Professional Documents

Culture Documents

Belt Specification Layout

Belt Specification Layout

Uploaded by

Sai Sudheer KattaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Belt Specification Layout

Belt Specification Layout

Uploaded by

Sai Sudheer KattaCopyright:

Available Formats

BELT SPECIFICATION

BROCHURE

For technical assistance please contact our Technical Advisor on:

028 9335 2844 or sales@irelandsconveyors.com

30 CHURCH ROAD, BALLYNURE, CO ANTRIM, BT39 9UF

Tel: 028 9335 2844 Fax: 028 9334 2382

www.irelandsconveyors.com

Introduction

Sythentic fibre materials are increasingly superseding both the natural and semi-synthetic raw materials also in

technical applications. TECNIFLEX rubber conveyor belt with fully synthetic inserts based on polyester/ polyamide

follows this trend. Only first class fabric is used for production.

This conveyor belt has the following important features:

· Highly resistant to dynamic stress

· Extremely puncture proof

· Capable of troughing up to 36 degree

· Low strain

· Non rotting

TECNIFLEX rubber conveyor belts with EP inserts stand their daily tests under the tough conditions in the steel

industry, in metallurgy, coal mining, in the chemical and potash industries and in lime and rock working fields,

above all in the continuous handling of bulk goods. In connection with one or two puncture protective inserts

(breakers) giving the belt a high weft strength, these heavy-duty conveyor

belts can be extremely loaded under maximum stress.

Conveyor Belt Designs

Corresponding to our production programme, the following belt types, belt widths and cover panel thickness have

proven themselves in the field.

Cover Panel Thickness Carcass Thickness Belt Thickness

Belt Width Kg/m2

TS (mm) LS (mm) (mm) (mm)

3 1.5 8 2.2 6.7

EP 250/2

5 1.5 10.4 2.2 8.7

3 1.5 8.3 2.4 6.9

EP 315/2

5 1.5 10.7 2.4 8.9

3 1.5 9 3 7.5

5 1.5 11.4 3 9.5

EP 315/3

6 2 13.2 3 11

8 3 16.8 3 14

3 1.5 9.4 3.3 7.8

5 1.5 11.8 3.3 9.8

EP 400/3

6 2 13.6 3.3 11.3

8 3 17.2 3.3 14.3

3 1.5 9.7 3.6 8.1

5 1.5 12.1 3.6 10.1

EP 500/3 6 1.5 13.9 3.6 11.6

8 3 17.5 3.6 14.6

10 3 19.9 3.6 16.6

3 1.5 10.7 4.4 6.9

5 1.5 13.1 4.4 10.9

EP 500/4 6 2 14.9 4.4 12.4

8 2 18.5 4.4 15.4

10 3 20.9 4.4 17.4

47A MOOR ROAD, COALISLAND, CO. TYRONE,BT71 4QB www.screenspares.co.uk

TEL +44 (0)28 8774 1418

Cover Panel Thickness Carcass Thickness Belt Thickness

Belt Width Kg/m2

TS (mm) LS (mm) (mm) (mm)

3 1.5 11.2 4.8 9.3

5 1.5 13.6 4.8 11.3

EP 630/4 6 2 15.4 4.8 12.8

8 3 19 4.8 17.8

10 3 21.4 4.8 17.8

3 1.5 11.6 5.2 9.7

5 1.5 14 5.2 11.7

EP 800/4 6 6 2 5.2 13.2

8 3 19.4 5.2 16.2

10 3 21.8 5.2 18.2

3 1.5 12.6 6 10.5

5 1.5 15 6 12.5

EP 800/5 6 2 15.8 6 14

8 3 20.4 6 17

10 3 22.8 6 19

3 1.5 12.1 5.6 10.1

5 1.5 14.5 5.6 12.1

EP 1000/4 6 2 16.3 5.6 13.6

8 3 19.9 5.6 16.6

10 3 22.3 5.6 18.6

3 1.5 13.2 6.5 11

5 1.5 15.6 6.5 13

EP 1000/5 6 2 17.4 6.5 14.5

8 3 21 6.5 17.5

10 3 23.4 6.5 19.5

3 1.5 14.8 7.8 12.3

5 1.5 17.2 7.8 14.3

EP 1200/6 6 2 19 7.8 15.8

8 3 22.6 7.8 18.8

10 3 25 7.8 20.8

3 1.5 13.1 6.4 10.9

5 1.5 15.5 6.4 12.9

EP 1250/4 6 2 17.3 6.4 14.4

8 3 20.9 6.4 17.4

10 3 23.3 6.4 19.4

5 1.5 17.4 8 14.5

6 2 19.2 8 16

EP 1600/5

8 3 22.8 8 19

10 3 25.2 8 21

5 15 18.6 9 15.5

6 2 20.4 9 17

EP 2000/5

8 3 24 9 20

10 3 26.4 9 22

FOR TECHNICAL ASSISTANCE PLEASE CONTACT OUR TECHNICAL ADVISOR ON:

+44 (0)28 8774 1418 OR sales@screenspares.co.uk

Selection of Rubber Cover Panels

The quality of Rubber cover panels is developed from natural rubber or blends of natural and synthetic

rubber for most varied applications.

Cover Tensile Strength Elongation at Failure Abrasion

Remarks

Quality Min N/mm2 Min % Max mm3

For conveyor belts up to type EP 1000/4

Z 15 350 250 under low stress in temperature climates.

For conveyor belts from type EP500/3

Y 20 400 150 under high stress in temperature climates.

For conveyor belts from type EP 500/3

X 25 450 120 under high stress in arid, humid and

alternate climates.

For conveyor belts from EP 500/3 under

W 18 400 90 very high stress (abrasion).

Best abrasion quality.

WS 15 400 60

For oil – resistant applications.

G 15 400 150

For flame – resistant applications.

SD 20 400 150

For cold resistant applications

R 17 450 100 up to-60oC.

For heat resistant applications

T 10 300 180 110– 130oC.

For heat resistant applications

TW 10 200 200 150– 170oC.

For heat resistant applications

TH 10 200 200 180– 200oC.

For heat resistant applications

THS 10 200 200 200– 220oC.

Rupture Strength

Of major importance to the service life of a conveyor belt is the interaction and interconnection between

the individual fabric inserts and rubber cover panels. Modern impregnating and rubberising process in

production for a uniform belt structure.

The following minimum rupture strengths are guaranteed:

- Between cover panels and carcasses 3.5 – 4.5 N/mm

- Between the individual fabric inserts of the carcass 5 N/mm

Rupture Strength

Rubber conveyor belts with EP inserts have a strain of 1.3 to 2%. Special processes in fabric production and fur-

ther processing guarantee strain figures lying below 1.3% of the specified rupture force of 10%.

The added use of breaker inserts does not change the strain behaviour.

47A MOOR ROAD, COALISLAND, CO. TYRONE,BT71 4QB www.screenspares.co.uk

TEL +44 (0)28 8774 1418

Application

TECNIFLEX conveyor belts with EP inserts and breaker inserts are especially applicable to conveyors of

production handling facilities and belt installations up to axle base of 1,500m.

Belt Speeds

The following belt speeds are permissible:

- Equipment with carrying roller stations 6m/sec

- Equipment with cable-braced garland stations and stations with single cushioning 8.5m/sec

- Equipment with solely cable-braced garland stations 10m/sec

Minimum Drum Diameter

To reach an optimum life of the conveyor belt and the joint, we recommend that the following minimum

drum diameters be kept:

Minimum drum diameter for EP conveyor belt (mm)

Utilisation of the permissible belt tension

Belt

60%... 100%... 30%... 60%... Under 30%...

Type Return Return

Driving Return Snub Driving Snub Driving Snub

Drum Drum

Drum Drum Drum Drum Drum Drum Drum

250/2 200 160 125 160 125 100 125 100 80

315/2 200 160 125 160 125 100 125 100 80

315/3 315 250 200 250 200 160 200 160 125

400/3 315 250 200 250 200 160 200 160 125

500/3 315 250 200 250 200 160 200 160 125

500/4 400 315 250 315 250 200 250 200 160

630/3 400 315 250 315 250 200 250 200 160

630/4 500 400 315 400 315 250 315 250 200

800/4 630 500 400 500 400 315 400 315 250

1000/3 500 400 315 400 315 250 315 250 250

1000/4 630 500 400 500 400 315 400 315 315

1250/3 630 500 400 500 400 315 400 315 315

1250/4 800 630 500 630 500 400 500 400 315

1600/4 800 630 500 630 500 400 500 400 315

2000/4 1000 800 630 800 630 500 630 500 400

2500/4 1252 1000 800 1000 800 630 800 630 500

3150/5 1400 1250 1000 1250 1000 800 1000 800 630

FOR TECHNICAL ASSISTANCE PLEASE CONTACT OUR TECHNICAL ADVISOR ON:

+44 (0)28 8774 1418 OR sales@screenspares.co.uk

Formulas

Max Product Weight on Belt

Belt Length Belt Speed in Feet per Minute

at any one Time

When pulleys are approximately

When load is known per square

the same size

foot:

L=(D+d)/2 x 3.1416 +2C

P + G1 x C (in feet) x W (in feet)

When one pulley is much larger S = D X RPM X 2618 X 1.021

When Load is known by lbs. per

than other(atleast 3 times

hour:

larger)

P= G2 / (S X 60(minutes)) x C

L+(D+d)/2 x 3.1416 +2C +((Dd)

(feet)

2)/4C

Horsepower to Drive

Effective Tension Tight Side Tension

a Conveyor Belt

(pull need to move belt and load (total tension to move belt and

For level conveyors:

horizontally) load horizontally)

Load

E = F x (P+M) E2= E + E1

HP= (F x S x (P+M))/33,000

Effective Tension Tight Side Tension

For inclined conveyors:

HP= ((PxB) + (P+M) x F x (determines working strength of belt

(addition tension required to

S)/33,000 to handle job on per inch width basis)

prevent slippage on pulley drive)

T= E2 / W

Key Symbols

G1 Load per sq. Or cu. Ft. (lbs.) W Belt Width

B Sine of angle of include HP Horse Power

(inches)

C Centre to centre distance (inches) K Drive factor

G2 Load per hour (lbs.)

(see table 2 below)

HP Horse Power

D Diameter drive pulley (inches) L Belt length

K Drive factor (see table 2 below)

(inches) d Diameter tail pulley (inches) M Belt

L Belt length (inches)

weight (overall length not c2c)

M Belt weight (overall length not c2c)

E Effective tension (lbs.) P Product weight (lbs.)

P Product weight (lbs.)

E1 Slack side tension (lbs.) RPM Revolutions per

RPM Revolutions per minute

minute

S Speed feet per minute

E2 Tight side tension (lbs.) S Speed feet per minute

T Operating tension PIW (lbs.)

F Coefficient of friction (see table 1 below) T

W Belt Width (inches)

Operating tension PIW (lbs.)

Table 1 – Coefficient of Friction Table 2 – Drive factor F

Screw belt Gravity

Belt to slider bed or rollers Take–up Weighted Takeup

wrap on or

Steel or Metal Drive

Belt Bare Lagged Bare Lagged

Aluminium Rollers Pulley

Fs pulley side .30 to .35 .10 to .15 1800 1.6 1.0 .84 .5

Bare Duck or

.20 to .25 .10 to .15 1800 1.2 .6 .62 .35

BB side

Cover on

.50 to .55 .10 to .15 1800 1.0 .5 .547 .3

pulley side

47A MOOR ROAD, COALISLAND, CO. TYRONE,BT71 4QB www.screenspares.co.uk

TEL +44 (0)28 8774 1418

Chevron Conveyor Belting Type C-15 (385)

12mm

15mm

A

C

20mm

A b C

Belt Width Cleated Width Pitch

400mm (16”) 385 250

450mm (18”) 385 250

500mm (20”) 385 250

600mm (24”) 385 250

650mm (26”) 385 250

750mm (30”) 385 250

800mm (32”) 385 250

FOR TECHNICAL ASSISTANCE PLEASE CONTACT OUR TECHNICAL ADVISOR ON:

+44 (0)28 8774 1418 OR sales@screenspares.co.uk

Chevron Conveyor Belting Type C-15 (750)

12mm

A 15mm

C

20mm

A b C

Belt Width Cleated Width Pitch

900mm (36”) 750 250

1000mm (40”) 750 250

1050mm (42”) 750 250

1200mm (48”) 750 250

47A MOOR ROAD, COALISLAND, CO. TYRONE,BT71 4QB www.screenspares.co.uk

TEL +44 (0)28 8774 1418

Cheveron Conveyor Belting Type C-25 (550)

12mm

25mm

A

C 20mm

A b C

Belt Width Cleated Width Pitch

600mm (24”) 450 330

650mm (26”) 450 330

750mm (30”) 500 330

800mm (32”) 500 330

FOR TECHNICAL ASSISTANCE PLEASE CONTACT OUR TECHNICAL ADVISOR ON:

+44 (0)28 8774 1418 OR sales@screenspares.co.uk

Chevron Conveyor Belting Type C-25 (750)

12mm

25mm

A

C 20mm

A b C

Belt Width Cleated Width Pitch

900mm (36”) 750 330

1000mm (40”) 750 330

1050mm (42”) 750 330

1200mm (48”) 750 330

47A MOOR ROAD, COALISLAND, CO. TYRONE,BT71 4QB www.screenspares.co.uk

TEL +44 (0)28 8774 1418

How to Place an Order

Rubber Conveyor Belt 1400 EP 1250 /5 -1 Y 10 +3 Din 250m

22 102

A Name

B Belt Width

C Textile Fibre Material

D Belt Type

E Number of Inserts, Consisting of Number

of insert Transmitting the Tensile Force

F Number of Breaker Inserts

G Rubber Quality

H Thickness of Rubber Panel, carrying Side

I Thickness of Rubber Panel, running Side

J Standard No

K Belt Length

Products and Services

Please check our website www.screenspares.co.uk for further information regarding our other products and

services (listed below):

• Vulcanising Services • Full Support Service

• Rollers • Technicial Assistance

• Scrapers • Onsite Maintenance

• Skirting Rubber • Onsite Vulcanising

• Flexco Product range • Fast Response Time

• Rubber Screens • Highly Skilled Professional Workforce

• Polyurethane Screens • Full Health & Safety Training

• Modular Systems • High Stock Levels

• Impact Bars

• Miscellaneous Rubber Products

If you have a specific query then please contact our Technical Advisor direct on: +44 (0)28 8774 1418.

Alternatively all written queries including diagrams should be sent to sales@screenspares.co.uk.

FOR TECHNICAL ASSISTANCE PLEASE CONTACT OUR TECHNICAL ADVISOR ON:

+44 (0)28 8774 1418 OR sales@screenspares.co.uk

47a Moor Road

Coalisland,

Co. Tyrone

BT71 4QB

T +44 (0)28 8774 1418

E sales@screenspares.co.uk

W www.screenspares.co.uk

You might also like

- Hdpe Pipe Weight & Dimensional Chart As Per Is: 4984:2016Document1 pageHdpe Pipe Weight & Dimensional Chart As Per Is: 4984:2016Procurement ACPL92% (24)

- 1000MT Cap DesignDocument5 pages1000MT Cap Designrbalmodal100% (1)

- Heat Exchanger DesignDocument27 pagesHeat Exchanger DesignPrateek Mall83% (6)

- Demag - Terex Roadmaster5300Document5 pagesDemag - Terex Roadmaster5300Bharadwaj RangarajanNo ratings yet

- Richard Lisle Peter Leyshon Stereographic Projection Techniques For Geologists and Civil Engineers Cambridge University Press 2004 PDFDocument121 pagesRichard Lisle Peter Leyshon Stereographic Projection Techniques For Geologists and Civil Engineers Cambridge University Press 2004 PDFGabi Levente100% (1)

- Ammonia-Based Flue Gas Desulfurization - Power EngineeringDocument4 pagesAmmonia-Based Flue Gas Desulfurization - Power EngineeringsharemwNo ratings yet

- Gre Pipe 1Document7 pagesGre Pipe 1stephenNo ratings yet

- Mud Pump DataDocument12 pagesMud Pump DataPedro TorresNo ratings yet

- 01 Manual - Detector Metales - MSM-210-MD-01Document194 pages01 Manual - Detector Metales - MSM-210-MD-01Emilio Alejandro Molina Salvo100% (2)

- Ut Scanning Step For ExaminationDocument3 pagesUt Scanning Step For ExaminationMohdHuzairiRusliNo ratings yet

- Carbon Steel / Alloy Steel / Seamless Pipe: Download SpecificationDocument2 pagesCarbon Steel / Alloy Steel / Seamless Pipe: Download SpecificationSreenubabu Kandru100% (1)

- Wall Thickness CalculatorDocument5 pagesWall Thickness CalculatorbillyNo ratings yet

- Heat Tracing CalculationDocument22 pagesHeat Tracing CalculationflyzalNo ratings yet

- Thread Standard BSPDocument7 pagesThread Standard BSPĐạt TrầnNo ratings yet

- Medium Storage Silos C 101460023 EngDocument7 pagesMedium Storage Silos C 101460023 EngBruno100% (1)

- Basics of Dental Technology: A Step by Step ApproachFrom EverandBasics of Dental Technology: A Step by Step ApproachRating: 5 out of 5 stars5/5 (1)

- Wood Design Manual 2017 ErrataDocument20 pagesWood Design Manual 2017 ErratanoobfNo ratings yet

- Grove GMK 4070-1Document6 pagesGrove GMK 4070-1philip_cadNo ratings yet

- 3327hd - Ludman Compaction PDFDocument116 pages3327hd - Ludman Compaction PDFsharemwNo ratings yet

- Keyway Sizing ChartDocument1 pageKeyway Sizing Chartpstechnical_43312697No ratings yet

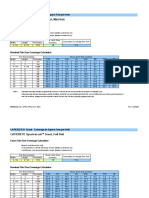

- LATICRETE Grout Coverage Calculator - by Unit Size - US Version3Document14 pagesLATICRETE Grout Coverage Calculator - by Unit Size - US Version3Ilyas Chaudhary LahoreNo ratings yet

- NP T Am Eric An Tape Red Pipe Thre AdDocument1 pageNP T Am Eric An Tape Red Pipe Thre AdAdeel Ehtasham KhokharNo ratings yet

- Blade Angle Chart-Steven Penner-Blade ForumsDocument2 pagesBlade Angle Chart-Steven Penner-Blade ForumsMoises TinteNo ratings yet

- Teava Apa-Date-TehniceDocument9 pagesTeava Apa-Date-TehnicestroiebogdanNo ratings yet

- Conversion - Chart - IADC BIT CODEDocument1 pageConversion - Chart - IADC BIT CODEHamid Reza BabaeiNo ratings yet

- 3 Grove GMK 3050Document3 pages3 Grove GMK 3050Mostafa MohamedNo ratings yet

- GMK 2035Document4 pagesGMK 2035sefazNo ratings yet

- 03 Mammoth WSHP E Series 50HZ R410A Catalogue 2020Document22 pages03 Mammoth WSHP E Series 50HZ R410A Catalogue 2020Anonymous oKTCFZNTmNo ratings yet

- BS 3293 Weld Neck and Slip On Flanges Class 150lbsDocument1 pageBS 3293 Weld Neck and Slip On Flanges Class 150lbsJavier Alejandro Herrera MadariagaNo ratings yet

- Steel Plate Thickness and Weight: Nominal Size Thickness Weight (lb/ft2) in MMDocument2 pagesSteel Plate Thickness and Weight: Nominal Size Thickness Weight (lb/ft2) in MMNaufal HadiNo ratings yet

- Rib ChartDocument1 pageRib ChartAzwan ShahmeeNo ratings yet

- DAR Piping SupportsDocument1 pageDAR Piping SupportsAbdul Rawoof ShaikNo ratings yet

- PVC-U Pressure Pipes: Lifelines For The NationDocument2 pagesPVC-U Pressure Pipes: Lifelines For The NationElisha WankogereNo ratings yet

- Plasco - PVC U Pipes Brochure S Min PDFDocument2 pagesPlasco - PVC U Pipes Brochure S Min PDFadam rahaNo ratings yet

- Standard Key WayDocument2 pagesStandard Key WaySuresh DatalNo ratings yet

- Operation Manual For TA ElevatorDocument7 pagesOperation Manual For TA ElevatortraidenNo ratings yet

- Isc at The Receiving End of A Feeder As A Function of The Isc at Its Sending End - Electrical Installation GuideDocument3 pagesIsc at The Receiving End of A Feeder As A Function of The Isc at Its Sending End - Electrical Installation GuidedhruvNo ratings yet

- Eips) Working Load Limit Chart Acc Asme B.30 9 (GradeDocument1 pageEips) Working Load Limit Chart Acc Asme B.30 9 (GradeMitra PelangiNo ratings yet

- Table III Load Criteria Uniform Bearing On Soil Type "C": Notes For Load TablesDocument1 pageTable III Load Criteria Uniform Bearing On Soil Type "C": Notes For Load TablesDhina karanNo ratings yet

- TERMINACIONES 13411-3 T-LOCTcase123and4 PDFDocument2 pagesTERMINACIONES 13411-3 T-LOCTcase123and4 PDFKarloz FernandoNo ratings yet

- Tabla Roscas Dibujo IndustrialDocument2 pagesTabla Roscas Dibujo Industrialahs00022No ratings yet

- Continuous Infusion Rate ChartDocument2 pagesContinuous Infusion Rate ChartabeNo ratings yet

- Hyper Focal Distances Nikon DXDocument1 pageHyper Focal Distances Nikon DXazoth7No ratings yet

- Flow GPM Nominal Size: Pressure Loss Through Water Meters - PsiDocument1 pageFlow GPM Nominal Size: Pressure Loss Through Water Meters - PsiDon Clerance Denzil WeerakkodyNo ratings yet

- Wall Thickness CalculatorDocument7 pagesWall Thickness CalculatorHanafiahHamzahNo ratings yet

- Purge Time 7-00Document1 pagePurge Time 7-00Mohamad ArrajNo ratings yet

- 6x36WS (Warrington Seale) - 6x19 & 6x36 Classification Wire RopeDocument2 pages6x36WS (Warrington Seale) - 6x19 & 6x36 Classification Wire RopeTawfiq ZidanNo ratings yet

- Dailey Hydraulic Fishing Jar 6 PDFDocument1 pageDailey Hydraulic Fishing Jar 6 PDFMuhammad ShahrukhNo ratings yet

- Fisatehnicaaspersor PGPUltraDocument4 pagesFisatehnicaaspersor PGPUltraDan DanubiusNo ratings yet

- Setting Time + 50% at 37 °C 99% RH Before TestDocument9 pagesSetting Time + 50% at 37 °C 99% RH Before TestAhmed Febri Hertama 'Sinosuke'No ratings yet

- Ansi B36.10 Carbon Steel / Alloy Steel / Seamless Pipe Weight Perkg/Mtr Astm Pipe Schedule - Wall Wall Thickness Millimetere - WT Weights in KG./MTRDocument3 pagesAnsi B36.10 Carbon Steel / Alloy Steel / Seamless Pipe Weight Perkg/Mtr Astm Pipe Schedule - Wall Wall Thickness Millimetere - WT Weights in KG./MTRSURAJ PANDEYNo ratings yet

- BSlip-on 150 PDFDocument2 pagesBSlip-on 150 PDFRichard Piscoya VillegasNo ratings yet

- L1 Per 100Document5 pagesL1 Per 100Nur PriantoNo ratings yet

- interest_rate_factor_chartDocument2 pagesinterest_rate_factor_chartSanay ChauhanNo ratings yet

- Month/ Year Number of Numerator Cases Number of Denominator CasesDocument10 pagesMonth/ Year Number of Numerator Cases Number of Denominator CasesDearRed FrankNo ratings yet

- Pipe (OK)Document1 pagePipe (OK)Black AutumnNo ratings yet

- HDPE Pipe Flow RatesDocument2 pagesHDPE Pipe Flow Ratesalaa sadikNo ratings yet

- ISO 4422-2.pdf 2Document3 pagesISO 4422-2.pdf 2Ashraf MansourNo ratings yet

- TDC ACME General PurposeDocument1 pageTDC ACME General Purposedlemay06No ratings yet

- Brida Sli On Flat FaceDocument1 pageBrida Sli On Flat Facejuan ormacheaNo ratings yet

- All Units in Metric Tons: BS 13414 Wire Rope Chart For Sling SetsDocument1 pageAll Units in Metric Tons: BS 13414 Wire Rope Chart For Sling SetsHelmiNo ratings yet

- 6 × 19 & 6 × 37 Class Wire Rope, Bright & GalvanizedDocument3 pages6 × 19 & 6 × 37 Class Wire Rope, Bright & GalvanizedCody GeisendorferNo ratings yet

- Hollow Core PDFDocument19 pagesHollow Core PDFAlessandro BicegoNo ratings yet

- Data Dan Grafik Sondir: Nama Proyek: Hari, TGL: Lokasi: Juru Sondir: Nomor Sondir: Kedalaman Ahir: MDocument7 pagesData Dan Grafik Sondir: Nama Proyek: Hari, TGL: Lokasi: Juru Sondir: Nomor Sondir: Kedalaman Ahir: MIlyas NannmarNo ratings yet

- Pipe Series: Wall Thickness and MassDocument24 pagesPipe Series: Wall Thickness and MassTammam HassanNo ratings yet

- Types of Strand - Extra High Strength: Minimum Breaking Strength in Pounds Minimum Weight of Coating OZ./SQ. FTDocument1 pageTypes of Strand - Extra High Strength: Minimum Breaking Strength in Pounds Minimum Weight of Coating OZ./SQ. FTmiguelpaltinoNo ratings yet

- Socket 150# AnsiDocument2 pagesSocket 150# AnsiANDERSON NERESNo ratings yet

- ATEC - Process FlowDocument10 pagesATEC - Process FlowsharemwNo ratings yet

- Determine The Outer Diameter and Shaft Diameter of The Conveyor Pulley - SKE IndustriesDocument9 pagesDetermine The Outer Diameter and Shaft Diameter of The Conveyor Pulley - SKE IndustriessharemwNo ratings yet

- Urea PhosphateDocument2 pagesUrea PhosphatesharemwNo ratings yet

- Designation GuideDocument3 pagesDesignation GuidesharemwNo ratings yet

- Organic Composting - Fast Composting - Composting - Compost Maker - How To CompostDocument10 pagesOrganic Composting - Fast Composting - Composting - Compost Maker - How To CompostsharemwNo ratings yet

- Chitosan Jeas 1215 3092Document5 pagesChitosan Jeas 1215 3092sharemwNo ratings yet

- D ZeoliteDocument6 pagesD ZeolitesharemwNo ratings yet

- Chitosan 22Document13 pagesChitosan 22sharemwNo ratings yet

- 2010 DorotaDocument18 pages2010 DorotasharemwNo ratings yet

- Adsoprtion EA13Document11 pagesAdsoprtion EA13sharemwNo ratings yet

- Chitosan 55910823Document4 pagesChitosan 55910823sharemwNo ratings yet

- Jacobs Signs THIOPAQ O&G Sulfur Recovery Technology Licensor Agreement With Paqell - Business WireDocument1 pageJacobs Signs THIOPAQ O&G Sulfur Recovery Technology Licensor Agreement With Paqell - Business WiresharemwNo ratings yet

- The Circular Economy of Sulfuric AcidDocument3 pagesThe Circular Economy of Sulfuric AcidsharemwNo ratings yet

- SO2 Removal & SO2 Absorption by METDocument2 pagesSO2 Removal & SO2 Absorption by METsharemwNo ratings yet

- Argus-Sulphuric-Acid PriceDocument9 pagesArgus-Sulphuric-Acid PricesharemwNo ratings yet

- Investor Relations - Sulfuric Acid Regeneration PlantDocument3 pagesInvestor Relations - Sulfuric Acid Regeneration PlantsharemwNo ratings yet

- Carrier Idler - Idler - JRC Co., LTD., The Top Brand of Belt Conveyor PartsDocument4 pagesCarrier Idler - Idler - JRC Co., LTD., The Top Brand of Belt Conveyor PartssharemwNo ratings yet

- Sulfuric Acid Regeneration PlantDocument8 pagesSulfuric Acid Regeneration PlantsharemwNo ratings yet

- An Efficient Ammonia-Based SRU Tail Gas Desulfurization ProcessDocument25 pagesAn Efficient Ammonia-Based SRU Tail Gas Desulfurization ProcesssharemwNo ratings yet

- Amy Evans - Marsulex Environmental Technologies - 7-26-12Document18 pagesAmy Evans - Marsulex Environmental Technologies - 7-26-12sharemwNo ratings yet

- 01-Apctme-0707 - Japan FGDDocument7 pages01-Apctme-0707 - Japan FGDsharemwNo ratings yet

- Argus-Phosphate - Phosphoric Acid Price Metholodogy PDFDocument11 pagesArgus-Phosphate - Phosphoric Acid Price Metholodogy PDFsharemwNo ratings yet

- Polysulphate 10 Reasons enDocument12 pagesPolysulphate 10 Reasons ensharemwNo ratings yet

- 02c. Integration of VectorDocument19 pages02c. Integration of VectorYudha AgungNo ratings yet

- Ignition TimingDocument2 pagesIgnition TimingleitordNo ratings yet

- E KMT CatalogDocument164 pagesE KMT CatalogzoranmiskovicNo ratings yet

- 1st Year Syllabus 23-24 - New CompressedDocument183 pages1st Year Syllabus 23-24 - New Compressedmsyashwanth432005No ratings yet

- Echinoderm Lab ReportDocument7 pagesEchinoderm Lab ReportVictoria LiuNo ratings yet

- Next-Generation Nozzle Check Valve Reduce Operating Costs - Engineer LiveDocument3 pagesNext-Generation Nozzle Check Valve Reduce Operating Costs - Engineer LiveTONNo ratings yet

- Power Clean Bio Mechanics SouzaDocument8 pagesPower Clean Bio Mechanics SouzakrayfieldNo ratings yet

- 2022 Wang Ishihara - New P-Y Model For Seismic Loading Predition of Pile FoundationsDocument22 pages2022 Wang Ishihara - New P-Y Model For Seismic Loading Predition of Pile FoundationsMarcus Girão de MoraisNo ratings yet

- Define Egyptian Response Function in ETABSDocument7 pagesDefine Egyptian Response Function in ETABSBehairy AhmedNo ratings yet

- Group 2 Group 2 - Physical Properties Properties: Atomic RadiusDocument1 pageGroup 2 Group 2 - Physical Properties Properties: Atomic RadiusAn Trương Nguyễn HoàngNo ratings yet

- APhO 2017 Theory 1 SolutionDocument18 pagesAPhO 2017 Theory 1 SolutionmpecthNo ratings yet

- 4LoveandScience Booking PacketDocument3 pages4LoveandScience Booking PacketKendra KruegerNo ratings yet

- FCC Unit Optimization Using The Magna Cat ProcessDocument17 pagesFCC Unit Optimization Using The Magna Cat Process3668770No ratings yet

- DC Motor Parameter EstimationDocument10 pagesDC Motor Parameter EstimationElmer HCNo ratings yet

- The Exponential FunctionDocument18 pagesThe Exponential FunctionLucas BonifacioNo ratings yet

- Winning Solutions: Printed BookDocument1 pageWinning Solutions: Printed BookcYbernaTIc enHancENo ratings yet

- Linear Bushing: by SAMICK The Linear InstinctDocument54 pagesLinear Bushing: by SAMICK The Linear InstinctJorgeGonzálezNo ratings yet

- Evolution of Indian OceanDocument36 pagesEvolution of Indian OceanMaxzero EdgeNo ratings yet

- Biology Form 4 Notes Chapter 3Document8 pagesBiology Form 4 Notes Chapter 3MSKNo ratings yet

- Effect of Nb-Doping On Electrochemical Stability of Li4Ti5O12 Discharged To 0 V 58c9223ab7f60Document9 pagesEffect of Nb-Doping On Electrochemical Stability of Li4Ti5O12 Discharged To 0 V 58c9223ab7f60Kuanzong FungNo ratings yet

- F-QC-02 MSA PlanDocument5 pagesF-QC-02 MSA PlanKaran MalhiNo ratings yet

- "Smart Water" For Enhanced Oil Recovery: A Comparison of Mechanism in Carbonates and SandstonesDocument28 pages"Smart Water" For Enhanced Oil Recovery: A Comparison of Mechanism in Carbonates and SandstonesLulut Fitra FalaNo ratings yet

- Exercise 2.3: Part (A)Document3 pagesExercise 2.3: Part (A)Miguel SantanaNo ratings yet

- ONU Reacciones QuimicaDocument19 pagesONU Reacciones QuimicaDomingo AlegríaNo ratings yet