Professional Documents

Culture Documents

Technical News: Power Cables - Conductor Design

Uploaded by

parallax19570 ratings0% found this document useful (0 votes)

19 views2 pages1) Compact round conductors are a variation of concentric round conductors that are designed more efficiently by removing air spaces between wires to reduce the overall diameter up to 10%.

2) Compared to standard concentric round conductors, compact round conductors can reduce the diameter by 3-10% while still meeting resistance and weight requirements for the conductor size.

3) During installation, cable accessories like splices and terminations must be selected based on the conductor diameter, whether it is standard concentric, compressed, or compact round.

Original Description:

Original Title

Tech 14.Design

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1) Compact round conductors are a variation of concentric round conductors that are designed more efficiently by removing air spaces between wires to reduce the overall diameter up to 10%.

2) Compared to standard concentric round conductors, compact round conductors can reduce the diameter by 3-10% while still meeting resistance and weight requirements for the conductor size.

3) During installation, cable accessories like splices and terminations must be selected based on the conductor diameter, whether it is standard concentric, compressed, or compact round.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

19 views2 pagesTechnical News: Power Cables - Conductor Design

Uploaded by

parallax19571) Compact round conductors are a variation of concentric round conductors that are designed more efficiently by removing air spaces between wires to reduce the overall diameter up to 10%.

2) Compared to standard concentric round conductors, compact round conductors can reduce the diameter by 3-10% while still meeting resistance and weight requirements for the conductor size.

3) During installation, cable accessories like splices and terminations must be selected based on the conductor diameter, whether it is standard concentric, compressed, or compact round.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

g

TECHNICAL NEWS Engineertinion

Informa

from

for the ional

THE OKONITE COMPANY

Profess r

January 31, 2003 Edition: 0014 Enginee

Power Cables - Conductor Design

Power cable sizes are generally defined as #8 AWG and larger. Today, the design of these con-

ductors, industry wide, is likely to be compact round. What is compact round?

Compact round is a variation of the basic concentric round conductor. Concentric conductors

are made up of identical wire diameters. The configuration follows a pattern of twisting six (6)

wires around a straight center wire. Additional wire layers are added in multiples of six (6) to

provide the necessary cross sectional area. The wire lay up pattern is concentric layers of alter-

nate clockwise and counter clockwise twisting.

7 wire = 1 + 6 , 7X

19 wire = 1 + 6 + 12 , 19X

37 wire = 1 + 6 + 12 + 18 , 37X

61 wire = 1 + 6 + 12 + 18 + 24 , 61X

The individual wire diameter follows the industry convention of defining the wire area in circu-

lar mils. A circular mil equals the area of a circle 1 mil in diameter.

A = (n)x(d)2

A = circular mils

n = number of wires

d = wire diameter in mils

The concentric round conductor can be designed more efficiently by removing the air spaces in

the wire lay up. If the concentric diameter can be reduced by 3%, the conductor has been com-

pressed. If the concentric diameter can be reduced up to 10%, the shape is now compact round.

Shown below is a sketch illustrating this comparison. The ASTM standards for electrical con-

ductors permit the individual strands to be shaped for a more efficient reduction in diameter.

The chart below compares the diameter of the popular sizes of conductors. More complex de-

signs for compact round conductors can be referenced to ASTM standards for wire sizes, indi-

vidual shapes and twisting methods.

Diameter, mils

Kcmil Concentric Compressed Compact

4/0, 19X 528 512 475

350, 37X 661 661 616

500, 37X 813 789 736

750, 61X 998 968 908

For any of the above designs, the manufactured conductor must meet the required resistance

and metal weight for the size selected. For instance, a 500 kcmil design must yield a resistance

of 0.021 ohms/1000’ at 25C and a weight of 1544 pounds per 1000’. The only change from

concentric to compressed to compact is the overall diameter.

During installation, the usual cable accessories, splices and terminations, must be selected

based on diameter.

Standard ASTM copper concentric references are:

B3 - Individual Wire Characteristics

B8 - Concentric/Compressed Conductors

B496- Compact Round Strand

Reference Okonite’s web site, www.okonite.com, select the “Engineering Technical Center”

for detailed conductor characteristics; dimensions, weights and resistances.

J. V. Fitzgerald

V.P. Application Engineering

You might also like

- Tech 21Document2 pagesTech 21Felipe GustavoNo ratings yet

- The Use of Insulated Wires Milliken Conductors in High Voltage Power Transmission Underground Ac LinesDocument6 pagesThe Use of Insulated Wires Milliken Conductors in High Voltage Power Transmission Underground Ac Linessaghaee.rezaNo ratings yet

- Milliken Conductors in HV CablesDocument6 pagesMilliken Conductors in HV CablesYahya AlzarooniNo ratings yet

- Power Transformer Design, Manufacturing and TestingDocument19 pagesPower Transformer Design, Manufacturing and TestingAbd ALRahmanNo ratings yet

- En - How Planar Magnetics Improve Performance in Power ElectronicsDocument20 pagesEn - How Planar Magnetics Improve Performance in Power ElectronicsMuhammad Qasim RaufNo ratings yet

- Bend Radius For CableDocument6 pagesBend Radius For CableTamjid KabirNo ratings yet

- B 172 - 01 - Qje3mi1sruqDocument5 pagesB 172 - 01 - Qje3mi1sruqCarlos LiceaNo ratings yet

- Distribution Transformers: Your Partner in Energy SolutionsDocument32 pagesDistribution Transformers: Your Partner in Energy SolutionsBoussaid SouheilNo ratings yet

- 194 - EE6604 Design of Electrical Machines - Important QuestionsDocument28 pages194 - EE6604 Design of Electrical Machines - Important QuestionsNiteshNarukaNo ratings yet

- Advance Connection Design - 1Document298 pagesAdvance Connection Design - 1amitkumar8946No ratings yet

- Imc 12p GuideDocument12 pagesImc 12p GuideWaleed Mohammed FekryNo ratings yet

- NAM Cat CombinedCh1Document16 pagesNAM Cat CombinedCh1Thanh Do VanNo ratings yet

- Conductores ACAR PD Wire & CableDocument7 pagesConductores ACAR PD Wire & Cablesb_al20No ratings yet

- PPC Catálogo Aislador Soporte ANSIDocument28 pagesPPC Catálogo Aislador Soporte ANSIMateo AlvezNo ratings yet

- Introduction To Common Printed Circuit Transmission Lines: Guiding The WaveDocument6 pagesIntroduction To Common Printed Circuit Transmission Lines: Guiding The WaveHabib Ur RehmanNo ratings yet

- Sec09 - Wire and CableDocument17 pagesSec09 - Wire and CableYusufNo ratings yet

- ESP Replacement Parts: Wet & Dry: Air Pollution Control Systems: Parts and Service GuideDocument22 pagesESP Replacement Parts: Wet & Dry: Air Pollution Control Systems: Parts and Service GuideAmogh AbhyankarNo ratings yet

- WTEC 35KV MV Cable LLDPE Rev S 20160226Document5 pagesWTEC 35KV MV Cable LLDPE Rev S 20160226carloNo ratings yet

- Mogul Unilet Conduit Outlet Bodies: NEC 6x8x Series (C, LB and UB) and Types LL, LR and TDocument8 pagesMogul Unilet Conduit Outlet Bodies: NEC 6x8x Series (C, LB and UB) and Types LL, LR and TMiguel angel leon bautistaNo ratings yet

- Irjet V5i5220Document4 pagesIrjet V5i5220afaq AhmadNo ratings yet

- How To Determine Bending RadiusDocument7 pagesHow To Determine Bending RadiusariefNo ratings yet

- An 916Document10 pagesAn 916Socheat SonNo ratings yet

- Project Report On Abc CableDocument8 pagesProject Report On Abc CableEIRI Board of Consultants and PublishersNo ratings yet

- Carlite: Grain Oriented Electrical SteelsDocument27 pagesCarlite: Grain Oriented Electrical SteelsRichard SyNo ratings yet

- Sec07 - RacewaysDocument10 pagesSec07 - RacewaysYusufNo ratings yet

- Question Bank: Dayananda Sagar College of EngineeringDocument15 pagesQuestion Bank: Dayananda Sagar College of EngineeringshashikumarNo ratings yet

- Iv RepotDocument16 pagesIv Repotneethurj9No ratings yet

- Accouplement MecDocument19 pagesAccouplement MecAli Ben Belgacem MahroukNo ratings yet

- Transformer DesignDocument27 pagesTransformer DesignNitesh BharadwajNo ratings yet

- Fabrication and Test Results of A Prototype, NB SN Superconducting Racetrack Dipole MagnetDocument5 pagesFabrication and Test Results of A Prototype, NB SN Superconducting Racetrack Dipole MagnetLei WuNo ratings yet

- General Brochure ConductorsDocument12 pagesGeneral Brochure ConductorsAhmed Bilal KhanNo ratings yet

- Cable Accessories: Systems, IncDocument4 pagesCable Accessories: Systems, IncLuis MurilloNo ratings yet

- Esternila D. Gadugdug Bsee 3 Assignment: Elctrical Machines-2 5/19/2022Document2 pagesEsternila D. Gadugdug Bsee 3 Assignment: Elctrical Machines-2 5/19/2022Kyle Christian CeprezNo ratings yet

- NEXANS ACSR BareOverheadDocument9 pagesNEXANS ACSR BareOverheadJohn FonsecaNo ratings yet

- Macalloy Cable Systems - Macalloy SC460, Macalloy GL Architectural Cable System and Macalloy GL Standard SystemDocument8 pagesMacalloy Cable Systems - Macalloy SC460, Macalloy GL Architectural Cable System and Macalloy GL Standard SystemJuan Garcia ArevalilloNo ratings yet

- Design Guide Pt2 RoofsDocument20 pagesDesign Guide Pt2 RoofsEdward Millward50% (2)

- Natsteel MeshDocument9 pagesNatsteel MeshShumei ZhouNo ratings yet

- B496Document3 pagesB496rohit kumarNo ratings yet

- CATCTCESSEXITALYed 3 Rev 1Document38 pagesCATCTCESSEXITALYed 3 Rev 1Kailash ChandraNo ratings yet

- Sheet 1Document38 pagesSheet 1kaushiki bhadauriaNo ratings yet

- Catálogo Burndy ConectoresDocument129 pagesCatálogo Burndy ConectoresJoséNo ratings yet

- Performance Comparisons of Radial and Axial Field Permanent Magnet Brushless MachineDocument8 pagesPerformance Comparisons of Radial and Axial Field Permanent Magnet Brushless Machinerakeshee2007No ratings yet

- 3 KTA DesignguideDocument32 pages3 KTA Designguideodin_auerNo ratings yet

- Producing Wound ComponentsDocument12 pagesProducing Wound ComponentsIloilo Coolest100% (1)

- Linear Actuator Re GenerationDocument6 pagesLinear Actuator Re GenerationEr Chetan BachhavNo ratings yet

- Magnetics Ferrite Power Design 2013Document9 pagesMagnetics Ferrite Power Design 2013brihamNo ratings yet

- Design Analysis and Fabrication of Hydra PDFDocument9 pagesDesign Analysis and Fabrication of Hydra PDFMac NyandoroNo ratings yet

- BARRAMENTO FLEXIVEL DA RITTAL Rittal White Paper The Flexible Busbar AdvantageDocument10 pagesBARRAMENTO FLEXIVEL DA RITTAL Rittal White Paper The Flexible Busbar AdvantagedarkfacemooNo ratings yet

- Adea Company BroucherDocument15 pagesAdea Company BroucherVelu SamyNo ratings yet

- Carlite: ® Grain Oriented Electrical SteelsDocument41 pagesCarlite: ® Grain Oriented Electrical SteelsVelkinPorllesNo ratings yet

- Caledonian: Caledonian ACSR Cables Aluminum Conductor Steel Reinforced (ACSR) CablesDocument2 pagesCaledonian: Caledonian ACSR Cables Aluminum Conductor Steel Reinforced (ACSR) Cablesrose chenNo ratings yet

- Ak Carlite Lite 042413Document46 pagesAk Carlite Lite 042413ecaph244No ratings yet

- 015 ASP CatalogueDocument24 pages015 ASP CatalogueJavan Omiti100% (1)

- Development of Axial Flux HTS Induction Motors: International Meeting of Electrical Engineering Research ENIINVIE-2012Document10 pagesDevelopment of Axial Flux HTS Induction Motors: International Meeting of Electrical Engineering Research ENIINVIE-2012Nilton Ramos EstebanNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Small Dynamos and How to Make Them - Practical Instruction on Building a Variety of Machines Including Electric MotorsFrom EverandSmall Dynamos and How to Make Them - Practical Instruction on Building a Variety of Machines Including Electric MotorsNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Sanet Me0803120575Document169 pagesSanet Me0803120575parallax1957No ratings yet

- ApprovedMeterSocket 01-19-2018r.polkDocument9 pagesApprovedMeterSocket 01-19-2018r.polkparallax1957No ratings yet

- TH3Document59 pagesTH3parallax1957No ratings yet

- Newfoundland Power Service and Metering Guide: Date Rev. DescriptionDocument53 pagesNewfoundland Power Service and Metering Guide: Date Rev. Descriptionparallax1957No ratings yet

- Tax Deductions For ProfessionalsDocument109 pagesTax Deductions For Professionalsparallax1957No ratings yet

- Jamaica Electricity Book of Codes.2016Document437 pagesJamaica Electricity Book of Codes.2016parallax1957No ratings yet

- Electric Power Wheeling and DealingDocument268 pagesElectric Power Wheeling and Dealingparallax1957No ratings yet

- Ontario Regulation 278/05 Designated Substance - Asbestos On Construction Projects and in Buildings and Repair OperationsDocument19 pagesOntario Regulation 278/05 Designated Substance - Asbestos On Construction Projects and in Buildings and Repair Operationsparallax1957No ratings yet

- Ontario Regulation 385/96 Joint Health and Safety Committees - Exemption From RequirementsDocument1 pageOntario Regulation 385/96 Joint Health and Safety Committees - Exemption From Requirementsparallax1957No ratings yet

- Wind Power BookDocument245 pagesWind Power Bookparallax1957No ratings yet

- Technical News: Questions and Answers Domestic USA Reel Design and ApplicationDocument3 pagesTechnical News: Questions and Answers Domestic USA Reel Design and Applicationparallax1957No ratings yet

- IEEETransPaperJan1996Neher McGrathDocument20 pagesIEEETransPaperJan1996Neher McGrathparallax1957No ratings yet

- The Calculation or The Temperature Rise - Aiee 57-660.10.1.1.460.2093Document13 pagesThe Calculation or The Temperature Rise - Aiee 57-660.10.1.1.460.2093parallax1957No ratings yet

- EEE301Sen Electromechanical Energy ConversionDocument35 pagesEEE301Sen Electromechanical Energy ConversionDilekNo ratings yet

- The Philco Restorer: Click Below To See What I Have To SayDocument26 pagesThe Philco Restorer: Click Below To See What I Have To SayRafael G. Garcia SanchezNo ratings yet

- C&D 2-200LBT: Valve Regulated Lead Acid BatteryDocument2 pagesC&D 2-200LBT: Valve Regulated Lead Acid BatteryRifky ZuliansyahNo ratings yet

- 950F Wheel Loader Electrical System: Vehicle Harness Connector and Component LocationsDocument2 pages950F Wheel Loader Electrical System: Vehicle Harness Connector and Component LocationsBrahian Mijael Garrado Gonzales100% (1)

- MA TER DR Rev.1Document13 pagesMA TER DR Rev.1AbdulSattarNo ratings yet

- DTC P0182, P0183 FTT SENSOR Component DescriptionDocument4 pagesDTC P0182, P0183 FTT SENSOR Component DescriptionWillie AustineNo ratings yet

- Philips TV CH A02e Aa Service ManualDocument82 pagesPhilips TV CH A02e Aa Service ManualAnonymous YWmB9HDgNo ratings yet

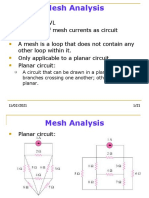

- Mesh AnalysisDocument28 pagesMesh Analysisarlox_arloxNo ratings yet

- PASS For Wind Farm ApplicationDocument23 pagesPASS For Wind Farm ApplicationMr.SonerNo ratings yet

- X 019 Current Carrying Capacity and Indications For Calculat PDFDocument19 pagesX 019 Current Carrying Capacity and Indications For Calculat PDFLucas Vinícius CostaNo ratings yet

- Tesla PumpsDocument132 pagesTesla PumpsTanaka Masocha100% (1)

- Edoc - Pub - Oled Led TV Repair TipsDocument91 pagesEdoc - Pub - Oled Led TV Repair TipsRuth Charmae Omid BalawagNo ratings yet

- Servopack DR2 YaskawaDocument513 pagesServopack DR2 YaskawaAlejandro Gálvez Cubías100% (1)

- Transformers KuestionDocument13 pagesTransformers KuestionAnonymous RwJdmJ100% (1)

- CONVERTERSDocument32 pagesCONVERTERSMichael CampbellNo ratings yet

- 2507 Spec SheetDocument22 pages2507 Spec SheetzhangjieNo ratings yet

- NivoPress DataSheet 2Document4 pagesNivoPress DataSheet 2Svetlana GabricNo ratings yet

- j201, j202, j203, sst201, sst202, sst204 VishayDocument6 pagesj201, j202, j203, sst201, sst202, sst204 VishayАлексей ГомоновNo ratings yet

- Sony EF29M31Document8 pagesSony EF29M31Rodolfo ArosemenaNo ratings yet

- BN TACH100 Standalone Digital Tachometer Datasheet 176063Document9 pagesBN TACH100 Standalone Digital Tachometer Datasheet 176063Yasmine SalehNo ratings yet

- Samsung Gd17as Gd17n Gd17aDocument64 pagesSamsung Gd17as Gd17n Gd17aluis francisco heras parragaNo ratings yet

- Mmuh Slides s04Document10 pagesMmuh Slides s04Murali GowdaNo ratings yet

- CV Zeeshan RehmanDocument4 pagesCV Zeeshan RehmanStameco EnergyNo ratings yet

- BE 1st Midterm Sep2009Document3 pagesBE 1st Midterm Sep2009YASHNo ratings yet

- Dla 2 ADocument7 pagesDla 2 AHugues ValotNo ratings yet

- United States Patent (10) Patent No.: US 7,928,345 B2Document8 pagesUnited States Patent (10) Patent No.: US 7,928,345 B2alfarisyi27No ratings yet

- 5KV Automatic Surge Comparison Tester With Go/No-Go Test: JabbalsDocument2 pages5KV Automatic Surge Comparison Tester With Go/No-Go Test: JabbalsLingaraj Suresh LingaianNo ratings yet

- BP OBE English Version 2009-2010Document84 pagesBP OBE English Version 2009-2010f2t7No ratings yet

- Women Security Assistance System With GPS Tracking and Messaging SystemDocument4 pagesWomen Security Assistance System With GPS Tracking and Messaging Systemhamed razaNo ratings yet

- OMN-FAC-170 Specification For MV & LV Electrical CableDocument13 pagesOMN-FAC-170 Specification For MV & LV Electrical Cablesumit kumarNo ratings yet