0% found this document useful (0 votes)

3K views2 pagesg78 Threading Cycle

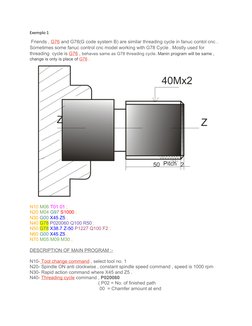

G76 and G78 are similar threading cycles in Fanuc CNC controls. G76 is most commonly used for threading cycles and functions the same as G78. The main program for a threading cycle using either G76 or G78 would be the same, with the only change being substituting G76 for G78. An example program provided uses G78 for a threading cycle, specifying parameters such as tool number, spindle speed, positions for rapid moves and threading, and cycle data including pitch, depth of cut, and chamfer amount.

Uploaded by

Tatiana OlegovnaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

3K views2 pagesg78 Threading Cycle

G76 and G78 are similar threading cycles in Fanuc CNC controls. G76 is most commonly used for threading cycles and functions the same as G78. The main program for a threading cycle using either G76 or G78 would be the same, with the only change being substituting G76 for G78. An example program provided uses G78 for a threading cycle, specifying parameters such as tool number, spindle speed, positions for rapid moves and threading, and cycle data including pitch, depth of cut, and chamfer amount.

Uploaded by

Tatiana OlegovnaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

- Example 1

- Detailed Program Description