Professional Documents

Culture Documents

Remplazo de Un Solenoide

Uploaded by

Edwin Cordoba0 ratings0% found this document useful (0 votes)

11 views1 page1) Disconnect power from the loom and remove the solenoid unit. Note any screws or spacers used so they can be replaced correctly.

2) Unscrew the white nylon tip from the non-working plunger and remove the plunger.

3) Replace the old plunger with a new one and screw the white nylon tip back onto the new plunger, being careful not to damage the threads.

Original Description:

Original Title

Remplazo de un solenoide

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1) Disconnect power from the loom and remove the solenoid unit. Note any screws or spacers used so they can be replaced correctly.

2) Unscrew the white nylon tip from the non-working plunger and remove the plunger.

3) Replace the old plunger with a new one and screw the white nylon tip back onto the new plunger, being careful not to damage the threads.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views1 pageRemplazo de Un Solenoide

Uploaded by

Edwin Cordoba1) Disconnect power from the loom and remove the solenoid unit. Note any screws or spacers used so they can be replaced correctly.

2) Unscrew the white nylon tip from the non-working plunger and remove the plunger.

3) Replace the old plunger with a new one and screw the white nylon tip back onto the new plunger, being careful not to damage the threads.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

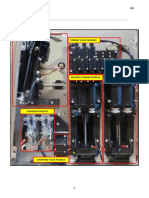

Inspecting and Changing the Solenoid Plunger on Vérifier et changer le poussoir de solénoïde

the Weavebird loom.

1) Disconnect the cables from the loom to

remove the power.

1) Dévisser le nylon

du poussoir

2) Unscrew the white nylon tip on the new

plunger by rotating it counterclockwise as

2) Retirer l’unité

shown in the diagram until it comes off. It

solénoïde du métier

may be necessary to prevent the metal plung-

Noter chaque vis

er shaft from turning by holding the other

ou espaceurs. Si

end of the shaft with your hand. If a pair of

vous avec le dernier

pliers is required, attach them to the other

modèle ne pas chang-

end of the metal shaft, gripping it at the tip to

er la position des

avoid damaging parts of the shaft that move

écroux autobloquant

in and out of the solenoid body.

(E)

Retirer (déplacer vers

3) Remove the solenoid unit from the loom.

l’arrière l’arrière de

You should not have to disconnect the elec-

l’unité (P)

trical wires but note any screws and spacers

that you remove to make sure they are rein-

3) Dévisser le nylon

stalled the same way.

du poussoir qui ne

fonctionne pas.

If you have the latest version, do not change

the position of this autolock nut (E)

4) Retirer le poussoir

4) Unscrew the white nylon tip from the

non-working plunger in the solenoid.

Remove (vove backword the board (P)

P 5) Insérer le nouveau

poussoir.

5) Remove the plunger from the Solenoid

6) Bien visser (droit)

and replace it with the new plunger

le nouveau nylon au

bout du poussoir.

6) Screw the new white nylon tip clockwise

onto the plunger being careful not to damage

7) Vérifier s’il y a

E

the threads. Turn it until the threads on the

d’autres problèmes

metal plunger shaft are inside the white nylon

de friction entre les

tip.

poussoirs de nylon et

le guide de nylon.

7) Re-install the Solenoid and make sure that

this new white nylon tip is in the centre of

G = Très bien

G

the Nylon Guide (G)

X = Pas bon

8) Check all the other plungers to make sure

that the plunger white nylon tip is not touch-

ing the nylon guide and that it doesn’t touch

it when the plunger is rotated 360 degrees. X

G = Good plunger change.indd

X = Not Good

You might also like

- TM 5-2410-241-23-2Document1,340 pagesTM 5-2410-241-23-2"Rufus"100% (2)

- Rebuilding The Kenwood Piggybacked Power SwitchDocument4 pagesRebuilding The Kenwood Piggybacked Power SwitchJohn Snyder100% (1)

- Valve Body F4A222 PDFDocument1 pageValve Body F4A222 PDFSanun Automatictranmission100% (1)

- Energy Losses in BendsDocument8 pagesEnergy Losses in BendsVikramSingh0% (3)

- Shimano Nexus3 178 ManualDocument12 pagesShimano Nexus3 178 Manualgrazka20No ratings yet

- EBK 360 Shop Manual-1Document12 pagesEBK 360 Shop Manual-1swasty10% (1)

- 1989 Garden Way Tomahawk Chipper Technical Manual WMDocument12 pages1989 Garden Way Tomahawk Chipper Technical Manual WMgodiboNo ratings yet

- Carl Zeiss Jena Tessar 50mm f2.8 (M42 Mount) Servicing by Michel PolletDocument7 pagesCarl Zeiss Jena Tessar 50mm f2.8 (M42 Mount) Servicing by Michel PolletdamiafixNo ratings yet

- Master Solenoid Kit: MS KM-175Document1 pageMaster Solenoid Kit: MS KM-175Guilherme ZoboliNo ratings yet

- TSR-009 - EngDocument7 pagesTSR-009 - EngA2139No ratings yet

- GN128 Explosion Proof Piston - 0Document2 pagesGN128 Explosion Proof Piston - 0Luz Stella Calixto GomezNo ratings yet

- Nanoject-Ii User ManualDocument4 pagesNanoject-Ii User ManualR SmithNo ratings yet

- Disassembly ReassemblyDocument18 pagesDisassembly ReassemblyIsidro MendozaNo ratings yet

- 143367-Hyd Cylinder Repair GuideDocument3 pages143367-Hyd Cylinder Repair GuideheartofdixieNo ratings yet

- Igen4 and 3 Developer Housing Rebuild-Repair ProceedureDocument16 pagesIgen4 and 3 Developer Housing Rebuild-Repair ProceedureEling EsworoNo ratings yet

- Fitting A MK2.5 Spoiler PDFDocument7 pagesFitting A MK2.5 Spoiler PDFAlexandru-Mihai NitaNo ratings yet

- 2 Piece Threaded Steel Ball Valves With Spring Return Installation, Operation, & Maintenance Guide 76-500/89-500 SeriesDocument3 pages2 Piece Threaded Steel Ball Valves With Spring Return Installation, Operation, & Maintenance Guide 76-500/89-500 SeriesRicardo OrdoñezNo ratings yet

- One Way ValveDocument2 pagesOne Way ValveOzan EGEMENNo ratings yet

- One Way Valve LoDocument2 pagesOne Way Valve LoLuis Fernando Flores CarrilloNo ratings yet

- H30 Removal Instruction v1.0Document45 pagesH30 Removal Instruction v1.0Romuald Eric TefongNo ratings yet

- Isuzu N-Series (Elf) 1994-2016Document11 pagesIsuzu N-Series (Elf) 1994-2016Emmanuel FlautaNo ratings yet

- xv1000bk PDFDocument80 pagesxv1000bk PDFHung PhuNo ratings yet

- 600ae 28Ae-Ribbon Cable ReplacementDocument4 pages600ae 28Ae-Ribbon Cable ReplacementcARLOSNo ratings yet

- Group 4 Disassembly and Assembly: 1. Priority ValveDocument38 pagesGroup 4 Disassembly and Assembly: 1. Priority ValveREMZONANo ratings yet

- MACKIE SA1232z Repair GuideDocument19 pagesMACKIE SA1232z Repair GuideCarlos Andres Espitia ReyesNo ratings yet

- Tacoma 2010 4.0LDocument8 pagesTacoma 2010 4.0LBraulio BracamontesNo ratings yet

- How To Guide - Changing Spark Plugs On A RB25DETDocument4 pagesHow To Guide - Changing Spark Plugs On A RB25DETseastate100% (1)

- Qtrinh Shimadzu Mux10Document3 pagesQtrinh Shimadzu Mux10Kuni KazeNo ratings yet

- Panoura15 ManualDocument26 pagesPanoura15 ManualWajahat SheikhNo ratings yet

- Modification of The Feed ShaftDocument1 pageModification of The Feed Shaftnhatnguyen101No ratings yet

- Operations Manual 1S03 Sand Probe RelayDocument2 pagesOperations Manual 1S03 Sand Probe RelayantonioNo ratings yet

- Assembly Instructions: For Key-Lock Mechanical Joints in Sizes 2 To 40 Inch (50-1000 MM)Document6 pagesAssembly Instructions: For Key-Lock Mechanical Joints in Sizes 2 To 40 Inch (50-1000 MM)Valeri CreciunNo ratings yet

- LSDDocument14 pagesLSDJohn RyanNo ratings yet

- Afridev Handpump MaintenanceDocument2 pagesAfridev Handpump Maintenancealkhwarizmi1968No ratings yet

- Torque Converter Clutch Case: Automatic TransmissionDocument4 pagesTorque Converter Clutch Case: Automatic TransmissionAnton FortovNo ratings yet

- Syncro Trak Service ManualDocument26 pagesSyncro Trak Service ManualMelina SbhNo ratings yet

- In-Vehicle Repair: Output Shaft Speed (OSS) SensorDocument11 pagesIn-Vehicle Repair: Output Shaft Speed (OSS) SensorAlex Maceira GraterolNo ratings yet

- MC-10001 Service SeminarDocument25 pagesMC-10001 Service SeminarAndreiNo ratings yet

- YOKOGAWA CMZ700 OverhaulDocument35 pagesYOKOGAWA CMZ700 OverhaulHardik NandaNo ratings yet

- Master Solenoid Kit: MS KM-175 93Document1 pageMaster Solenoid Kit: MS KM-175 93Guilherme ZoboliNo ratings yet

- N7100 Cleaning Consumable Guide CG00002 291401Document20 pagesN7100 Cleaning Consumable Guide CG00002 291401Rafał Krzysztof KowalskiNo ratings yet

- 604 605 610 611 612 InstructionsDocument1 page604 605 610 611 612 InstructionsTaller PahrNo ratings yet

- E38 & E39 Heater Control Valve RebuildDocument11 pagesE38 & E39 Heater Control Valve RebuildJohnNo ratings yet

- MN01023Document4 pagesMN01023hyarub9No ratings yet

- Mz380433ex Lancer Evolution PG1Document5 pagesMz380433ex Lancer Evolution PG1fonid53894No ratings yet

- Blower k430 Snh60 Overhaul ProcedureDocument39 pagesBlower k430 Snh60 Overhaul ProcedurejamiekuangNo ratings yet

- Popular Mechanics Encyclopedia 04 PDFDocument262 pagesPopular Mechanics Encyclopedia 04 PDFeuqehtbNo ratings yet

- Interruptor de PresionruelcoDocument3 pagesInterruptor de PresionruelcoantonioNo ratings yet

- Axial Fan Series O&M ManualDocument11 pagesAxial Fan Series O&M ManualSebastian PrzybylowiczNo ratings yet

- Clutch Pressure Solenoid Valve (A, B & C) Screen Replacement For 5-Speed Transmissions (2002-2004 Odyssey's)Document23 pagesClutch Pressure Solenoid Valve (A, B & C) Screen Replacement For 5-Speed Transmissions (2002-2004 Odyssey's)gregmasNo ratings yet

- Installation Manual: AN-PH10EX AN-PH20EZ AN-PH30EZ AN-PH40EZ AN-PH50EZ AN-PH60EZDocument2 pagesInstallation Manual: AN-PH10EX AN-PH20EZ AN-PH30EZ AN-PH40EZ AN-PH50EZ AN-PH60EZCol BoyceNo ratings yet

- Ruelco Quick ExhaustDocument2 pagesRuelco Quick Exhaustjonobel567No ratings yet

- 7-1gr-Fe Engine MechanicalDocument39 pages7-1gr-Fe Engine Mechanicaljhon greig100% (2)

- Axle TragaDocument80 pagesAxle TragaAsep SetiawanNo ratings yet

- Replacement: 1. Work For Preventing Gasoline From Spilling Out (See Page)Document4 pagesReplacement: 1. Work For Preventing Gasoline From Spilling Out (See Page)dmc constructionNo ratings yet

- Propeller Shaft: A: On-Car ServiceDocument3 pagesPropeller Shaft: A: On-Car ServicemiguelNo ratings yet

- KYB and Showa Shock ServiceDocument4 pagesKYB and Showa Shock ServiceJose Luis SabinoNo ratings yet

- fs-60c ManualDocument19 pagesfs-60c Manualapi-302545246No ratings yet

- Transmission Tower RestorationDocument21 pagesTransmission Tower Restorationjorge Angel LopeNo ratings yet

- Vacuum Bazookas, Electric Rainbow Jelly, and 27 Other Saturday Science ProjectsFrom EverandVacuum Bazookas, Electric Rainbow Jelly, and 27 Other Saturday Science ProjectsRating: 5 out of 5 stars5/5 (2)

- 06 SKKK1113 201415 - 2 Chap 4.4 4.6Document13 pages06 SKKK1113 201415 - 2 Chap 4.4 4.6Eunice AnneNo ratings yet

- QAP Tanks PDFDocument3 pagesQAP Tanks PDFPREETOMDEB7No ratings yet

- Compactpci 9056Rdk-860: Rapid Development Kit For Pci 9056 With Motorola Powerquicc DesignsDocument2 pagesCompactpci 9056Rdk-860: Rapid Development Kit For Pci 9056 With Motorola Powerquicc DesignsYACINE NABILNo ratings yet

- Resonant Inductive Coupling PDFDocument2 pagesResonant Inductive Coupling PDFWaqas AyubNo ratings yet

- Electric Traction Multiple Choice Questions and Answers Preparation For Competition Exams PDF - Preparation For Engineering PDFDocument11 pagesElectric Traction Multiple Choice Questions and Answers Preparation For Competition Exams PDF - Preparation For Engineering PDFER Mukesh ThakurNo ratings yet

- Product DataDocument2 pagesProduct DatapoerwntiNo ratings yet

- OMRON - Motion & DrivesDocument64 pagesOMRON - Motion & Drivestanto_deep_15No ratings yet

- Préfixe Gamme CATDocument356 pagesPréfixe Gamme CATChristopheNo ratings yet

- ChaDocument34 pagesChachayani sarumahaNo ratings yet

- "Internship Report'' ON Mitter Fasteners''Document21 pages"Internship Report'' ON Mitter Fasteners''Aadil KakarNo ratings yet

- Reciprocating Compressors For Industrial Refrigeration Series Grasso VDocument56 pagesReciprocating Compressors For Industrial Refrigeration Series Grasso VVadimNo ratings yet

- Unique Well Identifier Dec2000 PDFDocument23 pagesUnique Well Identifier Dec2000 PDFSony LazarusNo ratings yet

- 3107 eDocument2 pages3107 ektchaNo ratings yet

- SECTION III SCOPE OF WORK - 12.11.2018 - Without WIW 215Document273 pagesSECTION III SCOPE OF WORK - 12.11.2018 - Without WIW 215Kamila WehbeNo ratings yet

- Cyble SensorDocument2 pagesCyble SensorJohn BandaNo ratings yet

- MS ISO 1158 2002 Con.2012 PDFDocument16 pagesMS ISO 1158 2002 Con.2012 PDFakmamanan85No ratings yet

- IMO Performance Standards For Heading Control SystemsDocument2 pagesIMO Performance Standards For Heading Control Systemsatinder13No ratings yet

- 870.5.383 WA UsDocument136 pages870.5.383 WA UssffqgfegNo ratings yet

- Comandos Basicos OltDocument5 pagesComandos Basicos OltCordobes CordobaNo ratings yet

- Journal of Molecular Catalysis A: ChemicalDocument27 pagesJournal of Molecular Catalysis A: ChemicalAMANo ratings yet

- V1000 Manual PDFDocument487 pagesV1000 Manual PDFMohammed SajidNo ratings yet

- 1 s2.0 S0960148101000568 Main PDFDocument10 pages1 s2.0 S0960148101000568 Main PDFPrateek GargNo ratings yet

- Electrochimica ActaDocument6 pagesElectrochimica Actasladjana laketicNo ratings yet

- Highway and Traffic Engineering ReportDocument24 pagesHighway and Traffic Engineering Reportnurhaslizana0% (2)

- Versaflow 80 C Plus: Product DataDocument2 pagesVersaflow 80 C Plus: Product DataMuhammad victoryan nadezulNo ratings yet

- Unit Test Integral Calculus Set ADocument4 pagesUnit Test Integral Calculus Set ADEATH WISHNo ratings yet

- 9286-2-Detroit Integrated Powertrain BrochureDocument8 pages9286-2-Detroit Integrated Powertrain BrochureCapacitaciones RutasNo ratings yet

- Conservado SP: Water-Repellent For Facades With A High Protective PowerDocument2 pagesConservado SP: Water-Repellent For Facades With A High Protective PoweracarisimovicNo ratings yet