Professional Documents

Culture Documents

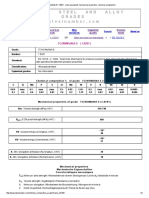

drg.-N000676 - Mounting Bracket For Knocker PKL2100

Uploaded by

Maarif MaarifOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

drg.-N000676 - Mounting Bracket For Knocker PKL2100

Uploaded by

Maarif MaarifCopyright:

Available Formats

Diese Zeichnung darf ohne unsere Genehmigung weder kopiert, noch vervielf ltigt, noch dritten Personen oder

Konkurrenzfirmen zug ngig gemacht werden.

G1/8" - NW6x1

3

This drawing and relevant information must not be used in any way contrary to interests of Fa. EME Maschinenfabrik Clasen GmbH and may not be copied without written permission.

373

4

welded assembly 5

6

Bolt torque M12 =90Nm

welded assembly

no painting

1 180 180 All welding seams without dimensions continuous:

Fillet weld

12

Butt weld

t a t t >= 3mm t < 3mm

a s s

60

60

-1

20

t

72

a

60

for t>3 a min= 3mm s=t

600 8 8

2 for t<3

Weld seam:

a=0,5 x tmin

Base material:

fillet weld, single V, I-weld

S235JRG2 / 1.0038

Preparation of welds:

single V: 60

Welding procedure: Additional material

a4 110 tMAG (135) DIN EN ISO 14341 - SM 70

Alternative welding procedure: Additional material:

E-Hand (111) DIN EN ISO 2560 - MTC MT- B10

Quality demands acc. to: Position of welding:

ISO 5817 - C PA, PB, PF

General tolerance: Preheating:

DIN EN ISO 13920 - B

4x 13 12 single parts

1

600

2 225 150 225 8

10 50

60

152

180

rev. date name revision

protection notice for restricting the use of documents: DIN ISO 16016 break all corners and edges general tolerances: DIN ISO 2768-mK, DIN EN ISO 13920-B

Euro.

Projection

scale: 1:5 project: NORM

paper size: A4 drawing: drg.-N000676

date name

Mounting bracket for Knocker PKL2100

01.10.2020 S. Senger

drawn

check. 01.10.2020 S. Senger

Member of SORG Group appro. 01.10.2020 S. Senger Page 1 of 1

II est interdit de copier ce dessin, de le multiplier, de le donner des tiers ou des concurrents sans notre permission par crit.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Die Correction Manual PDFDocument10 pagesDie Correction Manual PDFLUAI BARAKAT100% (3)

- Powder MetallurgyDocument24 pagesPowder MetallurgyNitin Gupta100% (1)

- Building A CNC Router: About This Instructable 473,771 2,348Document37 pagesBuilding A CNC Router: About This Instructable 473,771 2,348Rizwan Akram RizwanNo ratings yet

- TM23 - Heat Treatment of Metals PDFDocument32 pagesTM23 - Heat Treatment of Metals PDFAlessio NotariNo ratings yet

- Pressure & Leakage TestDocument2 pagesPressure & Leakage Testfizahwanhanif100% (2)

- Piping ChecklistDocument1 pagePiping Checklistsiva8000No ratings yet

- Unit 7: Dimensional Accuracy: Dr. Basil Hamed Technical EnglishDocument14 pagesUnit 7: Dimensional Accuracy: Dr. Basil Hamed Technical EnglishmuntaserNo ratings yet

- Welding WorkbookDocument1 pageWelding WorkbookChris NenovNo ratings yet

- Table 4A Comparison of SSPC and Iso Surface Preparation Standards For Power-And Hand-Tool Cleaned SteelDocument2 pagesTable 4A Comparison of SSPC and Iso Surface Preparation Standards For Power-And Hand-Tool Cleaned Steelshahid khanNo ratings yet

- Typical Corosion Test BankDocument2 pagesTypical Corosion Test BankSamuel AnemeNo ratings yet

- IEPL-Weekly Safety Information Bulletin Issue 27: Safety During Hot WorkDocument3 pagesIEPL-Weekly Safety Information Bulletin Issue 27: Safety During Hot Workkirandevi1981No ratings yet

- Application Guide Jota ArmourDocument1 pageApplication Guide Jota ArmourTamerTamerNo ratings yet

- European Steel and Alloy Grades: 7crwvmonb9-6 (1.8201)Document2 pagesEuropean Steel and Alloy Grades: 7crwvmonb9-6 (1.8201)farshid KarpasandNo ratings yet

- Polycrete MCDocument2 pagesPolycrete MCdinescNo ratings yet

- Tumbler Screening Machine InfoDocument2 pagesTumbler Screening Machine InforoyNo ratings yet

- 8 SMST-Tubes Urea Plants Brochure 2009Document12 pages8 SMST-Tubes Urea Plants Brochure 2009Lee Hui YiNo ratings yet

- Jora RaiseDocument11 pagesJora RaiseANSHUL YADAVNo ratings yet

- Fabrication: Socket Head Cap ScrewsDocument3 pagesFabrication: Socket Head Cap Screwsnemi90No ratings yet

- Steel MinimillsDocument16 pagesSteel Minimillsratninp9368No ratings yet

- ASTM Welding Procedures A36 To A930Document5 pagesASTM Welding Procedures A36 To A930solrac4371No ratings yet

- Progress Card HUMSSDocument35 pagesProgress Card HUMSSwiljhon sunioNo ratings yet

- PB Impax Supreme English160604175245Document8 pagesPB Impax Supreme English160604175245Filipe BastosNo ratings yet

- WGA PDF Plan - Contemporary TV StandDocument7 pagesWGA PDF Plan - Contemporary TV StandSajith ShivashankaranNo ratings yet

- WELLHEAD SchematicDocument16 pagesWELLHEAD Schematicabbas ansariNo ratings yet

- Nonmetallic Abrasives: H. William Hitzrot (Original Chapter) James Hansink (2002 Revision)Document6 pagesNonmetallic Abrasives: H. William Hitzrot (Original Chapter) James Hansink (2002 Revision)Ngô Trung NghĩaNo ratings yet

- Cico System Polymer FlooringDocument2 pagesCico System Polymer FlooringSanjay ChopraNo ratings yet

- Welding 5 Course SyllabusDocument5 pagesWelding 5 Course Syllabusapi-272067539No ratings yet

- A-173 Orotan-731a-Dispersant-TdsDocument2 pagesA-173 Orotan-731a-Dispersant-Tdswiwat dussadinNo ratings yet

- MRF - S-Data-Sheet-Form-Official FOR THE MONTH OF JUNEDocument3 pagesMRF - S-Data-Sheet-Form-Official FOR THE MONTH OF JUNEBarangay657 Zone70No ratings yet

- EN36 Case Hardening Steel: Shipping PolicyDocument2 pagesEN36 Case Hardening Steel: Shipping PolicyMohit YadavNo ratings yet