Professional Documents

Culture Documents

3 TSS - TRSV Safety Valve

Uploaded by

parag padoleCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3 TSS - TRSV Safety Valve

Uploaded by

parag padoleCopyright:

Available Formats

Safety Systems

Optimax Series Tubing- TM

Retrievable Surface-Controlled

Subsurface Safety Valves

Models WSP(E)-5, WSP(E)-7.5 and WSP(E)-10

Weatherford’s Optimax models WSP(E)-5, WSP(E)-7.5, and WSP(E)-10 tubing-retrievable

surface-controlled subsurface safety valves (TRSCSSVs) are rod-piston, curved flapper-type

safety valves designed to shut in a well in the event of uncontrolled flow caused by equipment

failure or damage. An integral part of the completion string, each model is controlled by a single

hydraulic control line. Application of control-line pressure keeps the valve in the open position;

when pressure is bled off, the valve closes to protect property, personnel, and the environment.

In the unlikely event the safety valve malfunctions, Weatherford’s Optimax WLT lockout tool and

Optimax WCT control-line communication tool can be deployed to adapt the valve to accept

the Weatherford’s WIT-10 wireline-insert safety valve, thus minimizing disruption to production

operations.

The models, like all Optimax series TRSCSSVs, are designed to maximum simplicity and

reliability of operation. The WSP(E)-5 has a working pressure rating of 5,000 psi (34 MPa).

The WSP(E)-7.5 has a working pressure rating of 7,500 psi (52 MPa). The WSP(E)-10 has a

working pressure rating of 10,000 psi (69 MPa). All the models have a premium piston with full-

open and full-closed stop seals.

Applications

• Fluid and gas environments

• High-pressure production and injection applications

weatherford.com 1 © 2007–2011 Weatherford. All rights reserved. 2656.01

Safety Systems

Optimax Series Tubing-Retrievable Surface-Controlled

TM

Subsurface Safety Valves

Models WSP(E)-5, WSP(E)-7.5 and WSP(E)-10

Features, Advantages and Benefits

• Design, material, manufacturing, assembly, and test documentation retention in accordance with API Q1 and API

14A quality programs ensure design and manufacturing integrity and conformance to industry standards.

• Curved flapper technology enables a smaller OD, which eases running and accommodates bypass lines.

• Several features of the models maximize reliability:

–– The hydraulic control system has only two potential leak paths (the industry minimum).

–– Metal-to-metal premium housing connections are standard.

–– The non-elastomeric flapper soft seat reinforces the primary metal-to-metal seat for low-pressure seal integrity.

–– The simple design of the valves incorporates no sleeves, plugs, or other mechanisms that can be inadvertently

actuated, causing premature control-line communication.

• The field-proven non-elastomeric dynamic seal system avoids fluid-compatibility and explosive-decompression

issues, enhancing safety.

• Accessories can be deployed on slickline, avoiding complex operational requirements.

• The optimized safety valve design facilitates the use of control-line communication and lockout tools to insert a

wireline-insert safety valve in the event of a malfunction, thus minimizing production disruption.

• The safety valve contains a premium piston mechanism for demanding gas or high-pressure applications.

weatherford.com 2 © 2007–2011 Weatherford. All rights reserved. 2656.01

Safety Systems

Optimax Series Tubing-Retrievable Surface-Controlled

TM

Subsurface Safety Valves

Models WSP(E)-5, WSP(E)-7.5 and WSP(E)-10

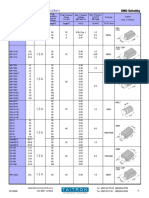

Specifications

Large Bore

5-1/2 5-1/2 7

Size (in./mm) 139.7 139.7 177.8

92 84 99

Overall length (in./cm)

234 213 251

4.578 4.750 6.000 and 5.963a

Standard sealbore (minimum bore) (in./mm)

116.281 120.650 152.400 and 151.460

6.937 and 5.500 7.125 and 5.600 8.465 and 7.088

Weatherford housing threads (in./mm)

176.200 and 139.700 180.975 and 142.240 215.011 and 180.035

7,500 11,250 15,000 7,500 7,500 11,250 15,000

Test pressure (psi/MPa)

52 78 103 52 52 78 103

5,000 7,500 10,000 5,000 5,000 7,500 10,000

Working pressure (psi/MPa)

34 52 69 34 34 52 69

7.700 7.760 8.100 7.700 9.200 9.288 9.430

Maximum OD (in./mm)

195.580 197.104 205.740 195.580 233.680 235.915 239.522

Standard nipple profile Petroline® QN profileb

Control-line connection Industry-standard metal-seal compression fitting for 1/4-in. (6.35-mm) control line

30° to 300°

Rated working temperature (°F/°C)

–1° to 149°

2,000

Failsafe setting depth (ft/m)

610

2,000

Operating pressure, full open (psi/MPa)c

14

1,000

Operating pressure, full closed (psi/MPa)c

7

Proprietary design non-elastomeric rod-piston seal stack, verified in tests to 10,000-psi (69-MPa)

Dynamic seal system

gas differential pressure at 300ºF (149ºC)d

Standard metallic materialse

Housing and internal components 9 chrome, 1 moly or 13% minimum chrome; 80,000-psi (552-MPa) minimum yield

Flapper and seat INCONEL® 718

Piston rod and power spring MP 35 N

Tubing thread connection As requested

Design and manufacturing compliance API Q1 and API 14A

Class of service API 14A 3S2

a

Staggered sealbore.

b

Other manufacturers’ profiles available upon request.

c

Values shown are estimates, subject to verification.

d

P feature safety valve also contains a non-elastomeric piston stop seal, which isolates the dynamic seals at the full-open and full-closed positions.

e

All materials heat-treated in accordance with NACE MR 01 75.

INCONEL® is a registered trademark of the Special Metals Corporation group of companies

weatherford.com 3 © 2007–2011 Weatherford. All rights reserved. 2656.01

Safety Systems

Optimax Series Tubing-Retrievable Surface-Controlled

TM

Subsurface Safety Valves

Models WSP(E)-5, WSP(E)-7.5 and WSP(E)-10

Options

• An optional internal through-the-flapper self-equalizing feature simplifies safety valve operation while

ensuring reliability.

Available Accessories

• Optimax WLT lockout tool • Optimax WET exercise tool

• Optimax WCT control-line communication tool • Optimax WIT-10 wireline-insert safety valve

For internal use

Link to Endeca assembly part numbers: Optimax WSP Tubing Retrievable Safety Valve

weatherford.com 4 © 2007–2011 Weatherford. All rights reserved. 2656.01

Weatherford products and services are subject to the Company’s standard terms and conditions, available on request or at weatherford.com. For more information contact an authorized Weatherford representative.

Unless noted otherwise, trademarks and service marks herein are the property of Weatherford and may be registered in the United States and/or other countries. Weatherford products named herein may be protected

by one or more U.S. and/or foreign patents. For more information, contact patents@weatherford.com. Specifications are subject to change without notice. Weatherford sells its products and services in accordance

with the terms and conditions set forth in the applicable contract between Weatherford and the client.

You might also like

- ECV Storm Valve: ApplicationsDocument2 pagesECV Storm Valve: Applicationsparag padoleNo ratings yet

- Arrowset I-X, I-X 10K, and I-X HP Mechanical Packers: ApplicationsDocument4 pagesArrowset I-X, I-X 10K, and I-X HP Mechanical Packers: Applicationsparag padoleNo ratings yet

- Bridge PlugsDocument19 pagesBridge Plugsparag padoleNo ratings yet

- Production and Test Packer - RetrievableDocument25 pagesProduction and Test Packer - Retrievableparag padoleNo ratings yet

- Seal Bore Packer System - PermanentDocument18 pagesSeal Bore Packer System - Permanentparag padoleNo ratings yet

- Wire Line Set Retrievable Packer: Drilling & Down-Hole Completion ToolsDocument11 pagesWire Line Set Retrievable Packer: Drilling & Down-Hole Completion Toolsparag padoleNo ratings yet

- Premier Packer PO 0911Document2 pagesPremier Packer PO 0911parag padoleNo ratings yet

- Data Sheet Title Packer Penetrator Rubber Molded: Flexibility and ReliabilityDocument1 pageData Sheet Title Packer Penetrator Rubber Molded: Flexibility and Reliabilityparag padoleNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Issue 34012Document300 pagesIssue 34012Abni TenajNo ratings yet

- Sustainable Construction in Developing Countries PDFDocument8 pagesSustainable Construction in Developing Countries PDFAdil LoroNo ratings yet

- Mobil Glygoyle 11, 22, and 30: Product DescriptionDocument3 pagesMobil Glygoyle 11, 22, and 30: Product DescriptionttchangcodonNo ratings yet

- PT Ascon PDF Company Profile 2019Document10 pagesPT Ascon PDF Company Profile 2019Ika SetiawatyNo ratings yet

- Vat On Sale of Services AND Use or Lease of PropertyDocument67 pagesVat On Sale of Services AND Use or Lease of PropertyZvioule Ma FuentesNo ratings yet

- Ies Exam Paper 2019 General Studies and Engineering Aptitude PDFDocument20 pagesIes Exam Paper 2019 General Studies and Engineering Aptitude PDFsuhrud mhatreNo ratings yet

- Lecture-1 (2018)Document87 pagesLecture-1 (2018)Rabia SabirNo ratings yet

- 2CDS252001R0065 Miniature Circuit Breaker s200 2p BDocument4 pages2CDS252001R0065 Miniature Circuit Breaker s200 2p BSheila Rose Bacerra-VillafloresNo ratings yet

- 01 Policy and Regulations On AgDSMDocument29 pages01 Policy and Regulations On AgDSMAnonymous R7eyaT6qKNo ratings yet

- MHOD District Cooling - Arup 29-09-2011Document52 pagesMHOD District Cooling - Arup 29-09-2011Mrityunjay MallikNo ratings yet

- Fomtec Foam Equipment BrochureDocument7 pagesFomtec Foam Equipment Brochureambition1340cnNo ratings yet

- MBM362 3 PDFDocument17 pagesMBM362 3 PDFzeybek_144649143No ratings yet

- Shell History Timeline PDFDocument3 pagesShell History Timeline PDFGabriel Enciso CoralNo ratings yet

- Pile Design With 5 ComponentsDocument12 pagesPile Design With 5 ComponentsIrfan Ahmed100% (2)

- Calculate No of Street Light Poles - Electrical Notes & ArticlesDocument5 pagesCalculate No of Street Light Poles - Electrical Notes & ArticlesRath NithNo ratings yet

- 5 Clase 5 Paper Incentives RE V - FINALDocument40 pages5 Clase 5 Paper Incentives RE V - FINALFranko EncaladaNo ratings yet

- EDS 05-2010 Main Substation Feeder and Ring Main Unit Protection Settings (LPN) PDFDocument14 pagesEDS 05-2010 Main Substation Feeder and Ring Main Unit Protection Settings (LPN) PDFLimuel EspirituNo ratings yet

- High Energy Rate FormingDocument29 pagesHigh Energy Rate FormingAbhijeetSethiNo ratings yet

- Rvtti Competition Application Form FurahaDocument4 pagesRvtti Competition Application Form FurahaManfred GithinjiNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityfeyayel990No ratings yet

- SMD Schottky RectifierDocument3 pagesSMD Schottky RectifierArthur BaxNo ratings yet

- MEP SpecificationDocument2 pagesMEP SpecificationcarlomaderazoNo ratings yet

- HTP Nozzle Repairs SNECMADocument2 pagesHTP Nozzle Repairs SNECMAzakaria mansouriNo ratings yet

- Mah22Pr: Save Up TO 60%Document2 pagesMah22Pr: Save Up TO 60%mantenimientoNo ratings yet

- Topic 1 - Fundamental of Electrical System in BuildingDocument25 pagesTopic 1 - Fundamental of Electrical System in BuildingsyakirohNo ratings yet

- Bài tập câu điều kiện gián tiếpDocument8 pagesBài tập câu điều kiện gián tiếpThùy AnhNo ratings yet

- Carlsberg PrintDocument2 pagesCarlsberg Printharjoicatalin3722No ratings yet

- Cupola Furnace FundamentalsDocument1 pageCupola Furnace FundamentalsKishoreNo ratings yet

- Solar Advice: Buonassisi GroupDocument10 pagesSolar Advice: Buonassisi GroupsujithaprethiNo ratings yet

- SE Annual Report 2022 enDocument108 pagesSE Annual Report 2022 ens201062740No ratings yet