Professional Documents

Culture Documents

Techno Economic Viability Study: Name of The Account: Branch: State

Uploaded by

Rajesh BogulOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Techno Economic Viability Study: Name of The Account: Branch: State

Uploaded by

Rajesh BogulCopyright:

Available Formats

TECHNO ECONOMIC VIABILITY STUDY

NAME OF THE ACCOUNT : M/s. OM SHANTI RICE MILL

BRANCH : Dhanbad

STATE : Jharkhand

DISCLAIMER

Green & Co. has prepared this TEV Report, in their capacity as technical and financial consultant for

Bank of Baroda for financing the project.

The objective of this report is to provide comprehensive information on the project to potential lenders

to facilitate their evaluation of the financing opportunity.

Site visit and Interaction with management personnel & others have been made by the consultant to the

extent possible within limitations and constraints. This TEV report is not and should not be construed as

a recommendation by the consultant that any recipient of the report should participate in the financing.

The information contained in this TEV study has been provided by the consultant, the project sponsors

or has been collated from publicly available sources or other sources that the consultant deems reliable.

Any statements contained herein characterizing the financing and the project is a statement of opinion

and should not be construed to be representations or warranties.

This TEV report has been prepared solely for the benefit of financing bank to whom it is

distributed.

TEV Study M/s. Om Shanti Rice Mill

Introduction :

Bank of Baroda, Dhanbad Branch (Jharkhand) has engaged the services of ours for carrying out a

Techno Economic Viability Study of the project of M/S. OM SHANTI RICE MILL for setting up of a

modern parboiled rice mill at Plot No.2280, 2327, 2329, 2328, 2296 & 2279, Mauza- Golkunda, Khata

No-73, Purulia-2, West Bengal, Pin-723126.

We have studied the various aspects of project report prepared by the firm and the matter was discussed

in details with the officials and promoters responsible for implementation of the project. We also

discussed the modalities of various parameters given to us by the firm. We have also compared the data

submitted by the promoters of the firm with similar type of rice mill which are running in nearby

districts.

Based on the information /data & documents furnished by the firm and also market information

available before us we hereby furnish our report.

Background of the firm and it’s Promoter Directors :

M/s OM SHANTI RICE MILL is a Partnership firm and was incorporated under Indian Partnership Act,

1932 on 08.11.2017and having its Registered office – at Jaluka House, Shastri Nagar (West), LRD

More, P.S.-Bank More, Dhanbad, Jharkhand-826001. The firm has been promoted by Mr. Ashok Kumar

Jaluka, Mr. Shekhar Jaluka, Mr. Nitesh Jaluka, Mr. Piyush Jaluka, Mrs. Reena Jaluka & Mr. Ashish

Jaluka all being family members. The firm was established with the main object of setting up of rice

mill.

The promoters are from well known business family. The partner’s based on their rich experience and

after detail study of paddy production and looking at prospect of food processing units they have

decided to establish a modern automatic rice mill at Plot No.2280, 2327, 2329, 2328, 2296 & 2279,

Mauza- Golkunda, Khata No-73, Purulia-2, West Bengal, Pin-723126 with installed capacity of paddy

processing 38400 MT per annum (8 TPH).

TEV Study M/s. Om Shanti Rice Mill

The descriptions, names & address of the Promoters / Partners are as under:

1) MR. ASHOK KUMAR JALUKA

Father’s Name Late Mali Ram Jaluka

Age/ Date of birth 58 Years

Residential Address Jaluka House, Shastri Nagar (West), LRD More, P.S.-Bank More,

Dhanbad, Jharkhand-826001.

Functional responsibilities in the unit Partners

Educational Qualification Graduate

PAN Card No. ABOPJ1014A

Adhaar Card No. 2526 0429 8097

Experience Having 35 years experience in trading & 5 years in industry

2) MR. SHEKHAR JALUKA

Father’s Name Mr. Ashok Kumar Jaluka

Age/ Date of birth 35 Years

Residential Address Jaluka House, Shastri Nagar (West), LRD More, P.S.-Bank More,

Dhanbad, Jharkhand-826001.

Functional responsibilities in the unit Partners

Educational Qualification Graduate

PAN Card No. ADUPJ4189Q

Adhaar Card No. 8434 2069 2243

Experience Having 18 years experience in trading.

3) MR. NITESH JALUKA

Father’s Name Mr. Ashok Kumar Jaluka

Age/ Date of birth 31 Years

Residential Address Jaluka House, Shastri Nagar (West), LRD More, P.S.-Bank More,

Dhanbad, Jharkhand-826001.

Functional responsibilities in the unit Partners

Educational Qualification B.E.

PAN Card No. AFIPJ0195G

Adhaar Card No. 9638 3568 5012

Experience Having 9 years experience in Service of Infosys Pune & Com

Nugent Kolkata

TEV Study M/s. Om Shanti Rice Mill

4) MR. PIYUSH JALUKA

Father’s Name Mr. Rajesh Kumar Jaluka

Age/ Date of birth 22 Years

Residential Address Jaluka House, Shastri Nagar (West), LRD More, P.S.-Bank More,

Dhanbad, Jharkhand-826001.

Functional responsibilities in the unit Partners

Educational Qualification BBA

PAN Card No. BGFPJ7337H

Adhaar Card No. 4072 3649 7436

Experience Having 12 years experience in Service.

5) MRS. REENA JALUKA

Husband’s Name Mr. Rajesh Kumar Jaluka

Age/ Date of birth 44 Years

Residential Address Jaluka House, Shastri Nagar (West), LRD More, P.S.-Bank More,

Dhanbad, Jharkhand-826001.

Functional responsibilities in the unit Partners

Educational Qualification Graduate

PAN Card No. ACAPJ8823E

Adhaar Card No. 4649 6049 7453

Experience Having 12 years experience in trading.

6) MR. ASHISH JALUKA

Father’s Name Late Suresh Kumar Jaluka

Age/ Date of birth 36 Years

Residential Address P.O.-Jharia, Near Little Star School, Amtal,

Dhanbad, Jharkhand- 828111

Functional responsibilities in the unit Partners

Educational Qualification Graduate

PAN Card No. AGUPJ3760C

Adhaar Card No. 5464 0642 6126

Experience Having 18 years experience in trading.

TEV Study M/s. Om Shanti Rice Mill

Financial Assistance Required from Bank for the Proposed Rice Mill:

Limit – Requested :

a. Term Loan : Rs. 700.00 lacs

b. Working Capital : Rs. 350.00 lacs

Total Limit : Rs.1050.00 lacs

Tenure of Proposed Term Loan :-

Total time period for implementation of the project has been considered about 9 months starting from

2nd quarter of F.Y. of 2018-19. We have assumed that the entire project will be implemented by end of

4th quarter of F.Y. 2018-19 and commercial operation will start from 1st quarter of F.Y. 2019-20. The

entire loan has been proposed to be repaid in 23 quarterly installments. The Repayment of the term loan

will start from 3rd quarter of 2019-20. The door to door repayment of the loan considered 7 years.

Schedule of disbursement of Fresh Term Loan :

Sl. Particulars Date of Disbursement Amount

No. (Rs in lacs)

1. 1st Disbursement nd

2 quarter of 2018-19 Rs.250.00 lacs

2. 2nd Disbursement 3rd quarter of 2018-19 Rs.250.00 lacs

3. 3rd Disbursement th

4 quarter of 2018-19 Rs.200.00 lacs

Total -- Rs.700.00 lacs

TEV Study M/s. Om Shanti Rice Mill

Proposed Repayment Period of Fresh Term Loan :

a) Tern Loan (New) :

This loan will be repaid in 23 quarterly installments (Ballooning Method) starting from 3rd

quarter of 2019-20. Total period of loan 84 months including 15 months gestation period.

Schedule of installment payment as given below:

(Rs in lacs)

Year Opening Installment Closing Balance Interest

Balance

2018-19 0.00 700.00 29.86

2019-20 700.00 50.00 650.00 67.03

2020-21 650.00 100.00 550.00 58.50

2021-22 550.00 116.00 434.00 47.96

2022-23 434.00 128.00 306.00 36.08

2023-24 306.00 136.00 170.00 23.21

2024-25 170.00 136.00 34.00 9.95

2025-26 34.00 34.00 0.00 0.41

Total Interest 273.00

** Bank may consider charging of installment on monthly basis.

The Project and Its Present Status :

The Om Shanti Rice Mill has decided to establish a rice mill with a processing capacity of 38400

MTPA. The partners and their family members has already purchased land in the own name for this

purpose. The land owners will give the land on lease to the firm for construction of the rice mill. The

firm to start construction of factory building only after receiving of all the statutory clearance and

approval of loan from bank. The factory will be implemented by March’ 2019 and commercial

production is expected to start from April’ 2019.

TEV Study M/s. Om Shanti Rice Mill

Details cost of the project & Means of Finance:

A) Project Cost

(Rs in lacs)

Sl. No Particulars Considered Considered by Us

by the

Total Cost Margin Bank Finance

Company

1) Land & Site Development 109.23 109.23 100% 0.00

2) Factory Shed & Building 206.02 200.02 30% 140.01

3) Plant & Machinery 603.78 603.79 25% 452.84

4) Cost of Electrification 118.71 118.71 25% 89.03

5) Furniture & Fixture 26.43 26.43 25% 19.82

6) Contingencies 20.13 18.98 100% 0.00

7) Pre-operative Expenses 33.71 49.86 100% 0.00

8) Margin on Working Capital 113.71 126.98 100% 0.00

9) Security Deposit 18.00 18.00 100% 0.00

Total Project Cost 1249.72 1272.00 - 701.71

The difference in project cost is mainly due to following factors:-

a) While working out the project cost contingencies was considered Rs.20.13 lacs. We have worked

out the same at Rs.18.98 lacs. Detailed worksheet given separately in this report.

b) Margin on working capital was considered Rs.113.71 lacs. We have computed the same

Rs.126.98 lacs under 2nd Method of Lending. Detailed working given in the report.

c) There has been some increase in preoperative expenses primarily due to interest during

implementation period. Calculation of interest during pre-operating period has also been given in

our report.

To arrive at the aforesaid estimated capital cost of the project following factors have been considered :

a) Land & Site Development : The factory will be constructed in the land owned by the Promoters/

family members in their personal name at Plot No.2280, 2327, 2329, 2328, 2296 & 2279, Mauza-

Golkunda, Khata No-73, Purulia-2, West Bengal, Pin-723126. The land is purchased in the name of

Mrs. Reena Jaluka, Mr. Shekhar Jaluka, Mr. Nitesh Jaluka & Mr. Piyush Jaluka and it has been given on

lease to the firm for setting up this unit. All sort of infrastructural facilities are available at site. The cost

of the land is Rs.109.23 lacs. We have considered 100% margin against the land cost.

TEV Study M/s. Om Shanti Rice Mill

b) Building & Civil Construction : The total cost of factory shed & building has been considered at

Rs.200.02 lacs (inclusive of GST @ Rs.18%). While working out the permissible bank finance we have

proposed a margin of 30% against the said cost. Detailed working of building & civil work cost has been

shown separately in this report.

c) Plant & Machinery : The cost of plant & machinery has been worked out on the basis of quotations

received from the suppliers. The aggregate cost of plant & machinery has been worked out at Rs.603.79

lacs. We have considered a margin of 25% of the said cost. Details of plant & machinery cost is also

given separately in this report.

d) Electrification : Cost of electrification has been considered at Rs.118.71 lacs which include GST

also at the applicable rate. We have considered a margin of 25% of the said cost. Detailed break up &

cost of electrification given separately in this report.

e) Other Misc. Assets/Furniture & Fixture : Cost of other misc. fixed assets/furniture & fixture has

been considered at Rs.26.43 lacs. We have considered a margin of 25% of the said cost. Details of other

misc. assets cost is also given separately in this report.

f) Contingencies : The overall contingencies cost has been estimated at Rs.18.98 lacs. Details of

contingencies cost is also given separately in this report.

g) Preliminary & Pre-operative Expenses : A provision of Rs.49.86 lacs has been kept under these

head. Detailed break-up has been attached with this report.

h) Security Deposit : The security deposit of Rs.18.00 lacs has been consider for giving security to

Damodar Valley Corporation (DVC) and various others statutory bodies.

i) Margin Money for Working Capital : Detailed working of working capital requirement has been

shown separately in this report.

The cost of the project as has been worked out appears reasonable.

TEV Study M/s. Om Shanti Rice Mill

B) Means of Finance

(Rs in lacs)

Sl No. Particulars Considered by the Considered by

Firm Us

1) Term Loan 800.00 700.00

2) Promoter's contribution 449.72 572.00

Total 1739.10 1272.00

Project Debt Equity 1.79 1.22

Banker before considering sanction of this proposal should ensure about source of

promoter’s contribution.

The company on implementation of the project will be entitled for capital subsidy from

State Govt. But as they will get it only after implementation of the project we have ignored

that fact of subsidy. The viability of the unit will improve further in case they received the

subsidy.

TEV Study M/s. Om Shanti Rice Mill

Implementation Schedule :

The implementation schedule for proposed parboiled rice manufacturing unit at Plot No.2280, 2327,

2329, 2328, 2296 & 2279, Mauza- Golkunda, Khata No-73, Purulia-2, West Bengal, Pin-723126

depicted in the Table below.

Table – Implementation Schedule

Activity Commencement Completion

Acquisition of Land Already acquired

Site Development Already Started August’ 18

Civil Work July’ 18 December’ 18

Power & Electrical line To be applied for By November’ 18

Plant & Machinery

Placement of Order August’ 18

Erection/Commissioning of Plant & Machinery January’19 February’ 19

Trial Run February/March, 19

Commercial Operation April, 19 -

10

TEV Study M/s. Om Shanti Rice Mill

Details of Capacity Assessment, Capacity Utilization & Sales Realization :

Assessment of Capacity of the Plant :

Proposed Capacity

Installed Capacity 8 MT/hr

No of Shift in a Day 2 Shift

Hrs/Shift of operation 8 Hr

Processing Capacity per Day in MT 128 MT

No of Working Days 300

Annual Processing Capacity of the plant 38400 MT

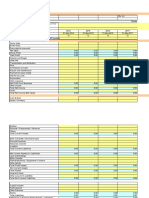

Capacity Utilization & Sales Realization : (Rs in lacs)

Particulars 19-20 20-21 21-22 22-23 23-24 24-25 25-26

Annual Processing Capacity for the year (in MT) 38400 38400 38400 38400 38400 38400 38400

Capacity Utilization 60% 65% 70% 75% 75% 75% 75%

Processing during the Yr (in MT) 23040 24960 26880 28800 28800 28800 28800

Production Loss 20% 4608 4992 5376 5760 5760 5760 5760

Husk & Dry Loss

Actual Production (in M.T) 18432 19968 21504 23040 23040 23040 23040

Details of Item wise Production ( in M.T)

Rice (67% of paddy) 84% 15437 16723 18010 19296 19296 19296 19296

Broken Rice (6% of paddy) 8% 1382 1498 1613 1728 1728 1728 1728

Bran (7% of paddy) 9% 1613 1747 1882 2016 2016 2016 2016

Sales Value of Production (Per MT)

Rice 23500 3627.65 3929.95 4232.26 4534.56 4534.56 4534.56 4534.56

Broken Rice 16000 221.18 239.62 258.05 276.48 276.48 276.48 276.48

Bran 15000 241.92 262.08 282.24 302.40 302.40 302.40 302.40

Total Sales Value of Production 4090.75 4431.65 4772.54 5113.44 5113.44 5113.44 5113.44

Add : Opening Stock of FG 0.00 79.54 86.17 92.80 99.43 99.43 99.43

Less : Closing Stock of FG 79.54 86.17 92.80 99.43 99.43 99.43 99.43

Gross Sales Value 4011.21 4425.02 4765.92 5106.81 5113.44 5113.44 5113.44

11

TEV Study M/s. Om Shanti Rice Mill

Details of Raw Material Cost:

(Rs. In Lacs)

Particulars 19-20 20-21 21-22 22-23 23-24 24-25 25-26

Production (in MT) 23040 24960 26880 28800 28800 28800 28800

Consumption of RM (Paddy) (in MT) 23040 24960 26880 28800 28800 28800 28800

Purchase Price of paddy in Rs 15000 15000 15000 15000 15000 15000 15000

Purchase Cost of Raw Material 3456.00 3744.00 4032.00 4320.00 4320.00 4320.00 4320.00

Raw Materials :

India has the largest paddy output in the world and is also the fourth largest exporter of rice in the world.

In India, Paddy fields are a common sight throughout India Paddy is cultivated twice a year in most

parts of India, the two seasons being known as Rabi and Kharif respectively. The former cultivation is

dependent on irrigation, while the latter depends on Monsoon. The paddy cultivation plays a major role

in socio-cultural life of rural India. There are basic commercial product rice, bran oil, broken rice are

obtained directly from paddy. Rice is the main product of a paddy processing unit. The rice is the main

food product of India’s entire population.

As states like West Bengal, Bihar, Jharkhand, Uttar Pradesh, Madhya Pradesh, Andhra Pradesh, Punjab

are major producers of paddy the availability of raw materials should not be a problem for the firm.

Technical aspects /Manufacturing Process :

12

TEV Study M/s. Om Shanti Rice Mill

13

TEV Study M/s. Om Shanti Rice Mill

The Proposed Infrastructures :

a) Location -

The proposed rice mill will be located at Plot No.2280, 2327, 2329, 2328, 2296 & 2279, Mauza-

Golkunda, Khata No-73, Purulia-2, West Bengal. The place is most conveniently located having

all the infrastructural facilities.

Following are some of the locational advantages of the site :

Nearness to source of Raw Materials i.e. Paddy

Convenient transportation

Adequate sources of water supply

Availability of adequate power supply.

b) Power-

The unit will apply for the 600 KVA bulk industrial power connections to West Bengal State

Electricity Board (WBSEB). In the cost of the project Rs.18.00 lacs has been considered as

security deposit for this purpose.

c) Water -

Water is one of the essential compositions for the process of food processing units. The company

will be setting up the required bore well to meet its water requirements.

d) Manpower -

The total requirement of the manpower and their cost of the operation have been given in the

manpower Chart shown separately in this report. Required technician and labour force will be

available locally.

Statutory clearance / Agreement/ Licenses etc. :

Pollution control & Statutory licenses :

As it is a rice mill it is treated as Green Industry for pollution purpose. However the Bank to ensure that

the Company has obtained NOC from State Pollution Control Board & other statutory licenses from the

respective authority. The company is also to obtain necessary registration from GST authority.

14

TEV Study M/s. Om Shanti Rice Mill

Basic Assumptions : -

1. While examining the cost of the project we have seen that the civil construction cost more or less

has been worked out as per PWD rate. They have also considered GST on building materials and

labour charges. Cost of plant & machinery has been worked out on the basis of quotations

received from leading rice mill machinery manufacturer.

2. Project work is yet to start. The company is in the process of obtaining various statutory

clearances and also bank finance.

3. Cost of power & fuel- Detailed working in respect of consumption of power and fuel at various

level of capacity utilization has been shown in separate page of this report.

4. The cost of paddy varies in between Rs.12000/- to Rs.19000/- per MT depending on season. So

for arriving the purchase cost we have taken average purchase cost of raw materials @ 15,000/-

per MT.

The selling price of rice the main product also vary from Rs.22,000/- MT to Rs.29,000/- MT

depending upon quality of paddy and season. We have considered the selling cost at rs.23,500/-

per MT. Similarly the selling price of broken rice and bran considered at Rs.16,000/- &

Rs.15,000/- per MT.

5. Break up of production of rice, broken rice & rice bran has been shown separately in this report.

6. Detailed workings salary & Wages payable to production & administrative staff has been

attached separately with this report.

7. Other manufacturing expenses have been considered @ 0.50% of sales.

8. Repairs & maintenance cost has been considered @ 0.50% on gross block of FA with an increase

of 10% from next year & onwards.

9. Selling, general & administrative expenses have also been considered @ 1.00% of sales.

10. It is an agricultural processing unit and as such as per Bank’s guideline the interest rate should be

1% above MCLR i.e. at present 9.40%. However considering upward trend in interest rate we

have considered interest @ 9.75%. Interest on term loan during project implementation period

considered in the cost of the project as pre-operative expenses.

11. Detailed workings of depreciation calculation have been given in separate pages in this report.

12. Provision for Income Tax has been made @ 30.90%.

13. Detailed workings for computation of working capital limit have also been given separately in

this report.

14. The firm will have to raise necessary capital from the partners to finance the promoter’s

contribution for this project.

15

TEV Study M/s. Om Shanti Rice Mill

Strength, Weakness, Opportunity & Threats (SWOT) :

Strengths

The promoters are seasoned businessman and have experience of running rice mill.

The advantage for setting up this unit in Purulia-2 is the availability of raw materials, power,

supply of labour and surface of transport facility.

Human resources are cheap and abundant in Purulia-2, West Bengal.

Weaknesses

The raw material of the unit is seasonally cultivated and is price volatile.

The project is capital intensive and also requires high level of working capital funds.

Opportunities

The rice is the main food product of our country’s entire population. So there is no dearth of

demand.

Paddy is plenty available in West Bengal & its neighboring states.

Threats

The cultivation of paddy in the area by large depends on nature. Any nature calamity can affect

the cultivation of paddy.

Comments on TEV:-

Considering reasonability of the project cost estimate & the envisaged pattern of financing,

reasonableness of the projected profitability, cash flow & the adequacy for discharging repayment

obligation pertaining to the financial assistance from bank we feel the project may be considered

Techno-Economically viable at a financing pattern shown in this report.

16

TEV Study M/s. Om Shanti Rice Mill

Usage of water Breakup

OM SHANTI RICE MILL is setting up a Rice Mill at plot nos. 2270, 2271, 2272, 2273, 2274, 2275, 2279, 2280,

2296, 2327, 2328, 2329, Mouza Golkunda, Barakar Road, Purulia II, P.S. Purulia(M), P.O. Mamurjore Dist. Purulia,

Pin code – 723126, West Bengal. We believe in efficient and conservative usage of water.

Total Water usage per day is approximately 12 KLD.

Usage of water for domestic Purpose: .9 KLD

Usage of water for milling rice: 0.1 KLD

Usage of water for parboiling Rice: 11 KLD

We are planning to save water by using Water recycle system. In which Water used for parboiling rice will be

reused to approximately 90 %. And only 10% fresh water will be added in each batch. This will result in saving

water and energy. Also, waste water will be treated in an effluent treatment plant and will be discharged in a

pond so that this water can recharge ground water.

17

TEV Study M/s. Om Shanti Rice Mill

You might also like

- The Citizen Co-Operative Society LTD: Loan AppraisalDocument7 pagesThe Citizen Co-Operative Society LTD: Loan AppraisalP.V RAMANA REDDYNo ratings yet

- Green Heaven Institute of Management and Research, NagpurDocument21 pagesGreen Heaven Institute of Management and Research, NagpurPrasad Mujumdar100% (1)

- Networth - Certificate For IDBIDocument4 pagesNetworth - Certificate For IDBISandip DasNo ratings yet

- Appointment Latter-1Document2 pagesAppointment Latter-1Mohit LahotiNo ratings yet

- KP ResumeDocument4 pagesKP ResumegadherkamleshNo ratings yet

- Job Application Fillup PDFDocument5 pagesJob Application Fillup PDFAnkit KumarNo ratings yet

- Kenan Loan Form SignedDocument6 pagesKenan Loan Form SignedPadmanabhan R.No ratings yet

- Taken Up by Prop-Ramaji Prasad: Gopalganj-841505Document6 pagesTaken Up by Prop-Ramaji Prasad: Gopalganj-841505AK Singh & AssociatesNo ratings yet

- Kenan Loan FormDocument6 pagesKenan Loan FormPadmanabhan R.No ratings yet

- Mohammad ShadabDocument63 pagesMohammad Shadabrlc2108No ratings yet

- GogglesDocument39 pagesGogglesVatsal GadhiaNo ratings yet

- Gujarat State Financial Corporation-Bba-Mba-Project ReportDocument84 pagesGujarat State Financial Corporation-Bba-Mba-Project ReportpRiNcE DuDhAtRaNo ratings yet

- Sheetal SongadeDocument2 pagesSheetal Songadesanket100% (1)

- Binod Salary CertificateDocument1 pageBinod Salary CertificateSujan MalbulNo ratings yet

- SHASHIKANT SHARMA CVDocument3 pagesSHASHIKANT SHARMA CVsanamsharmaNo ratings yet

- Refex Ibdst Annual RPTDocument171 pagesRefex Ibdst Annual RPTJeet SinghNo ratings yet

- AgentDocument1 pageAgentPradeep DwivediNo ratings yet

- Ashapuri, Naira, Khodiyar & Yashoda Revdi BazarDocument7 pagesAshapuri, Naira, Khodiyar & Yashoda Revdi Bazarvishal.nithamNo ratings yet

- 0 - New JAGDISH RESUME-15-3-2022Document4 pages0 - New JAGDISH RESUME-15-3-2022Jagdish RathodNo ratings yet

- Banka Bioloo Annual Report 2018-19 FinalDocument76 pagesBanka Bioloo Annual Report 2018-19 FinalPuneet367No ratings yet

- Proposal FormDocument7 pagesProposal Formdharmesh1986No ratings yet

- Introduction To S.S.IDocument36 pagesIntroduction To S.S.IAshish VoraNo ratings yet

- Page 1 of 4: $$HEADER$$FOOTER$$Document4 pagesPage 1 of 4: $$HEADER$$FOOTER$$infoski khan100% (1)

- Schedule 2Document2 pagesSchedule 2blue venomNo ratings yet

- RanjitDocument4 pagesRanjitRanjith ArNo ratings yet

- Teps - Annual Report Fy 2019-20 - Final 20.12.2020Document58 pagesTeps - Annual Report Fy 2019-20 - Final 20.12.2020PrinoyDharNo ratings yet

- FIG Evaluation Tracker 22 June 2017Document16 pagesFIG Evaluation Tracker 22 June 2017Shekhar chanderNo ratings yet

- Rakesh Kumar Tiwari: Curriculum-VitaeDocument3 pagesRakesh Kumar Tiwari: Curriculum-Vitaerajeshmohan44No ratings yet

- Sachin GhateDocument3 pagesSachin GhateyesindiacanngoNo ratings yet

- Sudam Charan Behera: Miningmanager (1St Class) (R) (M.Tech in Mining Engineering)Document3 pagesSudam Charan Behera: Miningmanager (1St Class) (R) (M.Tech in Mining Engineering)Innovative MiningNo ratings yet

- WP15872 19 08 07 2019Document30 pagesWP15872 19 08 07 2019Varun KannanNo ratings yet

- Syngenta India Ltd. Annual Report 2017-18Document76 pagesSyngenta India Ltd. Annual Report 2017-18Ashok PNo ratings yet

- Project K (1) .K.KadriDocument53 pagesProject K (1) .K.Kadri19478800No ratings yet

- Rahul MohapekarDocument4 pagesRahul MohapekarRahul MohapekarNo ratings yet

- A Vas ProposalDocument2 pagesA Vas ProposalAakash DebnathNo ratings yet

- DSA Application BOB PDFDocument4 pagesDSA Application BOB PDFRhu ShiNo ratings yet

- Auction Notice19032021Document3 pagesAuction Notice19032021harishkumar700617No ratings yet

- Dir 2Document2 pagesDir 2Jagjit SinghNo ratings yet

- Resume: Pratik VinchurkarDocument2 pagesResume: Pratik VinchurkarpratikNo ratings yet

- Application Preview PDF - Application PDFDocument3 pagesApplication Preview PDF - Application PDFAsk PrasannaNo ratings yet

- Résumé:: Amardeep Singh Personal DetailsDocument3 pagesRésumé:: Amardeep Singh Personal DetailsAmardeep SinghNo ratings yet

- Satyanarayan KumawatDocument2 pagesSatyanarayan Kumawatpradeepsaini28No ratings yet

- MEAI - Life Membership Application FormDocument3 pagesMEAI - Life Membership Application FormVedansh Thakur VedanshNo ratings yet

- Khadi, 2Document8 pagesKhadi, 2bhagyanagarkhadiNo ratings yet

- Sundram Fasteners Annual Report 2023Document247 pagesSundram Fasteners Annual Report 2023vijayNo ratings yet

- Kusum Haranath AshramDocument7 pagesKusum Haranath Ashramanon_559248185No ratings yet

- BusinessmenDocument3 pagesBusinessmenArman AliNo ratings yet

- Elanjiyam Agro Services 15/A, South Street, Udayar Palayam, Ariyalur-612804Document11 pagesElanjiyam Agro Services 15/A, South Street, Udayar Palayam, Ariyalur-612804ramNo ratings yet

- Employment Application Form (Joining Form)Document4 pagesEmployment Application Form (Joining Form)amardeepkaushal06No ratings yet

- GogglesDocument42 pagesGogglesVatsal GadhiaNo ratings yet

- English News Paper Publication 05.01.2022Document1 pageEnglish News Paper Publication 05.01.2022VishalNo ratings yet

- Resume: EducationDocument2 pagesResume: EducationManoj NegiNo ratings yet

- Withholding Agreement of Mrs. Priyanka Rathore Referred As Branch Head of Sanfort School, JodhpurDocument1 pageWithholding Agreement of Mrs. Priyanka Rathore Referred As Branch Head of Sanfort School, JodhpurLucky BherwaniNo ratings yet

- The Essential 500 WordsDocument5 pagesThe Essential 500 Wordspenusila6941No ratings yet

- MD AfsarDocument3 pagesMD AfsarAshish SinghNo ratings yet

- Miss Suman Rajnath Yadav: Prudent Corporate Advisory Services LTDDocument8 pagesMiss Suman Rajnath Yadav: Prudent Corporate Advisory Services LTDPramod YadavNo ratings yet

- Renewal NoticeDocument2 pagesRenewal NoticeMuzammil KhanNo ratings yet

- AnnualReport2022 23Document111 pagesAnnualReport2022 23sidishereagain688No ratings yet

- Energy Auditor App. FormDocument4 pagesEnergy Auditor App. Formabhi6784No ratings yet

- Due Diligence Checklist Inhouse BSPDocument3 pagesDue Diligence Checklist Inhouse BSPRajesh BogulNo ratings yet

- Standard Survey Form For PV Solar Energy Project: 100 General DataDocument2 pagesStandard Survey Form For PV Solar Energy Project: 100 General DataPhani ArvapalliNo ratings yet

- Plywood Industry ProfileDocument28 pagesPlywood Industry ProfileRheinhart PahilaNo ratings yet

- Profile GK Healthcare - Canara BankDocument23 pagesProfile GK Healthcare - Canara BankRajesh BogulNo ratings yet

- Guide To Road Slope Proctection Works CH 2Document14 pagesGuide To Road Slope Proctection Works CH 2Mahendra SuryavanshiNo ratings yet

- A Design-Centric Activity-Based Cost Estimation MoDocument13 pagesA Design-Centric Activity-Based Cost Estimation MoRajesh BogulNo ratings yet

- Beml Limited: Insta Summary ReportDocument13 pagesBeml Limited: Insta Summary ReportRajesh BogulNo ratings yet

- PRGFEE 20062018 Final AEEEDocument33 pagesPRGFEE 20062018 Final AEEERajesh BogulNo ratings yet

- Bureau of Energy Efficiency Bureau of Energy Efficiency: Partial Risk Guarantee Fund For Energy Efficiency (PRGFEE)Document3 pagesBureau of Energy Efficiency Bureau of Energy Efficiency: Partial Risk Guarantee Fund For Energy Efficiency (PRGFEE)Rajesh BogulNo ratings yet

- A Business Plan Readymade Garment ShopDocument33 pagesA Business Plan Readymade Garment ShopRohit NairNo ratings yet

- (Kindly Provide Maximum Information Possible) : Annexure-Ii Questionnaire For Sellers of Solar Power Projects in IndiaDocument4 pages(Kindly Provide Maximum Information Possible) : Annexure-Ii Questionnaire For Sellers of Solar Power Projects in IndiaRajesh BogulNo ratings yet

- RBI Circular For FourclosureDocument58 pagesRBI Circular For FourclosureRajesh BogulNo ratings yet

- MSME Schemes English 0Document266 pagesMSME Schemes English 0Sk.Abdul NaveedNo ratings yet

- FoodDocument57 pagesFoodKula Aqua Consultant Private LimitedNo ratings yet

- 001 Iee enDocument215 pages001 Iee enRajesh BogulNo ratings yet

- Financial Due Diligence - ChecklistDocument6 pagesFinancial Due Diligence - ChecklistRanganathan PKNo ratings yet

- GTR20Document80 pagesGTR20Bouhafs AbdelkaderNo ratings yet

- Model Project Report On Fruit & Vegetable Processing UnitDocument24 pagesModel Project Report On Fruit & Vegetable Processing UnitSuhas Ninghot100% (1)

- Detailed Project Report On Establishment of A Bakery Unit by PacsDocument24 pagesDetailed Project Report On Establishment of A Bakery Unit by PacsAdityaNo ratings yet

- 11180405208.sample DPR - Malt Processing UnitDocument18 pages11180405208.sample DPR - Malt Processing UnitRajesh BogulNo ratings yet

- Summary Operating Statement (For Operators)Document29 pagesSummary Operating Statement (For Operators)Rajesh BogulNo ratings yet

- P P O R & S E A: Product Code (Asicc)Document11 pagesP P O R & S E A: Product Code (Asicc)MathewsNo ratings yet

- DepreciationDocument1 pageDepreciationRajesh BogulNo ratings yet

- Project Report of M/S.Abc CoDocument10 pagesProject Report of M/S.Abc CoRajesh BogulNo ratings yet

- Work Status: Company Name or LogoDocument29 pagesWork Status: Company Name or LogoRajesh BogulNo ratings yet

- Copy of Cma For Less Than 1 Crore With CalculationDocument18 pagesCopy of Cma For Less Than 1 Crore With CalculationRajesh BogulNo ratings yet

- Workbook Developed by K C Vaid, DGM, Sidbi, MumbaiDocument11 pagesWorkbook Developed by K C Vaid, DGM, Sidbi, MumbaiRajesh BogulNo ratings yet

- Project Profile For Cold Storage Project: LocationDocument3 pagesProject Profile For Cold Storage Project: LocationHussain NazNo ratings yet

- Project Profile For Cold Storage Project: LocationDocument3 pagesProject Profile For Cold Storage Project: LocationHussain NazNo ratings yet

- Answers To End of Chapter QuestionsDocument59 pagesAnswers To End of Chapter QuestionsBruce_scribed90% (10)

- Suggested Solutions/ Answers Fall 2016 Examinations 1 of 8: Business Taxation (G5) - Graduation LevelDocument8 pagesSuggested Solutions/ Answers Fall 2016 Examinations 1 of 8: Business Taxation (G5) - Graduation LevelQadirNo ratings yet

- Engineering Competency IndicatorsDocument23 pagesEngineering Competency IndicatorsSyed Muhammad JahangeerNo ratings yet

- Bpo 102 Part 1Document30 pagesBpo 102 Part 1Mary Lynn Dela PeñaNo ratings yet

- UPRevised Banking ReviewerDocument76 pagesUPRevised Banking ReviewerRomel TorresNo ratings yet

- BA 421-Feasibility StudyDocument14 pagesBA 421-Feasibility StudyMary Ann Jacolbe BaguioNo ratings yet

- An Assignment OnDocument25 pagesAn Assignment OnJalal HossainNo ratings yet

- International Cold Calling ReportDocument69 pagesInternational Cold Calling ReporthoangkhanhNo ratings yet

- Documentary Stamp TaxDocument120 pagesDocumentary Stamp Taxnegotiator50% (2)

- PXP Energy Corporation (Formerly Philex Petroleum Corporation) ("PXP" or "The Company"), Is ADocument2 pagesPXP Energy Corporation (Formerly Philex Petroleum Corporation) ("PXP" or "The Company"), Is ABERNA RIVERANo ratings yet

- 26nov2022 - 30jan2023Document12 pages26nov2022 - 30jan2023Srishti SharmaNo ratings yet

- Partnership & ClubsDocument8 pagesPartnership & ClubsGary ChingNo ratings yet

- Important Points of Our Notes/Books:: TH THDocument42 pagesImportant Points of Our Notes/Books:: TH THpuru sharmaNo ratings yet

- E1.developments in The Indian Money MarketDocument16 pagesE1.developments in The Indian Money Marketrjkrn230% (1)

- Cryptocurrencies and Its Contemporary Impact On The Preparation of The Financial StatementDocument4 pagesCryptocurrencies and Its Contemporary Impact On The Preparation of The Financial StatementAziz Rajim BundaNo ratings yet

- Bank Baroda Project.Document106 pagesBank Baroda Project.Ketul SahuNo ratings yet

- Mays Mba Resume - Korbin King v8Document1 pageMays Mba Resume - Korbin King v8api-478389721No ratings yet

- Namra Finance LimitedDocument5 pagesNamra Finance LimitedPramila TyagiNo ratings yet

- Advanced Valuation ErasmusDocument7 pagesAdvanced Valuation Erasmusduc anh100% (7)

- Margin of Safety Formula - Guide To Performing Breakeven AnalysisDocument4 pagesMargin of Safety Formula - Guide To Performing Breakeven AnalysisGerald HandersonNo ratings yet

- Investment Environment and Investment Management Process-1Document1 pageInvestment Environment and Investment Management Process-1CalvinsNo ratings yet

- The Accounting Cycle: Preparing An Annual Report: Irwin/Mcgraw-HillDocument36 pagesThe Accounting Cycle: Preparing An Annual Report: Irwin/Mcgraw-HillJumma KhanNo ratings yet

- ADVANCED FA Chap IIIDocument7 pagesADVANCED FA Chap IIIFasiko Asmaro100% (1)

- Sample Copy - Mphasis &finsource PDFDocument2 pagesSample Copy - Mphasis &finsource PDFSameer ShaikhNo ratings yet

- A. Under Statement of Financial Position: Typical Account Titles UsedDocument6 pagesA. Under Statement of Financial Position: Typical Account Titles UsedAshlyn MaeNo ratings yet

- Villaluz Repair ShopDocument5 pagesVillaluz Repair ShopJoy SantosNo ratings yet

- Framework For Preparation and Presentation of Financial StatementsDocument5 pagesFramework For Preparation and Presentation of Financial Statementssamartha umbareNo ratings yet

- Bangladesh BankDocument35 pagesBangladesh Bankihshourov60% (5)

- CAPE 2003 AccountingDocument13 pagesCAPE 2003 AccountingStephen WhiteKnight BuchananNo ratings yet

- AFM Assignment 3Document6 pagesAFM Assignment 3Zuhair NasirNo ratings yet