Sublevel Caving

Uploaded by

ANSHUL YADAVTopics covered

- Sublevel Spacing,

- Automation in Mining,

- Mining Case Studies,

- Dilution Control,

- Bibliography,

- Caving Systems,

- Coal Extraction,

- Mechanization,

- Production Rate,

- Ore Recovery

Sublevel Caving

Uploaded by

ANSHUL YADAVTopics covered

- Sublevel Spacing,

- Automation in Mining,

- Mining Case Studies,

- Dilution Control,

- Bibliography,

- Caving Systems,

- Coal Extraction,

- Mechanization,

- Production Rate,

- Ore Recovery

- Introduction: Explains the importance and mechanics of sublevel caving as a mining method.

- Classification: Describes different types of sublevel caving methods such as conventional, hydraulic, and gravity caving.

- Method: Details the procedure and logistical setup involved in sublevel caving, including ore handling and excavation.

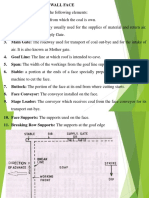

- Mechanism: Discusses the underlying geological mechanisms that facilitate sublevel caving.

- Dimensions: Explains the spatial specifications and engineering considerations of sublevel caving operations.

- Application: Highlights the scenarios and types of ore bodies best suited for sublevel caving.

- Preparation and Development: Covers the preparatory processes required before undertaking sublevel caving, including necessary engineering works.

- Applicability: Lists the conditions and geological factors under which sublevel caving is applicable.

- Advantages: Enumerates the benefits of sublevel caving, focusing on its economic and operational efficiency.

- Disadvantages: Outlines the challenges and limitations associated with sublevel caving.

- Sublevel Caving Being Used: Describes current global practices of sublevel caving and its use in various countries.

- Case Study: Kirunavaara Iron Mine: Presents a case study on how sublevel caving is applied in the Kirunavaara Iron Mine in Sweden.

- Kiruna Mines Method: Outlines the specific procedural steps followed in the Kiruna mining method of sublevel caving.

- Bibliography: Lists references and sources used in the preparation of this document.

Common questions

Powered by AISublevel caving is adaptable to both hard and moderately weak ground conditions because all operations occur in well-supported drift-sized areas, allowing safe and efficient mining . This flexibility means no pillars are left behind, thus preventing loss of ore and reducing recovery challenges . However, while facilitating thorough ore recovery, development work remains extensive and costly due to the need for comprehensive drifting and support .

Subsidence is advantageous in sublevel caving because it allows for continuous caving of the hanging wall, which is essential for ore extraction continuity . However, it poses a disadvantage as it destroys surface conditions, impacting land use and potentially causing environmental concerns . This duality means subsidence can enhance or hinder mining operations, depending on surface land use priorities .

Mechanization transformed sublevel caving from a labor-intensive method to a highly mechanized one, significantly enhancing production efficiency and safety. The adoption of mechanized equipment allowed larger scale operations with greater production rates and reduced the reliance on manual labor, which subsequently lowered accident rates . Innovations such as the use of LHDs and computer-controlled locomotives further reduced human error and increased operational precision, facilitating higher productivity and better worker safety conditions .

Sublevel caving is feasible for ore bodies that are tabular to massive and have a steep dip (>60 degrees) or thick geometry . The rock strength must allow for caving, suggesting weak to fairly strong formations that are fractured or jointed . These conditions influence method selection by favoring sublevel caving in deposits that are extensive vertically or areal, enabling efficient ore extraction while handling the structural mechanisms of the rock .

Modern sublevel caving techniques have mitigated the limitations of traditional mining methods primarily through increased mechanization, which allows for larger scale operations and eliminates the need for labor-intensive processes. This mechanization includes advanced drilling systems and automated transport, such as in the Kiruna mine, which uses computer-controlled locomotives . These advancements enhance worker safety by reducing exposure to hazardous conditions and lower accident rates through automation and mechanical support systems. Additionally, mechanization supports high-volume, continuous production processes, optimizing mining efficiency .

To optimize productivity in a mine using sublevel caving, technological advances such as employing three-boom drilling jumbos for efficient hole drilling, utilizing ANFO explosives with the Nonel system for effective blasting, and integrating LHDs with computer-controlled operations for material handling could be implemented, as demonstrated in the Kiruna mine . Automation, such as driverless locomotives for ore transport, would further enhance efficiency by ensuring continuous, precise, and safer operations .

Sublevel caving is less suitable in the United States largely due to geological differences; ore deposits in the US are not as conducive to this method as they are in countries like Sweden, Canada, and Australia. These countries have more deposits with steep dips and suitable thicknesses for which sublevel caving is ideal . Moreover, historical development and mechanization levels have also contributed to this disparity .

Conventional sublevel caving involves the cyclic technology of drilling and blasting to fragment the ore, accompanied by mechanized transportation . In contrast, hydraulic sublevel caving uses water as a medium both to fragment and transport the ore, making it particularly suited for the extraction of pitching coal seams .

Early mechanized sublevel caving had sublevel spacing as close as 30 ft (9 m) and cross-cuts at 20 ft (6 m). However, improved understanding of flow patterns led to current spacings of 94 ft (28.5 m) between sublevels and 82 ft (25 m) between cross-cuts. These adjustments have significantly improved the production tonnage to development tonnage ratio, facilitating better utilization of equipment and enhancing productivity .

Draw control is critical in sublevel caving as it regulates the withdrawal of ore to optimize economic outcomes. Premature cut-offs can lead to poor recovery, while delayed cut-offs increase dilution of the ore, affecting its quality. Therefore, a cut-off grade based on economic viability is typically employed to determine when mucking should cease, thus helping in maximizing recovery and minimizing waste .