Professional Documents

Culture Documents

Technical News: Questions and Answers Domestic USA Reel Design and Application

Uploaded by

parallax1957Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical News: Questions and Answers Domestic USA Reel Design and Application

Uploaded by

parallax1957Copyright:

Available Formats

g

TECHNICAL NEWS Engineertinion

Informa

from

for the ional

THE OKONITE COMPANY

Profess r

April, 2002 Edition: 012 Enginee

Questions and Answers

Domestic USA Reel Design and Application

Question: Where do I find standard reel sizes and protective coverings?

Answer: NEMA WC 26 / EEMAC 201 the BINATIONAL WIRE AND CABLE PACKAGING

STANDARD contains reels and packaging for use in the United States and Canada.

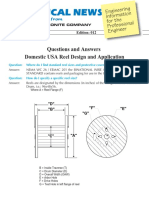

Question: How do I specify a specific reel size?

Answer: Reels are designated by the dimensions (in inches) of the Flange x Inside Traverse x

Drum, i.e.: 96x48x56.

Where A = Reel Flange (F)

"D"

"B" "F" "E"

"G"

"C" "A"

B = Inside Traverse (T)

C = Drum Diameter (D)

D = Overall Width (OAW)

E = Arbor Hole

F = Drive Holes

G = Test Hole in left flange of reel

Question: How do I specify the maximum reel width that will fit my reel truck?

Answer: The designation OAW is used to indicate the maximum desired overall reel width,

i.e.: OAW 63.

Question: How do I specify the maximum reel flange diameter that will fit my reel truck?

Answer: The designation OAF is used to indicate the maximum desired overall flange, i.e.:

OAF 96. In addition, a statement addressing the gross weight handling capability of

the installers equipment or the gross weight associated with local construction per-

mits will effect the reel size and length.

Question: What is a reusable wood reel?

Answer: A Class 1 (Standard duty) or Class 2 (Heavy duty) wood reel returned to the reel manu-

facturer for refurbishing as new is recognized as a reusable wood reel. The high cost

experienced by the end user for disposing of wood reels previously recognized as

nonreturnable led to the establishment of the reusable reel program. Where an end

user has a sufficient quantity of reels to make it economically profitable for a reel man-

ufacturer to pick up the reels, they will be picked up at the users end point without

cost. The reels upon refurbishing to the level of new reels are then sold back to cable

manufacturers at the price of new reels.

Question: What information is stenciled on the reel flange?

Answer: A wood reel has the following information stenciled on each flange.

1. The name of the cable supplier.

2. The class of the reel.

3. A reel rolling direction arrow.

4. The reel dimensions as Flange X Inside Traverse X Drum

5. The identification of the reel manufacturer.

6. The date that the reel was assembled by the reel manufacturer.

On reels with flanges less than 40 inches, Only items 4, 5, and 6 are normally sup-

plied.

Question: Are reels shipped with cable protruding through the test hole?

Answer: This is not standard practice. Users must specify the requirement to field test cables

on the shipping reel.

Question: What safeguards should be taken in handling and storing reels?

Answer: Reels should not be handled in any way that would result in damage to the cable or to

the reel.

• The preferred method to lift the reel is to use an arbor shaft and slings.

• Fork lift trucks having adequate capacity can lift the reels from the side flange avoid-

ing damage to the reel covering.

• Hooks or forks are not to be applied to the cable to lift the reel.

• Reel should not be dropped from any height.

• Reels should only be rolled in a direction to tighten the cable wind. Surfaces on

which reels are to be rolled should be flat, clear of debris and protrusions which

could damage the cable if straddled by the reel flange.

• Reels should be stored with both flanges on solid, hard surfaces and in a manner to

prevent damage to the reel or cable.

• Reels should not be stored near or come in contact with chemical spills, oils, or

other harmful materials injurious to the cable or reel.

• Loose bolts should be tightened before handling a wood reel.

• Factory applied reel coverings should remain in place until removal is necessary for

cable installation.

• Laying reels on their side and picking the reels up by a toggle bolt device inserted

into the arbor hole (E) is not recommended.

Question: What type of reel wrap is normally used?

Answer: Reel wrap is determined by the type of cable to be protected and the type of shipping

and storage the cable will be subjected to.

Normal reel wraps are:

• Solid Film Fiberboard laminate also known as NEMA WC 26, Class 2, Protector.

• Solid Fiberboard also known as NEMA WC 26, Class 3, Heavy Duty.

• Wood Lagging or a Double Wrap of Solid Fiberboard also known as NEMA WC 26,

Class 4, Extra Heavy Duty.

• Wood Lagging greater than 2 inches in thickness known as NEMA WC 26, Class 5,

Export (not containerized).

Question: What are the most common reusable reels?

Answer: In 1999, the Okonite Company purchased over 85,000 wood and plywood reels and

spools of which more than 76,000 were in the reusable wood reel category. The

greatest number of reusable reels were sized as follows:

F T D Class OAW Arbor Weight

38 18 10 2 22.5” 3” 68 lbs.

54 32 26 1 37” 3” 164 lbs.

58 32 28 1 3” 3” 187 lbs.

30 18 12 2 21.5” 3” 39 lbs.

42 24 17 1 28” 3” 80 lbs.

Cable manufacturers literature can be referenced for reel footage capacities.

Question: How is a reel size selected for shipment?

Answer: 1. The cable’s construction and overall diameter set the minimum drum

dimension, “C”, meeting the cable’s bending characteristics. NEMA WC26

establishes the minimum drum diameters for various cable categories.

2. The length requested is checked against the nearest standard reel size. Each cable man-

ufacturer has standardize clearances between the last turn of cable and the edge of the

flange.

3. The gross cable weight is checked against the selected reels loading weight.

Question: Are the reels used for overseas cable shipments the same design as domestic reels?

Answer: Yes. The overall reel wrap can be more substantial, the inside cable end is not

shipped protruding from the test hole and the wood may be treated to suit specific

country requirements. The inside cable end can be made accessible using special de-

signed reels.

Frank H. Rocchio

You might also like

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Technical News: Questions and Answers Domestic USA Reel Design and ApplicationDocument3 pagesTechnical News: Questions and Answers Domestic USA Reel Design and ApplicationFelipe GustavoNo ratings yet

- Alco Cable Gland Tutorial - V3 0Document26 pagesAlco Cable Gland Tutorial - V3 0ykresna1631No ratings yet

- Cable Solutions Amercable GexolDocument36 pagesCable Solutions Amercable GexolMadel D.No ratings yet

- Faculty of Engineering Petroleum Engineering Department: Drilling Engineering II Fourth StageDocument23 pagesFaculty of Engineering Petroleum Engineering Department: Drilling Engineering II Fourth StageSarbast TaqanaNo ratings yet

- Introducing Pulleys Into Cable SystemsDocument4 pagesIntroducing Pulleys Into Cable SystemsYudi SusantoNo ratings yet

- Type of GlandDocument10 pagesType of GlandShrikant KajaleNo ratings yet

- Development of Elevator Ropes: Tech Tip 15Document2 pagesDevelopment of Elevator Ropes: Tech Tip 15أحمد دعبسNo ratings yet

- Gexol PDFDocument36 pagesGexol PDFJNo ratings yet

- Gexol PDFDocument36 pagesGexol PDFLimuel EspirituNo ratings yet

- Offshore Cables Catalogue Nexans AmerCable GexolDocument36 pagesOffshore Cables Catalogue Nexans AmerCable GexolEduardo RateikeNo ratings yet

- Gland SelectionDocument8 pagesGland SelectionJignesh ParmarNo ratings yet

- Carc Buildathon Project: A Tuneable Magnetic Loop Antenna For 7Mhz Made From Coaxial CableDocument9 pagesCarc Buildathon Project: A Tuneable Magnetic Loop Antenna For 7Mhz Made From Coaxial CableLuca Di ColaNo ratings yet

- TCB Brochure 2018Document12 pagesTCB Brochure 2018Jorge PenichéNo ratings yet

- Installation of Electric CablesDocument14 pagesInstallation of Electric Cablesmn090078dNo ratings yet

- Indus Institute of Technology & EngineeringDocument31 pagesIndus Institute of Technology & Engineeringkeval patelNo ratings yet

- Wire Rope CriteriaDocument7 pagesWire Rope CriteriaAnkit VyasNo ratings yet

- Manual For EOT CranesDocument39 pagesManual For EOT CranesManish Jha67% (12)

- 2178CL-S Series F/O Splice Case: InstructionDocument13 pages2178CL-S Series F/O Splice Case: InstructionHữu Khánh NguyễnNo ratings yet

- Gexol: World Class Type P Land & Offshore Oil & Gas CablesDocument32 pagesGexol: World Class Type P Land & Offshore Oil & Gas CablesMarcela SuarezNo ratings yet

- Terminator II TMCX PDFDocument2 pagesTerminator II TMCX PDFAldi NasohaNo ratings yet

- BARRAMENTO FLEXIVEL DA RITTAL Rittal White Paper The Flexible Busbar AdvantageDocument10 pagesBARRAMENTO FLEXIVEL DA RITTAL Rittal White Paper The Flexible Busbar AdvantagedarkfacemooNo ratings yet

- HVS-LR Repair Kit For PILC/VCLC Cable Sheaths or Lead SplicesDocument8 pagesHVS-LR Repair Kit For PILC/VCLC Cable Sheaths or Lead SplicesAbdul Muneeb MohammedNo ratings yet

- Flat Cables Ribbon Cables: Works Photo: HELUKABELDocument10 pagesFlat Cables Ribbon Cables: Works Photo: HELUKABELOzanNo ratings yet

- Wire Rope GuideDocument28 pagesWire Rope Guideajz677100% (1)

- Raci Brochure 2019 03 Single PagesDocument16 pagesRaci Brochure 2019 03 Single PagesIrina CretuNo ratings yet

- Notes 1Document20 pagesNotes 1Ruben ChirinosNo ratings yet

- Nuts and Bolts: DescriptionDocument9 pagesNuts and Bolts: Descriptionvignesh varmaNo ratings yet

- Securing Straps & RatchetsDocument2 pagesSecuring Straps & RatchetsKhurram S. MuzammilNo ratings yet

- Timco Sheave DesignDocument10 pagesTimco Sheave DesignAyman SaadNo ratings yet

- Gexol PDFDocument36 pagesGexol PDFclaudiogut123No ratings yet

- Cable Carrier CatalougeDocument146 pagesCable Carrier Catalougebachir diengNo ratings yet

- VFD Cable Termination GuideDocument12 pagesVFD Cable Termination Guidemehdi227100% (1)

- ITS Installation & Civil Specification & Guidelines-05Document14 pagesITS Installation & Civil Specification & Guidelines-05N V Sumanth VallabhaneniNo ratings yet

- CN Maintenance Practices IIDocument10 pagesCN Maintenance Practices IIavijayakumar_1964No ratings yet

- Cer Alum Ladder Tray CatalogDocument37 pagesCer Alum Ladder Tray Catalogmashan98No ratings yet

- HB RopeDocument104 pagesHB Ropemuhammad-ahmed-salman-2537No ratings yet

- Recoil Screw Thread InsertsDocument61 pagesRecoil Screw Thread InsertsAce Industrial SuppliesNo ratings yet

- Gexol PDFDocument36 pagesGexol PDFLimuel EspirituNo ratings yet

- Threads and Thread CuttingDocument56 pagesThreads and Thread Cuttingjaydip2410chhatrala100% (1)

- Stewmac Schatten Pickup Winder-2105 PDFDocument6 pagesStewmac Schatten Pickup Winder-2105 PDFKakikoNo ratings yet

- Endurance of Compacted Steel Wire Ropes: ObjectivesDocument7 pagesEndurance of Compacted Steel Wire Ropes: ObjectivesYadi KusmayadiNo ratings yet

- Cable Splicing Procedure 005Document6 pagesCable Splicing Procedure 005RenzNo ratings yet

- PT 1LEEA Training Slide ShowDocument34 pagesPT 1LEEA Training Slide ShowMohmed AllamNo ratings yet

- Socketing Procedures For Wire Ropes Resin Socketing: Technical Report Iso/Tr 7596-1982 (E)Document6 pagesSocketing Procedures For Wire Ropes Resin Socketing: Technical Report Iso/Tr 7596-1982 (E)Jason RobertsNo ratings yet

- Technical Specification For 33 KV Aerial Bunched Cable - 2Document7 pagesTechnical Specification For 33 KV Aerial Bunched Cable - 2BijuNo ratings yet

- Developments in Steel CablesDocument27 pagesDevelopments in Steel CablesxforceNo ratings yet

- Ancon Tapered Thread Couplers International VersionDocument16 pagesAncon Tapered Thread Couplers International VersionRanjan SinghNo ratings yet

- Duct Installation of Fiber Optic Cable PDFDocument9 pagesDuct Installation of Fiber Optic Cable PDFnecmettinsengunNo ratings yet

- Bis CodesDocument65 pagesBis CodesPreksha NahataNo ratings yet

- Cat-CMP Cable GlandDocument64 pagesCat-CMP Cable GlandSyahirul Alim100% (1)

- Forag 3Document25 pagesForag 3Soufiane Frahtia30100% (1)

- Basic Cable&Cable CareDocument45 pagesBasic Cable&Cable CarePrakhar Sarkar100% (1)

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Knots You Need to Know: Easy-to-Follow Guide to the 30 Most Useful KnotsFrom EverandKnots You Need to Know: Easy-to-Follow Guide to the 30 Most Useful KnotsNo ratings yet

- ApprovedMeterSocket 01-19-2018r.polkDocument9 pagesApprovedMeterSocket 01-19-2018r.polkparallax1957No ratings yet

- Sanet Me0803120575Document169 pagesSanet Me0803120575parallax1957No ratings yet

- Jamaica Electricity Book of Codes.2016Document437 pagesJamaica Electricity Book of Codes.2016parallax1957No ratings yet

- Tax Deductions For ProfessionalsDocument109 pagesTax Deductions For Professionalsparallax1957No ratings yet

- Newfoundland Power Service and Metering Guide: Date Rev. DescriptionDocument53 pagesNewfoundland Power Service and Metering Guide: Date Rev. Descriptionparallax1957No ratings yet

- TH3Document59 pagesTH3parallax1957No ratings yet

- Ontario Regulation 278/05 Designated Substance - Asbestos On Construction Projects and in Buildings and Repair OperationsDocument19 pagesOntario Regulation 278/05 Designated Substance - Asbestos On Construction Projects and in Buildings and Repair Operationsparallax1957No ratings yet

- Ontario Regulation 385/96 Joint Health and Safety Committees - Exemption From RequirementsDocument1 pageOntario Regulation 385/96 Joint Health and Safety Committees - Exemption From Requirementsparallax1957No ratings yet

- Wind Power BookDocument245 pagesWind Power Bookparallax1957No ratings yet

- Electric Power Wheeling and DealingDocument268 pagesElectric Power Wheeling and Dealingparallax1957No ratings yet

- Technical News: Power Cables - Conductor DesignDocument2 pagesTechnical News: Power Cables - Conductor Designparallax1957No ratings yet

- IEEETransPaperJan1996Neher McGrathDocument20 pagesIEEETransPaperJan1996Neher McGrathparallax1957No ratings yet

- The Calculation or The Temperature Rise - Aiee 57-660.10.1.1.460.2093Document13 pagesThe Calculation or The Temperature Rise - Aiee 57-660.10.1.1.460.2093parallax1957No ratings yet

- Horse Reel ProjectDocument23 pagesHorse Reel ProjectpatrickNo ratings yet

- Byasghat and Brigadier ChakrabortyDocument9 pagesByasghat and Brigadier ChakrabortySubroto MukerjiNo ratings yet

- SPORTEX Catalogue 2008Document36 pagesSPORTEX Catalogue 2008Nora SüslüNo ratings yet

- SEA JET Reel Brochure - Submersible Movable Pump With Hose SupportDocument4 pagesSEA JET Reel Brochure - Submersible Movable Pump With Hose SupportMohamed MostafaNo ratings yet

- DM Guide To FishingDocument9 pagesDM Guide To Fishing678ojyhiop100% (1)

- Instrukciq Mashina Za Vryzvane Na Armatura Makita Dtr181rte Bez Cena 19637Document22 pagesInstrukciq Mashina Za Vryzvane Na Armatura Makita Dtr181rte Bez Cena 19637GregoryNo ratings yet

- 2010 Ross CatalogDocument32 pages2010 Ross CatalogmedphotoNo ratings yet

- LJ CatalogueDocument28 pagesLJ CatalogueLuis MuñozNo ratings yet

- Coiled Tubing ReelsDocument1 pageCoiled Tubing ReelsJose Leonardo Materano PerozoNo ratings yet

- Manual Nagra 4.2Document64 pagesManual Nagra 4.2manuelpgNo ratings yet

- TV I Air BalancerDocument4 pagesTV I Air Balancerandri putrantoNo ratings yet

- Indian Standard: Legal Metrology - Material Measures of LengthDocument9 pagesIndian Standard: Legal Metrology - Material Measures of LengthDiptiNo ratings yet

- Solas V Safety of Navigation Regulation 23 Pilot LaddersDocument12 pagesSolas V Safety of Navigation Regulation 23 Pilot LaddersdhaneshbhorNo ratings yet

- Cablejet Brochure CMP PDFDocument10 pagesCablejet Brochure CMP PDFnecmettinsengunNo ratings yet

- Instruction Manual: MIG210SDocument20 pagesInstruction Manual: MIG210SMani ShankerNo ratings yet

- The Falcon, From Stolt Comex Seaway To GSP - Multi-LayDocument6 pagesThe Falcon, From Stolt Comex Seaway To GSP - Multi-LayDak KaizNo ratings yet

- E-1205942 - 03-04 Reductor 49 PDFDocument46 pagesE-1205942 - 03-04 Reductor 49 PDFWilfredo Loyo0% (1)

- SBM 1250 Double Twist Bunching LineDocument12 pagesSBM 1250 Double Twist Bunching LineEMRE KAAN USTANo ratings yet

- Beginner Guide To SW FishingDocument60 pagesBeginner Guide To SW FishingJean-Mikaël TilinNo ratings yet

- Rods, Reels, Line - Scenario Guide PDFDocument5 pagesRods, Reels, Line - Scenario Guide PDFCătă SicoeNo ratings yet

- 1 A Varco Company: Part Number TW606Document27 pages1 A Varco Company: Part Number TW606Luis AlbarracinNo ratings yet

- Fuji CatalogDocument64 pagesFuji CatalogAitor UgidosNo ratings yet

- Technical Specification For Coiled Tubing Unit Model Lgt450Document11 pagesTechnical Specification For Coiled Tubing Unit Model Lgt450juancieNo ratings yet

- Ultra-Light Spinning: The Origins ofDocument8 pagesUltra-Light Spinning: The Origins ofMuhammad AsadiNo ratings yet

- Meia Rab (14-3-2022)Document542 pagesMeia Rab (14-3-2022)Arif BinorikaNo ratings yet

- Walker1 PDFDocument2 pagesWalker1 PDFDian SikumbangNo ratings yet

- Wire Rope Gen InfoDocument5 pagesWire Rope Gen InfobugseNo ratings yet