Professional Documents

Culture Documents

Unesco - Eolss Sample Chapters: Food Rheology

Unesco - Eolss Sample Chapters: Food Rheology

Uploaded by

AmmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Unesco - Eolss Sample Chapters: Food Rheology

Unesco - Eolss Sample Chapters: Food Rheology

Uploaded by

AmmanCopyright:

Available Formats

RHEOLOGY – Vol.

II - Food Rheology - Mats Stading

FOOD RHEOLOGY

Mats Stading

SIK – The Swedish Institute for Food and Biotechnology and Chalmers University of

Technology, Gothenburg, Sweden

Keywords: Food, biopolymers, colloids, foam, emulsion, suspension, processing,

rheometry, gel .

Contents

1. Introduction

2. Food rheology vs. food texture

TE SS

3. Rheology of food dispersions

S

4. Food polymers and gels

5. Foams and dough rheology

R

AP L

6. Processing and food rheology

7. Experimental considerations

H O

8. Conclusions

Glossary

C E

Bibliography

Biographical Sketch

E O–

Summary

Food includes a wide range of biological materials with diverse rheological character.

PL C

They are mostly a mixture of different structures previously treated in this book:

M ES

emulsions, suspensions, foams, gels, solutions and melts. This means that the food

rheologist deals with complex fluids which often are substantially inhomogeneous. The

variability in the biological food systems is large in contrast to synthetic, well

characterized systems, and is an effect of cultivation conditions, species variations,

SA N

processing and recipe. Nevertheless, rheological characterization is an important tool

U

for development, optimization and processing of foods.

Food rheology to a large extent determines food texture. The perception of the food on

touching or in the mouth depends not only on rheological flow properties, but also on

solid particles, fracture moisture release and absorption etc. which is not rheology. Food

processing is substantially influenced by the rheology of the raw materials. Heat

treatment is a common operation where the rheological properties influences heat

transfer as well as residence times in addition to the energy required for fluid transport.

The rheological properties are also important for the mass transfer involved in drying,

fermentation and separation operations.

Foods behave much like the corresponding non-food, model systems previously

discussed in this book, but with a few exceptions, e.g. food dispersion particles are

mostly non-spherical, flexible, interacting and have a broad size distribution. The

continuous medium usually contains several solutes and is often non-Newtonian. Gels

©Encyclopedia of Life Support Systems (EOLSS)

RHEOLOGY – Vol. II - Food Rheology - Mats Stading

are commonly formed from associating food polymers with physical crosslinking rather

than by permanent bonds.

Fluid and viscoelastic foods often consist of weak structures since disintegration in the

mouth is desirable. This also means that special attention has to be paid in food

rheometry. The sample handling is especially important not to destroy the delicate

structures before the actual measurement. Wall slip is another common feature,

especially for fatty foods and food dispersions.

1. Introduction

Food rheology covers a wide range of fluids and semi-solid materials from dilute juices,

through gels and emulsions to solid cheese and breads. Food is familiar to all and

TE SS

everybody can relate to the texture or consistency and thus get a feel for its rheological

properties. Unfortunately familiarity sometimes also leads the notion that foods relate

S

more to cooking than to science. When surveying the huge range of different

R

rheological behaviors of foods one realizes quite the opposite – the science of foods is

AP L

rather challenging. Most foods are complex, heterogeneous systems difficult to

H O

characterize experimentally and to describe theoretically. They often consist of phase

separated mixtures of polymers, mixed colloid and polymers systems or cellular

C E

biological structures. The behavior of food obeys the laws of physics but often

empirical descriptions are used rather than physical models due to the complexity.

E O–

Rheology is important for many aspects of foods:

• Physical characterization of fluid and semi-solid foods

PL C

• Process engineering and process design

• Development of new products

M ES

• Quality control during production and of final products

• Instrumental evaluation of sensory properties

• Indirect understanding of food microstructure

SA N

U

The physical conditions for food rheology generally are limited to atmospheric pressure,

temperatures approximately ranging from -20°C to 150°C, observations times from

fractions of a second to a shelf life of a year. There are obviously exceptions but the

general composition of a food includes water and biopolymers which limit the heat

treatment and even modern processing techniques do not significantly differ from the

heat treatments used for thousands of years. There are exciting new processing

techniques entering the market such as high pressure treatment with pressure

approaching 1000 MPa which clearly goes beyond conventional cooking. The majority

of the flow conditions for foods in processing and consumption involve laminar flow,

mostly due to the high level of viscosity of foods. Again, there are exceptions e.g.

during processing of low-viscosity fluids such as juices, milk and soups where turbulent

flow dominates.

Despite the vastly different texture occurring in foods they can be treated in terms of the

previously described fluids in this book: emulsions, suspensions, foams, gels, solutions

©Encyclopedia of Life Support Systems (EOLSS)

RHEOLOGY – Vol. II - Food Rheology - Mats Stading

and melts, or mixtures thereof. Foods which are sufficiently described as Hookean

solids, such as crackers, dry extruded snacks, dry pasta and hard cheese, will not be

dealt with here. Such elastic foods are sufficiently described by their fracture properties

and by fracture mechanics.

2. Food Rheology vs. Food Texture

Food rheology is not equal to food texture but there is considerable overlap. The

perception of the bolus of a chewed food in the mouth depends on the flow of the fluid

and the disintegrated semi-solid food i.e. the rheology of the food. The perception also

depends on the release or absorption of moisture and oil and grinding and fracture of

solid particles, i.e. the texture. Similarly, the perception of a food item squeezed

between the fingers depends on several factors – rheology, Hookean elasticity, fracture

TE SS

mechanics and tribology, all related to the food in question. Rheological properties are

related to perceived texture but are not fully describing the picture.

S

R

The International Standards Organization (ISO) defines food texture in their standard

AP L

for vocabulary for sensory analysis (5492/3) as “all the rheological and structure

H O

(geometrical and surface) attributes of a food product perceptible by means of

mechanical, tactile, and, where appropriate, visual and auditory receptors” which further

C E

shows that rheology is an integral part of food texture. When a food is consumed

different textural characteristics are perceived during the mastication cycle, from the

E O–

first bite to the final swallow. During the dynamic process of mastication food is

crushed and diluted with saliva and its temperature is brought to body temperature. The

rheological properties of the food change due to temperature, dilution, disintegration

and the action of enzymes in the saliva. The stresses acting on the bolus are

PL C

compressive during chewing whereas shear stresses dominate during the flow in the

mouth. The flow is predominantly extensional when the bolus is squeezed to the back of

M ES

the mouth between the tongue and the pallet and there is a considerable extensional

flow component during swallowing.

SA N

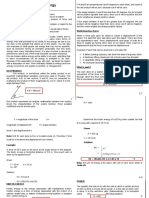

State Approximate Process Location Implement

particle mass [g]

U

Whole cookie 20 Biting off Mouth Incisors

Mouth size 5 Grinding, Mouth Molars

portion crushing

Swallowable 0.01 Biochemical Stomach, Acid,

paste (bolus) attach intestine enzymes

Hexose sugar 3 10-22 Absorption Intestines –

molecule

Table 1. Steps in the comminution of a large cookie before absorption by the body.

Adapted from Bourne, M.C. (1982) Food texture and viscosity. Consept and

measurement, Academic Press, New York

During mastication the food is ground into a fine state and diluted by saliva as a

preparation for digestion starting in the stomach. A portion of mouth size is about 5 g

which is reduced by two to three orders of magnitude before swallowing. The size is

©Encyclopedia of Life Support Systems (EOLSS)

RHEOLOGY – Vol. II - Food Rheology - Mats Stading

further reduced in the stomach by another 20 orders of magnitude to start the

biochemical processes of the digestion system. If the food is not reduced to molecular

dimensions it will not be absorbed, but excreted. The size reduction is exemplified in

Table 1 and clearly demonstrates the large range of particle sizes during mastication.

The particle size directly affects the rheological properties of the bolus in the mouth and

during swallowing.

3. Rheology of Food Dispersions

Common foods such as mayonnaise, dressings, tomato paste and baby food are

dispersions, more precisely emulsions or suspensions. In addition, foods such as

chocolate and marmalades are suspensions during processing, before they solidify to

form the final product. The rheological behavior of dispersions can be described by

TE SS

parameters such as particle size distribution, particle concentration and inter-particle

interactions (see Suspensions, emulsions and foams). Suspensions consist of solid

S

particles in a fluid medium whereas emulsions consist of liquid droplets in a liquid

R

medium, i.e. deformable particles. The common descriptor of dispersion systems is the

AP L

volume fraction of particles, Φ , which varies from zero to the maximum packaging

H O

fraction Φ m . The maximum packaging fraction depends on the arrangement of the

particles as well as the particle size distribution and is for foods mostly Φ < 0.5 .

C E

3.1. Suspensions

E O–

Many food dispersions are plant based such as vegetable pastes and juices. Most, but

not all of them display shear-thinning viscous flow behavior. Some also display a yield

stress under specific flow conditions. The rheology of suspensions has previously been

PL C

described (see Suspensions, emulsions and foams) for non-food suspensions but food

M ES

suspensions differ from non-food suspensions in several ways:

• The particles are mostly non-spherical, flexible and have broad multi-modal size

distributions

SA N

• The particles in food suspensions are hydrated and show significant inter-particle

U

interaction affecting the flow behavior.

• The continuous medium usually contains sugars, organic acids, salts and

biopolymers, and sometimes display non-Newtonian behavior.

Plant food suspensions serve as a good example of the complex nature of food

suspensions and will be elucidated in more detail. The above mentioned characteristics

all apply and in addition the processing adds to the complexity by heat induced changes

of the constituents and formation of complex particle sizes and size distributions.

Viscous flow parameters and the concentration of solids are presented in Table 2 for a

range of plant based suspensions.

©Encyclopedia of Life Support Systems (EOLSS)

RHEOLOGY – Vol. II - Food Rheology - Mats Stading

Product % T [°C] n K σyield α β

solids [Nsn/m2] [Pa]

Apple sauce 87 – 99 25 0.15 – 7.4 – 77 18 – 46

0.40

Apple 2.8 10- 7.5

15

concentrate

Apricot 69 – 72 4.5 – 0.28 – 3.5 – 46

puree 60 0.46

Banana 17.7 22 0.28 12

puree

Blackcurrant 35 – 64 5 – 60 1.0 2.4 – 500 2.2 10-9 6.2 –

juice – 3.5

8.9 10-6

TE SS

Grape juice 55 – 68 -10 –

S

40

Lemon 9.5 – 62 0.72 – 1 0.43 – 1.7 2.1

R

AP L

products

Orange juice 59-65 30 0.30 – 0.26 – 0.49 –

H O

concentrate 0.40 0.45 0.78

C E

Tomato 81 2.4

juice

Tomato 0.04 800 0.03 2.4

E O–

paste

Table 2. Viscous flow parameters and concentration of solids for plant based

suspensions including the constants α and β from eq. 1. Data from Gallegos, C., Franco,

PL C

J. and Partal, P. (2004) “Rheology of food dispersions”, Rheology Reviews, 19-65.

M ES

Tomato based suspensions are industrial commodities in the food industry and exist as

paste, puree, concentrate and sauce. They are well studied due to being a commercial

SA N

commodity. The skin and seeds are removed during processing and the amount of solids

is increased to a varying degree depending on the type of product. Enzymes affecting

U

pectin are inactivated by heat, also to a varying degree depending on product type. The

products pass through several sieves during processing which determine the particle

size as well as the particle shape.

Power Law behavior is usually sufficient for describing the shear thinning of these

suspensions in industrial flow and the consistency index has been correlated to the

solids content in several plant based suspensions by

K = α (total solids) β (1)

where α and β are constants presented for a selected plant based suspensions in

Table 2.

Yield stress models have also been used to describe the flow of plant based suspensions

under specific flow conditions. The “ketchup effect” occurring when attempting to

©Encyclopedia of Life Support Systems (EOLSS)

RHEOLOGY – Vol. II - Food Rheology - Mats Stading

extract ketchup from a bottle is well known. At these flow conditions it is suitable to

use a yield stress. Below the yield stress the ketchup remains in the bottle and does not

flow out until the yield stress is exceeded. Herschel-Bulkley and variants of the Casson

models (see Non-Newtonian fluids) have been used to describe the flow of plant based

suspensions including the yield behavior.

Apart from flow processing parameters, the viscosity of the suspensions also depends

on variety, cultivation conditions and heating, as it indeed does for many other foods. It

is therefore difficult to present general facts on these systems. An example of this is the

effect of particle size on suspension viscosity. Small particles are more affected than

large ones by the ever present Brownian motion caused by the thermal energy in the

system. When shearing a suspension the particles still line up in the direction of flow

when hydrodynamic forces are large enough to dominate over Brownian motion. Since

TE SS

small particles are more sensitive to Brownian motion their suspension will retain a

high viscosity to higher shear rates compared to a large particle suspension, thus

S

displaying a higher apparent viscosity at a specific shear rate. This is not necessarily the

R

case for plant based suspensions which in many cases have been reported to display

AP L

higher viscosity for large particle suspensions than for small particle suspensions. The

H O

particle size was set by the screen size used in the preparation which also is responsible

for the unexpected behavior. The screen does not only affect particle size but also

C E

particle shape. Elongated, more rod-like particles have higher resistance to flow thus

giving higher apparent viscosity. Food systems are complex and great care have to be

E O–

taken when attempting to explain their rheological behavior in terms of model system

behavior.

Tomato pastes have been shown to have a mechanical spectrum similar to that found for

PL C

other concentrated suspensions. They display G′ substantially higher than G′′ at ω in

the range 10-1 – 102 rad/s with a tendency towards a G ′ − G ′′ crossover at ω <10-2 rad/s

M ES

and have therefore been classified as “weak gels”. This further emphasizes the inter-

particle interactions responsible for the unexpected suspension flow behavior as well as

the observed yield stress.

SA N

3.2. Emulsions

U

Food emulsions are not too dissimilar compared to dispersions with equal parameters

(volume fraction particles/droplets, size distribution, interaction, continues medium

rheology). The dispersed droplets are generally more mobile and fluid than

corresponding dispersed particles thus giving lower viscosity. However, with small

droplet size and strong adsorption layers of emulsifier the droplets can actually be very

rigid and such an emulsion would behave similar to a dispersion. Emulsions also lack a

well defined close packing limit since the droplets can deform. Indeed, most food

emulsions are highly concentrated resulting in droplet deformation and flocculation

giving non-Newtonian behavior of the emulsion. For example mayonnaise, which is an

oil-in-water emulsion may well exceed a packing fraction of 0.8. For increasingly

higher packing fraction the emulsion will resemble a filled foam rather than an

emulsion.

©Encyclopedia of Life Support Systems (EOLSS)

RHEOLOGY – Vol. II - Food Rheology - Mats Stading

-

-

TO ACCESS ALL THE 24 PAGES OF THIS CHAPTER,

Visit: http://www.eolss.net/Eolss-sampleAllChapter.aspx

Bibliography

Almdal, K., J. Dyre, J, Hvidt, S. and Kramer, O. (1993). "Towards a Phenomenological Definition of the

Term 'Gel'." Polymer Gels and Networks 1, 5-17. [A rheological definition of a gel]

Barnes, H.A. (2002) “Viscosity”, Cambrian Printers, Aberystwyth, Wales. [A comprehensive overview

TE SS

of measurement and interpretation of viscosity results including both scientific and industrial methods]

S

Barnes, H.A., Hutton, J.F. and Walters, K. (1989) “An introduction to rheology”, Elsevier Amsterdam,

R

ISBN 0-444-87140-3. [A suitable starting point for beginners in rheology as an introduction and

AP L

overview of all fields of rheology].

H O

Belton, P.S. (2003) “The molecular basis of dough rheology” in Bread making: Improving quality,

ed. S.P. Cauvain, CRC Press, Boca Raton, USA. [Molecular explanation of wheat dough viscoelasticity]

C E

Dobraszczyk, B.J. (2004) “The physics of baking: rheological and polymer molecular structure–function

relationships in breadmaking”, J. Non-Newtonian Fluid Mech., 124, 61–69. [Rheological parameters

E O–

important for breadmaking.]

Dobraszczyk, B.J. and Morgenstern, M.P. (2003) “Rheology and the breadmaking process”, J. Cereal

Sci., 38, 229–245. [A broad and clear review of the rheology involved in the different steps of

breadmaking.]

PL C

Fischer, D.T., Clayton, S.A., Boger, D.V. and Scales, P.J. (2007) “The bucket rheometer for shear stress-

shear rate measurement of industrial suspensions”, J. Rheol. 51, 821-831. [Methodology for viscosity

M ES

measurements using a vane in an infinite medium.]

Gallegos, C., Franco, J.M. and Partal, P. (2004) “Rheology of food dispersions”, Rheology Reviews, 19-

55. [Review of rheological properties of food emulsions and suspensions, especially egg yolk stabilized

emulsions and tomato dispersions.]

SA N

Macosco, C. W. (1994) “Rheology Principles, measurements and applications", VCH Publishers, New

U

York, ISBN 1-56081-579-5 [Thorough text book explaining rheology from a fluid mechanics approach]

Mezger, T. (2006) “The Rheology handbook”, Vincentz Network, Hannover, ISBN 978 3878 70174 3

[An engineering textbook on rheology with detailed advice for experimental rheology.]

Morris, E.R. (1995) “Polysaccharide rheology and in-mouth perception”, pp 517-546 in Food

polysaccharides and their applications, ed. Stephen, A.M., Marcel Dekker, New York. [An overview of

biopolymer gels and solutions, especially polysaccharides.]

Phillips, G.O. and Williams, P.A. (2000) Handbook of hydrocolloids, Woodhead Publishing, Cambridge.

[Physical and chemical properties of hydrocolloids.]

Steffe, J.F. and Morgen, R.G. (1986) “Pipeline design and pump selection for non-Newtonian fluid

foods”, Food Technol., 40, (12) 78-85. [Processing considerations for fluid foods]

Welti-Chanes, J., Barbosa-Cánovas, G.V. and Aguilera, J.M. (2002) Engineering and Food for the 21st

Century, CRC Press, Boca Raton, USA. [This book contains ten chapters on food rheology including e.g.

food texture by M.C. Bourne, processing by J. Vélez-Ruíz, suspensions by Carreau et al. and mixing by

E. Brito-De La Fuente.]

Wiklund, J., and Stading, M. (2007), “Application of in-line ultrasound Doppler based UVP-PD

©Encyclopedia of Life Support Systems (EOLSS)

RHEOLOGY – Vol. II - Food Rheology - Mats Stading

rheometry method to concentrated model and industrial suspensions”, Flow Measurement and

Instrumentation, in press. [The presented UVP-PD method gives the viscous properties of

inhomogeneous, opaque, large particle fluids in-line in real time]

Winter, H. H. (1987). "Can the gel point of a cross-linking polymer be detected by the G' – G''

crossover?" Polym. Eng. Sci. 27, 1698-1702. [Correlation between different ways of determining the gel

point.]

Biographical Sketch

Mats Stading of Gothenburg, Sweden is an engineer by basic training with an MSc in Engineering

Physics from Chalmers University of Technology, Gothenburg. Mats Stading also had a PhD in Food

Science with a thesis entitled “Rheological Behaviour of Biopolymer Gels in Relation to Structure” at

Chalmers University of Technology in 1993.

After a Post-doc at MIT in Boston, USA working in the area of tissue engineering he returned to a

position as assistant professor in Food Science at Chalmers. He was then associate professor in polymer

TE SS

technology at the same university before joining SIK – The Swedish Institute for Food and

S

Biotechnology in Gothenburg in 2000. After a shorter period as visiting professor at MIT he 2003 was

appointed Adjunct Professor at Chalmers in Materials Science. He is presently also Manager of the

R

Material Design group at SIK. He has numerous peer reviewed papers and conference proceedings and

AP L

has supervised a number of MSc and PhD students. After moving from physics to food rheology he now

H O

combines materials science and rheology applied to foods and biopolymer materials.

Professor Stading has been active in the Nordic Rheology Society since its funding in 1992 and is

C E

presently the Nordic representative in the European Society of Rheology and in the International

Committee on Rheology.

E O–

PL C

M ES

SA N

U

©Encyclopedia of Life Support Systems (EOLSS)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- College Physics 10Th Global Edition Full ChapterDocument41 pagesCollege Physics 10Th Global Edition Full Chapterwilliam.kellar832100% (22)

- 15MA102 Advanced Calculus and Complex Analysis PDFDocument2 pages15MA102 Advanced Calculus and Complex Analysis PDFArjun AzhagiriNo ratings yet

- Chapter 2-1 Motion in One DimensionDocument38 pagesChapter 2-1 Motion in One Dimensionمحمد يعقوبNo ratings yet

- Representation Theory, Complex Analysis, and Integral Geometry Bernhard Krötz, Omer Offen, Eitan Sayag PDFDocument286 pagesRepresentation Theory, Complex Analysis, and Integral Geometry Bernhard Krötz, Omer Offen, Eitan Sayag PDFLuix70No ratings yet

- Which One of The Following Statement Is NOT True About PhotoelectricDocument11 pagesWhich One of The Following Statement Is NOT True About PhotoelectricVidhi ShekhawatNo ratings yet

- States of Matter Questions For Test PaperDocument5 pagesStates of Matter Questions For Test PaperNevin ShajiNo ratings yet

- Dak 13003 Formatted Final ExamDocument7 pagesDak 13003 Formatted Final ExamMuiz UdinNo ratings yet

- Difference Between Space Frame and TrussDocument6 pagesDifference Between Space Frame and TrussKhalida ParveenNo ratings yet

- Standard Practices For General Techniques of Infrared Quantitative AnalysisDocument18 pagesStandard Practices For General Techniques of Infrared Quantitative AnalysisviverefeliceNo ratings yet

- GC1 - Q2 - Week 1Document10 pagesGC1 - Q2 - Week 1Inol DuqueNo ratings yet

- Crystal Momentum - WikipediaDocument4 pagesCrystal Momentum - WikipediaAboubakr AtefNo ratings yet

- HW6Document4 pagesHW6callum174753No ratings yet

- Synopsis of MadihaDocument14 pagesSynopsis of MadihaMuhammad RizwanNo ratings yet

- ConfTokyo2014Mini Particle TracingDocument40 pagesConfTokyo2014Mini Particle TracingthynameisraymondNo ratings yet

- CHG 503 Tutorial 2 - Boundary Layer - 220129 - 215132Document3 pagesCHG 503 Tutorial 2 - Boundary Layer - 220129 - 215132Todeyon ViavoNo ratings yet

- Basic Concepts of Heat TransferDocument3 pagesBasic Concepts of Heat TransferOsama Hasan100% (3)

- Sixth Semester Notes-1 PDFDocument85 pagesSixth Semester Notes-1 PDFJavidNo ratings yet

- Atomic Structure Jee Main SelectedDocument5 pagesAtomic Structure Jee Main SelectedfopjfvmhdNo ratings yet

- Module1 - Set 1bDocument5 pagesModule1 - Set 1bindhubalab200413chNo ratings yet

- A Hermetic On-Cryostat Helium Source For Low Temperature ExperimentsDocument5 pagesA Hermetic On-Cryostat Helium Source For Low Temperature ExperimentsadsdasdassadsadNo ratings yet

- NPSH Made Simple For Metering PumpsDocument7 pagesNPSH Made Simple For Metering PumpspietroNo ratings yet

- Vesselin Petkov - Seven Fundamental Concepts in Spacetime PhysicsDocument94 pagesVesselin Petkov - Seven Fundamental Concepts in Spacetime PhysicsJuan Felipe BravoNo ratings yet

- A Review On Gravity Flow of Free-Flowing Granular Solids in Silos - BasicsDocument25 pagesA Review On Gravity Flow of Free-Flowing Granular Solids in Silos - BasicsElkyn BohórquezNo ratings yet

- Tor PDFDocument45 pagesTor PDFKartik PatilNo ratings yet

- Work, Energy and Energy Conservation: Learning CompetenciesDocument4 pagesWork, Energy and Energy Conservation: Learning CompetenciesNathalie SerafinNo ratings yet

- GRADE 9-SCIENCE Modules 1-9 211 PagesDocument211 pagesGRADE 9-SCIENCE Modules 1-9 211 PagesVince PatarayNo ratings yet

- Medical Physis CareersDocument93 pagesMedical Physis CareersShakeel Ahmad KasuriNo ratings yet

- Fields and Constants in The Theory of GRDocument146 pagesFields and Constants in The Theory of GRaliakouNo ratings yet

- Big-Bang Cosmology: Hitoshi Murayama 129A F2002 SemesterDocument66 pagesBig-Bang Cosmology: Hitoshi Murayama 129A F2002 Semesteralvaro ramirez ortizNo ratings yet

- MSC Physics Part-I - Part-IIDocument16 pagesMSC Physics Part-I - Part-IIkumaradarshx321No ratings yet