Professional Documents

Culture Documents

Lyophilized Product Cakes An Improved Method For Visualizing The Morphology of

Uploaded by

vijay narayanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lyophilized Product Cakes An Improved Method For Visualizing The Morphology of

Uploaded by

vijay narayanCopyright:

Available Formats

Downloaded from on June 21, 2021

An Improved Method for Visualizing the Morphology of

Lyophilized Product Cakes

Philippe Lam and Thomas W. Patapoff

PDA J Pharm Sci and Tech 2011, 65 425-430

Access the most recent version at doi:10.5731/pdajpst.2011.00749

Downloaded from on June 21, 2021

Technology/Application

An Improved Method for Visualizing the Morphology of

Lyophilized Product Cakes

PHILIPPE LAM1 and THOMAS W. PATAPOFF2,*

1

Late Stage Pharmaceutical Development and 2Early Stage Pharmaceutical Development, Genentech, Inc. ©PDA,

Inc. 2011

ABSTRACT: Due to low optical contrast, the morphology of lyophilized product cakes is difficult to observe and

photograph. Furthermore, internal structures are normally not visible unless the cake is fractured. Because most

lyophilized substances are hygroscopic and quite fragile, the product cake, once removed from the vial, will rapidly

degrade. We propose herein a technique that allows a lyophilized product cake to be preserved, manipulated, and

easily observed outside the vial. This technique yields high-quality, cross sectional images that reveal intricate fine

structures without the use of expensive specialized equipment.

KEYWORDS: Lyophilization, Visualization, Cake, Structure, Encapsulation, Freeze-drying

Introduction Previously, Patapoff and Overcashier (1) introduced a

technique that involved embedding a lyophilizate cake

During lyophilization cycle development or investiga- in a low-melting-temperature paraffin. Once solidified,

tions of production lyophilization process deviations, the cake-containing paraffin plug could be removed by

a visual inspection of the lyophilizate cake is generally breaking the vial. The authors have shown that even

performed as part of the assessment. Particular cake microscopic, intricate structures can be easily photo-

features can provide some clues to events that trans- graphed and preserved for a substantial length of time

pired during the freeze drying operation. For example, in this fashion. There are, however, several require-

a cake that exhibits regions of partial collapse can be ments, such as the need to incorporate a fluorescent

indicative of excessive shelf temperature during the dye to the liquid prior to freeze-drying and the expo-

primary drying step. Frequently, these regions of par- sure of the final cake to a temperature of ⬃60 °C,

tial collapse cannot be seen by external inspection which limit the utility of the technique to lyophiliza-

while the the cake remains in the vial. tion runs carried in the laboratory and to cakes that can

withstand higher temperatures without significant

It is desirable to maintain a photographic record of the

structural change.

various lyophilizate cakes for documentation purpose.

However, properly imaging a low-contrast sample

In this paper we present an improved technique that is

through the highly curved surface of a glass vial presents

not subject to the limitations mentioned above and that

significant challenges. Extracting the cake from the vial

produces comparable image quality. The new proce-

can improve the quality of the final images and allow for

dure still involves encapsulation of the lyophilizate

the observation of internal structures by sectioning with

cake and a fluorescent dye for imaging, but in this

a sharp blade. However, due to their fragile nature, the

instance a silicone elastomer is used as the matrix and

manipulation of naked cakes is difficult and, for hygro-

the dye is added just before visual observation. Prod-

scopic products, the cakes may also “melt” rapidly once

uct vials from both laboratory and large-scale produc-

exposed to ambient conditions.

tion facilities have been successfully processed and

imaged in this manner.

* Corresponding author: Thomas W. Patapoff, Genen-

tech, Inc., 1 DNA Way, South San Francisco, CA For the purpose of illustration, we have encapsulated

94080, (650) 225-8006, tomp@gene.com and imaged lyophilized samples that had been frozen

in a controlled manner and show that the resulting

doi: 10.5731/pdajpst.2011.00749

cake morphologies are as expected (1, 2).

Vol. 65, No. 4, July–August 2011 425

Downloaded from on June 21, 2021

Material and Methods 2. The samples were immersed in a slurry of dry

ice– ethanol until completely frozen

Preparation of Lyophilized Samples

3. Each sample was then placed on the lyophilizer

Two solutions were used to demonstrate the usefulness shelf that was precooled to ⫺50 °C

of the embedding and imaging technique. One solution

(with no protein) contained 4% trehalose, 50 mM 4. The shelf temperature was then held at ⫺50 °C for

sodium phosphate at pH 6.2, and 0.02% polysorbate at least 5 h

20. A second solution contained 25 mg/mL protein (a

monoclonal antibody) in the same base formulation as These cooling strategies, although impractical for

described above. Vials (10 cc) were filled with 4 mL manufacturing, demonstrate the ability of the embed-

of the above solutions and frozen by methods as ding and imaging method to resolve finer structures

described below, and reported previously (1). found in some cakes.

The following procedure was used to prepare vials Once frozen all the samples were dried under the

under the “normal” freezing conditions: following conditions:

1. Samples were equilibrated on the lyophilizer shelf 1. The chamber pressure was set to 150 m Hg pres-

at 5 °C for several hours sure absolute

2. The shelf temperature was ramped linearly from 5 2. The shelf temperature was ramped linearly from

to ⫺50 °C at 0.3 °C/min ⫺50 to 20 °C at 0.25 °C/min

3. The shelf temperature was held at ⫺50 °C for at 3. The self temperature was held at 20 °C for 47 h

least 5 h (this is the combined primary and the secondary

drying steps)

This cooling strategy resulted in vials that were su-

percooled to between ⫺15 to ⫺25 °C prior to sponta- Upon completion of the drying, the vials were stop-

neous ice nucleation. Our estimates were based on the pered under vacuum and stored at ambient tempera-

shelf temperature and visual observation of the sam- ture.

ples during the freezing ramp.

Encapsulation

To produce directional ice growth, samples were pre-

pared as follows: We used two different methods for encapsulating ly-

ophilized cakes in Dow Corning Sylgard 184 polydi-

1. Samples were equilibrated under wet ice methylsiloxane (PDMS) polymer, as discussed below.

2. The lyophilizer shelf temperature was ramped from The polymer, received as a two-component kit com-

5 to ⫺50 °C at 0.3 °C/min prised of a base elastomer and a curing agent, was

prepared according to the manufacturer’s instructions.

3. Once the shelf temperature reached less than 0 °C, After mixing, repeated cycling between 10 –20 kPa

each sample from step 1 was briefly contacted on absolute pressure and ambient pressure greatly facili-

the bottom of the vial with a piece of dry ice to tated the removal of entrained and dissolved air from

induce ice nucleation then immediately placed on the PDMS. The mixture has a working time of several

the lyophilizer shelf hours (⬎2 h according to manufacturer documenta-

tion), providing ample time to perform all subsequent

4. Upon completion of the ramp, the shelf temperature operations.

was held at ⫺50 °C for at least 5 h

During the encapsulation procedure, each sample vial

To produce rapidly frozen ice growth, samples were must be uncapped and briefly exposed to ambient

prepared as follows conditions. To minimize the possibility of excessive

moisture pickup by the lyophilized cake, a gentle dry

1. Samples were equilibrated under wet ice gas purge over the opened vial can be used.

426 PDA Journal of Pharmaceutical Science and Technology

Downloaded from on June 21, 2021

rapidly. The lyophilizer shelves were then partially

collapsed, just enough as to sufficiently push the

plunger down and dislodge the Parafilm plug. The

PDMS was allowed to flow from the funnel and flood

the vial for up to 1 h. Subsequently, the lyophilizer

chamber was brought back to ambient pressure, forc-

ing the polymer into the lyophilized cake interstitial

space. The vial assembly was unloaded from the ly-

ophilizer, and the funnel and wire bracket were re-

moved. The vial was then placed into an oven set at

35– 40 °C for 3– 4 days to allow the PDMS to fully

cure. Note that the PDMS can be cured at still lower

temperatures but the curing time will be lengthened.

Method 2

The setup for this method is simpler than for Method

1 in that the PDMS is introduced into the vial prior to

the application of vacuum. However, upon reducing

the pressure, substantial amount of foaming occurs.

Therefore, a funnel attached to the vial opening is

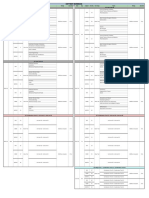

needed to prevent the PDMS from spilling out. Figure

1b shows a vial assembly ready to be filled with the

Figure 1

polymer. In this case, the funnel comprises a section of

a 50 mL centrifuge tube carefully attached to the vial

Encapsulation setups. a) Method 1, b) Method 2. (1)

mouth using adhesive tape so as to prevent the PDMS

modified 50 mL Eppendorf Combitip, (2) parafilm

from leaking out. A retaining bracket for the lyophi-

plug, (3) wire retaining bracket, (4) 50 mL centri-

lized cake must also be in place before introduction of

fuge tube funnel.

the polymer.

To encapsulate a lyophilized cake, an appropriate

Method 1

amount of PDMS was poured into the funnel and the

Each vial containing a lyophilized cake for encapsu- assembly was transferred to a lyophilizer (a vacuum

lation was set up as shown in Figure 1a. A modified 50 oven can also be used in lieu of a lyophilizer). The

mL Eppendorf Combitip Plus pipette tip was used as chamber pressure was then reduced to ⬃5 kPa abso-

the reservoir for the PDMS. The tip of the Combitip lute. Depending on the size of the cake, more than 1 h

was trimmed down to the base leaving ⬃5 mm, and a may be required for the foam to collapse sufficiently

small Parafilm M plug was inserted in the opening. before the pressure can be restored to ambient condi-

Some notches were made in the plastic plunger of the tions. Once the PDMS fully penetrated the cake, the

pipette tip to allow for venting. A retaining bracket vial assembly was unloaded from the lyophilizer and

fashioned from wire (here copper was used) served to the funnel and wire bracket removed. The vial was

prevent the lyophilized cake from floating atop the then placed into an oven set at 35– 40 °C for 3– 4 days

PDMS once the polymer is introduced in the vial. The to allow the PDMS to fully cure.

wire bracket and the Combitip funnel were secured to

the vial using adhesive tape. Sufficient amount of Extraction of the Embedded Lyophilized Cake

PDMS was poured into the funnel, and the plunger

was set in place. The assembly was placed inside a The embedded cake was extracted by placing the vial

lyophilizer and the pressure was lowered to ⬃5 kPa in a plastic bag and a vise was used to carefully shatter

absolute; the shelf temperature remained at ambient. it. Methanol or isopropanol can be used as wetting

At this pressure additional degassing of the PDMS agent to facilitate the removal of adhered glass frag-

occurred but most of the bubbles dissipated reasonably ments from the PDMS plug.

Vol. 65, No. 4, July–August 2011 427

Downloaded from on June 21, 2021

Visualization

The embedded cake that was released from the vial

was sectioned by cutting it with a sharp blade. Lon-

gitudinal and cross-sectional cuts were made and im-

aged under white illumination or illumination to en-

hance fluorescence. For the latter, a fluorescent dye

was applied from a felt tip marker (Sharpie Accent

Liquid Highlighter, orange color). The water-based

dye did not adhere to the hydrophobic polymer, and

excess dye was easily wiped off with a clean cloth.

For fluorescence imaging, the sample was lighted with

a Prolight High Power 1 watt UV LED (UV-1WS, 400

nm) equipped with a 15° focusing lens and powered by

a 350 mA Buckpuck LUXDRIVE (03021-DE-350)

LED driver. A Hoya B-390 blue filter was added to the

front of the LED focusing lens to minimize higher

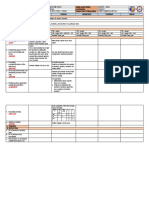

wavelength light. Photographs were taken through a Figure 2

Leica MZ16 stereo microscope equipped with a PLAN

APO 0.63⫻ objective and a Canon 5D SLR camera. A Encapsulated cake containing 25 mg/mL protein

Hoya K2 yellow filter was placed in front of the from normal freezing regiment, liquid was sub-

microscope objective to further enhance contrast. jected to supercooling and ice nucleated between

ⴚ15 and ⴚ25 °C. a– c) vertical section, d–f) hori-

Results and Discussion zontal section. Frames a and d are sections photo-

graphed under white light before dye staining; all

In the majority of cases, either proposed encapsulation others are from UV lighting post-staining. White

method can be used successfully. Method 1 may re- outline in frames b and e indicate magnified areas

duce the potential for entrapping bubbles, particularly shown in frames c and f.

with larger cakes because vacuum is applied prior to

the introduction of the polymer. If the cake volume is

more than half the vial volume, then Method 2 should highlights the edges of all cake features that were

be used to prevent overfilling the vial before the imprinted in the PDMS. It is also possible to see

polymer can penetrate the cake. features below the exposed surface because the poly-

mer is clear and the fluorescent dye tends to penetrate

While the PDMS has relatively high pre-cure viscosity some distance into the lyophilizate.

(3900 cP), it exhibits very low surface tension. In most

instances, full penetration and “wetting” of lyophi- Figure 2 shows photographs of a protein containing

lized cake has not been an issue in our experience. The sample frozen under normal condition (cooled from 5

polymer cures into a hydrophobic, crystal-clear, me- to ⫺50 °C at 0.3 °C/min) that resulted in a cake that

dium-soft material (Shore A durometer value of 48) exhibits sponge-like morphology. This is the expected

with excellent dimensional stability. outcome for liquid vials that have undergone super-

cooling (ice nucleation occurred between ⫺15 to

Figures 1– 4 are photographs of samples that have ⫺25 °C) and are subsequently frozen rapidly (1, 2). In

been encapsulated and sectioned both vertically and this instance, some cake shrinkage and cracking also

horizontally at about mid-section. The images, usually occurred during the drying. The spatial relationship

taken a few minutes after sectioning the cakes, dem- between the various parts of the cake has been cap-

onstrate the resolving power of this technique, and the tured by the PDMS, and the internal fractures are

advantage of using fluorescent staining is dramatically easily observable. Some liquid phase separation may

apparent. Note that once a sample has been sectioned also have occurred in this sample as evidenced by the

and stained, the lyophilizate will melt. However, no larger and less dense cell structure near the upper

loss of optical resolution occurs because the lighting portion of the cake (3). This latter feature would have

428 PDA Journal of Pharmaceutical Science and Technology

Downloaded from on June 21, 2021

center of the cake. This example also demonstrates the

ability to apply the fluorescence stain to samples that

do not contain protein.

Figure 5 are images of actual protein products pre-

pared in a pilot-scale lyophilizer. Figures 5a and 5b

show the vertical and horizontal cross-section, respec-

tively, of a cake that exhibits partial collapse on the

bottom half. In addition, strong neighboring vial ef-

fects are present as evidenced by the hexagonal shape

of the cake bottom. Figure 5c and 5d show the result-

ing cake structure from a vial that contained a moni-

toring thermocouple as compared with a vial without.

It is known that the presence of thermocouples tends

to induce ice nucleation at higher temperatures (lower

degree of supercooling). The sample in Figure 5c

seems to include structures formed by directional ice

crystals, consistent with slower ice crystal growth rate,

Figure 3 whereas that in Figure 5d exhibits a mostly sponge-

like morphology, consistent with fast ice crystal

Encapsulated cake containing 25 mg/mL protein

from directional freezing regiment; liquid was

equilibrated on wet ice and ice nucleation was in-

duced by briefly touching a piece of dry ice to the

vial bottom. The vial was then placed on back the

lyophilizer shelf at slightly <0 °C. a– c) vertical

section, d–f) horizontal section. Frames a and d are

sections photographed under white light before dye

staining; all others are from UV lighting post-stain-

ing. White outline in frames b and e indicate mag-

nified areas shown in frames c and f.

been very difficult detect without the support of the

cake structure by PDMS.

The protein-containing sample shown in Figure 3 un-

derwent directional freezing from bottom up, resulting

in a final lyophilized cake that exhibits large lamellar

structures. This morphology is consistent with a solu-

tion where ice nucleation occurred close to the freez- Figure 4

ing point and ice growth proceeded relatively slowly

such as to form large ice crystals (1, 2). The voids seen Encapsulated cake without protein from direc-

in areas near the vial wall may be localized cake tional fast freezing regiment, liquid was equili-

fractures due to moderate cake shrinkage. brated on wet ice and completely frozen in a dry

ice-ethanol bath. The vial was then placed on the

Figure 4 shows a non-protein sample that underwent lyophilizer shelf at ⴚ50 °C. a– c) vertical section,

rapid directional freezing from the bottom and sides of d–f) horizontal section. Frames a and d are sections

the vial. This freezing regime resulted in very fine photographed under white light before dye stain-

lamellar structures oriented toward the center of the ing; all others are from UV lighting post-staining.

vial. In addition, there is also evidence of cake shrink- White outline in frames b and e indicate magnified

age causing large cracks in the periphery as well the areas shown in frames c and f.

Vol. 65, No. 4, July–August 2011 429

Downloaded from on June 21, 2021

vial to over 40 mL in a 100 mL vial. With care, even

highly hygroscopic material can be processed with

good results. However, very fragile lyophilized cakes

may present difficulties because they can be crushed

by the weight of the polymer when it is introduced into

the vial. The technique can easily be refined and

adapted with experimentation to suit individual re-

quirements.

Conclusion

We have presented an improved technique that is

Figure 5 facile and can be used to image lyophilized products

cakes without the need for specialized or expensive

Encapsulated cakes of actual protein products pre- equipment. We believe this to be a valuable tool for

pared in pilot scale lyophilizer. a) vertical cross- lyophilization research and development as well as

section, b) horizontal cross-section take near the manufacturing investigations.

bottom (approximately indicated by white line) of a

sample containing 20 mg/mL protein in 0.5 M ar- Conflict of Interest Declaration

ginine succinate. c & d) vertical cross sections of

The authors declare that they have no competing in-

samples containing 20 mg/mL protein formulated

terests.

with 60 mM trehalose. Sample c was sectioned as

close to the thermocouple as possible.

References

growth. The sample in Figure 5d was also included to 1. Patapoff, T. W.; Overcashier, D. O. The impor-

demonstrate the effect of incomplete encapsulation, tance of freezing on lyophilization cycle develop-

where the bright areas at the center are regions the ment. BioPharm 2002, 15 (3), 16 –21.

PDMS did not fully penetrate. These regions subse-

quently collapsed due to moisture absorption from the 2. Searles, J. A.; Carpenter, J. F.; Randolph, T. W.

water-based fluorescent dye staining after the cake The ice nucleation temperature determines the pri-

was sectioned. mary drying rate of lyophilization for samples fro-

zen on a temperature-controlled shelf. J. Pharm.

In addition to the examples presented above, we have Sci. 2001, 90 (7), 860 – 871.

successfully employed this technique to image a vari-

ety of lyophilized substances, including products for- 3. Cromwell, M. E. M.; Carpenter, J. F.; Scherer, T.;

mulated with either sugars (i.e., sucrose, trehalose) or Randolph, T. W. Opalescence in Antibody Formu-

organic salts (i.e., arginine phosphate) and of solids lations Is a Solution-Critical Phenomenon. In 236th

contents ranging from less than 5 wt % to over 12 wt ACS National Meeting; A.O. Papers: Philadelphia,

%. Sample size ranged from a few milliliters in a 5 mL PA, 2008.

430 PDA Journal of Pharmaceutical Science and Technology

Downloaded from on June 21, 2021

An Authorized User of the electronic PDA Journal of Pharmaceutical Science and

Technology (the PDA Journal) is a PDA Member in good standing. Authorized Users are

permitted to do the following:

·Search and view the content of the PDA Journal

·Download a single article for the individual use of an Authorized User

·Assemble and distribute links that point to the PDA Journal

·Print individual articles from the PDA Journal for the individual use of an Authorized User

·Make a reasonable number of photocopies of a printed article for the individual use of an

Authorized User or for the use by or distribution to other Authorized Users

Authorized Users are not permitted to do the following:

·Except as mentioned above, allow anyone other than an Authorized User to use or access the

PDA Journal

· Display or otherwise make any information from the PDA Journal available to anyone other

than an Authorized User

·Post articles from the PDA Journal on Web sites, either available on the Internet or an Intranet,

or in any form of online publications

·Transmit electronically, via e-mail or any other file transfer protocols, any portion of the PDA

Journal

·Create a searchable archive of any portion of the PDA Journal

·Use robots or intelligent agents to access, search and/or systematically download any portion

of the PDA Journal

·Sell, re-sell, rent, lease, license, sublicense, assign or otherwise transfer the use of the PDA

Journal or its content

·Use or copy the PDA Journal for document delivery, fee-for-service use, or bulk reproduction or

distribution of materials in any form, or any substantially similar commercial purpose

·Alter, modify, repackage or adapt any portion of the PDA Journal

·Make any edits or derivative works with respect to any portion of the PDA Journal including any

text or graphics

·Delete or remove in any form or format, including on a printed article or photocopy, any

copyright information or notice contained in the PDA Journal

You might also like

- Sppeed Housing - East 1090 SFT PlanDocument1 pageSppeed Housing - East 1090 SFT Planvijay narayanNo ratings yet

- Electirc Bill Payment Jan 22Document1 pageElectirc Bill Payment Jan 22vijay narayanNo ratings yet

- Detection of Silicone Oil Leakages in Freeze Dryers: 65 PDA J Pharm Sci and TechDocument7 pagesDetection of Silicone Oil Leakages in Freeze Dryers: 65 PDA J Pharm Sci and Techvijay narayanNo ratings yet

- Water Bill Jan 2022Document1 pageWater Bill Jan 2022vijay narayanNo ratings yet

- Castor: Calibration CertificateDocument1 pageCastor: Calibration Certificatevijay narayanNo ratings yet

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document2 pagesIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)vijay narayanNo ratings yet

- ChromatographyDocument22 pagesChromatographyvijay narayanNo ratings yet

- Shri Mata Vaishno Devi Shrine Board - Yatra Parchi ServicesDocument1 pageShri Mata Vaishno Devi Shrine Board - Yatra Parchi Servicesvijay narayanNo ratings yet

- Acceleration of Heat Transfer in Vial Freeze-Drying of Pharmaceuticals. Corrugated Aluminum QuiltDocument9 pagesAcceleration of Heat Transfer in Vial Freeze-Drying of Pharmaceuticals. Corrugated Aluminum Quiltvijay narayanNo ratings yet

- PDA Technical SeriesDocument6 pagesPDA Technical Seriesvijay narayanNo ratings yet

- Mass Transfer in Freeze-Drying A Discussion of The Effect of Chamber Pressure On Heat andDocument5 pagesMass Transfer in Freeze-Drying A Discussion of The Effect of Chamber Pressure On Heat andvijay narayanNo ratings yet

- Wockhardt Warning LetterDocument6 pagesWockhardt Warning Lettervijay narayanNo ratings yet

- Application of Good Manufacturing Practice Regulations To Investigational Biologic ProductsDocument7 pagesApplication of Good Manufacturing Practice Regulations To Investigational Biologic Productsvijay narayanNo ratings yet

- Data Integrity JournalDocument11 pagesData Integrity Journalvijay narayanNo ratings yet

- Impact of Vial CappingDocument20 pagesImpact of Vial Cappingvijay narayanNo ratings yet

- Nondestructive Detection of Leaks in Packages by Vacuum Decay MethodDocument9 pagesNondestructive Detection of Leaks in Packages by Vacuum Decay MethodSlavaNo ratings yet

- Wockhardt Warning LetterDocument6 pagesWockhardt Warning Lettervijay narayanNo ratings yet

- Ausmetics Daily Chemicals FDA 483 2017Document3 pagesAusmetics Daily Chemicals FDA 483 2017vijay narayanNo ratings yet

- Mylan Pharmaceuticals Inc. Warning Letter SummaryDocument8 pagesMylan Pharmaceuticals Inc. Warning Letter Summaryvijay narayanNo ratings yet

- Ausmetics Daily Chemicals FDA 483 2017Document3 pagesAusmetics Daily Chemicals FDA 483 2017vijay narayanNo ratings yet

- Usfda Inspection at Alathur Facility With Zero 483 ObservationsDocument3 pagesUsfda Inspection at Alathur Facility With Zero 483 Observationsvijay narayanNo ratings yet

- Usfda Inspection at Alathur Facility With Zero 483 ObservationsDocument3 pagesUsfda Inspection at Alathur Facility With Zero 483 Observationsvijay narayanNo ratings yet

- US FDA 483 To ADMA Biologics IncDocument8 pagesUS FDA 483 To ADMA Biologics Incvijay narayanNo ratings yet

- US FDA WL To Hanlim Pharm Co., LTD., South KoreaDocument5 pagesUS FDA WL To Hanlim Pharm Co., LTD., South Koreavijay narayanNo ratings yet

- Walk-in Incubator Manufacturers in IndiaDocument8 pagesWalk-in Incubator Manufacturers in Indiavijay narayanNo ratings yet

- Cleaning Validation ArticleDocument11 pagesCleaning Validation Articlevijay narayanNo ratings yet

- FDA Cites Sterility Failures and Lack of Investigations at Outsourcing FacilityDocument10 pagesFDA Cites Sterility Failures and Lack of Investigations at Outsourcing Facilityvijay narayanNo ratings yet

- US FDA 483 To Gadea Biopharma S.L., SpainDocument3 pagesUS FDA 483 To Gadea Biopharma S.L., Spainvijay narayanNo ratings yet

- Validationofsystemforairquality Final 160920163215Document21 pagesValidationofsystemforairquality Final 160920163215vijay narayanNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- CEE9529 Project 2021Document10 pagesCEE9529 Project 2021Muntaha ZyanNo ratings yet

- Minimum Current For Detachment of Electrolytic BubblesDocument5 pagesMinimum Current For Detachment of Electrolytic Bubblesclean420No ratings yet

- Ferulok Flareless Bite Type Fittings: Visual IndexDocument14 pagesFerulok Flareless Bite Type Fittings: Visual IndexMauricioNo ratings yet

- Aqtesolv Manual 5Document1 pageAqtesolv Manual 5Kevin Tang0% (1)

- RCC Drain Design for Bilasipura - Guwahati Road ProjectDocument64 pagesRCC Drain Design for Bilasipura - Guwahati Road ProjectSubhajit Maitra100% (1)

- Chien1972 ANNULAR VELOCITY FOR ROTARY DRILLING Ops, Source of Viscosity CorrelationDocument14 pagesChien1972 ANNULAR VELOCITY FOR ROTARY DRILLING Ops, Source of Viscosity CorrelationAdam LyleNo ratings yet

- 1 s2.0 0169534786900637 MainDocument3 pages1 s2.0 0169534786900637 MainBruno Rover Dal PraNo ratings yet

- PHYSICS Form Four District 2023Document4 pagesPHYSICS Form Four District 2023Mukhusini SudiNo ratings yet

- Wind Turbines: Types and Momentum TheoryDocument4 pagesWind Turbines: Types and Momentum TheoryDanial KhanNo ratings yet

- Quantum Undergraduate Education and Scientific Training-2021Document23 pagesQuantum Undergraduate Education and Scientific Training-2021Tasos KoimasNo ratings yet

- Motor - How Do VFD Cause Bearing DamageDocument5 pagesMotor - How Do VFD Cause Bearing DamageLiang YongQuanNo ratings yet

- PFI Polypropylene High Flow HFCP Series Element Filter CartridgesDocument2 pagesPFI Polypropylene High Flow HFCP Series Element Filter Cartridgesbennypartono407No ratings yet

- 4.6 Method of ImagesDocument1 page4.6 Method of Images224883061No ratings yet

- CFS Composite BeamsDocument19 pagesCFS Composite BeamsOrhan YanyatmazNo ratings yet

- Differential Calculus Homework 22Document11 pagesDifferential Calculus Homework 22Sharmaine FajutaganaNo ratings yet

- Ami 310Document6 pagesAmi 310MumkoNo ratings yet

- Translate Variation RelationshipsDocument5 pagesTranslate Variation RelationshipsLady MaeNo ratings yet

- NPTEL Online Certification Course Mass Transfer Operations I Assignment 3: Detailed Solution Indian Institute of Technology GuwahatiDocument3 pagesNPTEL Online Certification Course Mass Transfer Operations I Assignment 3: Detailed Solution Indian Institute of Technology GuwahatiSagar ChaudharyNo ratings yet

- Ain Shams University Thermal and Statistical Physics Problem Set 7 EntropyDocument2 pagesAin Shams University Thermal and Statistical Physics Problem Set 7 EntropyMR. Legend?No ratings yet

- An Approach To Modeling and Scaling of Hysteresis in Magnetic Materials Magnetization CurveDocument4 pagesAn Approach To Modeling and Scaling of Hysteresis in Magnetic Materials Magnetization CurvefbaldnerNo ratings yet

- Numerical Modelling of Rainfall Effects On The Stability of Soil SlopesDocument14 pagesNumerical Modelling of Rainfall Effects On The Stability of Soil SlopesAdarsh ChatraNo ratings yet

- Problem SetDocument4 pagesProblem SetPhoebe Imee ThomasNo ratings yet

- CET Crash Course Test Schedule DetailedDocument3 pagesCET Crash Course Test Schedule DetailedDbebebdNo ratings yet

- En GJS 400 15CDocument1 pageEn GJS 400 15CCAT MINING SHOVELNo ratings yet

- Literature On FluidizationDocument23 pagesLiterature On FluidizationRafique AjmeriNo ratings yet

- Science Form 1 Chapter 1 (1.3)Document5 pagesScience Form 1 Chapter 1 (1.3)yasNo ratings yet

- Instruction Sheet V-152 Relief Valve: Important Receiving InformationDocument14 pagesInstruction Sheet V-152 Relief Valve: Important Receiving InformationRODRIGO RODRIGUEZNo ratings yet

- Test Bank For College Physics 7th Edition Jerry D WilsonDocument24 pagesTest Bank For College Physics 7th Edition Jerry D WilsonlouisadonaldlwrNo ratings yet

- Isidore Marie Auguste François Xavier ComteDocument6 pagesIsidore Marie Auguste François Xavier ComteSarah Rivie Mae BeloroNo ratings yet

- DLL - G8 Science - Q3 - F2FDocument2 pagesDLL - G8 Science - Q3 - F2FRAMIR BECOYNo ratings yet