Professional Documents

Culture Documents

HPGR - H P G R: Jkmetlab

Uploaded by

Dirceu ValadaresOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HPGR - H P G R: Jkmetlab

Uploaded by

Dirceu ValadaresCopyright:

Available Formats

JKMetLab HPGR

JKMetLab

hpgr - High Pressure Grinding Rolls

High Pressure Grinding Rolls (HPGR) are increasingly becoming a part of hard

rock processing due to their energy efficiency, ability to induce micro-cracks and

preferential liberation, coupled with high throughput and high reduction ratio.

HPGR Testing Equipment

High Pressure Grinding Rolls tests can be carried out

by JKTech. The tests are conducted at the JKTech pilot

plant using a laboratory-scale Krupp Polysius machine

(pictured, right).

Also visible is the feed chute/hopper (of about 80 kg

capacity), that is used to maintain a constant feed

rate into to the HPGR unit.

The unit is fitted with profiled liners, which are shown

below.

The rolls on this unit are 70 mm wide and have a

diameter of 300 mm. Each is independently driven by

a separate motor and the design of the unit allows the

user to choose from two fixed speed settings.

This translates to a choice between 0.33 m/s and 0.67

m/s for the roll perimeter speed. One of the rolls has

its axis of rotation fixed while the other roll is mounted

on blocks and is free to move along tracks aligned at

right angles to its rotation axis.

Force is applied to this roll along the direction of the

tracks through pistons driven by the unit’s hydraulic

system.

This force translates into a pressure that is applied to

the feed material by the rolls. Pneumatic accumulators

containing nitrogen gas are provided to act as shock

absorbers.

The hydraulic system thus tends to act as a spring, the

characteristics of which are determined by the initial

gap setting, the initial nitrogen gas pressure and the

initial hydraulic oil pressure.

The combination of these machine settings determines

the non-linear stiffness response of the spring.

JKTech Pty Ltd

Isles Road, Indooroopilly, QLD 4068, AUSTRALIA Delivering world class solutions to

Telephone: +61 7 3365 5842 Facsimile: +61 7 3365 5900 the minerals industry

info@jktech.com.au | www.jktech.com.au

Metallurgical Laboratory Services

Types of Testing Offered:

Type A: Ore energy response to HPGR

In this case a minimum of six tests is normally carried

out to achieve an effective characterization of an ore

under different HPGR operating pressures. The best

comminution to energy response is targeted during

this testwork. The specific energy input is usually in

the range 1-4 kWh/t, which corresponds to a specific

force of 2-6 N/mm2.

Type B: Ore variability to response to HPGR

Ore variability tests are carried out on as many ore

types as can be provided, to test the relative response

of the ore to the same HPGR process settings. Under

these circumstances, a pre-selected or the optimum

test conditions are chosen, and kept constant for the

remaining tests.

Test Methods

When samples arrive at JKTech, they are crushed to

pass 9.5 mm as a standard (or less if requested by client

– e.g. 6.7 mm), to comply with the feed requirements Reporting

of the JKTech laboratory machine. Test results are detailed and interpreted in a Report

which summarizes the behaviour of the test ores

A representative sub-sample of each of the feed

in the HPGR, with special reference to customer

samples will be subjected to sieve analysis and “bulk”

requirements.

density measurements. The product from each of the

HPGR tests will be subjected to de-agglomeration

and sieve analysis. The flake density will also be Sample Requirements

determined.

The recommended Type A test sample size is

between 20 and 30 kg.

References

This is the minimum amount considered

Daniel, M.J., 2002, HPGR Model verification and scale up, Masters Thesis,

University of Queensland, Australia necessary to obtain an assessment under steady

Daniel, M. J. and Morrell, S., 2004, “HPGR model verification and scale-up”, state processing conditions.

Elsevier, Minerals Engineering 17 (2004) 1149-1161, May (2004)

Other JKTech Services Contact

• Consulting (comminution, flotation, mine-to-mill) John Dixon

• Quantitative Mineralogy (MLA and JKMineralogy) Manager JKMetLab

• Specialist Software (JKSimMet, JKSimFloat, JKSimBlast) Telephone: +61 7 3365 5908

• Metallurgical Laboratory Services Facsimile: +61 7 3365 5900

• Training Courses Email: j.dixon@jktech.com.au

JKTech’s range of technologies is supported by the ongoing research activities of the world renowned JKMRC.

JKTech Pty Ltd

Isles Road, Indooroopilly, QLD 4068, AUSTRALIA Delivering world class solutions to

Telephone: +61 7 3365 5842 Facsimile: +61 7 3365 5900 the minerals industry

info@jktech.com.au | www.jktech.com.au

You might also like

- Study of a reluctance magnetic gearbox for energy storage system applicationFrom EverandStudy of a reluctance magnetic gearbox for energy storage system applicationRating: 1 out of 5 stars1/5 (1)

- Uses and Benefits of Laboratory HPGR TestsDocument13 pagesUses and Benefits of Laboratory HPGR TestsRoberto VeasNo ratings yet

- Paper # 107 - Enhanced Liberation in HPGR CircuitsDocument13 pagesPaper # 107 - Enhanced Liberation in HPGR CircuitsEdú BrizuelaNo ratings yet

- PAPER - Dimensionamiento HPGRDocument13 pagesPAPER - Dimensionamiento HPGRHernanPeraltaNo ratings yet

- Investigation Into Laboratory Scale Tests For The Sizing of HPGRDocument19 pagesInvestigation Into Laboratory Scale Tests For The Sizing of HPGRNicolas PerezNo ratings yet

- A Novel Approach For The Modelling of High-Pressure Grinding RollsDocument10 pagesA Novel Approach For The Modelling of High-Pressure Grinding RollsFernando BeroizaNo ratings yet

- Anton Paar MCRDocument12 pagesAnton Paar MCRIvona IvkovicNo ratings yet

- Methodology and Experimental WorkDocument11 pagesMethodology and Experimental WorkgudukumarNo ratings yet

- JK Rotatory Breakage TesterDocument2 pagesJK Rotatory Breakage TesterBenito Quispe A.No ratings yet

- Rock Bolt Anchor Pull Test: Standard Test Method ForDocument6 pagesRock Bolt Anchor Pull Test: Standard Test Method ForOscar EduardoNo ratings yet

- Microscope HD 675 PsDocument3 pagesMicroscope HD 675 Pssaedali22330044No ratings yet

- Minerals Engineering: M. Torres, A. CasaliDocument10 pagesMinerals Engineering: M. Torres, A. CasaliCarlosNo ratings yet

- IDM Lab4Document9 pagesIDM Lab4gudursrinath11No ratings yet

- HPGR Implementation at Cerro VerdeDocument9 pagesHPGR Implementation at Cerro Verdelucianotigre100% (1)

- Processing of China Clay by Super-Conducting High Gradient Magnetic SeparationDocument6 pagesProcessing of China Clay by Super-Conducting High Gradient Magnetic SeparationCharith LiyanageNo ratings yet

- Tensile Testing Faqs: February 2022Document9 pagesTensile Testing Faqs: February 2022AMIRTHARAAJ A/L VIJAYAN MBS211063No ratings yet

- S43 - Why The Multiple Stress Creep Recovery (MSCR) Test Should Be Implemented - LTC2013Document31 pagesS43 - Why The Multiple Stress Creep Recovery (MSCR) Test Should Be Implemented - LTC2013walaywanNo ratings yet

- Effect of Circulating Load and Classification Efficiency On HPGR and Ball Mill CapacityDocument7 pagesEffect of Circulating Load and Classification Efficiency On HPGR and Ball Mill CapacitydoxamariaNo ratings yet

- ASTM D4435 Pull Out Test Rock BoltDocument6 pagesASTM D4435 Pull Out Test Rock BoltCyrillus Arthur Saputra100% (1)

- 049InLinePressureJigPre ConcentrationPlantAtThePirquitasMine PDFDocument15 pages049InLinePressureJigPre ConcentrationPlantAtThePirquitasMine PDFChristine Sola MorrisonNo ratings yet

- TR 09 07 Lab Stength Testing of DGR 2 To DGR 6 Core R0Document70 pagesTR 09 07 Lab Stength Testing of DGR 2 To DGR 6 Core R0Daniel MarínNo ratings yet

- ASTM D4648-D4648M - 13, Laboratory Miniature Vane Shear Test For Saturated Fine-Grained Clayey Soil PDFDocument7 pagesASTM D4648-D4648M - 13, Laboratory Miniature Vane Shear Test For Saturated Fine-Grained Clayey Soil PDFMarcosNo ratings yet

- Whims IrelDocument7 pagesWhims IrelGanesh B NairNo ratings yet

- RST-XS.s EnglishDocument2 pagesRST-XS.s Englishbei wNo ratings yet

- Servo Hydraulic Universal Testing Machine Brand: JNG Model: JG-600L Capacity: 600kNDocument11 pagesServo Hydraulic Universal Testing Machine Brand: JNG Model: JG-600L Capacity: 600kNQc BPSNo ratings yet

- Geogrid - Chapter.3.Document73 pagesGeogrid - Chapter.3.T SuryaNo ratings yet

- Hkwol KKFN LVSFVD Iapj Ijh (K.K (Lh-Ch-Vkj-Ijh (K.K) : HKKJRH EkudDocument10 pagesHkwol KKFN LVSFVD Iapj Ijh (K.K (Lh-Ch-Vkj-Ijh (K.K) : HKKJRH EkudBinayak KumarNo ratings yet

- Research Article: Design of A PID Controller For A Linearized Magnetic BearingDocument13 pagesResearch Article: Design of A PID Controller For A Linearized Magnetic BearingsnowleoNo ratings yet

- Pinched Sluices IDocument13 pagesPinched Sluices IPatociririNo ratings yet

- Comminution Brochure May 20122 Compatibility Mode 21Document13 pagesComminution Brochure May 20122 Compatibility Mode 21Claudio LechugaNo ratings yet

- Simulation of Layout Rearrangement in The Grinding - Classification Process - For Increasing Throughput of Industrial Gold Ore PlantDocument13 pagesSimulation of Layout Rearrangement in The Grinding - Classification Process - For Increasing Throughput of Industrial Gold Ore PlantW ZuoNo ratings yet

- Jisk 6258Document15 pagesJisk 6258KhimeshNo ratings yet

- Hardness of Mineral Aggregate Used On Built-Up Roofs: Standard Test Method ForDocument2 pagesHardness of Mineral Aggregate Used On Built-Up Roofs: Standard Test Method ForMohammad YaseenNo ratings yet

- High Cycle Fatigue, Low Cycle Fatigue and Failure Modes of A Carburized SteelDocument6 pagesHigh Cycle Fatigue, Low Cycle Fatigue and Failure Modes of A Carburized Steelth34560No ratings yet

- Charge Behaviour and Power Consumption IDocument36 pagesCharge Behaviour and Power Consumption IAmit MondalNo ratings yet

- Mechanical Property Determination of Bone Through Nano - and Micro-Indentation Testing and Finite Element SimulationDocument20 pagesMechanical Property Determination of Bone Through Nano - and Micro-Indentation Testing and Finite Element SimulationHamim AhmedNo ratings yet

- Aggregate Lab-Report (Repaired)Document66 pagesAggregate Lab-Report (Repaired)h100% (1)

- 2 WP FDM ABSM30MaterialProperties en 0114 WebDocument14 pages2 WP FDM ABSM30MaterialProperties en 0114 WebkaledioskoppNo ratings yet

- D2845-Withdrawn 38349Document7 pagesD2845-Withdrawn 38349Felipe Ignacio Gómez ReyesNo ratings yet

- Capitulo Pag 93Document9 pagesCapitulo Pag 93VictorTintayaMedinaNo ratings yet

- Test Rig Design and Testing Performance of Linear Ball BearingDocument6 pagesTest Rig Design and Testing Performance of Linear Ball BearingthisisjineshNo ratings yet

- LTRC Capsule11-2B Evaluation of Dynamic Shear Rheometer Tests For EmulsionsDocument2 pagesLTRC Capsule11-2B Evaluation of Dynamic Shear Rheometer Tests For EmulsionswalaywanNo ratings yet

- D2845-Withdrawn 13696 PDFDocument7 pagesD2845-Withdrawn 13696 PDFeduardo bonillaNo ratings yet

- 2013 InductoheatDocument5 pages2013 InductoheatGustavo FagundesNo ratings yet

- Vibration Characteristics of Fiber Reinforced Self Compacting Mortars (FRSCM)Document10 pagesVibration Characteristics of Fiber Reinforced Self Compacting Mortars (FRSCM)apoorv mishraNo ratings yet

- Instron Ceast Model 9050 BrochureDocument20 pagesInstron Ceast Model 9050 Brochure김민근No ratings yet

- HPGR Versus Sag Mill Selection For The Los BroncesDocument7 pagesHPGR Versus Sag Mill Selection For The Los BroncesRuben AltamiranoNo ratings yet

- 2014 Impc Paper112 HPGRDocument11 pages2014 Impc Paper112 HPGRDirceu NascimentoNo ratings yet

- Mechanical Properties of MaterialsDocument43 pagesMechanical Properties of MaterialsVacker GuzelNo ratings yet

- Bond Rod Mill Index - JKTechDocument2 pagesBond Rod Mill Index - JKTechBenito Quispe A.No ratings yet

- Experimental Aspects in The Vibration-Based Condition of Large HydrogeneratorsDocument15 pagesExperimental Aspects in The Vibration-Based Condition of Large HydrogeneratorsGeraldo Carvalho Brito Jr.No ratings yet

- Comparative Study On The Effect of HPGR and Conventional Crushing On The Ball Mill EnergyDocument21 pagesComparative Study On The Effect of HPGR and Conventional Crushing On The Ball Mill Energyhasan70 sheykhiNo ratings yet

- Velocidad Sonica NormaDocument7 pagesVelocidad Sonica NormadanielitomenaNo ratings yet

- Effect of High Pressure Grinding Rolls On Comminution Circuit DesignsDocument4 pagesEffect of High Pressure Grinding Rolls On Comminution Circuit DesignstapanteNo ratings yet

- Laboratory High Intensity Induced Roll Magnetic SeparatorDocument2 pagesLaboratory High Intensity Induced Roll Magnetic SeparatorYousef Alipour100% (1)

- Seminar IIDocument39 pagesSeminar IImajiu58No ratings yet

- 35 HZ Shape Memory Alloy Actuator NatureDocument13 pages35 HZ Shape Memory Alloy Actuator NatureAbhishekNo ratings yet

- 35 HZ Shape Memory Alloy Actuator NatureDocument13 pages35 HZ Shape Memory Alloy Actuator NatureAbhishekNo ratings yet

- Reservoir Lab Manual 2016-17Document37 pagesReservoir Lab Manual 2016-17Amit Verma100% (1)

- Ultrafit Calibrated Test BagDocument2 pagesUltrafit Calibrated Test BagDirceu ValadaresNo ratings yet

- Esy8594/3 Esy8594/3 Esy8594/3 Esy8594/3 Esy8594/3 Esy8594/3 Esy8594/3Document1 pageEsy8594/3 Esy8594/3 Esy8594/3 Esy8594/3 Esy8594/3 Esy8594/3 Esy8594/3Dirceu ValadaresNo ratings yet

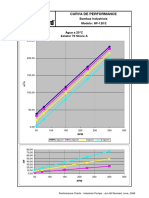

- Centrifugal Slurry Pumps: WarmanDocument2 pagesCentrifugal Slurry Pumps: WarmanDirceu ValadaresNo ratings yet

- Centrifugal Slurry Pumps: WarmanDocument2 pagesCentrifugal Slurry Pumps: WarmanDirceu ValadaresNo ratings yet

- HF 120-2Document1 pageHF 120-2Dirceu ValadaresNo ratings yet

- The Equivalence Between Different Residence Time Distribution Models in Ball MillingDocument7 pagesThe Equivalence Between Different Residence Time Distribution Models in Ball MillingDirceu ValadaresNo ratings yet

- Horizontal Pump 8 MF: WPA8D52/2 WPA8D52/2 WPA8D52/2 WPA8D52/2 WPA8D52/2 WPA8D52/2 WPA8D52/2Document1 pageHorizontal Pump 8 MF: WPA8D52/2 WPA8D52/2 WPA8D52/2 WPA8D52/2 WPA8D52/2 WPA8D52/2 WPA8D52/2Dirceu ValadaresNo ratings yet

- STND & Short Head WeightsDocument1 pageSTND & Short Head WeightsDirceu ValadaresNo ratings yet

- Gear Drive FeaturesDocument8 pagesGear Drive FeaturesDirceu ValadaresNo ratings yet

- CFD OpenfoamDocument4 pagesCFD OpenfoamKush VermaNo ratings yet

- PrintedDocument7 pagesPrintedFari PratomosiwiNo ratings yet

- Sensors: Using Smart Phone Sensors To Detect Transportation ModesDocument23 pagesSensors: Using Smart Phone Sensors To Detect Transportation Modesilie_vlassaNo ratings yet

- Insulfrax S BlanketDocument2 pagesInsulfrax S BlanketcanonplanosNo ratings yet

- Autoclave Full CatalogDocument481 pagesAutoclave Full CatalogGabriel Jamariqueli BueresNo ratings yet

- Physics Asl Project (Edited)Document23 pagesPhysics Asl Project (Edited)5cxd7r9nmdNo ratings yet

- Introduction To: ABB Machines Service CapabilitiesDocument60 pagesIntroduction To: ABB Machines Service CapabilitiessihamuNo ratings yet

- Ec8451 - Electromagnetic Fields Course OutcomesDocument28 pagesEc8451 - Electromagnetic Fields Course OutcomesdonavallishanmukasaiNo ratings yet

- Mathematics: Bansal ClassesDocument5 pagesMathematics: Bansal Classessuar90No ratings yet

- STAAD Seismic AnalysisDocument5 pagesSTAAD Seismic AnalysismabuhamdNo ratings yet

- Manufacturing Process of ScissorsDocument22 pagesManufacturing Process of ScissorsifahNo ratings yet

- Dubai ComplainDocument26 pagesDubai ComplainBikila RusiNo ratings yet

- Mechanical Engineering GuideDocument32 pagesMechanical Engineering GuideEduardo Andrés GonzálezNo ratings yet

- OBIS codes - OneMeter DocumentationDocument13 pagesOBIS codes - OneMeter Documentationsafaat rabbyNo ratings yet

- CBCS - Chemistry 2018 FINAL (Organic)Document16 pagesCBCS - Chemistry 2018 FINAL (Organic)kanuNo ratings yet

- KV Physics Study Material 2016-17Document330 pagesKV Physics Study Material 2016-17Theophilus ParateNo ratings yet

- Dura Bar Machining GuideDocument4 pagesDura Bar Machining GuidericassterNo ratings yet

- Schedule of Rates of LGED Bangladesh July 2015Document295 pagesSchedule of Rates of LGED Bangladesh July 2015kabir91% (32)

- Questionnaire Bras Empotage AnglaisDocument2 pagesQuestionnaire Bras Empotage AnglaisThao TaoNo ratings yet

- Production Engineering: (Third Edition)Document20 pagesProduction Engineering: (Third Edition)Rishabh Gehlot0% (1)

- QNH CalculationDocument12 pagesQNH CalculationMask550% (2)

- Dechow - Separation and Purification Techniques in BiotechnologyDocument498 pagesDechow - Separation and Purification Techniques in BiotechnologyahsanbasherNo ratings yet

- Robin Quotation Sheet Fiber Laser140326Document7 pagesRobin Quotation Sheet Fiber Laser140326Ricardo QueirogaNo ratings yet

- Arndt Schultz Law and HomoeopathyDocument7 pagesArndt Schultz Law and HomoeopathyDr. Rajneesh Kumar Sharma MD Hom100% (4)

- 5990 5266en PDFDocument10 pages5990 5266en PDFJames MossNo ratings yet

- Paper Biohybrid enDocument1 pagePaper Biohybrid enElena CrijanovschiNo ratings yet

- Treatment of EmulsionDocument7 pagesTreatment of EmulsionSaurab DevanandanNo ratings yet

- Answer Key For Apprenons Le Francais 2 PDFDocument4 pagesAnswer Key For Apprenons Le Francais 2 PDFMeera ChughNo ratings yet

- Lr10ia10 Flyer enDocument2 pagesLr10ia10 Flyer enmichelNo ratings yet

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- Bioinspired Materials Science and EngineeringFrom EverandBioinspired Materials Science and EngineeringGuang YangNo ratings yet

- Chemical Process Equipment - Selection and Design (Revised 2nd Edition)From EverandChemical Process Equipment - Selection and Design (Revised 2nd Edition)Rating: 5 out of 5 stars5/5 (3)

- Guidelines for the Management of Change for Process SafetyFrom EverandGuidelines for the Management of Change for Process SafetyNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Sodium Bicarbonate: Nature's Unique First Aid RemedyFrom EverandSodium Bicarbonate: Nature's Unique First Aid RemedyRating: 5 out of 5 stars5/5 (21)

- A New Approach to HAZOP of Complex Chemical ProcessesFrom EverandA New Approach to HAZOP of Complex Chemical ProcessesNo ratings yet

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesFrom EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesRating: 1 out of 5 stars1/5 (2)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlFrom EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlRating: 4 out of 5 stars4/5 (4)

- Bow Ties in Risk Management: A Concept Book for Process SafetyFrom EverandBow Ties in Risk Management: A Concept Book for Process SafetyNo ratings yet

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- An Applied Guide to Water and Effluent Treatment Plant DesignFrom EverandAn Applied Guide to Water and Effluent Treatment Plant DesignRating: 5 out of 5 stars5/5 (4)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- Piping Engineering Leadership for Process Plant ProjectsFrom EverandPiping Engineering Leadership for Process Plant ProjectsRating: 5 out of 5 stars5/5 (1)

- Troubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersFrom EverandTroubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersRating: 4.5 out of 5 stars4.5/5 (2)

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- Life Cycle of a Process PlantFrom EverandLife Cycle of a Process PlantMahdi NouriNo ratings yet

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesFrom EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNo ratings yet