Professional Documents

Culture Documents

No Enviar Ico3s Atex

Uploaded by

Ignacio BenitoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

No Enviar Ico3s Atex

Uploaded by

Ignacio BenitoCopyright:

Available Formats

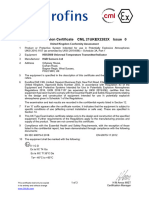

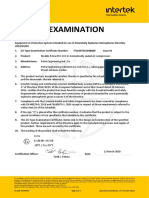

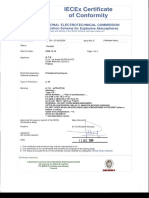

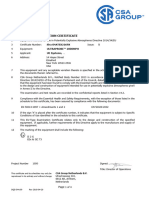

EU Type Examination Certificate CML 19ATEX1057X Issue 0

1 Equipment intended for use in Potentially Explosive Atmospheres Directive 2014/34/EU

2 Equipment ICO3 Solenoid Valves

3 Manufacturer Thompson Valves Ltd

4 Address 17 Balena Close

Creekmoor

Poole

Dorset

BH17 7EF

United Kingdom

5 The equipment is specified in the description of this certificate and the documents to which it

refers.

6 CML B.V. , Chamber of Commerce No 6738671, Hoogoorddreef 15, Amsterdam, 1101 BA,

The Netherlands, Notified Body Number 2776, in accordance with Article 17 of Directive

2014/34/EU of the European Parliament and of the Council, dated 26 February 2014, certifies

that this equipment has been found to comply with the Essential Health and Safety

Requirements relating to the design and construction of equipment intended for use in

potentially explosive atmospheres given in Annex II to the Directive.

The examination and test results are recorded in the confidential reports listed in Section 12.

7 If an ‘X’ suffix appears after the certificate number, it indicates the equipment is subject to

conditions of safe use (affecting correct installation or safe use). These are specified in

Section 14.

8 This EU Type Examination certificate relates only to the design and construction of the

specified equipment or component. Further requirements of Directive 2014/34/EU Article 13

apply to the manufacture of the equipment or component and are separately certified.

9 Compliance with the Essential Health and Safety Requirements, with the exception of those

listed in the confidential report, has been demonstrated through compliance with the following

documents:

EN 60079-0:2012:A11:2013, Corr3 EN 60079-1:2014 EN 60079-31:2014

10 The equipment shall be marked with the following:

I M2 II 2 G D

Ex db I Mb Ex db IIC T6 Gb, Ta= **°C to +50°C (Max 10W)

Ta= - 20°C to +50°C Ex db IIC T4 Gb, Ta= **°C to +90°C (Max 10W)

Ex db IIC T6 Gb, Ta= **°C to +40°C (Max 14W)

Ex db IIC T4 Gb, Ta= **°C to +90°C (Max 14W)

Ex tb IIIC T130°C Db IP66/X8, Ta= **°C to +90°C

(**Dependant on gasket material)

This certificate shall only be copied 1 of 3 H M Amos MIET

in its entirety and without change Certificate Manager

www.CMLEx.com

CML 19ATEX1057X

Issue 0

11 Description

The ICO3 Solenoid Valve is an electrically operated control valve consisting of a solenoid which

operates a poppet valve connected to the solenoid enclosure.

The solenoid consists of a cast stainless steel cylindrical enclosure (solenoid pot) and a top threaded

cover. The top cover provides access to the terminal compartment and is fitted with an O-ring

interface seal. The solenoid pot housing has a perpendicular raised flat boss moulded onto the side,

which has a locking set screw for the cover, an external earth connection point and a threaded

conduit entry point. The solenoid enclosure contains an internal encapsulated coil positioned below

the terminal compartment and secured within the solenoid pot by the enclosure base (Pot Base) and

circlip arrangement, the base is additionally fitted with two interface O-ring seals. The coil contains

internal magnetic steel core and armature components to form the solenoid.

The valve operates using electromagnetic force in the solenoid coil to actuate an armature which

passes through the solenoid pot base; both these are manufactured from magnetic steel. The

armature then operates the valve, therefore, controlling the flow of media through the valve.

The valve has the following ratings, number of ports and operation configurations:

24 Vac to 240 Vac, 40 to 60 Hz or 12 Vdc to 240 Vdc

Automatic 3/2, 2/2 and 5/2, manual reset and tamperproof manual reset, manual override and

automatic latching options.

The fasteners used on the ICO3 Solenoid Valves shall be an minimum of Steel Grade 12.9 or

Stainless Steel Grade A2-70.

Design options:

The internal circuitry can be either full-wave rectifying, half-wave rectifying or transient

suppression.

Transient suppression circuitry may be made up of diodes, Zener diodes or a voltage

dependant resistor.

Circuits may be fitted with line monitoring resistors.

The cable entry may be one of the following types and sizes:

- M20 x 1.5, in accordance with ISO965, parts 1 &3.

- ½” NPT, in accordance with ANSI/ASME B1.20.1

- PG 13.5, in accordance with DIN 40430

All entry threads comply with EN 60079-1:2014, clause 5, tables 4 or 5and clause C.2.2,

as applicable.

12 Certificate history and evaluation reports

Issue Date Associated report Notes

R1156B/00

0 18/02/2019 Issue of prime certificate

R12280A/00

Note: Drawings that describe the equipment or component are listed in the Annex.

This certificate shall only be copied 2 of 3 Version: 2.0 Approval: Approved

in its entirety and without change

www.CMLEx.com

CML 19ATEX1057X

Issue 0

13 Conditions of manufacture

The following conditions are required of the manufacturing process for compliance with the

certification.

13.1 The ICO3S solenoid valves shall be marked with one of the following minimum ambient

temperature:

Minimum ambient

O-Ring seal material

temperature

MFQ Fluorosilicone -60°C

NBR Nitrile -60°C

FKM Fluorocarbon (Viton) -40°C

EPDM -50°C

FFKM -30°C

VMQ Silicone -55°C

14 Special Conditions for Safe Use (Conditions of Certification)

The following conditions relate to safe installation and/or use of the equipment.

14.1 The ICO3S solenoid valves shall only be installed in accordance with EN 60079-14 and

the manufacturer’s instructions.

14.2 No repair shall be made to flamepaths.

This certificate shall only be copied 3 of 3 Version: 2.0 Approval: Approved

in its entirety and without change

www.CMLEx.com

Certificate Annex

Certificate Number CML 19ATEX1057X

Equipment ICO3S Solenoid Valves

Manufacturer Thompson Valves Ltd

The following documents describe the equipment or component defined in this certificate:

Issue 0

Drawing No Sheets Rev Approved Title

date

CD-7M-ATEX-IEC- 1 of 1 7 18/02/2019 Certification Drawing for ICO3 Label (ATEX

LABEL Group II)

CD-7M-ATEX- 1 of 1 3 18/02/2019 Certification Drawing for ICO3 Label (ATEX

GROUP I-LABEL Group I)

CD-7M-BASE 1 of 1 6 18/02/2019 Certification Drg for ICO3 Pot Base

CD-7M-POT 1 of 1 5 18/02/2019 Certification Drg for ICO3 Solenoid Pot

ICO3-ATEX-CERT-1 1 of 2 05 18/02/2019 ICO3 Flameproof Enclosure ATEX Certified

Drawing

ICO3-ATEX-CERT-2 2 of 2 5 18/02/2019 ICO3 Flameproof Enclosure ATEX Certified

Drawing

CD-7M-COVER 1 of 1 4 18/02/2019 Certification Drg for ICO3 Pot Cover

CD-7M-ARMATURE 1 of 1 5 18/02/2019 Certified Drg for ICO3 Armature

This certificate shall only be copied 1 of 1 Version: 2.0 Approval: Approved

in its entirety and without change

www.CMLEx.com

You might also like

- Cryogenics Safety Manual: A Guide to Good PracticeFrom EverandCryogenics Safety Manual: A Guide to Good PracticeNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- No Enviar Ico3s IecexDocument6 pagesNo Enviar Ico3s IecexIgnacio BenitoNo ratings yet

- CML 21UKEX3099 Iss.0 SignedDocument15 pagesCML 21UKEX3099 Iss.0 SignedXavier LefebvreNo ratings yet

- Pub109 141 00 0220Document4 pagesPub109 141 00 0220Auk ah PusingNo ratings yet

- EU Type Examination Certificate DetailsDocument4 pagesEU Type Examination Certificate DetailsBaoLCNo ratings yet

- Dekra 21ukex0304uDocument2 pagesDekra 21ukex0304uBazli Raja ShahrumNo ratings yet

- certificate-hbs5600-ukex-exiaDocument4 pagescertificate-hbs5600-ukex-exiaAzad ArashhaNo ratings yet

- IECEx BAS 17.0037 000Document5 pagesIECEx BAS 17.0037 000Mangesh MohiteNo ratings yet

- SA Equip SAF35 ITS SA CYCLONE EX ATEX CertificateDocument3 pagesSA Equip SAF35 ITS SA CYCLONE EX ATEX CertificateMuhammad ImanNo ratings yet

- IECEx Certificate of Conformity for CMP Products Limited Type 780/PX780 UnionsDocument6 pagesIECEx Certificate of Conformity for CMP Products Limited Type 780/PX780 UnionsAndrada Maria TudorNo ratings yet

- SENSOR J-BOX - 02ATEX3291Iss - 3 PDFDocument4 pagesSENSOR J-BOX - 02ATEX3291Iss - 3 PDFAdrian-Laurențiu RădulescuNo ratings yet

- ITS19ATEX104888X Issue 01Document3 pagesITS19ATEX104888X Issue 01tareqNo ratings yet

- AD H250 M40 II2GD en 150814 4002069602 R02 PRTwoPM 1000317527 1Document20 pagesAD H250 M40 II2GD en 150814 4002069602 R02 PRTwoPM 1000317527 1muhammad.wajahat194No ratings yet

- IP 4000 XPL9568 08321 Rev 2 Dresser InternationalDocument2 pagesIP 4000 XPL9568 08321 Rev 2 Dresser InternationalChristoNo ratings yet

- IECEx BVS 17.0045X 002Document10 pagesIECEx BVS 17.0045X 002Muhammad ImranNo ratings yet

- Operating and maintenance norms for Atos hydraulic cylindersDocument5 pagesOperating and maintenance norms for Atos hydraulic cylindersJesus N RodriguezNo ratings yet

- CML 18ATEX3372X BV Iss. 1Document5 pagesCML 18ATEX3372X BV Iss. 1Anderson SilvaNo ratings yet

- IECEx SIR 09.0103X 002Document7 pagesIECEx SIR 09.0103X 002Amelia KarmadiNo ratings yet

- IECEx ULD 18.0013XDocument5 pagesIECEx ULD 18.0013XRyan Mesina De GuzmanNo ratings yet

- EU Type Examination Certificate CML 19ATEX1192X Issue 0Document8 pagesEU Type Examination Certificate CML 19ATEX1192X Issue 0secondharbour ChinaNo ratings yet

- 08-Instruction Manual Fan UnitDocument20 pages08-Instruction Manual Fan Unitvodoley634No ratings yet

- IECEx BAS 10.0045X 000Document6 pagesIECEx BAS 10.0045X 000Marcos SiqueiraNo ratings yet

- Zone 1, 2, 21, 22 - Group IIB+H - Aluminium Junction Boxes - IP 66 / 67Document22 pagesZone 1, 2, 21, 22 - Group IIB+H - Aluminium Junction Boxes - IP 66 / 67Avoor Khan100% (1)

- AD OPTIFLUX2000 4000 IFC100 ATEX-IECEx en 140916 7312092200 R02Document20 pagesAD OPTIFLUX2000 4000 IFC100 ATEX-IECEx en 140916 7312092200 R02SofiaNo ratings yet

- IECEx TUN 18.0012X 000Document8 pagesIECEx TUN 18.0012X 000Mangesh MohiteNo ratings yet

- Explosion Protection Wall Chart BASEEFADocument1 pageExplosion Protection Wall Chart BASEEFAweby98No ratings yet

- Iecex Lci 08.0023x Issue 00 - CFDocument4 pagesIecex Lci 08.0023x Issue 00 - CFhassan329No ratings yet

- ITS09ATEX26868X Issue 6Document4 pagesITS09ATEX26868X Issue 6Amine DabbabiNo ratings yet

- IECEx KDB 12.0010X 002Document6 pagesIECEx KDB 12.0010X 002Catur Armand SusantoNo ratings yet

- Iecex Certificate of ConformityDocument6 pagesIecex Certificate of ConformityFrancesco_CNo ratings yet

- IECEx SIR 09.0111 Issue 0Document6 pagesIECEx SIR 09.0111 Issue 0Junardi SilabanNo ratings yet

- IECEx PRE 19.0093U 000Document5 pagesIECEx PRE 19.0093U 000Mangesh MohiteNo ratings yet

- 5 CCACDocument16 pages5 CCACrbvfv49hxdNo ratings yet

- UP2000 ATEX II CertificationDocument6 pagesUP2000 ATEX II CertificationGeorgeNo ratings yet

- IECEx BAS 14.0097X 002Document11 pagesIECEx BAS 14.0097X 002Marcos SiqueiraNo ratings yet

- IECEx SIR 10.0121X Wolf Fluorescent LeadlampDocument8 pagesIECEx SIR 10.0121X Wolf Fluorescent LeadlampandersonNo ratings yet

- Certificate St5484esw5484e Iecex Ex D Parent Doc 1185351 Rev eDocument43 pagesCertificate St5484esw5484e Iecex Ex D Parent Doc 1185351 Rev eMishal AbdulRahimNo ratings yet

- Eu-Type Examination: CertificateDocument3 pagesEu-Type Examination: CertificateDnyDnyNo ratings yet

- Certyfikat ATEX - enDocument22 pagesCertyfikat ATEX - enwiruNo ratings yet

- Iecex Certificate of Conformity: Iec Cer Tification System For Explosive Atmospher EsDocument3 pagesIecex Certificate of Conformity: Iec Cer Tification System For Explosive Atmospher EsdrangosaNo ratings yet

- IECEx BAS 17.0115X 0Document6 pagesIECEx BAS 17.0115X 044abcNo ratings yet

- Operating and Maintenance Norms For Cylinders and ServocylindersDocument4 pagesOperating and Maintenance Norms For Cylinders and Servocylindersrrogerr_07No ratings yet

- ATEX Operation Manual Rev94 GB2Document12 pagesATEX Operation Manual Rev94 GB2Angel Eduardo PeñaNo ratings yet

- Certification Manual: Servomex OxydetectDocument32 pagesCertification Manual: Servomex OxydetectfamelotNo ratings yet

- G2X Certificate ATEX 1Document2 pagesG2X Certificate ATEX 1Iwan NugrohoNo ratings yet

- Detectronic - Ec-Declaration-Of-Conformity-22-Detectronic-Ec-D-Of-C-Ec-DeclarationDocument9 pagesDetectronic - Ec-Declaration-Of-Conformity-22-Detectronic-Ec-D-Of-C-Ec-DeclarationAfumatoare VanbetNo ratings yet

- Iecex PTB 09.0027uDocument4 pagesIecex PTB 09.0027uFrancesco_CNo ratings yet

- IECEx BAS 13.0142X 003Document5 pagesIECEx BAS 13.0142X 003Marcos SiqueiraNo ratings yet

- Iecex Kem 10.0002XDocument6 pagesIecex Kem 10.0002XFrancesco_CNo ratings yet

- IECEx NEM 11.0009X 005Document6 pagesIECEx NEM 11.0009X 005Jessica M. SantosNo ratings yet

- IECEx BAS 10.0099X 001Document6 pagesIECEx BAS 10.0099X 001Marcos SiqueiraNo ratings yet

- CB CU Conveyor Belt Control Unit Safety CertificateDocument54 pagesCB CU Conveyor Belt Control Unit Safety CertificateBala Sasanka MadabhushiNo ratings yet

- IECEx Certificate SummaryDocument45 pagesIECEx Certificate SummaryRyan Mesina De GuzmanNo ratings yet

- Siemens - Ex-AI 4xTC 2RTD 2-3-4wireDocument3 pagesSiemens - Ex-AI 4xTC 2RTD 2-3-4wireHerbert RitzerNo ratings yet

- Iecex PTB 09.0048Document61 pagesIecex PTB 09.0048Francesco_CNo ratings yet

- IS Air Dryer Safety and Installation ManualDocument130 pagesIS Air Dryer Safety and Installation ManualvankarpNo ratings yet

- AtexNotes For BusTerminal enDocument17 pagesAtexNotes For BusTerminal enValkure OmegaNo ratings yet

- Sira 07atex1273x Issue 4 For DXX ExdDocument0 pagesSira 07atex1273x Issue 4 For DXX ExdGopinath GunasekaranNo ratings yet

- Iecex CML 14.0012XDocument6 pagesIecex CML 14.0012XFrancesco_CNo ratings yet

- BEE - Lab FileDocument91 pagesBEE - Lab FileshivamNo ratings yet

- Demagnetization methods for permanent magnetsDocument8 pagesDemagnetization methods for permanent magnetssniperpandabNo ratings yet

- Bill of Material of Control PanelDocument1 pageBill of Material of Control PanelTK BhattNo ratings yet

- Kelly KLS-M Brushless Motor Controller User 'S Manual: Devices SupportedDocument28 pagesKelly KLS-M Brushless Motor Controller User 'S Manual: Devices SupportedLuu JosNo ratings yet

- 6SL3130-6TE21-6AA4 Datasheet enDocument1 page6SL3130-6TE21-6AA4 Datasheet enAntonio BarriosNo ratings yet

- Converter Stations Design YG ZhangDocument5 pagesConverter Stations Design YG ZhangNunna BaskarNo ratings yet

- Design and Selection of Substation EquipmentDocument40 pagesDesign and Selection of Substation EquipmentHasan AlmatroodNo ratings yet

- Warning: Wiring DiagramDocument3 pagesWarning: Wiring DiagramEnmanuel J AriasNo ratings yet

- (J-1) Electrical Appliances: Std. IXDocument7 pages(J-1) Electrical Appliances: Std. IXGangaNo ratings yet

- Graphical Analysis Of: Non-Linear CircuitsDocument12 pagesGraphical Analysis Of: Non-Linear CircuitsNaveen ReddyNo ratings yet

- Quik-Lop BOPDocument2 pagesQuik-Lop BOPBoedi SyafiqNo ratings yet

- DatasheetDocument3 pagesDatasheetJuanNo ratings yet

- Diode Circuits: Essentials of Electrical and Electronics Engineering (EEE 1)Document10 pagesDiode Circuits: Essentials of Electrical and Electronics Engineering (EEE 1)Sarah Grace CabilteNo ratings yet

- UniGear medium voltage switchgearDocument8 pagesUniGear medium voltage switchgearHossam AlzubairyNo ratings yet

- L1 Series Hybrid Inverter User Manual (Neutral) V1.3-20211125142830Document23 pagesL1 Series Hybrid Inverter User Manual (Neutral) V1.3-20211125142830Ed Ruel RacomaNo ratings yet

- Datasheet APW7142Document22 pagesDatasheet APW7142José Aparecido BarbosaNo ratings yet

- Mosfet (J.B Gupta)Document13 pagesMosfet (J.B Gupta)rik banerjeeNo ratings yet

- Fetal Doppler Repair and TroubleshootingDocument4 pagesFetal Doppler Repair and TroubleshootingZaghi JuniorNo ratings yet

- Lsa 37 - 2 Pole - Acc: AlternatorsDocument16 pagesLsa 37 - 2 Pole - Acc: AlternatorsSubagyo Wahyu RiyadiNo ratings yet

- Iii. Literature Review (Pressure Transducer)Document2 pagesIii. Literature Review (Pressure Transducer)kathirRavanNo ratings yet

- Chapter 8 Small Sinal Analysis of FETDocument46 pagesChapter 8 Small Sinal Analysis of FETsakibNo ratings yet

- Tyco Inline Joint Single Core Unarmoured Xlpe Mechanical Conn PDFDocument8 pagesTyco Inline Joint Single Core Unarmoured Xlpe Mechanical Conn PDFYolnner SerranoNo ratings yet

- EnedelDocument57 pagesEnedelmohammed ahmedNo ratings yet

- Activity 2 Passive Filter Circuits and Frequency ResponseDocument8 pagesActivity 2 Passive Filter Circuits and Frequency ResponsewinteruptoautumnNo ratings yet

- OCL Power Amplifier 50watt - Electronic CircuitDocument1 pageOCL Power Amplifier 50watt - Electronic CircuitJosue Rafael BorjasNo ratings yet

- Troubleshooting For UV Detector of HPLCDocument3 pagesTroubleshooting For UV Detector of HPLCMubarak PatelNo ratings yet

- 15EC73Document307 pages15EC73KN DEEPSHINo ratings yet

- Notice Board Report 1Document2 pagesNotice Board Report 1goutham pNo ratings yet

- 2 6 SAT C1574 SAT Procedure PDFDocument7 pages2 6 SAT C1574 SAT Procedure PDFGooi Ming YanNo ratings yet

- Air Conditioner: Parts ListDocument4 pagesAir Conditioner: Parts ListDavid Lemos SanchezNo ratings yet