Professional Documents

Culture Documents

Loctite SI 595: Technical Data Sheet

Uploaded by

Santhosh Kumar Ravichandran0 ratings0% found this document useful (0 votes)

29 views2 pagesOriginal Title

SI 595-EN(1)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

29 views2 pagesLoctite SI 595: Technical Data Sheet

Uploaded by

Santhosh Kumar RavichandranCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

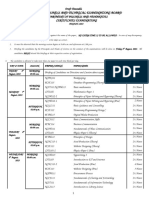

Technical Data Sheet

LOCTITE® SI 595

Known as LOCTITE® Superflex® Clear RTV Silicone

December-2013

PRODUCT DESCRIPTION TYPICAL PROPERTIES OF UNCURED MATERIAL

LOCTITE® SI 595 provides the following product Specific Gravity @ 25 °C 1.01

characteristics: Extrusion Rate, g/min 350 to 750LMS

Technology Silicone Flash Point - See SDS

Chemical Type Acetoxy silicone

Appearance (uncured) clearLMS

Components One component - TYPICAL CURING PERFORMANCE

requires no mixing

LOCTITE® SI 595 cures on exposure to moisture in the air.

Viscosity Thixotropic paste

The product dries tack free in 45 minutes and fully cures in 24

Cure Room temperature vulcanizing

(RTV) hours. Cure times will vary with temperature, humidity and

Odor Acetic Acid gap.

Application Sealing

Specific Benefit ● Non-slumping Tack Free Time / Surface Cure

● Superior adhesion and flexibility Tack Free Time, minutes ≤45LMS

Full cure time, hours 24

● Seals out moisture and

contaminants

● Fills large cracks and seams TYPICAL PROPERTIES OF CURED MATERIAL

● Non-flammable Cured for 1 week @ RT

● Non-toxic Physical Properties:

Tensile Strength, ISO 37 N/mm² ≥0.8LMS

® (psi) (≥120)

LOCTITE SI 595 is a single component, room temperature

vulcanizing compound designed to provide an excellent Elongation, ISO 37, % ≥275LMS

adhesive sealant for mechanical assemblies. This material Shore Hardness, ISO 868, Durometer A ≥14LMS

cures on exposure to moisture in the air to form a tough,

flexible, silicone rubber seal. This product resists aging,

weathering and thermal cycling without hardening, shrinking or

cracking. Designed for superior bonding and sealing properties

TYPICAL ENVIRONMENTAL RESISTANCE

to most surfaces (not recommended for concrete). Formulated

to withstand extreme temperature cycling, UV light and ozone.

Silicones provide excellent environmental resistance due to

Typical applications include electrical insulation, protection of their unique chemical structure and the inherent properties of

leads from mechanical shock, trim bonding, and sealing of the materials.

ductwork, vents, flues, doors, and windows.

NSF International GENERAL INFORMATION

Certified to ANSI/NSF Standard 51 for use with plastic This product is not recommended for use in pure oxygen

materials and components used in food equipment not and/or oxygen rich systems and should not be selected as

exceeding 204°C. Note: This is a regional approval. Please a sealant for chlorine or other strong oxidizing materials.

contact your local Technical Service Center for more

For safe handling information on this product, consult the

information and clarification.

Safety Data Sheet (SDS).

UL Classification

Classified by Underwriters Laboratories Inc.® E257711 -

Plastics & Components. Please visit the UL website for

additional information. Note: This is a regional approval.

Please contact your local Technical Service Center for more

information and clarification

TDS LOCTITE® SI 595, December-2013

Loctite Material SpecificationLMS Note:

The information provided in this Technical Data Sheet (TDS) including the

LMS dated July-6, 2005. Test reports for each batch are recommendations for use and application of the product are based on our

available for the indicated properties. LMS test reports include knowledge and experience of the product as at the date of this TDS. The product

selected QC test parameters considered appropriate to can have a variety of different applications as well as differing application and

specifications for customer use. Additionally, comprehensive working conditions in your environment that are beyond our control. Henkel is,

therefore, not liable for the suitability of our product for the production processes

controls are in place to assure product quality and and conditions in respect of which you use them, as well as the intended

consistency. Special customer specification requirements may applications and results. We strongly recommend that you carry out your own

be coordinated through Henkel Quality. prior trials to confirm such suitability of our product.

Any liability in respect of the information in the Technical Data Sheet or any other

written or oral recommendation(s) regarding the concerned product is excluded,

Directions for use: except if otherwise explicitly agreed and except in relation to death or personal

injury caused by our negligence and any liability under any applicable mandatory

1. Clean and dry surfaces. Remove all oil and grease. product liability law.

2. Apply product to surface. For bonding applications, apply

to one surface only and join surfaces immediately. When In case products are delivered by Henkel Belgium NV, Henkel Electronic

Materials NV, Henkel Nederland BV, Henkel Technologies France SAS and

using pressurized cans and cartridges, apply silicone by Henkel France SA please additionally note the following:

pushing the product in the direction of use (Forward) into In case Henkel would be nevertheless held liable, on whatever legal ground,

the surface. Henkel’s liability will in no event exceed the amount of the concerned delivery.

3. Wipe away excess material immediately. In case products are delivered by Henkel Colombiana, S.A.S. the following

disclaimer is applicable:

The information provided in this Technical Data Sheet (TDS) including the

Clean-up recommendations for use and application of the product are based on our

1. Allow excess material to extend beyond the extension knowledge and experience of the product as at the date of this TDS. Henkel is,

nozzle or aerosol tip to cure, sealing and protecting the therefore, not liable for the suitability of our product for the production processes

and conditions in respect of which you use them, as well as the intended

remaining product from moisture. For reuse, simply applications and results. We strongly recommend that you carry out your own

remove the cured product from the tip. prior trials to confirm such suitability of our product.

2. Remove uncured product from parts and hand-tools with a Any liability in respect of the information in the Technical Data Sheet or any other

written or oral recommendation(s) regarding the concerned product is excluded,

dry cloth. If skinned over, break film with a dry cloth to except if otherwise explicitly agreed and except in relation to death or personal

remove as much as possible. injury caused by our negligence and any liability under any applicable mandatory

3. Clean hands with a dry cloth or hand cleaner. product liability law.

In case products are delivered by Henkel Corporation, Resin Technology

Storage Group, Inc., or Henkel Canada Corporation, the following disclaimer is

applicable:

Store product in the unopened container in a dry location. The data contained herein are furnished for information only and are believed to

Storage information may be indicated on the product container be reliable. We cannot assume responsibility for the results obtained by others

labeling. over whose methods we have no control. It is the user's responsibility to

determine suitability for the user's purpose of any production methods mentioned

Optimal Storage: 8 °C to 21 °C. Storage below 8 °C or herein and to adopt such precautions as may be advisable for the protection of

greater than 28 °C can adversely affect product properties. property and of persons against any hazards that may be involved in the handling

Material removed from containers may be contaminated during and use thereof. In light of the foregoing, Henkel Corporation specifically

use. Do not return product to the original container. Henkel disclaims all warranties expressed or implied, including warranties of

merchantability or fitness for a particular purpose, arising from sale or use

Corporation cannot assume responsibility for product which of Henkel Corporation’s products. Henkel Corporation specifically

has been contaminated or stored under conditions other than disclaims any liability for consequential or incidental damages of any kind,

those previously indicated. If additional information is required, including lost profits. The discussion herein of various processes or

please contact your local Technical Service Center or compositions is not to be interpreted as representation that they are free from

domination of patents owned by others or as a license under any Henkel

Customer Service Representative. Corporation patents that may cover such processes or compositions. We

recommend that each prospective user test his proposed application before

repetitive use, using this data as a guide. This product may be covered by one or

Conversions more United States or foreign patents or patent applications.

(°C x 1.8) + 32 = °F

kV/mm x 25.4 = V/mil Trademark usage

mm / 25.4 = inches Except as otherwise noted, all trademarks in this document are trademarks of

Henkel Corporation in the U.S. and elsewhere. ® denotes a trademark

µm / 25.4 = mil

registered in the U.S. Patent and Trademark Office.

N x 0.225 = lb

N/mm x 5.71 = lb/in

N/mm² x 145 = psi

MPa x 145 = psi Reference 0.1

N·m x 8.851 = lb·in

N·m x 0.738 = lb·ft

N·mm x 0.142 = oz·in

mPa·s = cP

Henkel Americas Henkel Europe Henkel Asia Pacific

+860.571.5100 +49.89.320800.1800 +86.21.2891.8859

For the most direct access to local sales and technical support visit: www.henkel.com/industrial

You might also like

- Loctite Superflex Clear RTV Silicone: Technical Data SheetDocument2 pagesLoctite Superflex Clear RTV Silicone: Technical Data SheetAjay SutharNo ratings yet

- Sila Tech RD TdsDocument2 pagesSila Tech RD TdsChemicalProgrammerNo ratings yet

- Loctite 596™: SurfacesDocument2 pagesLoctite 596™: Surfaces楼淼森No ratings yet

- Loctite 595-EN PDFDocument2 pagesLoctite 595-EN PDFDhananjay LimayeNo ratings yet

- TDS Loctite Nickel LB 771-EnDocument2 pagesTDS Loctite Nickel LB 771-EnGregory Alan Francisco IINo ratings yet

- LOCTITE SF 7387 en - GLDocument2 pagesLOCTITE SF 7387 en - GLGregNo ratings yet

- 587 enDocument2 pages587 enabhayundaleNo ratings yet

- Loctite SF 7452™: Technical Data SheetDocument2 pagesLoctite SF 7452™: Technical Data SheetSyamsul BahriNo ratings yet

- Loctite 7471Document2 pagesLoctite 7471ksdjuhsdkjvNo ratings yet

- Loctite SF 8046 en UsDocument2 pagesLoctite SF 8046 en UsEdu Ochoa ArceNo ratings yet

- Locktite 8104 Data SheetDocument2 pagesLocktite 8104 Data SheetNyoman RakaNo ratings yet

- Loctite 5699™: Technical Data SheetDocument3 pagesLoctite 5699™: Technical Data Sheetgazwang478No ratings yet

- MOLYKOTEDocument2 pagesMOLYKOTEDavid Palm PNo ratings yet

- Loctite SF 790™: Technical Data SheetDocument2 pagesLoctite SF 790™: Technical Data SheetEdwin GallegosNo ratings yet

- Loctite 7386: Technical Data SheetDocument2 pagesLoctite 7386: Technical Data SheetIbrahim SamadNo ratings yet

- MOLYKOTE 111 Compound 22-1087L-01Document2 pagesMOLYKOTE 111 Compound 22-1087L-01If ChenNo ratings yet

- Molykote 111 Compound 22-1087j-01Document2 pagesMolykote 111 Compound 22-1087j-01dantewow1No ratings yet

- Henk Loctite Superflex Red TdsDocument2 pagesHenk Loctite Superflex Red TdsMariano DomenechNo ratings yet

- LOCTITE SI 5927 RED en - GLDocument2 pagesLOCTITE SI 5927 RED en - GLOmer IkhlasNo ratings yet

- Loctite LB 771-Nickel AntiseizeDocument2 pagesLoctite LB 771-Nickel AntiseizeChuckNo ratings yet

- Loctite MR 5923™: Technical Data SheetDocument2 pagesLoctite MR 5923™: Technical Data Sheetraffabox84yahoo.itNo ratings yet

- Ablestik 2114 BiPax-EN-1761143Document3 pagesAblestik 2114 BiPax-EN-1761143نور محمد وحيد القدسيNo ratings yet

- Loctite Solvo-Rust Super Penetrating Oil: Technical Data SheetDocument2 pagesLoctite Solvo-Rust Super Penetrating Oil: Technical Data SheetYAELNo ratings yet

- Loctite LB 8504: Technical Data SheetDocument2 pagesLoctite LB 8504: Technical Data SheetMridu Ranjan SrivastavaNo ratings yet

- PTDS Sicomet 100 v2 190615Document2 pagesPTDS Sicomet 100 v2 190615nhnamNo ratings yet

- LOCTITE SI 5331 en - GLDocument2 pagesLOCTITE SI 5331 en - GLkaplanuygarNo ratings yet

- Engineering Flourosilicone Elastomer: Description ApplicationDocument3 pagesEngineering Flourosilicone Elastomer: Description ApplicationLU CHUNHUINo ratings yet

- Emultex FR 728Document1 pageEmultex FR 728youssef mohamedNo ratings yet

- EVERBUILD® EVERFLEX® 565 Clean Room Silicone: Product Data SheetDocument3 pagesEVERBUILD® EVERFLEX® 565 Clean Room Silicone: Product Data Sheetsamira bashirvandNo ratings yet

- Loctite Chisel Paint Stripper TechDocument2 pagesLoctite Chisel Paint Stripper TechJuan Chavez ViladegutNo ratings yet

- Loctite 603: Technical Data SheetDocument3 pagesLoctite 603: Technical Data SheetRuiNo ratings yet

- Loctite 2432: Technical Data SheetDocument2 pagesLoctite 2432: Technical Data SheetFabio ParceroNo ratings yet

- Ficha Tecnica LubricanteDocument2 pagesFicha Tecnica LubricanteArmando JoyaNo ratings yet

- Loctite 5182Document3 pagesLoctite 5182ccorp0089No ratings yet

- Loctite 324™: Technical Data SheetDocument3 pagesLoctite 324™: Technical Data SheetUgan Git PadayacheeNo ratings yet

- MOLYKOTE High-Vacuum Grease 22-0911H-01Document2 pagesMOLYKOTE High-Vacuum Grease 22-0911H-01kippcamNo ratings yet

- Oxygen System - Thread SealantDocument2 pagesOxygen System - Thread SealantMoamenNo ratings yet

- Loctite SF 8046: Technical Data SheetDocument2 pagesLoctite SF 8046: Technical Data Sheeterick daniel veraNo ratings yet

- Acematt Ts 100 enDocument2 pagesAcematt Ts 100 enSeafar YachtingNo ratings yet

- Sylgard 160Document3 pagesSylgard 160diogocNo ratings yet

- DC 5 Compound Product InfoDocument2 pagesDC 5 Compound Product InfoluangkokNo ratings yet

- Loctite 2701: Technical Data SheetDocument3 pagesLoctite 2701: Technical Data SheethendrabudimanNo ratings yet

- Bpxe 9Q932NDocument2 pagesBpxe 9Q932NArthur Sanda LayukNo ratings yet

- Soudaflex Construction FCDocument2 pagesSoudaflex Construction FCAvijitSinharoyNo ratings yet

- Henk Loctite Gasket Seal 2 TdsDocument1 pageHenk Loctite Gasket Seal 2 TdsGabo TellezNo ratings yet

- Pu Sealant Mccoy Soudal Soudaflex 611 Pu SealantDocument2 pagesPu Sealant Mccoy Soudal Soudaflex 611 Pu SealantsasidharkanthetiNo ratings yet

- Loctite 641: Technical Data SheetDocument3 pagesLoctite 641: Technical Data SheetRuiNo ratings yet

- JOINLEADER 880 Weatherproof Silicone Sealant TDSDocument5 pagesJOINLEADER 880 Weatherproof Silicone Sealant TDSdasaNo ratings yet

- Loctite 242: Product Description TechnologyDocument3 pagesLoctite 242: Product Description TechnologyRuiNo ratings yet

- Loctite Liofol HS 59-670-EnDocument2 pagesLoctite Liofol HS 59-670-EnCharly DtNo ratings yet

- Molykote 7348Document2 pagesMolykote 7348Luz Angela GuerreroNo ratings yet

- HT Sikadur 32gelDocument4 pagesHT Sikadur 32gelQuerubin EboliNo ratings yet

- Loctite 262: Product Description TechnologyDocument3 pagesLoctite 262: Product Description TechnologyrajaramNo ratings yet

- 3M Novec 1700 Electronic Grade Coating: Product InformationDocument2 pages3M Novec 1700 Electronic Grade Coating: Product InformationraulitoroqueNo ratings yet

- LK 90C ImpregnationDocument2 pagesLK 90C ImpregnationTrầnCôngĐuaNo ratings yet

- Loctite 518™: Technical Data SheetDocument3 pagesLoctite 518™: Technical Data Sheetsaurabhjerps231221No ratings yet

- FREKOTE R180-EHenkel PVADocument2 pagesFREKOTE R180-EHenkel PVAOya ÜsküpNo ratings yet

- Loctite Silver Grade Anti-Seize Lubricant Stick: Technical Data SheetDocument2 pagesLoctite Silver Grade Anti-Seize Lubricant Stick: Technical Data SheetgoawayNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- Plastiment® VZ: 产品数据表 (Product Data Sheet)Document3 pagesPlastiment® VZ: 产品数据表 (Product Data Sheet)Mochamad Ardie NoegrohoNo ratings yet

- Lawson Industries, IncDocument4 pagesLawson Industries, IncTony DiStasioNo ratings yet

- B.arch Sem6 SyllabusDocument8 pagesB.arch Sem6 SyllabusNimish PanchalNo ratings yet

- Visual Slope User ManualDocument42 pagesVisual Slope User ManualJimmy ThomasNo ratings yet

- Rakib CVDocument4 pagesRakib CVapi-3824881No ratings yet

- Load Frequency Control in Power System: Md. Al-Amin Sarker and A K M Kamrul HasanDocument8 pagesLoad Frequency Control in Power System: Md. Al-Amin Sarker and A K M Kamrul Hasanmasoud aliNo ratings yet

- Variance and Standard DeviationDocument17 pagesVariance and Standard DeviationPuja GahatrajNo ratings yet

- CT13005 FullLine BrochureDocument6 pagesCT13005 FullLine BrochureJuve De la CruzNo ratings yet

- Heart Failure Prediction Using Hybrid MethodDocument8 pagesHeart Failure Prediction Using Hybrid Methodabhi spdyNo ratings yet

- New Text DocumentDocument73 pagesNew Text DocumentKoppula veerendra nadhNo ratings yet

- Rajat Chawla: About MeDocument2 pagesRajat Chawla: About MeRajat ChawlaNo ratings yet

- Simran KaurDocument8 pagesSimran KaurgarvitNo ratings yet

- Social Media Intelligence - Johnson & Johnson Identifying Digital Influencers - Case StudyDocument4 pagesSocial Media Intelligence - Johnson & Johnson Identifying Digital Influencers - Case StudyAishwarya BalasubramanyamNo ratings yet

- Chapter 4 Divide and ConquerDocument17 pagesChapter 4 Divide and ConquerAYUSHI NIGAMNo ratings yet

- Grade 11 General Mathematics: Evaluation of Function Operations & Composition of Functions Problems Involving FunctionsDocument16 pagesGrade 11 General Mathematics: Evaluation of Function Operations & Composition of Functions Problems Involving Functionsjoshua calmaNo ratings yet

- Draught and Its ClassificationDocument4 pagesDraught and Its ClassificationGopinath NNo ratings yet

- 2012TCD Workshop 2 PDFDocument295 pages2012TCD Workshop 2 PDFdmitriy100% (1)

- Air Cooled ASP Series PDFDocument13 pagesAir Cooled ASP Series PDFAAR143No ratings yet

- IOT Unit 4 Data and Analytics For IoT by Dr.M.K.Jayanthi KannanDocument41 pagesIOT Unit 4 Data and Analytics For IoT by Dr.M.K.Jayanthi KannanMK JAYANTHI KANNANNo ratings yet

- Cold Climate Application Guideline DuctlessDocument1 pageCold Climate Application Guideline DuctlessZineddine AlicheNo ratings yet

- Veeder-Root Specification Sheet 8600 & 8601 Series Consoles: Standard FeaturesDocument2 pagesVeeder-Root Specification Sheet 8600 & 8601 Series Consoles: Standard FeaturesEnrique ArmandoNo ratings yet

- Stratix 8000 Hardware User ManualDocument92 pagesStratix 8000 Hardware User ManualJesus Rebaza RomanNo ratings yet

- Business Certificate Timetable August 2023 Draft Edited 1 1pdf 1686898228811Document3 pagesBusiness Certificate Timetable August 2023 Draft Edited 1 1pdf 1686898228811Sada DahonestNo ratings yet

- GMA220 - SUT5 - Image Enhancement - 19 - 20April2021FNDocument47 pagesGMA220 - SUT5 - Image Enhancement - 19 - 20April2021FNFanelo FelicityNo ratings yet

- Super CapacityDocument2 pagesSuper CapacityNavneet RankNo ratings yet

- Power Electronics Lec 12Document11 pagesPower Electronics Lec 12Fahmeed Ali MeoNo ratings yet

- Acceleration Force Mass Word ProblemsDocument2 pagesAcceleration Force Mass Word ProblemsJuan TamadNo ratings yet

- Instant Download Elementary Statistics in Social Research Essentials 3rd Edition Levin Test Bank PDF Full ChapterDocument19 pagesInstant Download Elementary Statistics in Social Research Essentials 3rd Edition Levin Test Bank PDF Full ChapterJackCoxmozj100% (9)

- Transfer OrderDocument6 pagesTransfer OrderpsmNo ratings yet

- Ak 088 Worn Effects PDFDocument1 pageAk 088 Worn Effects PDFBENo100% (1)