Professional Documents

Culture Documents

Correct Grease For Hydraulic Hammers - NPK

Uploaded by

midalllllOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Correct Grease For Hydraulic Hammers - NPK

Uploaded by

midalllllCopyright:

Available Formats

Service Bulletin

SB16-5

SUBJECT: CORRECT GREASE FOR HYDRAULIC HAMMERS

MODEL(S): ALL HAMMER MODELS

Proper hammer maintenance depends on the regular greasing of the tool (chisel) with the

correct grease. The tool must be pressed against a hard surface until it stops up inside the

hammer. This ensures proper distribution of grease between the tool and tool bushings.

The hammer must be greased at regular intervals to get the best life from the tool and tool

bushings. There are two ways to determine grease intervals. First; grease the hammer at the

beginning of the job until grease comes out between the tool and the lower tool bushing. Run

the hammer until the shank of the tool starts to look dry. This determines the time interval for

the greasing of this particular hammer on this particular job. Typically, this is 1 to 4 hours.

Also, note the amount of grease needed to re-grease the tool. This gives you the amount of

grease and how often it must be applied. An example would be that a particular hammer, on

a particular job, requires half a tube of grease every 3 hours. This would be the greasing

schedule you would set up. If this hammer has moved to another job, another grease

schedule may have to be set up. Second; if you can’t control the grease schedule, such as

rental units, then have the operator grease the hammer once every hour of hammer

operation. Again, grease the hammer until grease comes out between the tool and tool

bushing. This is usually more often than required, but is far cheaper than replacing

prematurely worn tools and tool bushings.

The type of grease used is very important. NPK recommends a Lithium Base, Moly

(Molybdenum Disulfide) or other surface protecting additives, EP (Extreme Pressure), NLGI

#2 Grease. A high drop point (500°) grease is desirable.

Included with this bulletin is a list of greases available from NPK. NPK does not endorse any

one brand as being superior to another. If you or your customers use a different brand,

please contact the NPK Service Department at 1-800-225-4379.

9/26/2016 1 SB16-5 Correct Grease for Hydraulic Hammers

SB16-5

SUBJECT: CORRECT GREASE FOR HYDRAULIC HAMMERS

MODEL(S): ALL HAMMER MODELS

NPK HAMMER GREASE

NPK now offers hammer grease specially formulated to meet severe job requirements. The grease is

available in three different temperature ranges - 350°, 500°, and 2000°. All are compatible with NPK

Auto Lube Systems.

Universal Plus and Super Duty are lithium soap based products that resists washout and contain NPK-

10 additive for surface protection in friction affected areas.

Chisel Paste is an aluminum complex soap base with 12% graphite and copper additives for extreme

operating conditions.

UNIVERSAL PLUS NPK PART

350 deg NO.

14 OZ. CARTRIDGE G000-1010

120 LB. KEG G000-1020

35 LB. PAIL G000-1030

400 LB. DRUM G000-1040

SUPER DUTY NPK PART

500 deg NO.

14 OZ. CARTRIDGE G000-1011

120 LB. KEG G000-1021

35 LB. PAIL G000-1031

400 LB. DRUM G000-1041

CHISEL PASTE NPK PART

2000 deg NO.

14 OZ. CARTRIDGE G000-1050

HAMMER MOUNTED

AUTO LUBE CHISEL NPK PART

PASTE NO.

14 OZ. CARTRIDGE G025-1050

9/26/2016 2 SB16-5 Correct Grease for Hydraulic Hammers

You might also like

- Liebherr 964 C - Manual de PeçasDocument1,013 pagesLiebherr 964 C - Manual de PeçasTulio Cafezakis100% (6)

- Price Quotation-Harga OliDocument2 pagesPrice Quotation-Harga OliRidwan KurniawanNo ratings yet

- R 944C HDSL 1164 26891 en EsDocument881 pagesR 944C HDSL 1164 26891 en EsclescioNo ratings yet

- Catálogo R964 PDFDocument986 pagesCatálogo R964 PDFTom Souza100% (2)

- Lubriplate Synxtreme Fg/220 Series: ISO-9001 Registered Quality System. ISO-21469 CompliantDocument2 pagesLubriplate Synxtreme Fg/220 Series: ISO-9001 Registered Quality System. ISO-21469 Compliantnalky1975No ratings yet

- Lube Oil & Grease Consumption SummaryDocument2 pagesLube Oil & Grease Consumption SummaryAL HafidzkyNo ratings yet

- Ford Ranger ZCX 2753Document1 pageFord Ranger ZCX 2753Bong PelotinNo ratings yet

- Stok Dan Estimasi Pemakaian Chemical Jan 2024Document43 pagesStok Dan Estimasi Pemakaian Chemical Jan 2024slamet supriyadiNo ratings yet

- Catalogo de Peças R954C - HD - 1128 - 29253 - en - EsDocument781 pagesCatalogo de Peças R954C - HD - 1128 - 29253 - en - EsDaniel F BarrosNo ratings yet

- R 944 CHDSL1446 35846 en PTBDocument933 pagesR 944 CHDSL1446 35846 en PTBimil almox100% (1)

- Lubriplate Synxtreme FG Series: ISO-9001 Registered Quality System. ISO-21469 CompliantDocument2 pagesLubriplate Synxtreme FG Series: ISO-9001 Registered Quality System. ISO-21469 CompliantJonathan AlejosNo ratings yet

- Liebherr 976 Parts ManualDocument1,092 pagesLiebherr 976 Parts Manualerickbotha100% (1)

- Lista de Precios Agosto 2022Document9 pagesLista de Precios Agosto 2022RuvigleidysDeLosSantosNo ratings yet

- Oil List UtilityDocument3 pagesOil List UtilityM BNo ratings yet

- 312 DatasheetDocument1 page312 DatasheetGregory Alan Francisco IINo ratings yet

- Araldite: Tooling, Mouldmaking & Pattern Making ProductsDocument2 pagesAraldite: Tooling, Mouldmaking & Pattern Making Productsherysyam1980No ratings yet

- New LP 7505 Douple Drum RollerDocument15 pagesNew LP 7505 Douple Drum RollerRauf Gebreel100% (1)

- 20.02 Huancayo 3 ActDocument2 pages20.02 Huancayo 3 Act02-CF-HU-ELVIS CAPCHA ORIHUELANo ratings yet

- Mount Rubber Tools CatalogueDocument224 pagesMount Rubber Tools Cataloguecaterpillar971No ratings yet

- R 954 C-HD 1128 37541: Catalog CatálogoDocument891 pagesR 954 C-HD 1128 37541: Catalog CatálogoDaniel F BarrosNo ratings yet

- BPL Equiv Chart PDFDocument1 pageBPL Equiv Chart PDFmannajoe7No ratings yet

- Fombli Y 16-6 For O2 Vacuum PumpsDocument3 pagesFombli Y 16-6 For O2 Vacuum Pumpslaraujo76No ratings yet

- Grease Stock Date:30-06-2020: SR.# Code Grease Name Remaing QTY Required QTY RemarksDocument1 pageGrease Stock Date:30-06-2020: SR.# Code Grease Name Remaing QTY Required QTY RemarksMuhammad Waqar AhsanNo ratings yet

- TabachoiDocument2 pagesTabachoiadrian arzagaNo ratings yet

- Introducing A New Food Grade Lubricant: 3H DirectDocument2 pagesIntroducing A New Food Grade Lubricant: 3H DirectjjgonzalezquinaNo ratings yet

- AGCO Refrigerant CapacityDocument81 pagesAGCO Refrigerant CapacityJosenaldo Freitas SantosNo ratings yet

- Quotation 副本MR.016- JAMBI 2024Document3 pagesQuotation 副本MR.016- JAMBI 2024Agus HaryadieNo ratings yet

- 2018 Stonage Fittings and Accessories WebDocument35 pages2018 Stonage Fittings and Accessories WeblupiNo ratings yet

- Sr30je E04Document2 pagesSr30je E04freddy1115No ratings yet

- Grease FlyerDocument2 pagesGrease FlyerBình LươngNo ratings yet

- ClosingDocument8 pagesClosingRizwanNo ratings yet

- 954C HD 976 22210 en de PDFDocument696 pages954C HD 976 22210 en de PDFMANUTENÇÃO CAVA ENGENHARIANo ratings yet

- SplendorDocument72 pagesSplendorandres parragaNo ratings yet

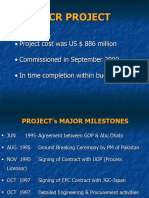

- MCR ProjectDocument40 pagesMCR ProjectHumair AhmedNo ratings yet

- Catalogo DespieceDocument84 pagesCatalogo DespieceBenjamin RomeroNo ratings yet

- BurquipDocument38 pagesBurquipBenjamin MurphyNo ratings yet

- 2 - MSC Lana IIDocument3 pages2 - MSC Lana IIUsman ANo ratings yet

- Brosur Motor 2023Document2 pagesBrosur Motor 2023Dimas Rama PradhityaNo ratings yet

- Tank Specification Sheet PDFDocument1 pageTank Specification Sheet PDFRaj Bahadur YadavNo ratings yet

- Industrial Steam Turbines PDFDocument56 pagesIndustrial Steam Turbines PDFmember1000No ratings yet

- Sparepart SimDocument34 pagesSparepart Simbintang fajarNo ratings yet

- Agip Rotra JD-F Sae 80W PDFDocument2 pagesAgip Rotra JD-F Sae 80W PDFJan HendriksNo ratings yet

- Super SaleDocument13 pagesSuper SaleHasan KhanNo ratings yet

- Lubriplate 630Document1 pageLubriplate 630Diego Fernando Pedroza UribeNo ratings yet

- R 944C HDSL 1164 30795 en EsDocument921 pagesR 944C HDSL 1164 30795 en Esdiego_egcaNo ratings yet

- Hyundai StarexDocument1 pageHyundai StarexBong PelotinNo ratings yet

- PB Full Synthetic Multi Vehicle Automatic Transmission Fluid 20230609Document2 pagesPB Full Synthetic Multi Vehicle Automatic Transmission Fluid 20230609Dick BrosigNo ratings yet

- Bin 1 Description Part# Qty Available: 508542889Document20 pagesBin 1 Description Part# Qty Available: 508542889Shiv AnandNo ratings yet

- Comparison of Roller Press With VRM For Slag Grinding: Dr. Stefan Seemann, Dr. York Reichardt Humboldt Wedag GMBHDocument19 pagesComparison of Roller Press With VRM For Slag Grinding: Dr. Stefan Seemann, Dr. York Reichardt Humboldt Wedag GMBHmohammed sulaimanNo ratings yet

- Lube Sale - Barrels (September 2019) : Date Client Details Product Packing Size Quantity Purchase Price (INR)Document4 pagesLube Sale - Barrels (September 2019) : Date Client Details Product Packing Size Quantity Purchase Price (INR)Najam KhanNo ratings yet

- 2019-01-14 United Oil Product Equivalent ChartDocument1 page2019-01-14 United Oil Product Equivalent ChartrandiNo ratings yet

- (21-09-2016) P.34 (MV Pioneer A)Document2 pages(21-09-2016) P.34 (MV Pioneer A)Abid LakhaniNo ratings yet

- Dongnam Marine Cranes - Operating ManualDocument28 pagesDongnam Marine Cranes - Operating Manualjohn smith100% (1)

- Cost Budget PM Service UnitDocument17 pagesCost Budget PM Service UnitRojer KalingaraNo ratings yet

- RptMutasiStockDailyQty 14Document142 pagesRptMutasiStockDailyQty 14ndut ajaNo ratings yet

- Packing List Lot-02Document1 pagePacking List Lot-02T M Murshed MukulNo ratings yet

- DAM Quick 7Document1 pageDAM Quick 7pikemanserbiaNo ratings yet

- Main PumpDocument11 pagesMain PumpmidalllllNo ratings yet

- TemperatureDocument10 pagesTemperaturemidalllllNo ratings yet

- Hydraulic Circuit Diagram (Back Hoe)Document1 pageHydraulic Circuit Diagram (Back Hoe)midalllllNo ratings yet

- Section 1 GeneralDocument10 pagesSection 1 GeneralmidalllllNo ratings yet

- 114 Series PDF 1Document33 pages114 Series PDF 1midalllllNo ratings yet

- Section A-ADocument11 pagesSection A-AmidalllllNo ratings yet

- Operation PC750, PC800-7 - KomatsuDocument62 pagesOperation PC750, PC800-7 - KomatsumidalllllNo ratings yet

- Allison Transmlssions: (Max) .......... (Max) - . Engine VehicleDocument2 pagesAllison Transmlssions: (Max) .......... (Max) - . Engine VehiclemidalllllNo ratings yet

- D9R تنظیمات زنجیر بلدوزرDocument5 pagesD9R تنظیمات زنجیر بلدوزرmidalllllNo ratings yet

- Skid Steer Loader Hydraulic System - CaterpillarDocument2 pagesSkid Steer Loader Hydraulic System - CaterpillarmidalllllNo ratings yet

- Allison AT540 - AT543 - AT545Document4 pagesAllison AT540 - AT543 - AT545midalllllNo ratings yet

- AllServiceCodes PDFDocument11 pagesAllServiceCodes PDFJose Pacheco Corrales100% (1)

- d8r تنظیمات زنجیر بلدوزرDocument4 pagesd8r تنظیمات زنجیر بلدوزرmidalllllNo ratings yet

- Hydraulic Hammer Safety Decals Cab - NPKDocument3 pagesHydraulic Hammer Safety Decals Cab - NPKmidalllllNo ratings yet

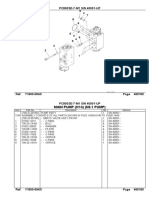

- Pc800se-7-M1 S/N 40001-Up: Main Pump (4/9) (N0.2 Pump)Document2 pagesPc800se-7-M1 S/N 40001-Up: Main Pump (4/9) (N0.2 Pump)midalllllNo ratings yet

- AutoLubeB Techman Automatsko Podmazivanje ŠpiceDocument3 pagesAutoLubeB Techman Automatsko Podmazivanje ŠpiceLuka BornaNo ratings yet

- Valves On Control Blocks (BBE)Document2 pagesValves On Control Blocks (BBE)midalllllNo ratings yet

- TAD1343GE: Volvo Penta Genset EngineDocument2 pagesTAD1343GE: Volvo Penta Genset EngineAndres SorinNo ratings yet

- Pc800se-7-M1 S/N 40001-Up: Main Pump (1/9) (N0.2 Pump)Document1 pagePc800se-7-M1 S/N 40001-Up: Main Pump (1/9) (N0.2 Pump)midalllllNo ratings yet

- Nitrogen Gas Pressure - NPKDocument5 pagesNitrogen Gas Pressure - NPKmidalllllNo ratings yet

- Hydraulic Circuit Diagram: PC750-7, PC750SE-7 PC800-7, PC800SE-7Document1 pageHydraulic Circuit Diagram: PC750-7, PC750SE-7 PC800-7, PC800SE-7midalllllNo ratings yet

- Pc800se-7-M1 S/N 40001-Up: Main Pump (3/9) (N0.2 Pump)Document2 pagesPc800se-7-M1 S/N 40001-Up: Main Pump (3/9) (N0.2 Pump)midalllllNo ratings yet

- Pc800se-7-M1 S/N 40001-Up: Main Pump (9/14) (N0.1 Pump)Document1 pagePc800se-7-M1 S/N 40001-Up: Main Pump (9/14) (N0.1 Pump)midalllllNo ratings yet

- Pc800se-7-M1 S/N 40001-Up: Main Pump (2/9) (N0.2 Pump)Document2 pagesPc800se-7-M1 S/N 40001-Up: Main Pump (2/9) (N0.2 Pump)midalllllNo ratings yet

- Pc800se-7-M1 S/N 40001-Up: Main Pump (13/14) (N0.1 Pump)Document1 pagePc800se-7-M1 S/N 40001-Up: Main Pump (13/14) (N0.1 Pump)midalllllNo ratings yet

- Pc800se-7-M1 S/N 40001-Up: Main Pump (14/14) (N0.1 Pump)Document1 pagePc800se-7-M1 S/N 40001-Up: Main Pump (14/14) (N0.1 Pump)midalllllNo ratings yet

- Pc800se-7-M1 S/N 40001-Up: Main Valve (4-Spool) (2/6)Document1 pagePc800se-7-M1 S/N 40001-Up: Main Valve (4-Spool) (2/6)midalllllNo ratings yet

- Pc800se-7-M1 S/N 40001-Up: Main Valve (4-Spool) (3/6)Document1 pagePc800se-7-M1 S/N 40001-Up: Main Valve (4-Spool) (3/6)midalllllNo ratings yet

- Pc800se-7-M1 S/N 40001-Up: Main Pump (12/14) (N0.1 Pump)Document1 pagePc800se-7-M1 S/N 40001-Up: Main Pump (12/14) (N0.1 Pump)midalllllNo ratings yet

- Aisc Research On Structural Steel To Resist Blast and Progressive CollapseDocument20 pagesAisc Research On Structural Steel To Resist Blast and Progressive CollapseFourHorsemenNo ratings yet

- Effect of Internet Use To Academic PerformaceDocument4 pagesEffect of Internet Use To Academic PerformaceLeonard R. RodrigoNo ratings yet

- Permit To Work Audit Checklist OctoberDocument3 pagesPermit To Work Audit Checklist OctoberefeNo ratings yet

- Attachment BinaryDocument5 pagesAttachment BinaryMonali PawarNo ratings yet

- Oddball NichesDocument43 pagesOddball NichesRey Fuego100% (1)

- BS en 118-2013-11Document22 pagesBS en 118-2013-11Abey VettoorNo ratings yet

- Brush Seal Application As Replacement of Labyrinth SealsDocument15 pagesBrush Seal Application As Replacement of Labyrinth SealsGeorge J AlukkalNo ratings yet

- Toshiba Satellite L200 M200 M203 M206 KBTIDocument59 pagesToshiba Satellite L200 M200 M203 M206 KBTIYakub LismaNo ratings yet

- Technical Engineering PEEDocument3 pagesTechnical Engineering PEEMariano Acosta Landicho Jr.No ratings yet

- How To Unbrick Tp-Link Wifi Router Wr841Nd Using TFTP and WiresharkDocument13 pagesHow To Unbrick Tp-Link Wifi Router Wr841Nd Using TFTP and WiresharkdanielNo ratings yet

- Chapter 11 Walter Nicholson Microcenomic TheoryDocument15 pagesChapter 11 Walter Nicholson Microcenomic TheoryUmair QaziNo ratings yet

- 16 Easy Steps To Start PCB Circuit DesignDocument10 pages16 Easy Steps To Start PCB Circuit DesignjackNo ratings yet

- Modal Case Data Form: GeneralDocument4 pagesModal Case Data Form: GeneralsovannchhoemNo ratings yet

- Questionnaire: ON Measures For Employee Welfare in HCL InfosystemsDocument3 pagesQuestionnaire: ON Measures For Employee Welfare in HCL Infosystemsseelam manoj sai kumarNo ratings yet

- Brand Guidelines Oracle PDFDocument39 pagesBrand Guidelines Oracle PDFMarco CanoNo ratings yet

- Gathering Package 2023Document2 pagesGathering Package 2023Sudiantara abasNo ratings yet

- Introduction To Radar Warning ReceiverDocument23 pagesIntroduction To Radar Warning ReceiverPobitra Chele100% (1)

- Tekla Structures ToturialsDocument35 pagesTekla Structures ToturialsvfmgNo ratings yet

- Self-Instructional Manual (SIM) For Self-Directed Learning (SDL)Document28 pagesSelf-Instructional Manual (SIM) For Self-Directed Learning (SDL)Monique Dianne Dela VegaNo ratings yet

- Revenue Management Session 1: Introduction To Pricing OptimizationDocument55 pagesRevenue Management Session 1: Introduction To Pricing OptimizationDuc NguyenNo ratings yet

- Consultancy Services For The Feasibility Study of A Second Runway at SSR International AirportDocument6 pagesConsultancy Services For The Feasibility Study of A Second Runway at SSR International AirportNitish RamdaworNo ratings yet

- Project 1. RockCrawlingDocument2 pagesProject 1. RockCrawlingHằng MinhNo ratings yet

- G JaxDocument4 pagesG Jaxlevin696No ratings yet

- 1 s2.0 S0304389421026054 MainDocument24 pages1 s2.0 S0304389421026054 MainFarah TalibNo ratings yet

- Strategic Management ModelsDocument4 pagesStrategic Management ModelsBarno NicholusNo ratings yet

- Simplified Concrete Modeling: Mat - Concrete - Damage - Rel3Document14 pagesSimplified Concrete Modeling: Mat - Concrete - Damage - Rel3amarNo ratings yet

- Integrated Building Managemnt SystemDocument8 pagesIntegrated Building Managemnt SystemRitikaNo ratings yet

- POM 3.2 Marketing Management IIDocument37 pagesPOM 3.2 Marketing Management IIDhiraj SharmaNo ratings yet

- Tajima TME, TMEF User ManualDocument5 pagesTajima TME, TMEF User Manualgeorge000023No ratings yet

- CORDLESS PLUNGE SAW PTS 20-Li A1 PDFDocument68 pagesCORDLESS PLUNGE SAW PTS 20-Li A1 PDFΑλεξης ΝεοφυτουNo ratings yet