.0 375 328 46.4

5/32 – 5052 – .0025 8.4 1530 1070 1600 1180 370 800 760 690 140.0 475 420 56.0

3/16 – 5052 – .0007 2.0 160 90 175 100 34 60 120 80 27.0 70 46 14.3

3/16 – 5052 – .001 3.1 290 200 335 215 75 130 210 155 45.0 125 90 22.0

3/16 – 5052 – .0015 4.4 520 360 550 385 145 250 330 280 68.0 215 160 30.0

3/16 – 5052 – .002 5.7 820 560 860 600 220 390 460 410 90.0 300 244 38.5

3/16 – 5052 – .0025 6.9 1120 770 1175 800 285 575 590 540 114.0 375 328 46.4

3/16 – 5052 – .003 8.1 1600 1000 1720 1100 350 750 725 670 135.0 480 400 54.0

1/4 – 5052 – .0007 1.6 90 60 100 70 20 40 85 60 21.0 50 32 11.0

1/4 – 5052 – .001 2.3 190 120 210 130 45 75 140 100 32.0 85 57 16.2

1/4 – 5052 – .0015 3.4 340 240 370 250 90 150 230 180 50.0 140 105 24.0

1/4 – 5052 – .002 4.3 500 350 540 370 140 230 320 265 66.0 200 155 29.8

1/4 – 5052 – .0025 5.2 690 500 760 510 190 335 410 360 82.0 265 200 35.4

1/4 – 5052 – .003 6.0 990 630 1100 660 235 430 530 445 96.0 340 265 40.5

1/4 – 5052 – .004 7.9 1420 970 1490 1050 340 725 700 650 130.0 440 390 52.8

3/8 – 5052 – .0007 1.0 50 20 55 20 10 25 45 32 12.0 30 20 7.0

3/8 – 5052 – .001 1.6 90 60 95 70 20 40 85 60 21.0 50 32 11.0

3/8 – 5052 – .0015 2.3 190 120 200 130 45 75 135 100 32.0 80 57 16.2

3/8 – 5052 – .002 3.0 285 190 310 200 70 120 200 145 43.0 125 85 21.2

3/8 – 5052 – .0025 3.7 370 270 410 285 105 180 250 200 55.0 160 115 26.0

3/8 – 5052 – .003 4.2 520 335 560 355 135 220 310 255 65.0 200 150 29.0

3/8 – 5052 – .004 5.4 740 500 800 535 200 360 430 380 86.0 280 228 36.8

3/8 – 5052 – .005 6.5 950 700 1000 750 265 505 545 500 105.0 350 300 43.5

P indicates preliminary data

The values shown are approximate and not binding.

Latest version 05/2016

Pag.2/2

I.MA.TEC. IMPIANTI MATERIALI & TECNOLOGIA srl

20019 SETTIMO MIL.SE - VIA A. Einstein 16/18 - Tel. 02 33 510140 – Fax 02 32 84036

e-mail info@imatec.it - www.imatec.it

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Astm d2863Document4 pagesAstm d2863sahiljain_146No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hexweb CR Iii: Corrosion Resistant Specification Grade Aluminum HoneycombDocument6 pagesHexweb CR Iii: Corrosion Resistant Specification Grade Aluminum Honeycombsahiljain_146No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- PAMG-PA3 5052 Aluminum Honeycomb: DescriptionDocument2 pagesPAMG-PA3 5052 Aluminum Honeycomb: Descriptionsahiljain_146No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Graco PR70 Adhesive DispenserDocument8 pagesGraco PR70 Adhesive Dispensersahiljain_146No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Mach4 Mill GCode ManualDocument60 pagesMach4 Mill GCode Manualsahiljain_146No ratings yet

- Advance Tech SolutionsDocument68 pagesAdvance Tech Solutionssahiljain_146No ratings yet

- Advanced Composites Market - Global AnalysisDocument52 pagesAdvanced Composites Market - Global Analysissahiljain_146No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- General Solution For U-ShapeDocument12 pagesGeneral Solution For U-ShapeDiana SoareNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Design and Evaluation of Sustained Release Microcapsules Containing Diclofenac SodiumDocument4 pagesDesign and Evaluation of Sustained Release Microcapsules Containing Diclofenac SodiumLia Amalia UlfahNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Drop of Water On Penny - HandoutDocument7 pagesDrop of Water On Penny - Handoutapi-240932330No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Lab 6 Translating Solving EquationsDocument8 pagesLab 6 Translating Solving Equationsapi-389057247No ratings yet

- The Andromedan Compendium - 7bDocument10 pagesThe Andromedan Compendium - 7bAnonymous XSNBQQ4yNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Simrit - Broșura Merkel PTFE U-RingsDocument20 pagesSimrit - Broșura Merkel PTFE U-Ringsjo_rz_57No ratings yet

- ST/ST Fiber Optic Patch CableDocument9 pagesST/ST Fiber Optic Patch CableMathivanan AnbazhaganNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Gates Timing Belt Product TrainingDocument25 pagesGates Timing Belt Product TrainingRoberto FernandesNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Material Balance: Lecture By: Ir. Dewi Tristantini Mt. Phd. University of IndonesiaDocument29 pagesMaterial Balance: Lecture By: Ir. Dewi Tristantini Mt. Phd. University of IndonesiaEdward Gustaf100% (3)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- MATH22558 Final Project - Winter 2018Document4 pagesMATH22558 Final Project - Winter 2018HardilazizNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Subject Review of IB 2023 Year - 1 - P2-2Document66 pagesSubject Review of IB 2023 Year - 1 - P2-2Duru SavdaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- HPLC: High Pressure Liquid ChromatographyDocument18 pagesHPLC: High Pressure Liquid ChromatographySyakirohFitriyati100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 3 IntroductionDocument5 pages3 IntroductionKhamvanh PhengnaoneNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Isolation and Purification of AlkaloidsDocument14 pagesIsolation and Purification of AlkaloidsLuděk SpurnýNo ratings yet

- Sample 7613Document11 pagesSample 7613VikashKumarNo ratings yet

- Max31856 PDFDocument30 pagesMax31856 PDFDiego Fernando ArpiNo ratings yet

- Characteristics and Firing Control of Thyristor Controlled Series Compensation InstallationsDocument5 pagesCharacteristics and Firing Control of Thyristor Controlled Series Compensation Installationsjm.mankavil6230No ratings yet

- BBS10 PPT MTB Ch04 ProbabiltyDocument37 pagesBBS10 PPT MTB Ch04 ProbabiltyAgenttZeeroOutsiderNo ratings yet

- RT Finalpresenatation08 161118104713Document56 pagesRT Finalpresenatation08 161118104713sajay2010No ratings yet

- Adavances in Positioning and FramesDocument407 pagesAdavances in Positioning and Framesoliwia.tolloczkoNo ratings yet

- Flexibility FactorsDocument61 pagesFlexibility FactorsCarlos BorgesNo ratings yet

- ELT1130 Anatomy of A Robot NotesDocument15 pagesELT1130 Anatomy of A Robot NotesEd PawliwNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- 3.2 - 3.4 NotesDocument4 pages3.2 - 3.4 NotesSamih AliNo ratings yet

- Hypocycloid - AnimatedDocument29 pagesHypocycloid - AnimatedJairus SamuelNo ratings yet

- LNG Receiving Terminals: BY CH - Satvika 16021A2545Document24 pagesLNG Receiving Terminals: BY CH - Satvika 16021A2545Ram Charan Konidela100% (1)

- MIT16 842F15 Ses 8 Sys IntDocument42 pagesMIT16 842F15 Ses 8 Sys IntssvivekanandhNo ratings yet

- Laws of Electric Circuits: R.Jayapragash, Associate Professor, SELECT 1Document25 pagesLaws of Electric Circuits: R.Jayapragash, Associate Professor, SELECT 1Devansh BhardwajNo ratings yet

- Strength Performance of Full-Size Structural Timber of Dryobalanops Species of Sarawak, MalaysiaDocument7 pagesStrength Performance of Full-Size Structural Timber of Dryobalanops Species of Sarawak, Malaysiaqidunk ipsiNo ratings yet

- PDFDocument2 pagesPDFbhavesh patelNo ratings yet

- ISMAIL 2019 A Review of Vibration DetectionDocument18 pagesISMAIL 2019 A Review of Vibration DetectionDiether PaderoNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)