Professional Documents

Culture Documents

Trzyna 1999

Uploaded by

Laiba GulOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trzyna 1999

Uploaded by

Laiba GulCopyright:

Available Formats

IEEE Transactions on Energy Conversion, Vol. 14, No.

4, December 1999 1417

Diagnostics of Mechanical Abnormalities in Induction Motors

Using Instantaneous Electric Power

Andrzej M. Trzynadlowski, Senior Member, IEEE Stanislaw F. Legowski, Senior Member, IEEE

Majid Ghassemzadeh, Student Member, IEEE University of Wyoming

University of Nevada, Department of Electrical Engineering Department of Electrical Engineering

Reno, NV 89557-0153, USA Laramie, WY 82071-3295, USA

Abstract: Results of a study on the use of instantaneous Determination of the torque or flux waveforms requires

electric power for diagnostics of mechanical abnormalities in use of an estimator tuned to the stator resistance. Measuring

induction motors are presented. The instantaneous power can he the instantaneous power is even simpler, for the stator

measured as the so-called product power, i.e., a product of one voltage is as easily accessible as the stator current. The

line-to-line voltage and one line current, or as a total input power cau he measured as a total input power or as a

power to the stator. Theoretical analysis, computer simulations, product of one line-to-line voltage and one line current. The

and laboratory experiments described demonstrate the input power in an ideal case (balanced, sinusoidal voltages,

superiority of the instantaneous power as a diagnostic medium perfect drive system, steady-state operation) represents a dc

over the traditionally used stator current. It is shown that in the signal, thanks to the cancellation of the ac components of

practical environment the product power is at least as indicative

the power in each phase. Under the same conditions, the

of the mechanical health of an induction motor as is the total

voltage-current product, subsequently called a product

power, which is more expensive to measure. A simple method

power, is a sum of a certain dc component and a sinusoidal

of filtering noisy spectra of the product power is proposed.

ac component with a frequency equal to twice the supply

Keywords: induction motors, diagnostics, mechanical frequency.

abnormalities, instantaneous power. A preliminary study of the product power as a medium

for the motor signature analysis was described in [17]. The

1. INTRODUCTION other two existing relevant literature positions concern the

detection of winding faults in the stator [15] and the

Preventive maintenance of induction motors bas been a topic torsional vibration in the drive system [16]. In this paper,

of great interest to industry and many related publications have the use of instantaneous electric power for detection of

appeared in the technical literature, e.g., [I]-[7]. Since the use mechanical abnormalities in induction motors is discussed.

of mechanical sensors, such as vibration probes, strain gauges,

and accelerometers, is often impractical, the motor current 11. MODULATION OF THE TNSTANTANEOUS POWER

signature analysis (MCSA) techniques have gained much

popularity as a diagnostic tool [8]-12]. Clearly, the stator The acquisition of the instantaneous input power

current is a very convenient medium because of the ease of its resembles the classic two-wattmeter method of measurement

measurement. In the search for further improvement of the non- of real power. In that method, one wattmeter measures the

invasive diagnostics of electrical machinery, other media have line-to-line voltage vABand line current iA, while the other

recently been proposed, such as the airgap torque [13], flux measures the line-to-line voltage vCRand line current i,. The

[ 141, and instantaneous stator power [ 15]-[17]. averagevalues of both the resultant product powers,p,, and

pCR,are then added to give the average value of the total

PE-1326-EC-0-2-1998 A paper recommended and approved by the power, pmC, supplied to the load. Here, however, the

IEEE Electlic Machinery Committee of the IEEE Power Engineering

Society for publication in the IEEE Transactions on Energy Convenion. instantaneous, not average, values are utilized.

Manuscript submitted August 27, 1997: made available for printing If for any reason an oscillation of the torque and speed of

February 18, 1998.

the motor develops, the amplitude and phase of stator

currents undergo modulation. For simplicity, the phase

modulation is neglected in the subsequent considerations,

and the amplitude modulation is assumed to be described by

0885-8969/99/$10.00 0 1998 IEEE

1418

corresponds to the motor running light, A,, is even greater

than Amc. Clearly, actual current modulation in induction

motors is more complicated than that described by (1).

Nevertheless, the importance of proper selection of the

measured product power is worth stressing.

where lAO(f) and ic,(t) denote ideal, unmodulated current

The signal of instantaneous electric power, in both the

waveforms, M is the modulation index, and w, is the radian

product power and input power forms, can be obtainedusing

frequency of oscillation Then, the instantaneous product powers

a dedicated hardware device or a computer with the data

and total input power become

acquisition capability. In the first case, the device performs

the on-line processing of the voltage and current signals and,

+~Mv,r,(cos[(zw+o,,,) t - p - 261

P A B ( t ) = pAB,o(t)

possibly, that of the power signal, such as filtering or FFT

+ cos [(zo-w,,,) t-p-Tl computation. In the computer, all the signal processing

6

I 2cos ( p + n ) c o s(m0&) operations are done by the software. Clearly, each technique

6 (2) has its advantages and disadvantages with regard to the cost,

1 5 versatility, and accuracy of the analysis.

p,( t) = pca,o( t )+5MvrlrLkos [ (2w+o,,,) t-p+--xl

6

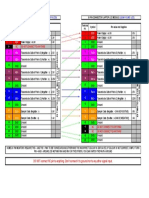

5 Motor spectral signatures using the stator current, product

+ cos [ (20-0,,,) t-ptxxl

power, and input power are illustrated in Figs. 1 through 3.

+ zcos(p-~)cos(~,,,t)l They were obtained from simulations of a three-phase, 10-

hp, 230-V, 60-Hz, six-pole induction motor driving a rated

paBc(

t) = P ~[l+Mcos(o,,,t)

~ ~ , I I ~

load. In most practical drive systems, the minor rotor

imbalance and eccentricity, and the nonideal alignment of

where ~ , , , ~ ( t ~) ,~ , , ~ (and

t), denote ideal waveforms of the motor and load shafts result in a pulsating torque

the product and input powers, VLL is the rms value of the line- synchronous with the rotational frequency of the rotor, here

to-line voltage, and I,, is that of the line current, while w and cp about 19 Hz (1140 rimin). The amplitude of that torque,

denote the supply radian frequency and load angle of the motor, simulated by imposing a 19-Hz ac component on the regular

respectively. torque developed in the motor, is about 5% of the load

It can be seen from (2) that the current spectra display only torque, It can be seen in Fig. 2, showing the spectrum of

two sideband components, at w + w,, and w w., -

In contrast, product power, that the amplitude of the characteristic

three oscillation-related components, at 2w + w,, 20 - w, component at 19 Hz, absent in the spectrum of current in

(sideband components), and w,, have appeared in the spectra Fig. 1, is distinctly higher than those of the sideband

of product powers. The component at the oscillation frequency components at 101 Hz and 139 Hz (is., 120 f 19 Hz).In

in these spectra, subsequently called a characteristiccomponent, the spectrum of input power, besides the dc component,

carries precious direct information about the oscillation. The only the characteristic component does appear.

spectrum of input power contains only the dc component,p,,,,

(average input power), and the characteristic component.

The amplitudes, A,,, A,,, and A,,,, of the characteristic

components of powers p,,,, p,,, and pAnc,are given by

A,, = MVLLI,cos(9+ 2 )

6

Since the load angle of induction motors is always positive

(meaning here that the current lags voltage), it can be deduced io

from (3) that product power pc, contains a stronger

characteristic component than p,,. If cp > GO", which

Fig. 1. Spectrum of stator current of the simulated motor.

1419

In a perfect agreement with (2), spectral components due to

the rotor imbalance, eccentricity, and misalignment of shafts

of the motor and load appear at 29.8 Hz, 90.2 Hz, and 149.8

Hz (i.e., 29.8 Hz and 120 f 29.8 Hz). These can be called

synchronous components, as they are directly related to the

rotor speed. Note other minor spectral components, e.g., in

the vicinity of 16 Hz and 80 Hz, that are difficult to explain

and must be attributed to the general noise.

THREE-PWIPE Ac LINE

-I

Fig. 2. Spectrum of product power of the simulated motor.

L I

Fig. 4. The experimental setup.

Fig. 3. Spectrum of input power of the simulated motor.

111. PRACTICAL EXAMPLES

Full assessment of the instantaneous electric power as a

diagnostic medium for induction motors requires extensive ...

.. .., ..

. ..

. .. . . .

experimental studies involving a variety of machines with a -1201

0

'

20

'

40

'

BO

'

80

'

100 120

' '

IW

'

180 180 200

Frequency. Hz

wide range of faults and degrees of their severity. Here, as

practical examples, results of laboratory experiments with a Fig. 5 . Spectrum of product power of the motor on no load.

well-worn 3-hp, 220-V, 60-Hz, four-pole motor are described.

The experimental setup, with a motor driving a dc generator The next experiment was designed to evaluate the

with an adjustable resistive load, is shown in Fig. 4. Laboratory detection of lateral vibration of the motor. This abnormal

probes supply the voltage and current signals to a dedicated condition, sometimes of an external origin, is of a great

analog processor, which produces the product power signal. concern in large electromechanical systems since if

This signal is then forwarded to a spectrum analyzer interfaced unchecked it may lead to a costly mechanical failure. A

with a laptop computer for data storage. nuclear reactor coolant pump can serve as an example. Its

Fig. 5 shows the spectrum of product power when the motor long vertical shaft on which the impeller is mounted is

run light, with therotational frequencyof 29.8 Hz (1788 r/min). susceptible to the lateral and torsional vibrations excited by

1420

the coolant turbulence. Unexpected breakage of the shaft may frequency. Thus, it is possible that the single characteristic

endanger the safety of the whole plant. Therefore, expensive spectral component of input power is drowned in the

vibration monitoring systems are often used [ 181. Here, the 24- surrounding noise. Such a case is illustrated in Fig. 8 for the

Hz vibration was generated by mechanically connecting the same experimental motor, but with strong, high-frequency

motor case to that of a strongly unbalanced dc motor rotating variations of the load torque. The presence of the sideband

at 1440 rimin. The investigated induction motor operatedon full components in the spectrum of product power provides here

load, with the rotational frequencyof29.1 Hz (1746 rimin). As a valuable verification of sustained oscillations.

seen in the spectrum of product power in Fig. 6, the frequency

components synchronous with the rotor speed have increased

significantly in comparison with those in the previous, no-load

situation. The 24-Hz, 96-Hz, and 144-Hz components due to the

vibration have even higher amplitudes.

. . .

-120; " " ' ' ' " I

1 2 3 1 5 8 7 8 0 1 0

F~~Y*IFI.

HI

Fig. I . Spectrum of product powcr of the motor with a r o t o h

sepmated from the end ring.

A simple but effective method of spectrum filtering is

demonstrated below, using a spectrum of product power

Fig. 6 . Spectrum of product power of the motor with full load and corresponding to that of input power in Fig. 8 and shown in

lateral vihration. Fig. 9. The 19-Hz characteristiccomponent can be expected,

but it is difficult to detect from inspection of the spectrum.

In the final experiment, a bar in the rotor cage was separated The filtering procedure consists of the following steps:

from the end ring. Such defects produce harmonic torques with (1) Determination of all the peaks of the spectrum.

frequencies at even multiples of the slip frequency [4]. The (11) Elimination of peaks that fall below an assumed no&

motor operated at a 60% capacity and a slip frequency of 0.55 level. Conservatively, it can be taken as the average

Hz. Indeed, as shown in Fig. 7, the characteristic components value (in dB) of all the peaks, including the dc and

have appeared at about 1.1 IHz and 2.2 Hz. For clarity, fundamental components.

harmonics at integer multiples of 60 Hz, introduced by the (111) Elimination of all peaks not having the corresponding

supply voltage, have been removed from all the shown spectra. sideband counterparts.

(IV) Elimination of all the remaining peaks that differ from

IV. ANALYSIS OF NOISY SPECTRA their sideband counterparts by more than 6 dB, i.e., by

the factor of 2 in the linear amplitude scale.

Comparing the simulated spectra in Figs. 1 through 3, the Justification for such an approach is provided by Eq. (31,

instantaneous input power might be perceived as the best especially with regard to steps Ill and IV.

diagnostic medium. However, practical spectra are often noisy, The frequency range of the spectrum subjected to filtration

with the noise generated by a distorted supply voltage, minor must be at least twice as large as the fundamental frequency

imperfections o f the motor, electromagnetic interference with of the product power, here equal 120 Hz. Otherwise, high-

the measuring equipment, and a fast-varying load torque. In frequency sideband components corresponding to IOW-

many loads, such as impellerpumps, grinders, or conveyors, the frequency characteristic components could be missed,

load variations have frequency bands overlapping the rotating causing elimination of the valid characteristic components

1421

components should be checked for the characteristic

0

frequencies of the bearings [I I].

-20

rr.qu.n*. HZ

Fig. 8. Noisy spectrum of the input power.

Fr.qY.ncy. HZ

Fig. 10. Filtered spectrum of the product power.

V. CONCLUSION

The reported study has shown great potentials of the

instantaneous electric power as a medium for non-invasive

preventive maintenance monitoring and diagnostics of

induction motor drives. The sideband components in the

spectrum of product power can be used for verification of

the characteristic components in noisy spectra, typical for

loads with random high-frequency variations of the load

0 25 50 76 100 125 1.50 175 200 225 250

F..w."c". "2

torque. Therefore, the product power, specifically pcs,

Fig. 9 Noisy spectrum of the product power constitutes a medium superior not only to the stator current

but also to the instantaneous input power to the motor.

The resultant filtered spectrum is shown in Fig. 10. Of the

sixty-three peaks in the original spectrum only three have VI. REFERENCES

survived the three elimination steps. The remaining frequency

components are: [I] J.T. Renwick, "Condition monitoring of machinery using

( I ) the 1 I-Hz dominant frequency component of the load computerizedvibration signature analysis,"lEEE Trans. Ind.

torque, Appl., vol. IA-20, no. 3, 1984, pp. 519-527.

(2) the expected 19-Hz frequency component synchronous [2] J.T. Renwick and P.E. Babson, "Vibration analysis- a proven

with the motor speed, the strongest of the three technique as a predictive maintenance tool," IEEE Trans.Ind.

Appl., vol. IA-21, no. 2, 1985, pp. 324-332.

components in the filtered spectrum,

[3] J.Penman,M.N. Dcy,A.J. Tail, and W.E. Bryan, "Condition

(3) the 109-Hz sideband frequency component of the load

monitoring of electrical drives," IEE Proceedings, vol. 133,

torque, which owes its survival to the coincidental noise pt. B, no. 3, 1986, pp. 142-148.

component at 229 Hz (if there really was a characteristic [4] P.J. Tavner and J. Penman, "Condition Monitoring o i

component at 109 Hz, sideband components would appear Electrical Machines," John W h y , 1987.

at 120 k 109 Hz, i.e., at 1 I Hz and 229 Hz). [ 5 ] J.R. Cameron, W.T. Thomson, and A.B. Dow, "On-line

It must be mentioned that high-frequency spectral monitoring of induction motors - a inelhod for calculatingthe

components may indicate worn or damaged bearings of the level of airgap eccentricity," in Proc. Conf on Electr. Mach.

motor. These constitute the most common cause of mechanical andDrives, 1987, pp, 173-178.

failures of electric motors. Therefore, the high-frequency [6] R. Natarajan, J.L. Kohler, and J. Soltile, "Condition

monitoring of slip-ring induction motors," Electr. Pow. Syst.

1422

Res., no. 15, 1988, pp. 189-195. in Iraq, University of Texas at Arlington, and University of

P. Vas, "Parameter Estimation, Condition Monitoring, and Wyoming. Since 1987he has been with the University ofNevada,

Diagnosis of Electrical Machines," Oxford Universify Press, Reno where he is now Professor of Electrical Engineering. He has

1993. authored or co-authored over ninety publications in the areas of

R.C. Kryter and H.D. Haynes, "Condition monitoring of power electronics and electric drive systems and has been granted

machinery using motor current signature analysis, Sound and eleven patents. He is the author of The FieldOrieniaiionPrinciple

Vibr., Septembcr 1989, pp. 14-21. in Control of Induction Motors (Kluwer, 1994).

G.B. Kliman and J. Stein, "Induction motor fault detection via Dr. Trzynadlowski is a member of the Industrial Drives and

passive current monitoring," in Proc. Intl. ConJ on Electr. Industrial Power Converters Committees, IEEE Industry

Mach., 1990, pp. 13-17. Applications Society. He was the recipient of the 1992 IEEE-IAS

G.B. Kliman and 1. Stein, "Methods of motor current signature Myron Zucker Student-Faculty Grant.

analysis," EIectricMachines and Power &stems, vol. 20, no. 5 Majid Ghassemzadeh (S'92)

1992, pp. 463-474. received the B.S. degree from the

R.R. Schoen, T.G. Habetler, F. Kamran, and R.G. Bartheld, California State University,

"Motor bearing damage detection using stator current Fullerton,in 1984,M.S. degree from

monitoring," IEEE Trans. Ind. Appl., vol. 31, no. 6, 1995, pp. the Calfornia State University, Los

1274-1279. Angeles, in 1989, and Ph.D. degree

R.R. Schoen, B.I<. Lin, T.G. Habetler, J.H. Schlag, and S. Farag, from the University of Nevada,

"An unsupervised on-line system for induction motor fault Reno, in 1995, all in electrical

detection using stator current monitoring," in Conf Rec. 1994 engineering. He was with the Leach

IEEE-IAS Ann. Mtg., pp. 103-109. Corporation from 1984 to 1988 and

1.S. Hsu, "Monitoringofdefects in induction motors through air- with the Teledyne Solid States from

gap torque observation," IEEE Trans. Ind. Appl., vol. 31, no. 5 , 1988 to 1990. From 1990 to 1992 he worked at the Toshiba

1995, pp. 1016-1021. America Information Systems and from I995 to 1996 at IIytek

X. Deng and E. Ritchie, "Detection of broken rotor bars in Microsystems. He is now a senior design engineer at the Pulse

induction motor rotors by investigating the flux linkage of the Corporation in San Diego. His research interests includc

stator winding," in Proc. Intl. Conf on Electr. Mach. in diagnostics of electric machines and control of ac drive systems.

Australia, 1993, pp. 164-169:. Dr. Ghassemzadeh is a member of Eta Kappa Nu.

R. Maier, "Protection of squirrel-cage induction motor utilizing Stanislaw F. Legowski (SM'84)

instantaneous power and phase information," IEEE Trans. Ind. receivedtheM.S. andPh.D. degrees

Appl., vol. 28, no. 2, 1992, pp. 376-380. in electronic engineering from the

II. Thomas and G. Hamilton, "Torque and electrical power Technical University of Gdansk,

measurements assist in the accuracy of machinery analysis," Poland, in 1962 and 1971,

Orbit, Sept. 1994, pp. 4-9. respectively. From 1958 to 1962he

S.F. Legowski, A.H.M.S. Ula, and A.M. Trzynadlowski, was a Research Assistant at the

"Instantaneous stator power as a medium for the signature Oceanographic Institute of the Polish

analysis of induction motors,'' IEEE Trans. Ind. Appl., vol. 32, Academy of Sciences in Sopot,

no. 4, 1996, pp. 904-909. Poland, where he conducted research

A. Muszynska and D.E. Bently, "Fundamentals of rotating in instrumentation and measurement

machine diagnostics," Bently Nevada Corp., 1992. methods used in hydrography. From 1962 to1983, he was with the

Technical University of Gdansk as a Teaching Assistant, Lecturer,

VII. BIOGRAPHIES and AssistantProfessor.His main research areas were the electrical

measurement of nonelectrical quantities and automated

Andrzej M. Trzynadlowski (M'83, measurement methods for analog integrated circuits. In 1983, he

SM'86) received the M.S. degree in joined the faculty of the University of Wyoming, where he is

electrical engineering in 1964, M.S. currently Professor of Electrical Engineering. His research interests

degree in electronics in 1969, and Ph.D. entail analog and digital system design and power electronics.

degree in electrical engineering in 1974, Dr. Legowski was elected The Best Teacher for the 1979-

all from the Technical University of 1980academic year in the Electronics Department of the Technical

Wroclaw, Poland. From 1966to 1979 he University of Gdansk, and the Outstanding Faculty Member of the

was a faculty member at the same College of Engineering of the University of Wyoming for the

university. In the following years, he 1983-1984 academic year, He is a member ofthe Industrial Drives

worked at the University of Salahuddin Committee, IEEE Industry Applications Society.

1423

DISCUSSION [A21 L. Ran, R. Yakamini, K.S. Smith, "Torsional Vibrations in

Electrical Induction Motor Drives During Stad-up",

Toshihisa Funabashi, Senior Member, Meidensha Corporation, Transactions of the ASME, Journal of Vibration and

36- 2, Nihonbashi- hakozakicho, Chuo- hu, Tokyo, ' 103- 8515, Acoustics, Vo1.118, pp.242-25IApril 1996.

Japan: [A31 J.R. Shadley, B.L. Wilson, M.S.Domey, "Unstable Self-

Excitation of Torsional Vibration in AC Induction Motor

The authors have proposed an interesting approach using Driven Rotational Systems", Transactions of the ASME,

instantaneous power for diagnostics of mechanical abnormalities Journal of Vibration and Acoustics, Vol.lI4, pp.226-

in induction motors. The method of using product power has an 231April 1992.

advantage that thc side band components can be used for [A41 B.L.Agrawal, J.A. Demcko, R.G. F m a e r , D.A. Selin,

verification of the characteristic component. To make use of this "Shaft Torque monitoring Using Conventional Digital Fault

merit, it is necessiuy that the modulation is only in the amplitude recorders", EEE 'Transactions on Power Systems, Vo1.7,

of the phase currents and the amplitude of the modulation is same No.3, pp.1211-1217, August 1992.

in each phase. In most practical situation, the mechanical vibration

in induction motor driven rotational system seems to have

multiple frequency components. It might be interesting to observe

how the proposed method work in these practical situations and A.M. Tnynsdlowski, M. Ghassenrzadeh, and S.F. Legowsld:

know whether any improvement is needed or not. When the

Comments of the discussant Funabashi are greatly appreciated.

modulation is not in the phase angle of the phase currents, the

Certainly, the theory of modulation of instantaneous power

angular velocity is constant and therefore the torque equals power.

In this case, the theoly wTitten in the section n of this paper might described hy Eqs. (1) through (3) is oversimplified, and the

have compatibility with the method using air-gap torque for practical vibrations and their impact on electrical quantities of

monitoring of defects in induction motors[Al]. To make it easy for the motor are of more complex nature. Still, typically, the

the readers to understand the theory explained in the section E of fundamental frequency component of torquelspeed oscillations

this paper, ACA should be replaced hy ACB in the equation (3) and is significantly stronger than the other components. Note that

&A and PCAshould be replaced by &a and PCB,respectively, in

in all known diagnostic methods based on the current spectra,

the sentences before and after the equation. It might be useful, to

study the performance of the proposed method in the case of motor it is that component that indicates the type and severity of an

start-up[M] and of the unstable self-excitation of torsional abnormality.

vibration in induction motor driven rotational system[A3]. It We thank the discussant for pointing out the typographic errors

seems to be interesting to extend the proposed method to concerning the amplitudes of characteristic components of

synchronous motors and generators[A4]. instantaneous powers. Both in Eq. (3) and the preceding

sentence, the thrice appearing subscript "CA" should be

References

replaced with "CB."

[AI] J.S. Hsu, "Monitoring of Defects in Induction Motors

Through Air-Gap Torque Observation", LEEE Transactions Suggestions on the other potential uses of the instantaneous

on hdushy Applications, Vo1.31, No.5, pp.1016-1021, electric power are very precious and they will definitely be

SeptemberIOctober 1995. considered when planning the further research.

You might also like

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlRating: 5 out of 5 stars5/5 (1)

- Practical Troubleshooting of Electrical Equipment and Control CircuitsFrom EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsRating: 4 out of 5 stars4/5 (5)

- 1996 - Instantaneous Power As A Medium For The Signature Analysis of Induction Motors PDFDocument6 pages1996 - Instantaneous Power As A Medium For The Signature Analysis of Induction Motors PDFAnislei Santiesteban VelázquezNo ratings yet

- Parameter Identification and Modelling of Separately Excited DC MotorDocument8 pagesParameter Identification and Modelling of Separately Excited DC MotorIJIERT-International Journal of Innovations in Engineering Research and TechnologyNo ratings yet

- Calculations and Analysis of Induction Motors Impact Short-Circuit CurrentDocument4 pagesCalculations and Analysis of Induction Motors Impact Short-Circuit CurrentAbcdNo ratings yet

- Estimation, Identification, and Sensorless Control in Motion SystemsDocument13 pagesEstimation, Identification, and Sensorless Control in Motion SystemsJLuis LuNaNo ratings yet

- Speed Control of DC Motor Using Neural Network ConfigurationDocument4 pagesSpeed Control of DC Motor Using Neural Network Configurationtariq76No ratings yet

- Artículo Base de DatosDocument6 pagesArtículo Base de DatosJuan Sebas Causil Causil RamirezNo ratings yet

- cp:19990995Document9 pagescp:19990995Venkat PrakashNo ratings yet

- A Comparison of Torque Capabilities of Axial Flux and Radial Flux Type of Brushless DC BLDC Drives For Wide Speed Range ApplicationsDocument6 pagesA Comparison of Torque Capabilities of Axial Flux and Radial Flux Type of Brushless DC BLDC Drives For Wide Speed Range ApplicationssosiNo ratings yet

- Extraction of Trafo Electrical ParametersDocument9 pagesExtraction of Trafo Electrical ParametersAshraf IrfanNo ratings yet

- Comparision Between Two Level and Three Level Inverter For Direct Torque Control Induction Motor DriveDocument8 pagesComparision Between Two Level and Three Level Inverter For Direct Torque Control Induction Motor DriveMatanAbutbulNo ratings yet

- Classification of Power Quality Events Using Wavelet Analysis and Probabilistic Neural NetworkDocument12 pagesClassification of Power Quality Events Using Wavelet Analysis and Probabilistic Neural NetworkIAES IJAINo ratings yet

- Frequency and Voltage Tuning of Series-Series Compensated Wireless Power Transfer System To Sustain Rated Power Under Various ConditionsDocument7 pagesFrequency and Voltage Tuning of Series-Series Compensated Wireless Power Transfer System To Sustain Rated Power Under Various ConditionsPatil MounicareddyNo ratings yet

- Traction Induction Drive For Railway CHUEV DenisDocument9 pagesTraction Induction Drive For Railway CHUEV DenisPABLO MAURONo ratings yet

- A General Magnetic Energy BasedDocument8 pagesA General Magnetic Energy Basedforum algerieDZNo ratings yet

- Analyzing The Starting Current of Induction Motor in ATP: Journal Paper ReviewDocument5 pagesAnalyzing The Starting Current of Induction Motor in ATP: Journal Paper ReviewAbhishek JoshiNo ratings yet

- Study On The Control System of The Phase ControlleDocument10 pagesStudy On The Control System of The Phase Controlledat nguyenNo ratings yet

- Simulation of Power System Transient DisturbancesDocument6 pagesSimulation of Power System Transient DisturbancesAhmed58seribegawanNo ratings yet

- Ijert Ijert: Performance of Single Phase Shunt Active Filter Based On P-Q Technique Using Matlab/SimulinkDocument5 pagesIjert Ijert: Performance of Single Phase Shunt Active Filter Based On P-Q Technique Using Matlab/SimulinkR.SRIKANTHNo ratings yet

- Emergency Power Supply of Control Rod For RDEDocument9 pagesEmergency Power Supply of Control Rod For RDEKarthick NatarajanNo ratings yet

- Power Quality Control Technology Based On Customer Power: ZHU Enguo', WU Guoliang', YANG GongxunDocument4 pagesPower Quality Control Technology Based On Customer Power: ZHU Enguo', WU Guoliang', YANG Gongxundog123No ratings yet

- Syllignakis J. Et AlDocument14 pagesSyllignakis J. Et Alali ghalibNo ratings yet

- Applying IEC 60909 Fault Current Calculations PDFDocument6 pagesApplying IEC 60909 Fault Current Calculations PDFsam alNo ratings yet

- Iinvestigation of Ppi and Fuzzy Controllers For Speed C Control of PMSM Motor DriveDocument4 pagesIinvestigation of Ppi and Fuzzy Controllers For Speed C Control of PMSM Motor DriveSatyam GuptaNo ratings yet

- Measuring of Real Value of Short-Circuit Power in Island Operation ConditionDocument5 pagesMeasuring of Real Value of Short-Circuit Power in Island Operation ConditionPadmo PadmundonoNo ratings yet

- Applying IEC 60909, Fault Current CalculationsDocument6 pagesApplying IEC 60909, Fault Current CalculationsgayarthrichandranNo ratings yet

- 10 - Overvoltage Calculation by Monte Carlo Method With Accurate Substation Components Modeling PDFDocument5 pages10 - Overvoltage Calculation by Monte Carlo Method With Accurate Substation Components Modeling PDFAnonymous IjLgxu9fXPNo ratings yet

- PSPICE Simulation of Single-Phase Induction MotorsDocument7 pagesPSPICE Simulation of Single-Phase Induction MotorsMohammad SubhanNo ratings yet

- Direct Torque Control (DTC) of PMSM Using Space Vector Modulated Inverter: A Simulink ApproachDocument4 pagesDirect Torque Control (DTC) of PMSM Using Space Vector Modulated Inverter: A Simulink ApproachKushagra KhamesraNo ratings yet

- STATCOM Control Reconfiguration Technique For Steady State and Dynamic Performance Optimization During Network Fault ConditionsDocument6 pagesSTATCOM Control Reconfiguration Technique For Steady State and Dynamic Performance Optimization During Network Fault Conditionsd ganeshNo ratings yet

- Evaluating Voltage Notch Problems Arising From AC/DC Converter OperationDocument9 pagesEvaluating Voltage Notch Problems Arising From AC/DC Converter Operationmeistehaft270No ratings yet

- Waskito 2011Document4 pagesWaskito 2011RorrachoNo ratings yet

- IEEE STATCOM PaperDocument6 pagesIEEE STATCOM Paperdustoff4No ratings yet

- The Distribution STATCOM For Reducing The Effect of Voltage Sag SwellDocument6 pagesThe Distribution STATCOM For Reducing The Effect of Voltage Sag SwellSavreet OttalNo ratings yet

- Steady State Analysis of Synchronous Generators by Coupled Field-Circuit MethodDocument4 pagesSteady State Analysis of Synchronous Generators by Coupled Field-Circuit MethodJara FeyisaNo ratings yet

- ICEM2020Document8 pagesICEM2020marinkokNo ratings yet

- Transient Stability Improvement Using Upfc and SVCDocument8 pagesTransient Stability Improvement Using Upfc and SVCSai Bhargav VeerabathiniNo ratings yet

- 06 - Power System ProtectionDocument99 pages06 - Power System ProtectionMohamed WahidNo ratings yet

- On The Stability of Volts-per-Hertz Control For Induction MotorsDocument10 pagesOn The Stability of Volts-per-Hertz Control For Induction Motorsm tpNo ratings yet

- Open Loop - Im - 786-1524713051Document12 pagesOpen Loop - Im - 786-1524713051control 4uonlyNo ratings yet

- Impulse Voltage Generator Modelling Using MATLABDocument7 pagesImpulse Voltage Generator Modelling Using MATLABKsr AkhilNo ratings yet

- Direct Power Control of PWM Converter Without Power Source VoltaDocument6 pagesDirect Power Control of PWM Converter Without Power Source Voltabalaji mendiNo ratings yet

- Direct Torque ControlDocument5 pagesDirect Torque ControljanusanusNo ratings yet

- Electric Machine Control of Starter-Generator Unit: Preobrazhensky, A.N. ReshelnikovDocument3 pagesElectric Machine Control of Starter-Generator Unit: Preobrazhensky, A.N. ReshelnikovsyazanaNo ratings yet

- Cascade PI Controller For Single-Phase STATCOM: Hossein Hafezi Eyup Akpinar Abdul BalikciDocument6 pagesCascade PI Controller For Single-Phase STATCOM: Hossein Hafezi Eyup Akpinar Abdul BalikciRahul YadavNo ratings yet

- Feedforward Flux-Weakening Control of Surface-Mounted Permanent-Magnet Synchronous Motors Accounting For Resistive Voltage DropDocument10 pagesFeedforward Flux-Weakening Control of Surface-Mounted Permanent-Magnet Synchronous Motors Accounting For Resistive Voltage DropTrần Tấn LộcNo ratings yet

- Direct Torque Control of Symmetrical and Asymmetrical Single Phase Induction MotorDocument4 pagesDirect Torque Control of Symmetrical and Asymmetrical Single Phase Induction MotorBook4AllNo ratings yet

- 100107Document5 pages100107Vol2No1No ratings yet

- Optimal Design of Interior Permanent Magnet - Lee - 2013Document6 pagesOptimal Design of Interior Permanent Magnet - Lee - 2013Maycon MaranNo ratings yet

- Design, Analysis and Simulation of Linear Model of A STATCOM For Reactive Power Compensation With Variation of DC-link VoltageDocument7 pagesDesign, Analysis and Simulation of Linear Model of A STATCOM For Reactive Power Compensation With Variation of DC-link VoltageAtiqMarwatNo ratings yet

- Sumanth 9Document13 pagesSumanth 9Chenchu TnvNo ratings yet

- Maximum Power Point Tracking Control of PV System For DC Motors Drive With Neural NetworkDocument6 pagesMaximum Power Point Tracking Control of PV System For DC Motors Drive With Neural NetworkHackbartNo ratings yet

- AEE 68 1 2019 - Art - 8Document14 pagesAEE 68 1 2019 - Art - 8Ali ErNo ratings yet

- A High Performance Field-Oriented Control For A Switched Reluctance Motor DriveDocument6 pagesA High Performance Field-Oriented Control For A Switched Reluctance Motor Driveapi-26587237No ratings yet

- Evaluation of An Impulse Current Test Generator Using Numerical Simulation ToolsDocument4 pagesEvaluation of An Impulse Current Test Generator Using Numerical Simulation ToolsMUHAMMAD ALINo ratings yet

- Full Text 302010Document8 pagesFull Text 302010belsebtiNo ratings yet

- ProjectControl, DC. AnalysisDocument15 pagesProjectControl, DC. AnalysisFir Dauss100% (1)

- 12 Pulse Rectifier For MeaDocument6 pages12 Pulse Rectifier For MeaJeevan KalraNo ratings yet

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1From EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Rating: 4.5 out of 5 stars4.5/5 (3)

- New Methodology To Faults Detection in Induction Motors Via MCSADocument6 pagesNew Methodology To Faults Detection in Induction Motors Via MCSALaiba GulNo ratings yet

- Car GRNTDocument21 pagesCar GRNTLaiba GulNo ratings yet

- Car GRNTDocument21 pagesCar GRNTLaiba GulNo ratings yet

- Tii 20 610Document9 pagesTii 20 610Laiba GulNo ratings yet

- Bearing Via Vibration AnalysisDocument11 pagesBearing Via Vibration AnalysisLaiba GulNo ratings yet

- P Type Metal Oxide Semiconductor Thin Films: Synthesis and Chemical Sensor ApplicationsDocument45 pagesP Type Metal Oxide Semiconductor Thin Films: Synthesis and Chemical Sensor ApplicationsLaiba GulNo ratings yet

- Siemens 7200 SHDocument546 pagesSiemens 7200 SHLaiba GulNo ratings yet

- Ae Tandon TechniqueDocument7 pagesAe Tandon TechniqueEmir AvcıoğluNo ratings yet

- Beraing Fault Detection Using CWT AVMDocument9 pagesBeraing Fault Detection Using CWT AVMLaiba GulNo ratings yet

- Comparing condition monitoring techniques for detecting defects in induction motor ball bearingsDocument13 pagesComparing condition monitoring techniques for detecting defects in induction motor ball bearingsLaiba GulNo ratings yet

- Beraing Fault Detection Using CWT AVMDocument9 pagesBeraing Fault Detection Using CWT AVMLaiba GulNo ratings yet

- PLC-based Fuzzy Logic Controller For Induction-Motor Drive With Constant V-HZ RatioDocument6 pagesPLC-based Fuzzy Logic Controller For Induction-Motor Drive With Constant V-HZ RatioAbcvdgtyio Sos RsvgNo ratings yet

- MatlabDocument180 pagesMatlabZilly MilikitiewNo ratings yet

- Cpu210 eDocument140 pagesCpu210 eKhaled OuniNo ratings yet

- Elevator Drive ControlDocument6 pagesElevator Drive ControlLaiba GulNo ratings yet

- Modeling Vibration from Single Point Defects in Rolling Element BearingsDocument14 pagesModeling Vibration from Single Point Defects in Rolling Element BearingsLaiba GulNo ratings yet

- PLC Based 3-Phase Motor Power Factor ControllerDocument7 pagesPLC Based 3-Phase Motor Power Factor ControllerLaiba GulNo ratings yet

- Integrated Circuit True RMS-to-DC Converter AD536A: Features Functional Block DiagramDocument16 pagesIntegrated Circuit True RMS-to-DC Converter AD536A: Features Functional Block Diagramarlan bey-beyNo ratings yet

- Guidelines On The Management of Sexual Problems in Men: The Role of AndrogensDocument12 pagesGuidelines On The Management of Sexual Problems in Men: The Role of AndrogensLaiba GulNo ratings yet

- Design and Implementation of PLC-Based Monitoring SystemDocument8 pagesDesign and Implementation of PLC-Based Monitoring SystemAsha Rani C KNo ratings yet

- Razik Rotor Modelling 2009Document9 pagesRazik Rotor Modelling 2009Laiba GulNo ratings yet

- BSSM Algorithm Premature Ejaculation v4Document1 pageBSSM Algorithm Premature Ejaculation v4Laiba GulNo ratings yet

- Modeling Low Speed Bearing FaultsDocument12 pagesModeling Low Speed Bearing FaultsLaiba GulNo ratings yet

- CM ISO StandardsDocument8 pagesCM ISO StandardsLaiba GulNo ratings yet

- Current Transducer SelectionDocument5 pagesCurrent Transducer SelectionLaiba GulNo ratings yet

- Event Management Study Material Free PDFDocument2 pagesEvent Management Study Material Free PDFKim0% (1)

- Nitro - Quiz 3 Ged102-A13Document3 pagesNitro - Quiz 3 Ged102-A13Eliezer NitroNo ratings yet

- HQ 170aDocument82 pagesHQ 170aTony WellsNo ratings yet

- LCD PinoutsDocument1 pageLCD PinoutsPablo Daniel MagallanNo ratings yet

- DSRD Ar05Document132 pagesDSRD Ar05djon888No ratings yet

- Manual SOC2 DVR Mini 90nDocument83 pagesManual SOC2 DVR Mini 90nDeybby Luna Laredo0% (1)

- Brazilian Labour Ministry Updates Machinery Safety RulesDocument89 pagesBrazilian Labour Ministry Updates Machinery Safety Rulestomy_ueziNo ratings yet

- Crestron Teams HardeningDocument20 pagesCrestron Teams HardeningmanishNo ratings yet

- Equalization of Lithium-Ion Battery Pack Based On Fuzzy Logic Control in Electric VehicleDocument10 pagesEqualization of Lithium-Ion Battery Pack Based On Fuzzy Logic Control in Electric VehicleSureshNo ratings yet

- EE370 L1 IntroductionDocument38 pagesEE370 L1 IntroductionAnshul GoelNo ratings yet

- Year Overview 2012 FinalDocument65 pagesYear Overview 2012 FinalArjenvanLinNo ratings yet

- Binders For: Architectural CoatingsDocument8 pagesBinders For: Architectural CoatingsAPEX SON100% (1)

- Total Standards: - Total Sub-Standards: - Total ESR StandardsDocument8 pagesTotal Standards: - Total Sub-Standards: - Total ESR StandardsHCX dghhqNo ratings yet

- Petitioner Vs Vs Respondents Marcial Esposo Eulogio F. Lerum M. A. FerrerDocument4 pagesPetitioner Vs Vs Respondents Marcial Esposo Eulogio F. Lerum M. A. Ferrerclarisse lyka hattonNo ratings yet

- Case Study - NISSANDocument5 pagesCase Study - NISSANChristy BuiNo ratings yet

- HistoryDocument13 pagesHistoryMuhamed Zimić ZimaNo ratings yet

- Hedonomics: Bridging Decision Research With Happiness ResearchDocument20 pagesHedonomics: Bridging Decision Research With Happiness ResearchgumelarNo ratings yet

- 1.3 Swot and PDP AnalysisDocument4 pages1.3 Swot and PDP AnalysismiroyNo ratings yet

- Personal Styling Service-Contract - No WatermarkDocument5 pagesPersonal Styling Service-Contract - No WatermarkLexine Emille100% (1)

- Supplementary Life Insurance - Enrolment FormDocument1 pageSupplementary Life Insurance - Enrolment FormjeevaNo ratings yet

- j00m HD FLV SQL Injection - PyDocument4 pagesj00m HD FLV SQL Injection - PyZeljko PanovicNo ratings yet

- SSRN Id983401Document43 pagesSSRN Id983401LeilaNo ratings yet

- General Education September 2016Document195 pagesGeneral Education September 2016Ronalyn AndaganNo ratings yet

- How Chips Are DesignedDocument46 pagesHow Chips Are DesignedAli AhmadNo ratings yet

- Research On HIBADocument9 pagesResearch On HIBAPixel GeekNo ratings yet

- Partial Full Volume of TankDocument8 pagesPartial Full Volume of TankBabita GuptaNo ratings yet

- Lesson2.1-Chapter 8-Fundamentals of Capital BudgetingDocument6 pagesLesson2.1-Chapter 8-Fundamentals of Capital BudgetingMeriam HaouesNo ratings yet

- Atlantic Revolutions: Ogé Insurrection Inspired Haitian IndependenceDocument18 pagesAtlantic Revolutions: Ogé Insurrection Inspired Haitian IndependenceNiara ChaneyNo ratings yet

- PTL Ls Programme HandbookDocument34 pagesPTL Ls Programme Handbooksalak946290No ratings yet

- Thesis Supervisor Recommendation With Representative Content and Information RetrievalDocument8 pagesThesis Supervisor Recommendation With Representative Content and Information RetrievalIlmiMardatillahNo ratings yet