Professional Documents

Culture Documents

AC - 43-14 Mantenimiento de Radar y Radome

Uploaded by

CARLOS GETAROriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AC - 43-14 Mantenimiento de Radar y Radome

Uploaded by

CARLOS GETARCopyright:

Available Formats

AC NO: 43-1*

ADVISORY

w CIRCULAR

DEPARTMENT OF TRANSPORTATION

FEDERAL AVIATION ADMINISTRATION

SUBJECT* MAINTENANCE OF WEATHER RADAR RADOMES

1. PURPOSE. This advisory circular provides guidance material useful to

repair facilities in the maintenance of weather radar radomes.

2. CANCELLATION. AC 43-202, dated 6/11/65, and AC 90-20, dated 11/12/64,

are cancelled.

3. GENERAL. A radome is a covering whose primary purpose is to protect a

.radar antenna from the elements. It is a part of the airframe and,

therefore,should have certain physical as well as electrical properties.

Physically, a radome should be strong enough to withstand the airloads

that it will encounter and it should be contoured to minimize drag.

These properties vary with the shape, design speed, and size of the

airplane on which it is to be installed. Electrically, a radome should

permit the passage .of the radar's transmitted signals and return echoes

with minimum distortion and absorption. In order to do this, it should

have a certain electrical thickness. The electrical thickness of a

radome is related to the physical thickness, operating frequency, and the

types of material and construction used. This relationship is defined by

a number of complex mathematical equations which are of interest only to

radome design engineers. These equations show that,for given physical

properties,a radome should have a certain electrical thickness for a

certain narrow range of operating frequencies. (This is the reason why

C-band radomes will not give optimum performance with X-band radars and

vice versa.) Also, a very small variation in physical thickness may cause

a sizable variation in electrical thickness. Radar efficiency, definition,

and accuracy of display depend upon a clear, nondistorted, reflection-free

antenna view through the radome. Consequently, a radome should be

precisely built for optimum performance.

4. RADOME CHARACTERISTICS. There are two general types of radomes, the

"thin wall" and "sandwich" types. Thin wall radomes are considered to be

thin relative to the wavelength of the radar. They are generally useful

when the radar frequency is low enough to permit a skin thickness which

will satisfy the structural requirements. Sandwich radomes consist of two

Initiated by: AFS-804

AC 43-14 2/24/77

or more plastic skins separated by a dielectric core. The core may

consist of honeycomb plastic sections, hollow flutes, or foam plastic.

The dielectric and separation of the skins will depend upon the wave

length of the radar frequency or frequencies.

5. RADOME DAMAGE. Probably the most frequent damage to radomes is holes in

the structure caused by static discharges. These can be large holes that

are readily apparent, or small pin holes that are almost imperceptible.

Any hole, regardless of size, can cause major damage to a radome since

moisture can enter the radome wall and cause internal delamination. If

the moisture freezes, more serious damage may occur. If enough moisture

collects, the radiation pattern will be distorted and the transmitted

signals and return echoes seriously attenuated. Ram air through a hole

can delaminate and break the inner surface of the radome and result in

separation of the skins or faces' of the material from the core, weakening

the radome structure. Other types of damage are characterized as dents

and scratches caused by impact with stones and birds and improper

handling of the radome when it is removed for maintenance of the radar

antenna. This type of damage is easily found by inspection.

6. MAINTENANCE.

a. High performance radar radomes are very precisely constructed and

sometimes the slightest change in their physical characteristics,

such as excessive layers of paint, can adversely affect radar system

performance. All repairs to radomes, no matter how minor, should

return the radome to its original or properly altered condition,

both electrically and structurally. The performance of

proper maintenance to precision radomes requires special knowledge

and techniques and the use of proper tools and materials- An

improper minor repair can eventually lead to an expensive major

repair. A radome having undergone major repairs should be tested to

ascertain that its electrical properties have not been impaired.

The testing of radomes requires test equipment that usually is found

only in repair facilities specializing in radome maintenance. Even

minor repairs may affect one or all of the following:

(1) Transmissivity. Which is the ability of a radome to pass radar

energy through it.

(2) Reflection. Which is the return or reflection of the outgoing

radar energy from the radome back into the antenna and waveguide

system.

(3) Diffraction. Which is the bending of the radar energy as it

passes through the radome.

b. These electrical properties, when altered, by improper repair, may

cause loss of signal, distortion and displacement of targets, and

can clutter the display to obscure the target. Poor radome

Page 2 Par £

2/24/77 AC 43-14

electrical performance can produce numerous problems which may

appear to be symptoms of deficiencies in other units of the radar

system. The following are examples of improper repair:

(1) Use of wrong materials - not compatible with original radome

materials.

(2) Patches of different thickness.

(3) Poor fabrication techniques.

(4) Nonvoid-free patches.

(5) Repairs overlapping.

(6) "Holes plugged with resin, screws, metal, wood, and plastic

plugs.

(7) Cuts or cracks simply coated with resin.

(6) Tape (including electrical tape) over hole or crack and

covered with resin.

(9) Oversize patches.

(10) Too much or too little resin.

(11) Exterior coatings - too many coats, too thick, uneven

thickness - metallic base paints.

(12) Filled honeycomb cells.

(13) Repairs made without removing moisture or moisture contamina

tion from inside of radome wall.

(14) Abrupt changes in cross-sectional areas.

(15) Patches projecting above outside contour lines.

(16) Improper cure.

(17) Wrong size cells or densitv of honeycomb.

(18) Excessive overlap in honeycomb joints.

(19) Poor bonding of skin to core.

(20) Gaps in honeycomb core.

Par 6 Page 3

AC 4 3 - U 2/24/77

7. RE COMMENDATION. Both the physical and electrical properties of radomes

should be given careful consideration during repair operations. These

properties are carefully controlled during manufacture and should not be

altered by improper repairs.

J . A. FERRARESE

Acting D i r e c t o r , F l i g h t S t a n d a r d s Service

You might also like

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- Performance of A RadomeDocument14 pagesPerformance of A Radomeshikhar6230% (1)

- Design and Analysis of Different Types of Aircraft Radome IJERTCONV3IS26038 PDFDocument5 pagesDesign and Analysis of Different Types of Aircraft Radome IJERTCONV3IS26038 PDFudaykumar8995No ratings yet

- Lighting Protection of Radom (Bagus)Document7 pagesLighting Protection of Radom (Bagus)fian officialstoreNo ratings yet

- Radar Radome and Its Design Considerations: December 2009Document6 pagesRadar Radome and Its Design Considerations: December 2009Suresh MadhevanNo ratings yet

- Radar Radome and Its Design Considerations: December 2009Document6 pagesRadar Radome and Its Design Considerations: December 2009Suresh RajNo ratings yet

- CCI Radome Whitepaper 190813Document9 pagesCCI Radome Whitepaper 190813bardaris100% (1)

- Stealth Technology and Its Usage in WarshipsDocument14 pagesStealth Technology and Its Usage in Warshipsyosermohamed09No ratings yet

- Radome April 03Document3 pagesRadome April 03Shanjeevan GovindasamyNo ratings yet

- RT Duroid 6002 Laminate Data SheetDocument2 pagesRT Duroid 6002 Laminate Data SheetAhmed UmarNo ratings yet

- A Fundamental and Technical Review of RadomesDocument2 pagesA Fundamental and Technical Review of RadomesK FinkNo ratings yet

- Monolithic Thin Walled Ellipsoidal RadomeDocument3 pagesMonolithic Thin Walled Ellipsoidal RadomeAsif RizwanNo ratings yet

- A Fundamental and Technical Review of RadomesDocument4 pagesA Fundamental and Technical Review of RadomesAmador Garcia IIINo ratings yet

- Laser Damage Resistant Anti-Reflection Microstructures in Raytheon Ceramic YAG, Sapphire, ALON, and QuartzDocument10 pagesLaser Damage Resistant Anti-Reflection Microstructures in Raytheon Ceramic YAG, Sapphire, ALON, and Quartzعلی فروتن اصلNo ratings yet

- Radiation Hardening: NAME-Saijal Rekhani ROLL NO-18D110008 BRANCH-MetallurgyDocument7 pagesRadiation Hardening: NAME-Saijal Rekhani ROLL NO-18D110008 BRANCH-MetallurgySaijal RekhaniNo ratings yet

- Radar Absorbing Materials - Mechanisms and Materials: February 1989Document37 pagesRadar Absorbing Materials - Mechanisms and Materials: February 1989Thanh Giang TrầnNo ratings yet

- Simulation of Cathodic Protection System Using Matlab: March 2013Document14 pagesSimulation of Cathodic Protection System Using Matlab: March 2013adnantanNo ratings yet

- RadomeDocument8 pagesRadomeANGEL SHINY C PRK21EC2002No ratings yet

- 9 Radome Caip Part 2 Pages 1171-1178Document8 pages9 Radome Caip Part 2 Pages 1171-1178NOOBplaysNo ratings yet

- Lightening Diverter PaperDocument7 pagesLightening Diverter PapersultanrandhawaNo ratings yet

- Stealth Coating For AerospaceDocument25 pagesStealth Coating For Aerospacerohankumar.6143No ratings yet

- Technical Seminar On STEALTH TECHNOLOGY IN AIRCRAFTDocument28 pagesTechnical Seminar On STEALTH TECHNOLOGY IN AIRCRAFTAnjanKumarDNo ratings yet

- Performance Requirements For Countermeasures LasersDocument15 pagesPerformance Requirements For Countermeasures LasersranitaNo ratings yet

- Elements of Cable Management WP-110965-EnDocument6 pagesElements of Cable Management WP-110965-EnheriNo ratings yet

- SPIE7302-0J ARMs WD2009aDocument12 pagesSPIE7302-0J ARMs WD2009aRamin ShojaNo ratings yet

- A Review On Ceramic and Polymer Materials For Radome ApplicationsDocument4 pagesA Review On Ceramic and Polymer Materials For Radome Applicationsrajaram huptaNo ratings yet

- Copperweld Grounding Wire & StrandDocument4 pagesCopperweld Grounding Wire & StrandNelson RuizNo ratings yet

- Wireline For Downhole ToolsDocument2 pagesWireline For Downhole ToolsLuqman HadiNo ratings yet

- Approaches To Making Antennas Stealthy: Jerome I. Glaser Glaser Associates Los Angeles, CADocument4 pagesApproaches To Making Antennas Stealthy: Jerome I. Glaser Glaser Associates Los Angeles, CAmaamriaNo ratings yet

- Design of Frequency-Selective Surfaces Radome For A Planar Slotted Waveguide AntennaDocument3 pagesDesign of Frequency-Selective Surfaces Radome For A Planar Slotted Waveguide AntennaTOUGHNo ratings yet

- Operator's Guide To Marine RadarDocument24 pagesOperator's Guide To Marine Radarحذيفة نايرNo ratings yet

- 10.1109/RFIT.2019.8929217: Deposited On: 01 July 2019Document4 pages10.1109/RFIT.2019.8929217: Deposited On: 01 July 2019Karni Aerospace Inc.No ratings yet

- Radiographic Inspection of WeldsDocument10 pagesRadiographic Inspection of WeldsFarhan HamidNo ratings yet

- A Frequency Selective Radome With Wideband Absorbing PropertiesDocument8 pagesA Frequency Selective Radome With Wideband Absorbing Propertiesajgarciacollado2019No ratings yet

- Ram 1Document84 pagesRam 1Ravi PanwarNo ratings yet

- Prevention of Dry-Band Arc Damage On ADSS CablesDocument9 pagesPrevention of Dry-Band Arc Damage On ADSS CablesHugh cabNo ratings yet

- A Frequency Selective Radome With Wideband Absorbing PropertiesDocument8 pagesA Frequency Selective Radome With Wideband Absorbing PropertiesTOUGHNo ratings yet

- Underground Cable Fault Distance Detector Using ATmega328 MicrocontrollerDocument7 pagesUnderground Cable Fault Distance Detector Using ATmega328 MicrocontrollerregecartNo ratings yet

- Cathodic Protection Strategies For FPSO'sDocument10 pagesCathodic Protection Strategies For FPSO'smysearchforbookNo ratings yet

- NaseerA alhabobiandShahadF AbedDocument14 pagesNaseerA alhabobiandShahadF AbedJorge LunaNo ratings yet

- 39Document26 pages39supriyo1970No ratings yet

- Rectangular Microstrip AntennaDocument7 pagesRectangular Microstrip AntennarameshdurairajNo ratings yet

- Broadband Low RCS Based On PolarizationDocument10 pagesBroadband Low RCS Based On PolarizationeceaitsrajampetNo ratings yet

- Multi-Chamber Arrester Study at Tropical Area For 20 KV Lines Lightning Protection SystemDocument5 pagesMulti-Chamber Arrester Study at Tropical Area For 20 KV Lines Lightning Protection SystemJARINGAN KTBNo ratings yet

- Use of Sea Clutter Models in Radar DesignDocument12 pagesUse of Sea Clutter Models in Radar DesignRisdilah MimmaNo ratings yet

- Radar Absorbing Material Design: Yuzcelik, Cihangir KemalDocument84 pagesRadar Absorbing Material Design: Yuzcelik, Cihangir KemalshahidNo ratings yet

- Radiation Effects and COTS Parts in SmallSatsDocument12 pagesRadiation Effects and COTS Parts in SmallSatstomek_zawistowskiNo ratings yet

- Cable Fault Location in Medium Voltage of Sonelgaz Underground Network Recherche de Défaut de Câblé Dans Le Réseau Souterrain de SonelgazDocument12 pagesCable Fault Location in Medium Voltage of Sonelgaz Underground Network Recherche de Défaut de Câblé Dans Le Réseau Souterrain de SonelgazKamel MoridNo ratings yet

- Thesis Topics For Microwave EngineeringDocument5 pagesThesis Topics For Microwave Engineeringjqcoplhld100% (2)

- Radome Full ProjectDocument54 pagesRadome Full ProjectWebsoft Tech-HydNo ratings yet

- Signature Reduction in Ships PDFDocument3 pagesSignature Reduction in Ships PDFshiva1978in@gmail.comNo ratings yet

- How To Get StealthyDocument5 pagesHow To Get Stealthyramneet91No ratings yet

- Design and Simulation of Microstrip Patch Single Element, 12 Array Design and 14 Array Design For SART ApplicationsDocument4 pagesDesign and Simulation of Microstrip Patch Single Element, 12 Array Design and 14 Array Design For SART ApplicationsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Gems l-2d9 Cathodic Protection SystemsDocument15 pagesGems l-2d9 Cathodic Protection SystemsMochamad TaufikNo ratings yet

- Sinha 2006Document4 pagesSinha 2006Emharion DinNo ratings yet

- VO2-based Ultra-Reconfigurable Intelligent Reflective Surface For 5G ApplicationsDocument9 pagesVO2-based Ultra-Reconfigurable Intelligent Reflective Surface For 5G ApplicationsWill RMNo ratings yet

- Aircraft Nose RadomeDocument2 pagesAircraft Nose RadomeAbdulkadir GüngörNo ratings yet

- Motheye SPIE6545-34ME20Mar07Document14 pagesMotheye SPIE6545-34ME20Mar07blurnewbieNo ratings yet

- European Aviation Safety Agency: Easa Type-Certificate Data SheetDocument20 pagesEuropean Aviation Safety Agency: Easa Type-Certificate Data SheetCARLOS GETARNo ratings yet

- Index de Publicaciones de R193 DowtyDocument8 pagesIndex de Publicaciones de R193 DowtyCARLOS GETARNo ratings yet

- AN 509 Flat Head Machine Screws: Item # Diameter-Thread Length Grip Material FinishDocument4 pagesAN 509 Flat Head Machine Screws: Item # Diameter-Thread Length Grip Material FinishCARLOS GETARNo ratings yet

- AC - 43-4B Programa de Control de CorrosionDocument127 pagesAC - 43-4B Programa de Control de CorrosionCARLOS GETARNo ratings yet

- Enviando Denso Mitsubishi l200 Common RailDocument55 pagesEnviando Denso Mitsubishi l200 Common Railisrael machicado calle100% (3)

- ResistorsDocument33 pagesResistorsCaine de Leon100% (1)

- EN VEGACAL 62 4... 20 Ma HART Two WireDocument60 pagesEN VEGACAL 62 4... 20 Ma HART Two WireVõ HòaNo ratings yet

- ARM Cortex M3 RegistersDocument22 pagesARM Cortex M3 RegistersRaveendra Moodithaya100% (2)

- 9098i Circuit Diagrams Overlays Issue 2Document321 pages9098i Circuit Diagrams Overlays Issue 2Robert Morris100% (1)

- Altronic Cpu-2000 Ignition System Installation Instructions FORM CPU-2000 II 9-97Document35 pagesAltronic Cpu-2000 Ignition System Installation Instructions FORM CPU-2000 II 9-97Bran DumitruNo ratings yet

- Ps Electricity and Magnetism HandoutDocument5 pagesPs Electricity and Magnetism HandoutMarcus 'stulla' AllisonNo ratings yet

- Total Station RObotic Topcon GT 501 With Automatic Control - TRANSSURVEYDocument4 pagesTotal Station RObotic Topcon GT 501 With Automatic Control - TRANSSURVEYTRANS SURVEYNo ratings yet

- Continental Directional-Proportional Valves PDFDocument98 pagesContinental Directional-Proportional Valves PDFhebert perezNo ratings yet

- VHDL Code For FilterDocument2 pagesVHDL Code For FilterArkadip GhoshNo ratings yet

- Fara Dimensiuni Transformator 2D 3D NatasaDocument30 pagesFara Dimensiuni Transformator 2D 3D NatasaFazacas DanielNo ratings yet

- Solid StateDocument5 pagesSolid StateDar KeyyNo ratings yet

- Nema SB 50-2008Document32 pagesNema SB 50-2008Irwin CastroNo ratings yet

- Fingerprint-Authentication Using BiometricDocument59 pagesFingerprint-Authentication Using BiometricDebashishParidaNo ratings yet

- Freemont ManualDocument352 pagesFreemont Manualcucioan1979No ratings yet

- F110 e 1 001Document39 pagesF110 e 1 001ameen hassanNo ratings yet

- SG1524Document9 pagesSG1524Med Habib AitNo ratings yet

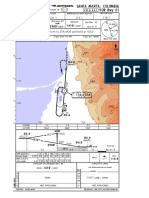

- Santa Marta, Colombia SKSM/SMR VOR Rwy 01: 13-1 119.1 118.7 VOR Cat A, B & C Simon Bolivar Intl 125.0 127.7Document1 pageSanta Marta, Colombia SKSM/SMR VOR Rwy 01: 13-1 119.1 118.7 VOR Cat A, B & C Simon Bolivar Intl 125.0 127.7Guillermo Serrano KelcyNo ratings yet

- MOSCAPDocument6 pagesMOSCAPEjder YildizNo ratings yet

- Lab LCDDocument6 pagesLab LCDJesus Cotrina100% (1)

- Workshop Manual: Service and RepairDocument24 pagesWorkshop Manual: Service and RepairJean Dupont100% (1)

- Buku ProgramDocument17 pagesBuku ProgramMieza Binti YusoffNo ratings yet

- HOKUSAI GreatWave Users Guide enDocument118 pagesHOKUSAI GreatWave Users Guide enGodwin LarryNo ratings yet

- RSL DisconnectedDocument2 pagesRSL DisconnectedGunawan HendroNo ratings yet

- D 3820Document41 pagesD 3820teja tejaNo ratings yet

- EdExcel A Level Chemistry Unit 1 Mark Scheme Results Paper 1 Jun 2005Document10 pagesEdExcel A Level Chemistry Unit 1 Mark Scheme Results Paper 1 Jun 2005ProdhanNo ratings yet

- Automatic Adjustable Sex Machine With Dildo STCSFM-003 PDFDocument1 pageAutomatic Adjustable Sex Machine With Dildo STCSFM-003 PDFJoelNo ratings yet

- Katalog MHPPDocument51 pagesKatalog MHPPDina ButkovićNo ratings yet

- Ofc LedDocument6 pagesOfc LedVignesh DevanNo ratings yet

- An Autonomous Flight Safety SystemDocument12 pagesAn Autonomous Flight Safety SystemWoofyNo ratings yet