Professional Documents

Culture Documents

Checklist of Mandatory Documentation Required by ISO 13485 2016 en

Checklist of Mandatory Documentation Required by ISO 13485 2016 en

Uploaded by

Diego Astorga Diaz LealOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Checklist of Mandatory Documentation Required by ISO 13485 2016 en

Checklist of Mandatory Documentation Required by ISO 13485 2016 en

Uploaded by

Diego Astorga Diaz LealCopyright:

Available Formats

Checklist of Mandatory Documentation

Required by ISO 13485:2016

WHITE PAPER

Copyright ©2021 Advisera Expert Solutions Ltd. All rights reserved.

Copyright © 2021 Advisera Expert Solutions Ltd. All rights reserved. 1

Table of Contents

Executive summary ................................................................................................................................. 3

Introduction ............................................................................................................................................ 3

Which documents and records are required? .......................................................................................... 4

Mandatory documents ........................................................................................................................4

Mandatory records..............................................................................................................................6

Commonly used non-mandatory documents ........................................................................................... 9

How to structure documents and records ............................................................................................. 10

Conclusion ............................................................................................................................................ 15

Sample documentation templates......................................................................................................... 15

References ............................................................................................................................................ 16

Copyright © 2021 Advisera Expert Solutions Ltd. All rights reserved. 2

Executive summary

The latest version of ISO 13485 was published in 2016, which means medical device companies need to

transition from the previous version of the standard and comply with the new requirements. One of the

most important steps in the transition process, as well as in the initial implementation, is determining

what documents and records are needed for an effective Quality Management System (QMS) based on

ISO 13485. This white paper is designed to help top management and employees involved in ISO 13485

implementation or transition, and to clear up any misunderstandings regarding the documents required

by the standard.

In this document, you will find an explanation of which documents are mandatory according to the ISO

13485:2016 standard, and which non-mandatory documents are commonly used in the QMS

implementation, in the same order and numbered clauses as in ISO 13485.

Introduction

The documentation needed for implementation of ISO 13485 includes those documents explicitly

required by the standard, plus those that the company determines to be necessary for effective

maintenance of the QMS based on ISO 13485. Many companies go overboard with documentation in the

belief that they need to document every single process that is in place in their organization, without

realizing that this is not necessary to meet the requirements of the ISO 13485 standard. While trying to

fulfill the standard’s requirements, organizations tend to generate too many documents to be on the

“safe side.”

Although it is sometimes helpful, this can be counterproductive, because it makes the implemented

processes and respective QMS hard to use and maintain, as well as making the QMS a bureaucratic

burden. While taking such an approach, organizations are missing a chance to improve their processes

for their own benefit, as well as that of their customers.

In this white paper, you will find, explained in plain English, what the minimum ISO 13485 requirements

for the documentation are, as well as a list of documents that are commonly in place and can help you

make your QMS more efficient.

Copyright © 2021 Advisera Expert Solutions Ltd. All rights reserved. 3

Which documents and records are

required?

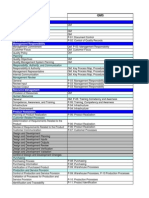

Mandatory documents

Clause of ISO

Mandatory document

13485:2016

Document the role(s) undertaken by the organization 4.1.1

Written Quality Agreements with outsource partners 4.1.5

Procedure for the Validation of the Application of Computer Software 4.1.6, 7.5.6, 7.6

Quality Manual 4.2.1

Quality Policy 4.2.1

Quality Objectives 4.2.1

Procedure for Document Control 4.2.4

Procedure for Record Control 4.2.5

Responsibilities and Authorities 5.5.1

Procedure for Management Review 5.6.1

Procedure for Competence, Training and Awareness 6.2

Requirements for the infrastructure 6.3

Requirements for the maintenance activities 6.3

Requirements for the work environment 6.4.1

Requirements for health, cleanliness and clothing of personnel 6.4.1

Arrangements for the control of contaminated or potentially 6.4.2

contaminated product

Requirements for control of sterile medical device contamination 6.4.2

Processes for risk management in product realization 7.1

Arrangements for communicating with customers 7.2.3

Procedure for Design and Development 7.3.1

Procedure for Purchasing and Evaluation of Suppliers 7.4.1

Copyright © 2021 Advisera Expert Solutions Ltd. All rights reserved. 4

Clause of ISO

Mandatory document

13485:2016

Procedure and methods for the control of production 7.5.1

Requirements for cleanliness of product 7.5.2

Requirements for medical device installation and acceptance criteria 7.5.3

for verification of installation

Procedure for Servicing Activities of Medical Device 7.5.4

Procedures for Validation of Processes 7.5.6

Procedure for the Validation of Processes for Sterilization 7.5.7

Procedure for Product Identification 7.5.8

Procedure for Traceability 7.5.9.1

Procedure for Preserving the Conformity of Product 7.5.11

Procedure for Monitoring and Measuring Equipment 7.6

Procedure for Customer Feedback Gathering 8.2.1

Procedure for Complaint Handling 8.2.2

Procedure for Internal Audit 8.2.4

Procedure for Control of Nonconforming Product 8.3.1

Procedure for Issuing Advisory Notices 8.3.3

Procedure for Rework 8.3.4

Procedure for Analysis of Data 8.4

Procedure for Corrective Actions 8.5.2

Procedure for Preventive Actions 8.5.3

Copyright © 2021 Advisera Expert Solutions Ltd. All rights reserved. 5

Mandatory records

Clause of ISO

Mandatory records

13485:2016

Quality Agreement with Outsourced Processes 4.1.5

Records of Software Validation Activities 4.1.6, 7.6

Medical Device File 4.2.3

Records of Management Review 5.6.1

Records of Education, Training, Skills and Experience 6.2

Records of the Maintenance Activities 6.3

Records of Risk Management Activities 7.1

Outputs of Product Realization Planning 7.1

Records of the Results and Actions Arising from Review of Requirements 7.2.2

Related to Product

Records of Product Requirements Changes 7.2.2

Design and Development Planning Documents 7.3.2

Design and Development Inputs 7.3.3

Design and Development Outputs 7.3.4

Records of Design and Development Review 7.3.5

Records of the Results and Conclusions of the Design and Development 7.3.6

Verification

Design and Development Validation Plans 7.3.7

Records of the Results and Conclusion of Design and Development 7.3.7

Validation

Results and Conclusions of the Design and Development Transfer 7.3.8

Records of Design and Development Changes 7.3.9

Design and Development File 7.3.10

Records of the Results of Evaluation, Selection, Monitoring and Re- 7.4.1

evaluation of Supplier

Records of the Purchased Product Verification 7.4.3

Record for Each Medical Device or Batch of Medical Devices 7.5.1

Copyright © 2021 Advisera Expert Solutions Ltd. All rights reserved. 6

Clause of ISO

Mandatory records

13485:2016

Records of Medical Device Installation and Verification of Installation 7.5.3

Records of Servicing Activities 7.5.4

Records of the Sterilization Process Parameters 7.5.5

Records of the Results and Conclusion of Validation 7.5.6

Records of the Results and, Conclusion of Sterile Medical Device Validation 7.5.7

Records of Traceability 7.5.9.2

Records of the Name and Address of the Shipping Package Consignee 7.5.9.2

Report to the Customer about Changes on his Property 7.5.10

Records of the Results of Calibration and Verification of Monitoring and 7.6

Measuring Equipment

Customer Feedback Report 8.2.1

Complaint Handling Records 8.2.2

Records of Reporting to Regulatory Authorities 8.2.3

Internal Audit Plan 8.2.4

Internal Audit Report 8.2.4

Evidence of Conformity of Products with the Acceptance Criteria 8.2.6

Identity of the Person Authorizing Release of product 8.2.6

Identity of Personnel Performing any Inspection or Testing of Implantable 8.2.6

Medical Devices

Record of Nonconformity 8.3.1

Records of the Product Acceptance by Concession and the Identity of the 8.3.2

Person Authorizing the Concession

Records of Actions relating to the Issuance of Advisory Notices 8.3.3

Records of Rework 8.3.4

Records of the Results of Data Analyses 8.4

Records of Corrective actions 8.5.2

Records of Preventive actions 8.5.3

Copyright © 2021 Advisera Expert Solutions Ltd. All rights reserved. 7

These are the documents and records that are required to be maintained for the ISO 13485 Quality

Management System, but you should also maintain any other records that you have identified as being

necessary to ensure that your management system can function, be maintained, and improve over time.

Copyright © 2021 Advisera Expert Solutions Ltd. All rights reserved. 8

Commonly used non-mandatory

documents

While ISO 13485 does not require that you document all of the procedures, there are a lot of processes

that must be established in order to generate the required records that are outlined in the first section.

Unlike ISO 9001, which leaves a lot of freedom in deciding whether to document a procedure or not, ISO

13485 doesn’t leave much room for different interpretations—basically, all major procedures must be

documented. In the table below, you can find examples of the documents that are not required by the

standard, but that can be beneficial to the QMS:

Clause of ISO

Document title

13485:2016

Procedure for measuring customer satisfaction 5.2

Procedure for identification of regulatory and customer requirements 5.2

Procedure for internal communication 5.5.3

Procedure for planning product realization 7.1

Quality Plan 7.1

Sales procedure 7.2

One rule of thumb when deciding if you want to document a process is this: if there is a chance that the

process won’t be carried out as planned, then you should document it. In many cases, this is the best way

to ensure that your Quality Management System is reliably implemented.

Copyright © 2021 Advisera Expert Solutions Ltd. All rights reserved. 9

How to structure documents and records

ISO 13485 has a lot of requirements regarding documentation, so it is imperative to optimize the volume

of your QMS documentation so that you develop enough to meet all of the requirements, while keeping

it simple and light. Although there are requirements for more than 20 procedures, many of them can be

merged together; this approach can provide you with a smaller number of documents, which is especially

important for the small and midsize companies that want to implement the standard. The general advice

is to identify common requirements, or requirements that relate to the same element of your QMS, and

try to merge documented procedures.

The following recommendations take into consideration best practices in developing QMS

documentation:

Written Quality Agreements with outsource partners. Between the manufacturer and the subcontractor,

there must be an agreement with detailed roles and responsibilities; for example: whether or not the

subcontractor needs to be certified, whether or not the manufacturer will conduct an audit of the

subcontractor, how the subcontractor will report non-compliances during the process, how these non-

compliances will be resolved, and how the manufacturer will report the subcontractor if it receives a

complaint related to the outsourced process.

Procedure for the Validation of the Application of Computer Software. Once the software is installed, it

must be checked periodically to make sure that it's configured correctly and working as it should. This

could be when a new version of the software is obtained, or in any other case when considered necessary.

Quality Manual. This is a roof document for your QMS; it usually includes the QMS scope, role(s)

undertaken by the organization, exclusions from the standard, references to relevant documents, and the

business process model. For more information on how to write the Quality Manual, see: ISO 13485: How

to write a short quality manual.

Quality Policy. A policy represents a declarative statement by an organization. A Quality Policy should

state the commitment of the organization to quality and continual improvement and provide a framework

for setting quality objectives. For more information on how to write the Quality Policy, see: How to Write

a Good Quality Policy. The article explains ISO 9001 requirements, but it is also applicable to ISO 13485.

Quality Objectives are derived from the goal stated in the Quality Policy, and they are the main method

used by companies to focus this goal into plans for improvement. The objectives are intended to be

S.M.A.R.T. (specific, measurable, achievable, realistic, and time-based) and should have relevance at all

levels of the company, meaning that all employees should understand how their jobs support meeting

the Quality Objectives. The article Setting good quality objectives for ISO 13485 gives more information

on this process.

Copyright © 2021 Advisera Expert Solutions Ltd. All rights reserved. 10

Procedure for Document and Record Control. This document defines how you approve, update, and re-

approve your documents. When a document is changed, how do you identify changes and make sure that

the people who need the current document have it and stop using older documents? How do you make

sure the documents can be read, and how do you control documents that come from outside of your

organization for use? Find out more about documentation with Some Tips to make Document Control

more useful for your QMS; the article explains ISO 9001 requirements, but it is also applicable to ISO

13485.

How do you maintain records that show your product is acceptable to use, and how do you identify, store,

and protect the records so that they can be retrieved as necessary, for the correct amount of time, and

destroyed when no longer needed but not before? In order to make the documentation more efficient,

this procedure for managing records is commonly merged with the procedure for document control; here

you can find a free preview of the Procedure for Document and Record Control.

Responsibilities and authorities. Each employee needs to know who is responsible for the various

elements of the management system to ensure a successful implementation. This is usually accomplished

through an organizational chart and job descriptions where roles, responsibilities, and authorities are

clearly defined. This organizational chart can be part of the Quality Manual.

Procedure for Management Review. How do you conduct your review of the system to ensure that all

areas of the system are functioning and that improvements are happening where planned and expected?

How do you control the flow of information on management decisions out to the company? Learn more

in this article about How to make Management Review more practical; the article explains ISO 9001

requirements, but it is also applicable to ISO 13485.

Procedure for Competence, Training and Awareness. This procedure should describe how the process of

identifying and achieving necessary competence is performed, as well as how the company raises its

employees’ awareness regarding the QMS. For more information about training and awareness, see:

Improving quality through effective training and ISO 9001 awareness training material: How to create it,

what it should contain; both articles explain ISO 9001 requirements, but they are also applicable to ISO

13485.

Requirements for infrastructure. The standard requires an organization to define and document

requirements for infrastructure needed to achieve conformity to product requirements, prevent product

mix-up, and ensure orderly handling of product.

Requirements for maintenance activities. In cases when the maintenance activities can affect the

product quality, the organization needs to document those requirements.

Requirements for work environment. When conditions for the work environment can have an adverse

effect on product quality, the organization needs to document the requirements for the work

environment and the procedures to monitor and control the work environment.

Copyright © 2021 Advisera Expert Solutions Ltd. All rights reserved. 11

Requirements for health, cleanliness, and clothing of personnel. When contact between personnel and

the product or work environment could affect medical device safety or performance, the organization

needs to document requirements for health, cleanliness, and clothing of personnel.

Arrangements for the control of contaminated or potentially contaminated product. In order to prevent

contamination of the work environment, personnel, or product, the organization needs to plan and

document arrangements for the control of contaminated or potentially contaminated product. For

organizations that aim to decrease the number of documents in the QMS, the requirements for

infrastructure, maintenance, and work environment can be merged into a single procedure. Here you can

find a free preview of the Procedure for Infrastructure and Work Environment.

Requirements for control of sterile medical device contamination. For sterile medical devices, the

organization must document requirements for control of contamination with microorganisms or

particulate matter and maintain the required cleanliness during assembly or packaging processes.

Processes for risk management in product realization. Part of the planning of product realization is the

assessment of risks that can result in noncompliance with the requirements for product or processes of

the Quality Management System. The organization needs to document one or more processes for risk

management for product realization.

Arrangements for communicating with customers. The organization must document arrangements for

communicating with customers in relation to product information, inquiries, contracts, or order handling,

including amendments, customer feedback (including complaints), and advisory notices. These

requirements are often merged with the Sales Procedure.

Procedure for Design and Development. Requirements regarding the design and development process

are among the most demanding in the standard. Every step of the design and development process needs

to be documented in the form of a record, from design and development inputs, controls, and outputs,

to changes in design and development. Considering all the requirements regarding the design and

development process, it is best to document the Procedure for Design and Development and define all

mandatory records that should accompany the procedure.

Procedure for Purchasing and Evaluation of Suppliers. The standard requires companies to establish

control over its externally provided processes, products, and services. Documenting the criteria for

evaluation, selection, monitoring, and reevaluation of the suppliers will enable the organization to ensure

that purchased product conforms to specified purchasing information. For more information about the

purchasing process, see Purchasing in QMS – The Process & the Information Needed to Make it Work; the

article explains ISO 9001 requirements, but it is also applicable to ISO 13485. With outsourced companies,

there needs to be a written Quality Agreement for Subcontractor.

Procedures and methods for the control of production. Control and monitoring procedures may include

in-process and/or finished device acceptance activities as well as environmental and contamination

control measures. Review the specific procedure(s) for the manufacturing process selected and the

methods for controlling and monitoring the process. Verify that the process is controlled and monitored.

The procedures are best documented in the Procedure for production and service provision.

Copyright © 2021 Advisera Expert Solutions Ltd. All rights reserved. 12

Requirements for cleanliness of product. The organization needs to define requirements for cleanliness

of product or contamination of product in cases when product is cleaned by the organization prior to

sterilization or its use, the product cleanliness is significant in use, and process agents are to be removed

from product during manufacture. This can be documented either separately, or within Procedures and

Methods for the Control of Production, or in some other appropriate document.

Requirements for medical device installation and acceptance criteria for verification of installation.

Requirements need to be documented, and the records of the installation and verification activities need

to be maintained. This can be a standalone procedure, or it can be a part of the Procedures and Methods

for the Control of Production.

Procedure for Servicing Activities. In cases when servicing activities are required, the organization needs

to document the servicing procedure, as well as reference materials and measurements, if they are

necessary for performing the servicing activity. Organizations with complex servicing activities will

document the procedure as a separate document, but those with a more simple servicing process can

include this procedure in the Procedures and Methods for the Control of Production.

Procedure for Validation Process. When the resulting output of the production and service provision

process cannot be verified by subsequent monitoring and measuring, the organization needs to validate

such processes and document the procedure for validation. It is also possible to merge this procedure

with the Procedures and Methods for the Control of Production in cases of more simple validation

activities.

Procedure for Validation of the Sterilization Process. Organizations that perform sterilization and have

sterile barrier systems need to validate the process prior to implementation, and the procedure for

sterilization needs to be documented.

Procedure for Product Identification. The product must be identified through processes of production,

storage, installation, and servicing of product to ensure that only product that has passed the required

inspections and tests is used or installed. The procedure for identification of the products must be

documented and, again, in the case of less complex processes, the procedure can be merged with the

Procedures and Methods for the Control of Production.

Procedure for Traceability. The organization needs to define the extent of traceability in accordance with

applicable regulatory requirements and to document the procedure for traceability. Depending on the

complexity of the traceability activities, the procedure can be merged with the Procedures and Methods

for the Control of Production.

Procedure for Preservation of Product. The organization must protect product from alteration,

contamination, or damage during processing, storage, handling, and distribution, and this can be achieved

with a documented procedure for preservation of product. These requirements are usually documented

in the Warehousing Procedure and in procedures defining each of the above-mentioned processes.

Procedure for Monitoring and Measuring Equipment. The purpose of the monitoring and measuring is

to provide evidence of conformity of product to determined requirements. In order to ensure that

Copyright © 2021 Advisera Expert Solutions Ltd. All rights reserved. 13

monitoring and measuring can be carried out and are carried out properly, the organization needs to

document the Procedure for Equipment Maintenance and Measurement Equipment.

Procedure for Gathering Customer Feedback. ISO 13485 emphasizes customer feedback over customer

satisfaction. As one of the measurements of the effectiveness of the QMS, the organization needs to

gather and monitor information relating to whether the organization has met customer requirements and

document the methods for obtaining and using this information. Since the sales process is most

commonly in contact with the customers, this procedure is often merged with the Sales Procedure.

Procedure for Complaint Handling. Considering the possible impact that some medical devices can have

on the quality of life of customers, there is a requirement to document how the complaint handling

process will be carried out. Again, very often, the sales process is the first in line when it comes to contact

with customers, so it can be useful to document the complaint handling process as a part of the Sales

Procedure.

Procedure for Internal Audit. The internal audit is the process that determines whether the QMS is

effective and performing as planned. The most important information regarding the internal audit, such

as responsibility for planning, method of conducting and reporting, as well as the follow-up activities,

need to be documented in the Procedure for Internal Audit.

Procedure for Control of Nonconforming Product. This procedure needs to provide answers to the

following questions: What controls are in place, and who is responsible, to make sure that nonconforming

product is not used? Are there terms that can be put in place to allow the use of nonconforming product,

such as Rework, Repair, or Acceptance by Customer? How do you ensure that corrected product is re-

verified, and what records are kept of the process? Find out more about ISO 13485:2016 nonconforming

product – How to approach the post-delivery actions.

Procedure for Issuing Advisory Notices. In cases when the nonconforming product is discovered after

delivery or use has started, the organization must not only take action to resolve the nonconformity, but

also to issue advisory notices to customers. The procedure for issuing advisory notices must be aligned

with relevant legislation and documented. Since this is a part of communication with customers, this

procedure can be merged with the Procedure for Customer Communication, Feedback and Complaints.

Procedure for Rework. The rework needs to be done in a way that takes into account the potential

adverse effects of the rework on the product. The procedure for rework needs to be documented and

undergo the same review and approval as the Procedure for Production and Service Provision, so it is

reasonable to merge these two procedures to decrease the amount of documentation in small and mid-

size companies.

Procedure for Analysis of Data. The organization needs to determine, collect, and analyze appropriate

data to demonstrate the suitability, adequacy, and effectiveness of the QMS and to document how this

process is conducted. The Procedure for Data Analysis defines how the data are gathered and processed.

Procedure for Corrective Action. The procedure for reviewing nonconformity, determining the causes,

and implementing and evaluating necessary actions needs to be documented. To learn more about the

Copyright © 2021 Advisera Expert Solutions Ltd. All rights reserved. 14

corrective action process, see: ISO 13485 continual improvement: Seven-step process for corrective and

preventive actions; the article explains ISO 9001 requirements, but it is also applicable to ISO 13485.

Procedure for Preventive Action. How do you handle nonconformity before it occurs? Preventive actions

are used to address such situations and, since the method of conducting the preventive actions is not so

different from the corrective action, it is common to merge those two procedures into the Procedure for

Corrective and Preventive Action.

At a minimum, these are the documented procedures that are necessary to meet the requirements, and

they are all that is needed to document a simple QMS. However, there is often a need to provide written

documents for more, and the trick is in knowing what else your company needs to document. If you are

implementing a Quality Management System, you may struggle with the decision of what needs to be

written down. This is common, but wisely answering the question “What should I document?” can avoid

complexity in your Quality Management System, saving time and money.

Conclusion

ISO 13485 implementation can turn into a problematic project if you don’t set it up correctly right from

the beginning. Documentation that is required by the standard, extended by non-mandatory documents,

forms a significant part of the QMS implementation. Knowing what the standard requires as mandatory

documentation helps the organization to be well prepared for the certification audit. On the other side,

the decisions on adding non-mandatory documents should represent a balance between competence of

employees and administrative controls that can help the organization avoid nonconformities.

Implementing both mandatory and non-mandatory documents in an optimal scope increases the

efficiency of the QMS and creates benefits for both the organization itself and its customers.

Sample documentation templates

Here you can download a free preview of the ISO 13485 Documentation Toolkit – in this free preview,

you will be able to see the Table of Contents of each of the mentioned policies and procedures, as well as

a few sections from each document.

Copyright © 2021 Advisera Expert Solutions Ltd. All rights reserved. 15

References

13485Academy

9001Academy

International Organization for Standardization

Copyright © 2021 Advisera Expert Solutions Ltd. All rights reserved. 16

Advisera Expert Solutions Ltd Email: support@advisera.com

for electronic business and business consulting U.S. (international): +1 (646) 759 9933

Zavizanska 12, 10000 Zagreb United Kingdom (international): +44 1502 449001

Croatia, European Union Toll-Free (U.S. and Canada): 1-888-553-2256

Toll-Free (United Kingdom): 0800 808 5485

Australia: +61 3 4000 0020

Copyright © 2021 Advisera Expert Solutions Ltd. All rights reserved. 17

You might also like

- Checklist of Mandatory Documentation Required by ISO 13485 2016 enDocument17 pagesChecklist of Mandatory Documentation Required by ISO 13485 2016 enGonzalo Maza100% (2)

- Good Distribution Practice A Complete Guide - 2020 EditionFrom EverandGood Distribution Practice A Complete Guide - 2020 EditionNo ratings yet

- Business Process Re-engineering (BPR) A Clear and Concise ReferenceFrom EverandBusiness Process Re-engineering (BPR) A Clear and Concise ReferenceNo ratings yet

- Good Distribution Practices A Complete Guide - 2021 EditionFrom EverandGood Distribution Practices A Complete Guide - 2021 EditionNo ratings yet

- ISO 9001:2015 for Everyday Operations: All Facts – Short, Concise and UnderstandableFrom EverandISO 9001:2015 for Everyday Operations: All Facts – Short, Concise and UnderstandableNo ratings yet

- DCC and QMS Coordinator - HandoutDocument17 pagesDCC and QMS Coordinator - HandoutRaymond PalisocNo ratings yet

- Quality Management System Software A Complete Guide - 2019 EditionFrom EverandQuality Management System Software A Complete Guide - 2019 EditionNo ratings yet

- Module-1-ISO 13485-DocumentDocument7 pagesModule-1-ISO 13485-Documentsri manthNo ratings yet

- FDA-IsO QMS Audit Checklist Greenlight GuruDocument3 pagesFDA-IsO QMS Audit Checklist Greenlight GuruNigel LimNo ratings yet

- New Iso-45001 2015Document65 pagesNew Iso-45001 2015Bibhudutta MishraNo ratings yet

- ISO 22000 Internal AuditDocument1 pageISO 22000 Internal AuditPushpinder Kaur Dhatt0% (1)

- ISO 17025 Process RequirementsDocument29 pagesISO 17025 Process Requirementsdinesh171989No ratings yet

- Conformity AssessmentDocument15 pagesConformity AssessmentMaruan MuhammadNo ratings yet

- Intro ISO 13485Document92 pagesIntro ISO 13485manu4u1984No ratings yet

- ISO 9001 2015 Mock AuditDocument15 pagesISO 9001 2015 Mock AuditMadan R HonnalagereNo ratings yet

- Maturity Organization Level ISO 9004Document2 pagesMaturity Organization Level ISO 9004abimanyubawono100% (2)

- IQA Training Workshop PPSCDocument221 pagesIQA Training Workshop PPSCChristianieAnn100% (2)

- Ms Iso 37001 - Oct 27 - DR - LKMDocument83 pagesMs Iso 37001 - Oct 27 - DR - LKMTenglum Low100% (1)

- Motorola Quality ManualDocument12 pagesMotorola Quality ManualHaroon MukhtarNo ratings yet

- ISO 13485 - 2016-WPS OfficeDocument4 pagesISO 13485 - 2016-WPS Officerajesh.bNo ratings yet

- QMS DocumentationDocument11 pagesQMS Documentationaji ibrahimNo ratings yet

- ISO 19011 Audit ManagementDocument38 pagesISO 19011 Audit ManagementRamesh GanapathyNo ratings yet

- Internal Auditing As ISO 1900:2000Document74 pagesInternal Auditing As ISO 1900:2000mwlwaji100% (2)

- What Are The Benefits of Performance Measurement?Document12 pagesWhat Are The Benefits of Performance Measurement?Faan Waliporn CheawchanNo ratings yet

- Jipl CL Pur 10 Testing Lab AuditDocument8 pagesJipl CL Pur 10 Testing Lab AuditMeghna SharmaNo ratings yet

- 2 Mapping ProcessesDocument73 pages2 Mapping ProcessesIr Moise MatabaroNo ratings yet

- Task Evidence: Mdsap Audit Checklist (For Audit Model Version 2016, Reflecting ISO 13485:2016)Document14 pagesTask Evidence: Mdsap Audit Checklist (For Audit Model Version 2016, Reflecting ISO 13485:2016)Norah Al-ShamriNo ratings yet

- Quality Manual CDocument50 pagesQuality Manual CRavikumar qsolutionsNo ratings yet

- TUV India Training Academy Brochure Compressed PDFDocument6 pagesTUV India Training Academy Brochure Compressed PDFMohammedBujairNo ratings yet

- IATF Rules Dec2016Document14 pagesIATF Rules Dec2016anthony dunnNo ratings yet

- SOP - Saint GobainDocument23 pagesSOP - Saint Gobainsaikumar selaNo ratings yet

- As Iso 10015-2006Document25 pagesAs Iso 10015-2006АлексейNo ratings yet

- Building A Culture of Compliance Through ISO 37301 Compliance Management SystemDocument2 pagesBuilding A Culture of Compliance Through ISO 37301 Compliance Management SystemSuhaimi Al-YahyaNo ratings yet

- QMS Audit - Checklist - IsO 9001 - 2008Document27 pagesQMS Audit - Checklist - IsO 9001 - 2008Rizaldi DjamilNo ratings yet

- Audit Plan Template For Internal Audit of Medical CollegeDocument5 pagesAudit Plan Template For Internal Audit of Medical CollegeJayabrata MajumdarNo ratings yet

- How To Budget An ISO 45001 Implementation ProjectDocument12 pagesHow To Budget An ISO 45001 Implementation ProjectShahnawaz PathanNo ratings yet

- Internal Audit Flow ChartDocument1 pageInternal Audit Flow ChartstevierayoNo ratings yet

- ISO 13485.2016 Internal Audit - Prem1Document59 pagesISO 13485.2016 Internal Audit - Prem1Ricky MarkNo ratings yet

- Isr 13485 Delta ChecklistDocument11 pagesIsr 13485 Delta ChecklistMs. ThuNo ratings yet

- Quality Management System Checklist P28a Al 0002 PDFDocument13 pagesQuality Management System Checklist P28a Al 0002 PDFBejo HokiNo ratings yet

- Audit MatrixDocument4 pagesAudit MatrixramschellamNo ratings yet

- Quality Management Gap AssessmentDocument28 pagesQuality Management Gap AssessmentVanessa GurrolaNo ratings yet

- Form - COTO LogDocument45 pagesForm - COTO LogAmit KuarNo ratings yet

- ISO 19011 TrainingDocument5 pagesISO 19011 TrainingHEMA SANTOSH KUMAR REDDY KARRINo ratings yet

- QMS Vol. 1 PDFDocument436 pagesQMS Vol. 1 PDFCamilo Jorquera100% (2)

- Introduction To CGMP Compliance CourseDocument111 pagesIntroduction To CGMP Compliance CourseHend maarofNo ratings yet

- How Can ISO 13485 Help Your Business Grow enDocument14 pagesHow Can ISO 13485 Help Your Business Grow enloboufrjNo ratings yet

- Day 1Document3 pagesDay 1Sandeep kulkarniNo ratings yet

- Auditor Observation Form MASTERDocument7 pagesAuditor Observation Form MASTERGavin JordanNo ratings yet

- FM 198 Q1 ISO 9001 Audit Report Form Revision 7 20210803Document17 pagesFM 198 Q1 ISO 9001 Audit Report Form Revision 7 20210803Supriya GothwalNo ratings yet

- RESUME CV Tabeti Abdelkader English 2017Document11 pagesRESUME CV Tabeti Abdelkader English 2017Habib TabetiNo ratings yet

- Initial Certification / Recertification: Audit ReportDocument14 pagesInitial Certification / Recertification: Audit ReportWhaOneNo ratings yet

- List of KPI For AuditsDocument6 pagesList of KPI For AuditsJosé Manuel Valdivia TenorioNo ratings yet

- ISO 13485 Lead Auditor Two Page BrochureDocument2 pagesISO 13485 Lead Auditor Two Page BrochurePECBCERTIFICATIONNo ratings yet

- Mechanical Properties For Stainless Steel FastenersDocument3 pagesMechanical Properties For Stainless Steel FastenersGonzalo MazaNo ratings yet

- Stainless Steel Technical InformationDocument10 pagesStainless Steel Technical InformationGonzalo MazaNo ratings yet

- Stainless Steel Composition Chart: TP304 TP304H TP304L TP310S TP316Document4 pagesStainless Steel Composition Chart: TP304 TP304H TP304L TP310S TP316Gonzalo MazaNo ratings yet

- Cold Finished Stainless Steel Tube Technology Flow Chart: PilgeringDocument6 pagesCold Finished Stainless Steel Tube Technology Flow Chart: PilgeringGonzalo MazaNo ratings yet

- Stainless Steel Tubing Sizes ChartDocument6 pagesStainless Steel Tubing Sizes ChartGonzalo MazaNo ratings yet

- Tolerance of Stainless Steel Tubes and PipesDocument3 pagesTolerance of Stainless Steel Tubes and PipesGonzalo MazaNo ratings yet

- 2304 Tubing ASTM A789 / ASME SA789 S32304 1.4362 Duplex Steel TubeDocument13 pages2304 Tubing ASTM A789 / ASME SA789 S32304 1.4362 Duplex Steel TubeGonzalo MazaNo ratings yet

- Stainless Steel Tubing Sizes ChartDocument7 pagesStainless Steel Tubing Sizes ChartGonzalo MazaNo ratings yet

- Gauge Sizes ChartDocument5 pagesGauge Sizes ChartGonzalo MazaNo ratings yet

- Stainless Steel Pipe Applications Stainless Steel Tubing ApplicationsDocument7 pagesStainless Steel Pipe Applications Stainless Steel Tubing ApplicationsGonzalo MazaNo ratings yet

- Inch To MM Conversion - Inch To MM ChartDocument8 pagesInch To MM Conversion - Inch To MM ChartGonzalo MazaNo ratings yet

- Stainless Steel Composition Chart: Specification Grade C Si MN P S CRDocument4 pagesStainless Steel Composition Chart: Specification Grade C Si MN P S CRGonzalo MazaNo ratings yet

- Magna Global Quality Standard: MQS 11 - Change ManagementDocument5 pagesMagna Global Quality Standard: MQS 11 - Change ManagementGonzalo MazaNo ratings yet

- EN 10305-2 E195 E235 E355 Welded Cold Drawn Precision Steel TubesDocument5 pagesEN 10305-2 E195 E235 E355 Welded Cold Drawn Precision Steel TubesGonzalo MazaNo ratings yet

- Stainless Steel Mechanical PropertiesDocument4 pagesStainless Steel Mechanical PropertiesGonzalo MazaNo ratings yet

- Stainless Steel Tube SpecificationsDocument8 pagesStainless Steel Tube SpecificationsGonzalo MazaNo ratings yet

- DIN EN 10111 (Jun. 2008)Document14 pagesDIN EN 10111 (Jun. 2008)Gonzalo Maza100% (1)

- Stainless Steel Pipe SpecificationsDocument11 pagesStainless Steel Pipe SpecificationsGonzalo MazaNo ratings yet

- DIN EN 10130 (Fev. 2007)Document14 pagesDIN EN 10130 (Fev. 2007)Gonzalo MazaNo ratings yet

- DIN EN 10049 (Fev. 2006)Document14 pagesDIN EN 10049 (Fev. 2006)Gonzalo Maza100% (2)

- Training Material: Cost Tracking 2 (Ct2) For Suppliers: © Allocation Network GMBHDocument11 pagesTraining Material: Cost Tracking 2 (Ct2) For Suppliers: © Allocation Network GMBHGonzalo MazaNo ratings yet

- Magna Global Quality Standard: MQS 13 - Warranty ManagementDocument11 pagesMagna Global Quality Standard: MQS 13 - Warranty ManagementGonzalo MazaNo ratings yet

- Magna Global Quality Standard: MQS 10 - Error Proofing and Detection Device VerificationDocument4 pagesMagna Global Quality Standard: MQS 10 - Error Proofing and Detection Device VerificationGonzalo MazaNo ratings yet

- Magna Global Quality Standard: MQS 14 - Avoidance of Wrong DeliveriesDocument4 pagesMagna Global Quality Standard: MQS 14 - Avoidance of Wrong DeliveriesGonzalo MazaNo ratings yet

- 10b Energy Manual Rev1Document94 pages10b Energy Manual Rev1Gonzalo MazaNo ratings yet

- Job Safety Observation Form Template - JotFormDocument4 pagesJob Safety Observation Form Template - JotFormGonzalo MazaNo ratings yet

- F M E A (FMEA) P 4 - C C: Ailure Ode and Ffects Nalysis ART Haracteristic LassificationDocument12 pagesF M E A (FMEA) P 4 - C C: Ailure Ode and Ffects Nalysis ART Haracteristic LassificationGonzalo MazaNo ratings yet

- Case Study 2Document4 pagesCase Study 2Ad ElouNo ratings yet

- 1120 UN Avenue Barangay 661 Ermita, City of Manila, NCR, Philippines, 1000Document31 pages1120 UN Avenue Barangay 661 Ermita, City of Manila, NCR, Philippines, 1000Nigel GarciaNo ratings yet

- A Case Study For Blockchain in Manufacturing FabRecDocument13 pagesA Case Study For Blockchain in Manufacturing FabRecJohnny AlvaradoNo ratings yet

- Sppa T3000Document16 pagesSppa T3000Vellai Pandi PNo ratings yet

- 20005AnnexesA HJMO P - RMO10 05Document18 pages20005AnnexesA HJMO P - RMO10 05Carlos Geronimo Averilla VillaflorNo ratings yet

- Vive La Diff Rence Research Software EngineersDocument8 pagesVive La Diff Rence Research Software Engineersmohammad.aman.ullah.khan.piNo ratings yet

- Oracle Product Lifecycle Management ENGDocument60 pagesOracle Product Lifecycle Management ENGRidwansyah HaryoNo ratings yet

- Agile Development: © Lpu:: Cap437: Software Engineering Practices: Ashwani Kumar TewariDocument28 pagesAgile Development: © Lpu:: Cap437: Software Engineering Practices: Ashwani Kumar TewariAnanth KallamNo ratings yet

- Optimization-Based Decision Support Systems For Process IndustryDocument184 pagesOptimization-Based Decision Support Systems For Process IndustryAbhaya Kumar SahooNo ratings yet

- CVJuan David Ramírezdelos RíosDocument1 pageCVJuan David Ramírezdelos Ríositzel083No ratings yet

- Olivier I 2012Document6 pagesOlivier I 2012HakimHabibiNo ratings yet

- Business PlanDocument24 pagesBusiness PlanSAJEEL ARSHAD100% (1)

- CRM (Customer Relationship Management) ProcessDocument11 pagesCRM (Customer Relationship Management) ProcessNguyễn Ngọc KhánhNo ratings yet

- Section 3 Answers PresentationDocument24 pagesSection 3 Answers PresentationSanchitNo ratings yet

- Cloud 1Document7 pagesCloud 1vikram kumar jonnalagaddaNo ratings yet

- Setting Up An Inventory Valuation Report in Dynamics AX Part 1 & 2Document18 pagesSetting Up An Inventory Valuation Report in Dynamics AX Part 1 & 2Fathy TahaNo ratings yet

- Tcs Agile For Practitioners Assessment DeliveryDocument5 pagesTcs Agile For Practitioners Assessment DeliveryDP65% (176)

- JAM Integration Marketing CloudDocument36 pagesJAM Integration Marketing Cloudpraveenr5883No ratings yet

- Machine Learning Projects For Final Year PDFDocument4 pagesMachine Learning Projects For Final Year PDFAslam NizamiNo ratings yet

- Software MetricsDocument40 pagesSoftware MetricsMazwin Abdul WahabNo ratings yet

- Sip CRMDocument82 pagesSip CRMAgney KudekarNo ratings yet

- Eugene TaylorDocument2 pagesEugene Taylorsav1oNo ratings yet

- Telstra Business Apps Shoeboxed BrochureDocument2 pagesTelstra Business Apps Shoeboxed BrochureHassan HamadyNo ratings yet

- CebuPacific Fuel Savings Case Study PDFDocument4 pagesCebuPacific Fuel Savings Case Study PDFAirbus330 Airbus330No ratings yet

- UntitledDocument287 pagesUntitledMarcos César Costa BarbosaNo ratings yet

- Role of IT in Lean Manufacturing: A Brief Scenario: G T Padmane, M T Sohel, P D PatilDocument6 pagesRole of IT in Lean Manufacturing: A Brief Scenario: G T Padmane, M T Sohel, P D PatilNatala WillzNo ratings yet

- Camunda BPM Compared To AlternativesDocument12 pagesCamunda BPM Compared To AlternativesLuciano GomesNo ratings yet

- Free Entry Level Network Engineer Resume Free WordDocument2 pagesFree Entry Level Network Engineer Resume Free WordasdfasdNo ratings yet

- 3009 10752 1 PBDocument10 pages3009 10752 1 PBWirid SuciartiNo ratings yet

- Oracle OOW19 Oracle WMS Cloud Update - Roadmap - Fastenal Case Study - 1569161499525001SPehDocument35 pagesOracle OOW19 Oracle WMS Cloud Update - Roadmap - Fastenal Case Study - 1569161499525001SPehNigel WhitmoreNo ratings yet