Professional Documents

Culture Documents

FIREGUARD Foam - Chamber - FCA

Uploaded by

Edward Chan AcostaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FIREGUARD Foam - Chamber - FCA

Uploaded by

Edward Chan AcostaCopyright:

Available Formats

FOAM CHAMBER

MODEL - FCA & FCA-S

TECHNICAL DATA

MODELS FCA-65, FCA-80 & FCA-100

Carbon Steel Construction

FCA-S 65, FCA-S 80 &

FCA-S 100

Stainless Steel Construction

INLET SIZE 65, 80, 100 NB

WORKING Min 2.8 Kg/cm2 (40 PSI)

PRESSURE Max 7 Kg/cm2 (100 PSI)

WEIGHT 65 NB - 34.5 Kg

(Approx) 80 NB - 49.5 Kg

100 NB - 72.0 Kg

VAPOUR SEAL 0.7 to 1.75 Kg/sq.cm.

RUPTURE (10 PSI to 25 PSI)

PRESSURE Running water/ water

foam solution pressure at

inlet of Foam Chamber

FEATURES

MAXIMUM 0.07 Kg/sq.cm. (1.0 PSI)

PERMISIBLE BACK • UL Listed

PRESSURE ON

VAPOUR SEAL • Heavy duty welded construction with choice of

Carbon Steel or Stainless Steel material

VAPOUR SEAL Glass

Deflector Solid or Split Deflector • Frangible Glass Vapour Seal

FINISH Red RAL 3000

• Controlled Air Flow proportional to liquid flow for

APPROVAL UL Listed optimum foam quality and rupture of vapour

ORDERING a) Model & Size seal in narrow pressure tolerances for

INFORMATION increased reliability

b) Flow & Pressure at inlet

of each Foam Chamber • Field replaceable orifice plate fitted with Foam

Chamber

c) Inlet, outlet flange

specification • Interchangeable with FG Foam Chamber Model FC

d) Type of Deflector

APPLICATION

e) Foam concentrate used

Foam Chamber is used in one of the most common

f) Tank number / Tag number application to protect vertical fixed roof (cone) liquid

storage tanks, with or without internal floating roof

with the low expansion foam system. The application

of foam is on the basis that the risk comprises the

total surface area of the fuel. The foam system

design guidelines generally used are in accordance

with NFPA-11, standard.

Foam chambers are defined by NFPA-11 as Type

II discharge outlets for delivering the foam to the

surface of a flammable liquid. The Foam Chambers

are widely used with the Inline Foam Inductor, Balance

Pressure Foam Proportioning system, Bladder Tank

Proportioner or Foam Tender.

Company Registration No. 5717368 • V.A.T No. 883908672 www.fireguard-uk.com

SPECIFICATION SYSTEM DESIGN REQUIREMENT

Foam Chamber is an air aspirating foam discharge The NFPA-11, a standard for low expansion foam,

device, covering wide range of flow from 150 to provides the essential requirement of an appropriate

1780 litres per minute at 2.8 to 7 kg/sq.cm. inlet designed foam pouring system, which are identified

pressure. The Foam Chamber contains a vapour and outlined as below:

seal to prevent the entry of vapour into the foam

chamber and the foam solution pipe. Each foam The Foam Deflector is used with the Foam Chamber.

chamber is supplied with an orifice plate, designed

for the required flow and inlet pressure. The orifice The aerated foam from the Foam Chamber is directed

is field replaceable in the event of change in design in to the deflector for the gentle application of the

parameters. The foam is produced by introducing expanded foam. The deflector reduces the expanded

air into the foam solution stream. The inlet of foam foam velocity and allows the foam to slide down the

chamber is designed to create venturi jet which tank wall.

draws air into the foam solution stream. The air

is drawn into the foam solution through the holes (a) Number of Foam Chamber:

located on the foam chamber covered with stainless

steel screen to exclude nesting birds and insects. The number of foam chambers required is

The aerated foam is directed into the deflector for determined by the tank diameter. Where two

the gentle application of the expanded foam. The or more foam chambers are required, they shall

deflectors are available in different models. be spaced equally around the tank periphery and

each Foam Chamber shall be sized to deliver

On removal of cover plate from the top of the foam at an approximately same rate. Please

chamber allows the system to be tested and to draw refer graph to select the unit that will provide

a sample of the expanded foam, without removing the required minimum foam solution application

the vapour seal or disconnecting the foam chamber rate at the available operating pressure of the

from the tank. Frangible glass bursting disc (vapour Foam Chamber.

seal) can be replaced by easily.

For minimum number of Foam Chamber

The vapour seal is designed to rupture within 0.7 requirement, kindly follow the recommendations

to 1.75 Kg/sq.cm. (10 to 25 PSI) at inlet flange as per NFPA/OISD/TAC or as per the governmental

of Foam Chamber, as required by NFPA, UL & FM codes or ordinances wherever applicable.

standard. The vapour seal will withstand maximum

back pressure of 0.07 Bar (1.0 PSI) or equal to (b) Minimum Foam Solution Application Rate:

686mm of water as specified by API for welded

storage tank. If the requirement is to exceed 0.07 The minimum foam solution application rate is

(1.0 PSI) back pressure, for example with nitrogen the rate at which the water and foam

blanket. concentrate in correctly proportioned ratio

should be delivered to the surface of a storage

The vapour seal is frangible glass. The vapour seal is tank under protection to control and

supplied with holder and for spares it can be with or extinguish the fire.

without holder. The ‘O’ ring used for seal are Nitride

rubber and optional Viton for polar solvent. For minimum application rate requirement,

follow the recommendations as per NFPA/OISD/

TAC or governmental codes or ordinances

wherever applicable.

Company Registration No. 5717368 • V.A.T No. 883908672 www.fireguard-uk.com

TESTING & MAINTENANCE NOTE:

Qualified and trained person must commission

1. A PROVISION IS TO BE MADE FOR

the system. After few initial successful tests,

PRESSURE GAUGE MOUNTING AT INLET OF

an authorized person must be trained to perform

FOAM CHAMBER, WHICH MAY BE PLUGGED

inspection and testing of the system. It is

AFTER SUCCESSFUL COMMISSIONING OF

recommended to carry out physical inspection of

THE SYSTEM. THIS WILL HELP TO ANALYSE

the system regularly. The system must be fully

THE SYSTEM WHILE COMMISSIONING.

tested at least once in a year or in accordance

with applicable NFPA/OISD/TAC standards or in

accordance with standards of the organization 2. REFER TO THE INDIVIDUAL FOAM LISTING

having local jurisdiction. FOR OPERATING LIMITATION WITH EACH

FOAM CONCENTRATE AND FOAM

CHAMBER.

Do not turn off the system or any valve to make

repair or test the system, without placing a roving

Fire Patrol in the area covered by the system. The

Selection of FG Foam Chamber:

Patrol should continue until the system is put back

in service. Also inform the local security guard and

control alarm station, so as to avoid false alarm. FOAM CHAMBER K - FACTOR

SIZE

Each system is to be flushed properly. The vapour 65 NB 89.6 TO 207.8

seal must be replaced if the system has been

80 NB 179.2 TO 385.9

operated. Normal testing of the chamber can be

carried out by removing the cover plate from the 100 NB 358.5 TO 672.7

top of the chamber. This allows the system to draw

a sample of the expanded foam without removing To select the size of the Foam Chamber use the

the vapour seal or disconnecting the Foam Chamber following formula:

from the tank.

Q=K√P

The air screen is to be inspected periodically for the

Q = Total solution flow in litres per minute.

obstruction of air inlet holes. If any obstruction is

K = Constant for Foam Chamber

noticed, remove the same and flush if necessary.

P = Inlet pressure in kg/sq.cm.

It is recommended to have regular maintenance

programme to inspect the Vapour Seal Chamber

discharge area and deflector for possible deposit or

obstruction.

CAUTION

Do not install Foam chambers on pressured storage

tanks (Inert gas blanketed tanks) and storage tanks

containing product which attack the foam chamber

standard construction material.

Maximum permissible back pressure on vapour seal

is 0.07 Kg/sq.cm.2 (1.0 PSI)

Company Registration No. 5717368 • V.A.T No. 883908672 www.fireguard-uk.com

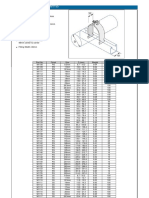

FOAM CHAMBER

C

6

F2

5 9

A

4

B

2

1 F1

DIMENSIONS OF FOAM CHAMBER PART LIST

in millimeter (Approximate)

INLET OUTLET ITEM MATERIAL SPECIFICATON

A B C DESCRIPTION

SIZE SIZE NO. FCA FCA-S

F1 F2

1 ORIFICE ASSEMBLY STAINLESS STEEL STAINLESS STEEL

65NB 100NB 756 600 175

80NB 150NB 1093 908 225 2 INLET FLANGE STEEL STAINLESS STEEL

100NB 200NB 1221 996 275 3 STRAINER ASSEMBLY STAINLESS STEEL STAINLESS STEEL

4 FOAM MAKING CHAMBER STEEL PIPE SS PIPE

5 FOAM CHAMBER STEEL STAINLESS STEEL

6 INSPECTION COVER STEEL STAINLESS STEEL

7 DISCHARGE PIPE STEEL PIPE SS PIPE

8 OUTLET FLANGE STEEL STAINLESS STEEL

9 VAPOUR SEAL ASSEMBLY GLASS GLASS

NOTE:

1. Pipes used are ERW (Seamless Pipe are optional)

2. Foam chambers are open to atmosphere & do not have internal shutoff device,hence no hydrotest is

offered during inspection.

Company Registration No. 5717368 • V.A.T No. 883908672 www.fireguard-uk.com

TYPICAL FOAM CHAMBER INSTALLATION WITH DEFLECTOR

TYPICAL INSTALLATION OF FOAM CHAMBER WITH STUD FLANGED SPLIT DEFLECTOR

FOAM CHAMBER

OUTLET FLANGE

GASKETS FOAM CHAMBER

MODEL FCA

TANK SHELL SPLIT DEFLECTOR

MODEL SD

MOUNTING PAD SPLIT DEFLECTOR

ASSEMBLY

INLET FLANGE

STUD MOUNTING PAD

STORAGE TANK

NOTE:

Stud Mounting Pad with gasket & split deflector

are optional items. To be ordered separately.

TANK CUTOUT FOR MOUNTING OF SPLIT DEFLECTOR

FLANGE OUTLINE

FOAM CHAMBER SIZE CUTOUT SIZE

PCD

RØ INLET OUTLET

TYPE FLANGE FLANGE RØ PCD

HOLE

Ø’d’

NO OF

HOLES

*

SIZE SIZE

FCA 65 65 100 114 191 19 4

FCA 80 80 150 168 241 22 4

Ø'd' FCA 100 100 200 219 298 22 8

* BY INSTALLER

TYPICAL INSTALLATION OF FOAM CHAMBER WITH STUD FLANGED TANK NOZZLE AND SOLID DEFLECTOR

FOAM CHAMBER TANK NOZZLE

(BY OTHERS)

200

MODEL FCA

SOLID DEFLECTOR

* MODEL FD

*

*

150 150

STORAGE TANK

GLASS VAPOUR SEAL

WITH HOLDER (STANDARD SUPPLY)

*

* BY INSTALLER

NOTE:

1. Above dimensions are general guidelines only. The system designer can adopt the dimensions as per

NFPA/TAC/OISD or as per the governing rules & ordinance having local jurdiction.

2. Tank Nozzle nutbolts & gasket are optional to be ordered separately.

3. Split deflector Model SD and solid deflector Model FD is standard supply in carbon steel material and

optional in stainless steel.

Company Registration No. 5717368 • V.A.T No. 883908672 www.fireguard-uk.com

PRESSURE VS FLOW PERFORMANCE CHARACTERISTIC

FCA 80 & FCA - S80

FCA 65 & FCA - S65

FCA 100 & FCA - S100

Company Registration No. 5717368 • V.A.T No. 883908672 www.fireguard-uk.com

You might also like

- Foam Chamber: Model - Fca & Fca-SDocument6 pagesFoam Chamber: Model - Fca & Fca-SDHAVAL PANCHALNo ratings yet

- Foam Chamber Data SheetDocument6 pagesFoam Chamber Data Sheetadilmomin45No ratings yet

- Foam Chamber: Model - Fca & Fca-SDocument8 pagesFoam Chamber: Model - Fca & Fca-SkalaiNo ratings yet

- Foam Chamber Model F PDFDocument6 pagesFoam Chamber Model F PDFDylan RamasamyNo ratings yet

- Foam Chamber Model FC PDFDocument6 pagesFoam Chamber Model FC PDFFadhila Ahmad AnindriaNo ratings yet

- Foam Chamber Model - FCDocument6 pagesFoam Chamber Model - FCtez tezNo ratings yet

- Foam Chamber: Model: NF-FC SeriesDocument6 pagesFoam Chamber: Model: NF-FC SeriesJESUS HUAMANINo ratings yet

- Naffco NF-FC Series Foam ChamberDocument8 pagesNaffco NF-FC Series Foam ChamberAl Wahdani RambeNo ratings yet

- HD 254 Foam Chamer Model-FCADocument6 pagesHD 254 Foam Chamer Model-FCAktc8120No ratings yet

- NDD100 MBS 9SA Type 2 Foam Makers Rev EDocument4 pagesNDD100 MBS 9SA Type 2 Foam Makers Rev EAlejandro Enrique Fernandez Echezuría100% (1)

- NDD010 MCS Type B Foam ChambersDocument6 pagesNDD010 MCS Type B Foam ChambersAndri AjaNo ratings yet

- FIREGUARD Foam - Maker - Model - FMDocument7 pagesFIREGUARD Foam - Maker - Model - FMEdward Chan AcostaNo ratings yet

- Mcs Type B: Foam Maker & Foam ChamberDocument6 pagesMcs Type B: Foam Maker & Foam ChamberViant NurulitaNo ratings yet

- NDD010-MCS Type BDocument5 pagesNDD010-MCS Type BShariq KhanNo ratings yet

- HD National Foam - MCSDocument4 pagesHD National Foam - MCSJavier Hinojosa Garrido LeccaNo ratings yet

- FM010Document4 pagesFM010olinser bacelisNo ratings yet

- Foam Chamber F-85154Document4 pagesFoam Chamber F-85154Juan VillavicencioNo ratings yet

- Camara de Espuma ANSUL AFC 170 PDFDocument6 pagesCamara de Espuma ANSUL AFC 170 PDFfercho`sNo ratings yet

- 15 Foam MakerDocument8 pages15 Foam MakerMatthew BennettNo ratings yet

- Rim Seal Foam Pourer: Model - Rpa & Rpa-SDocument2 pagesRim Seal Foam Pourer: Model - Rpa & Rpa-SEdward Chan AcostaNo ratings yet

- Installation & Maintenance of Foam ChambersDocument5 pagesInstallation & Maintenance of Foam ChambersvivicastedoNo ratings yet

- Foam ChamberFCADocument6 pagesFoam ChamberFCAarachman297988No ratings yet

- Foam Chamber AnsulDocument4 pagesFoam Chamber AnsulenolNo ratings yet

- Foam Chamber PDFDocument6 pagesFoam Chamber PDFAinur RohmanNo ratings yet

- Dike protection systemsDocument6 pagesDike protection systemsSTICK EDUARDO PINCAY SANCHEZNo ratings yet

- Foam Chamber Model FDocument6 pagesFoam Chamber Model FMaulia SabrinaNo ratings yet

- 05 Foam Chambers Install. and MA2Document3 pages05 Foam Chambers Install. and MA2Matthew BennettNo ratings yet

- RFC Cafs CubeDocument2 pagesRFC Cafs CubeForum PompieriiNo ratings yet

- Foam Chamber ImenDocument5 pagesFoam Chamber Imenحمزة العريبيNo ratings yet

- CG 2015238 01 Foam ChambersDocument6 pagesCG 2015238 01 Foam ChambersDavid TjNo ratings yet

- HD - SPS-9 Foam MakerDocument4 pagesHD - SPS-9 Foam MakerJavier Hinojosa Garrido LeccaNo ratings yet

- Fixed Foam Equipment 8pp Brochure Pages 2017 LRDocument8 pagesFixed Foam Equipment 8pp Brochure Pages 2017 LRAmirhosein605334No ratings yet

- CG 2015238 01 Foam ChambersDocument2 pagesCG 2015238 01 Foam ChambersIskandar HasibuanNo ratings yet

- Deck Pumps For Ballast: The World... Our Passion Since 1955Document5 pagesDeck Pumps For Ballast: The World... Our Passion Since 1955edgarNo ratings yet

- Bladder Tank Proportioning System Pre-Piped: HD Fire Protect Pvt. Ltd. Technical DataDocument8 pagesBladder Tank Proportioning System Pre-Piped: HD Fire Protect Pvt. Ltd. Technical DataSadegh AhmadiNo ratings yet

- CG 2015148 00 - 2016Document2 pagesCG 2015148 00 - 2016Siles LimberdsNo ratings yet

- CG 2015193 01 B 1 SprinklersDocument2 pagesCG 2015193 01 B 1 SprinklersIskandar HasibuanNo ratings yet

- Winan Fire: Foam ChamberDocument6 pagesWinan Fire: Foam ChamberHassan SleemNo ratings yet

- Foam ChamberrDocument4 pagesFoam ChamberrFauziAidilSukmaNo ratings yet

- 5 - Dry Corrosion Test CabinetsDocument16 pages5 - Dry Corrosion Test CabinetsammarNo ratings yet

- 052tankfarm Fire ProteDocument6 pages052tankfarm Fire ProtesaikiranNo ratings yet

- Foam Bladder Tanks: Everything You Need to KnowDocument11 pagesFoam Bladder Tanks: Everything You Need to KnowVINOD PAULNo ratings yet

- FLR-30-FP/FLR-90-FP Rim Seal Foam Pourer: FeaturesDocument2 pagesFLR-30-FP/FLR-90-FP Rim Seal Foam Pourer: FeaturesMarcela DuckardtNo ratings yet

- Air Foam Chamber: Fire Fighting Equipment Data SheetDocument8 pagesAir Foam Chamber: Fire Fighting Equipment Data SheetMihir JhaNo ratings yet

- Ndd010-Mcs Type B - Rev.j Mcs33Document4 pagesNdd010-Mcs Type B - Rev.j Mcs33edgarpatoNo ratings yet

- 07 Atmospheric Foam Concentrate Storage TanksDocument4 pages07 Atmospheric Foam Concentrate Storage TanksIskandar HasibuanNo ratings yet

- Viron Vvs Series Ver Ti Cal ScrubberDocument28 pagesViron Vvs Series Ver Ti Cal ScrubberИван ОхотаNo ratings yet

- Bladder Tank Proportioning SystemDocument8 pagesBladder Tank Proportioning SystemarbindNo ratings yet

- Bladder Tank Proportioning System Pre-Piped: HD Fire Protect Pvt. Ltd. Technical DataDocument8 pagesBladder Tank Proportioning System Pre-Piped: HD Fire Protect Pvt. Ltd. Technical DataarbindNo ratings yet

- Ansul F-85154Document2 pagesAnsul F-85154jlvega18No ratings yet

- Bladder Tanks & Foam Chambers CompressedDocument2 pagesBladder Tanks & Foam Chambers Compressedมธุรส สังข์วรรณะNo ratings yet

- FLOWMAX CL Variable Range ProportionerDocument4 pagesFLOWMAX CL Variable Range ProportionerAnonymous S9qBDVkyNo ratings yet

- POLY SKID EXTINGUISHING SYSTEM SL100-300Document2 pagesPOLY SKID EXTINGUISHING SYSTEM SL100-300Dante FloresNo ratings yet

- Gladiator: MID-RANGE 500, 750, 1000 OR 1250 GPM Foam/Water NozzleDocument2 pagesGladiator: MID-RANGE 500, 750, 1000 OR 1250 GPM Foam/Water NozzleJavier Hinojosa Garrido LeccaNo ratings yet

- BLADDER TANK PROPORTIONING SYSTEMDocument12 pagesBLADDER TANK PROPORTIONING SYSTEMakshay MahajanNo ratings yet

- High Back-Pressure Foam Makers: Data/SpecificationsDocument4 pagesHigh Back-Pressure Foam Makers: Data/SpecificationsRIGOBERTO PONCENo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Risk project management analysisDocument10 pagesRisk project management analysisEdward Chan AcostaNo ratings yet

- M1108-M1155 Standard SizesDocument2 pagesM1108-M1155 Standard SizesEdward Chan AcostaNo ratings yet

- F43 459 Venturi Type Flow Meter SubmittalDocument2 pagesF43 459 Venturi Type Flow Meter SubmittalEdward Chan AcostaNo ratings yet

- GVI Brochure - PDF 1Document11 pagesGVI Brochure - PDF 1Edward Chan AcostaNo ratings yet

- Method Statement For Fire ProtectionDocument34 pagesMethod Statement For Fire ProtectionEdward Chan AcostaNo ratings yet

- FirePreventionPlan 1Document16 pagesFirePreventionPlan 1Mohammad MasihullahNo ratings yet

- Glastonbury House Fire Safety Works PEPDocument25 pagesGlastonbury House Fire Safety Works PEPEdward Chan AcostaNo ratings yet

- S - F, - r250d: DescriptionDocument2 pagesS - F, - r250d: DescriptionEdward Chan AcostaNo ratings yet

- Fire Safety Management AND Fire Emergency Plan FOR (Premises) (Address) (Address) (Post Code)Document26 pagesFire Safety Management AND Fire Emergency Plan FOR (Premises) (Address) (Address) (Post Code)RonyWabia100% (2)

- Vertical bladder tank foam systemDocument4 pagesVertical bladder tank foam systemvinoj chandranNo ratings yet

- F43 459 Venturi Type Flow Meter SubmittalDocument2 pagesF43 459 Venturi Type Flow Meter SubmittalEdward Chan AcostaNo ratings yet

- Alarm Check Valve GLOBEDocument2 pagesAlarm Check Valve GLOBEEdward Chan AcostaNo ratings yet

- Foam Concentrate Control Valve Technical DataDocument2 pagesFoam Concentrate Control Valve Technical DataSaMi ChowdhuryNo ratings yet

- F43 459 Venturi Type Flow Meter SubmittalDocument2 pagesF43 459 Venturi Type Flow Meter SubmittalEdward Chan AcostaNo ratings yet

- FIREGUARD Foam - DeflectorDocument1 pageFIREGUARD Foam - DeflectorEdward Chan AcostaNo ratings yet

- FIREGUARD Foam - Maker - Model - FMDocument7 pagesFIREGUARD Foam - Maker - Model - FMEdward Chan AcostaNo ratings yet

- Stainless Steel Pipe SpecificationsDocument3 pagesStainless Steel Pipe SpecificationsEdward Chan AcostaNo ratings yet

- FIREGUARD Foam Branch PipeDocument1 pageFIREGUARD Foam Branch PipeEdward Chan AcostaNo ratings yet

- Monitor Branch Pipe: Technical DataDocument2 pagesMonitor Branch Pipe: Technical DataEdward Chan AcostaNo ratings yet

- Victaulic Alarm Check ValveDocument14 pagesVictaulic Alarm Check ValveEdward Chan AcostaNo ratings yet

- Rim Seal Foam Pourer: Model - Rpa & Rpa-SDocument2 pagesRim Seal Foam Pourer: Model - Rpa & Rpa-SEdward Chan AcostaNo ratings yet

- Catalogue Fire 0163ENDocument52 pagesCatalogue Fire 0163ENDanny M Hurtado TaypeNo ratings yet

- Brochure - Fire Protection US STDDocument6 pagesBrochure - Fire Protection US STDWash 2CleanNo ratings yet

- Waterflow Detector WFD Series - Detector de FujoDocument2 pagesWaterflow Detector WFD Series - Detector de Fujojhoger2012No ratings yet

- Catalogue Fire 0163ENDocument52 pagesCatalogue Fire 0163ENDanny M Hurtado TaypeNo ratings yet

- Viking Alarm Check Valve J-1Document7 pagesViking Alarm Check Valve J-1melgarcia829No ratings yet

- Supremepipe ProfileDocument20 pagesSupremepipe ProfileEdward Chan AcostaNo ratings yet

- Fd-Fan Blade FailureDocument8 pagesFd-Fan Blade FailurePRAMOD KUMAR NANDANo ratings yet

- Microreaction TechnologyDocument585 pagesMicroreaction TechnologywassermeloneNo ratings yet

- All Reso MT Paper & SolDocument401 pagesAll Reso MT Paper & SolAbhinav singhNo ratings yet

- Tablets of Potassium IodideDocument2 pagesTablets of Potassium IodideJai MurugeshNo ratings yet

- Arc Welding Single V Groove JointDocument15 pagesArc Welding Single V Groove Joint41 TANUJ SHANKARNo ratings yet

- ASTM A960-A960M-16aDocument11 pagesASTM A960-A960M-16aGabriel Perez CruzNo ratings yet

- Conductor Parameters-SI UnitsDocument17 pagesConductor Parameters-SI UnitsMunesu Innocent Dizamuhupe0% (1)

- MSDS-R170 Hangzhou Hongyan PigmentsDocument3 pagesMSDS-R170 Hangzhou Hongyan PigmentsJose E BatistaNo ratings yet

- Mass Transfer 16CE2004 - HandoutDocument80 pagesMass Transfer 16CE2004 - HandoutjAYNo ratings yet

- Reversible ReactionsDocument10 pagesReversible ReactionsHamza KhalidNo ratings yet

- Instruction Manual: pH/mV/°C/°F Bench MeterDocument18 pagesInstruction Manual: pH/mV/°C/°F Bench MeterAngeles SuarezNo ratings yet

- Automotive Air Conditioning: A Compact Guide For The WorkshopDocument84 pagesAutomotive Air Conditioning: A Compact Guide For The WorkshopMarcos Paulo Rocha MirandaNo ratings yet

- Trace Analysis of Acids and Bases by ConDocument7 pagesTrace Analysis of Acids and Bases by Conhr maNo ratings yet

- MQP Science Set 7 EnglishDocument8 pagesMQP Science Set 7 EnglishenigmavjNo ratings yet

- Tyrosinase MechanismDocument22 pagesTyrosinase MechanismEti ApriyantiNo ratings yet

- 1 21 Projects Including All HeadingsDocument98 pages1 21 Projects Including All HeadingsAarti MehraNo ratings yet

- Sample Chemical Engineering Student Team Powerpoint For AnalysisDocument25 pagesSample Chemical Engineering Student Team Powerpoint For Analysismkbm_5543No ratings yet

- Portable Centrifuge ManualDocument21 pagesPortable Centrifuge ManualZamir Danilo Morera ForeroNo ratings yet

- 2017 DrillbitsDocument40 pages2017 DrillbitsAdnane Bensmaine88% (8)

- Shortex CutterDocument2 pagesShortex CutterMuhammad SafdarNo ratings yet

- SLG Chem 3 LG 5.4 pKa and the Isoelectric Point pIDocument5 pagesSLG Chem 3 LG 5.4 pKa and the Isoelectric Point pIfranzachilleslindayagNo ratings yet

- Bhutan Higher Secondary Education Certificate Examination December2014 Marking Scheme - ChemistryDocument3 pagesBhutan Higher Secondary Education Certificate Examination December2014 Marking Scheme - ChemistryTsheyang LhazomNo ratings yet

- 28 ElectroplatingElectronicsDocument100 pages28 ElectroplatingElectronicsLaboratorium KIESOWNo ratings yet

- 1 ChemistryDocument3 pages1 ChemistryHabib SimbanNo ratings yet

- Water WorksheetDocument2 pagesWater WorksheetJohn OsborneNo ratings yet

- HOL Melting Point Lab ReportDocument32 pagesHOL Melting Point Lab ReportKyle Warfield100% (8)

- Technical Catalogue VSF Iec Atex en Rev0 2017 PDFDocument172 pagesTechnical Catalogue VSF Iec Atex en Rev0 2017 PDFshivv230No ratings yet

- FrosiopdfDocument568 pagesFrosiopdfAhmed MohamedNo ratings yet

- Chemsheets As 1005 Ionisation EnergiesDocument2 pagesChemsheets As 1005 Ionisation Energiesangel ranaNo ratings yet

- Waves and Rays Part IIDocument6 pagesWaves and Rays Part IIapi-292408320No ratings yet