Professional Documents

Culture Documents

Design and Manufacturing of Low Cost Scara Robot IJERTV10IS060027-With-cover-page-V2 3

Uploaded by

Omar MuhammadCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Manufacturing of Low Cost Scara Robot IJERTV10IS060027-With-cover-page-V2 3

Uploaded by

Omar MuhammadCopyright:

Available Formats

Accelerat ing t he world's research.

IJERT-Design and Manufacturing of

Low Cost SCARA Robot

IJERT Journal

International Journal of Engineering Research and Technology (IJERT)

Cite this paper Downloaded from Academia.edu

Get the citation in MLA, APA, or Chicago styles

Related papers Download a PDF Pack of t he best relat ed papers

IJERT-Cont rolling t he Bionic ARM t o Cert ain Gest ures using ROS Serial Communicat ions

IJERT Journal

IJERT-Deep Learning based 6DOF Robot Arm Cont rol wit h Comput er Vision

IJERT Journal

IJERT-Gest ure Cont rolled Robot ic Arm

IJERT Journal

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 10 Issue 06, June-2021

Design and Manufacturing of Low Cost SCARA

Robot

Rizwan Ul Haq1, Umashankar Kumar2, Mohd. Mursaleen1, Nazir Ahmad Sheikh2

Naveen Kumar3, Yash Baranwal4 Professors, Department of Mechanical Engineering,

Students, Bachelor of Technology, National Institute of Technology, Srinagar, Kashmir

Mechanical Engineering,

National Institute of Technology, Srinagar, Kashmir

Abstract— This report deals with the Design and Fabrication of calculated from CAD Software are compared with results

a Selective Compliance Articulated Robot Arm (SCARA). obtained from MATLAB. The mathematical modeling and its

SCARA robots are among the most widely used robots in the results in MATLAB are best explained through this paper.

industry due to their high accuracy and inherent rigidity. 2. Design and Fabrication of Pick and Place Robot To Be

Robotics is becoming popular and has achieved great success in

the last few decades but automation isn’t cheap so everyone

used in library by Anusha Ronaki M.Kranti

cannot afford to transform his unit from manual to automatic. The use of robots in library is becoming more popular in

The main objective of this project was to develop a low-cost recent years. The trend seems to continue as long as the

robotic arm that can be used for Pick and Place operations.

robotics technology meets diverse and challenging needs in

Here controlling of the robot has been done by using NEMA 17

Stepper Motors and Arduino UNO. This robot is having 4 DOF

educational purpose. The prototype consists of robotic arm

and can be controlled by a Graphic User Interface that features along with grippers capable of moving in the three axes and an

both Forward and Inverse Kinematics control. By changing the ATMEGA 8 microcontroller. Software such as AVR Studio is

program of the end-effector this robotic arm can be used in vast used for programming, PROTESUS is used for simulation and

applications but mainly it can be used in the automatic assembly PROGISP is used for dumping the program. RFID is used for

lines identifying the books and it has two IR Sensors for detecting

the path. This robot is about 4 kg in weight, and it is capable

Keywords— SCARA, Robotics, Fabrication, Automation, of picking and placing a book of weight one kg.’s.

Arduino, Graphic User Interface (GUI), Kinematics, Degree of

Freedom (DOF). 3. Robot Arm Control with Arduino by Abdullatif Baba

I. INTRODUCTION Today, technology is developing in the same direction in line

SCARA robots, developed in the early eighties, represent a with rapidly increasing human needs. The work done to meet

breakthrough in assembly automation (Makino, 1980). The these needs makes life easier every day, and these studies are

SCARA robots' performance, which included a large working concentrated in robotic arm studies. Robot arms work with an

area in the x-y plane, a suitable height in the z axis, and low outside user or by performing predetermined commands.

sensitivity for load speed, positioning, and control accuracy, Nowadays, the most developed field of robot arms in every

allowed them to be used in electronic printed circuit assembly, field is the industry and medicine sector. Designed and

as well as the automotive and home appliance industries. realized in the project, the robot arm has the ability to move in

Robotic arms used in assembly and production processes help 4 axis directions with 5 servo motors. Thanks to the holder,

to eliminate human error and increase production rates. you can take the desired material from one place and carry it

SCARA configurations are known for their fast speed, low to another place, and also mix it with the material it receives.

maintenance, great repeatability, and sturdy architecture. The While doing this, robot control is provided by connecting to

SCARA robot is a four-degree-of-freedom manipulator. This the android application via Bluetooth module connected to

sort of robot was created to increase the speed and Arduino Nano microcontroller.

repeatability of PICK & PLACE TASKS from one spot to

another, as well as to speed up and improve assembly stages. 4. Design, Manufacturing, and analysis of Robotic Arm with

SCARA Configuration by Kaushik Phasale, Praveen Kumar,

II. LITRATURE REVIEW Akshay Raut, Ravi ranjan Singh, Amit Nichat

1. Modeling, Simulation and Analysis of SCARA Robot for This paper deals with the design of 4-Axis SCARA Robot.

Deburring of circular components by PVS Subhashini, N.V.S The analysis is also performed in Ansys. For experimental

Raju and G. Venkata Rao setup, the robot with cardboard material is made by the author.

The experimental model is used to analyze the location of

This research study describes the study of SCARA Robot for motors, length of links and its movements. The designing of

deburring operation of circular profiles. The SCARA Robot the robotic arm is done in creo software. The animation is

with four degrees of freedom is modeled in CAD Software. done with various constraints in the software. This research

The Kinematics of Robot is also explained in the simplest study also includes the manufacturing and assembly processes

way. The results of joint positions and joint velocities of the robot.

IJERTV10IS060027 www.ijert.org 162

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 10 Issue 06, June-2021

5. Design and Development of A 4–Dof SCARA Robot for generation was performed based on the function analysis, the

Educational Purposes by Ksm Sahari and Hong Weng Khor specifications of requirements that had been established. From

the concept generation, twenty-four sustainable concepts

Robotics have become a common course in a lot of higher

divided into four groups (representing an individual part of the

institutions. Although there are many robots available in the

whole concept) were evaluated.

market, most of them are for industrial purposes and are

costly. There is a need to develop low-cost robots for students

in higher institutions to learn the elements of robotics such as III. METHODOLOGY

design, kinematics, dynamics, sensing and control. The aim of

this project is to design and develop a mechanical structure of

a SCARA robot that can perform certain tasks for educational,

research and exhibition purposes such as pick and place

operation. The paper discusses the steps used in design and

development of a 4 degree of freedom (DOF) SCARA robot

which includes specification definition, conceptual design,

product development, and testing. In specification definition

phase, the specifications of the SCARA robot are first

determined. After that, the best conceptual design of the

SCARA robot is chosen after making concept evaluation in

the conceptual design phase. Then, in third phase which is the

product generation, the chosen design of the SCARA robot is

fine-tuned. Stress analysis using finite element analysis is

carried out before a prototype is developed. The direct and

inverse kinematics, dynamics of the robot are then modeled.

Off shelf parts are also selected based on the derived

parameters from calculations. Electronic parts such as sensors

and dedicated controller using low-cost microcontroller are

then developed. Finally, the developed SCARA robot is tested

to see whether it fits the targeted specifications.

6. Auto & Manual Control of Robotic Arm Using PLC by R.

Jagan1, P. Rana Singh2, CH. Ashirvadam3, K. Navitha4

The main objective of this project is to control the Robotic

Arm manually and automatically by using Programmable

Logic Control (PLC) to pick the moving object on a conveyor

belt. In industries highly advanced robots are used, but still the

controlling is done by manually or processors like Arduino,

microprocessors etc. There are several disadvantages by using

these processors like micro controllers cannot work in the

environments with the high levels of vibrations, corrosion,

humidity, and other environmental factors. All these problems

are overcome by using Programmable Logic Controller (PLC)

which acts as a brain to control the robotic arm. This project

Figure 1. Rough Model

focuses to create and build more compact, useful, and cheaper

robotic arm to perform various functions where human is

proven too dangerous to perform a specific task and also to IV. DESIGN OF ROBOTIC ARM

eliminate human errors to get more precise work.

7. Review on Development of Industrial Robotic Arm by

Rahul Gautam1, Ankush Gedam2, Ashish Zade3, Ajay

Mahawadiwar4.

The use of industrial robots is increasing in areas such as food,

consumer goods, wood, plastics, and electronics, but is still

mostly concentrated in the automotive industry. The aim of

this project has been to develop a concept of a lightweight

robot using lightweight materials such as aluminum and

carbon fiber together with a newly developed stepper motor

prototype. The wrist also needs to be constructed for cabling

to run through on the inside. It is expensive to change cables

and therefore the designing to reduce the friction on cable, is Figure 2. Assembly in SolidWorks

crucial to increase time between maintenance. A concept

IJERTV10IS060027 www.ijert.org 163

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 10 Issue 06, June-2021

The designing of robotic arm was done in SolidWorks. The

various component’s part drawings are created separately and

by using these parts assembly was created.

Our goal for the robot was most of the parts to be 3D

printed. With the specifically built pulleys, we were able to

achieve a 20:1 reduction ratio for the first joint in two steps.

The GT2 belts we utilized here are closed loop and have

lengths of 200mm and 300mm, respectively. Two thrust

bearings and one radial bearing make up the robot joints. We

have a 16:1 reduction ratio for the second joint, which was

produced in the same way, and a 4:1 reduction ratio for the

third joint with only a single stage reduction. Because the

joints are hollow, we can use them to send wires from the

motors and micro switches through. There are slots on each of

the belts where we may attach idler pulleys to tension them.

Figure 3. Joints of Robotic Arm

The robot gripper is driven by an MG996R servo motor and

we can easily swap the gripper ends to get varied grasp sizes.

The robot's Z axis is powered by an 8mm lead screw, and the

entire arm assembly is supported by four 10mm smooth rods

and linear ball bearings. The length of the smooth rods, which

in this case are 40cm, determines the robot's height. To fit in

this layout, the lead screw must be 2 cm shorter, or the Z

motor can be lifted by 2 cm using spacer nuts.

V. WORKING

VI. CIRCUIT DIAGRAM

The robot is controlled by four NEMA 17 stepper motors and We'll be using an Arduino UNO board with a CNC shield and

has four degrees of freedom. It also features a small servo four A4988 stepper motors. Even though it's a robot and

motor for operating the end effector, or in this example, the appears to be more difficult, that's all the electronics we'll

robot gripper. The Arduino UNO board is the brain of this need for this project. It's worth noting that we could

SCARA robot, and it's combined with a CNC shield and four potentially use an Arduino MEGA in conjunction with a

A4988 stepper drivers to control the motors. RAMPS 3D printer controller board instead of an Arduino

UNO.

In terms of positioning and orientation, there are two

approaches for controlling robots: forward and inverse

kinematics. When we need to find the position and

orientation of the end-effector from specified joint angles, we

apply forward kinematics. Inverse kinematics, on the other

hand, is used to determine joint angles for a given end-

effector location.

Here are the equations we derived for forward and inverse

kinematics. Position and orientation of the end effector can

be calculated by joint angles Ɵ1 and Ɵ2 mm and the joint

angles for a given position of the end-effector can be

calculated by x and y.

Figure 4. Circuit Diagram

IJERTV10IS060027 www.ijert.org 164

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 10 Issue 06, June-2021

VII. FABRICATION 8. Arm 2 spin: 180°

9. Arm 3 spin: 180°

All the parts were printed on Creality CR-10 3D printer. As

10. Gripper opening: Adjustible

previously said, the pieces are also designed to fit on a smaller

3D printer, such as the Ender3. We utilized PLA+, the blue

X. REFRENCES

material, for most of the parts, as well as regular PLA for the [1] KSM Sahari and Hong Weng Khor, “Design and Development of

pulleys and gripper. In the slicing software, we enabled A 4-Dof SCARA Robot For Educational Purposes ” , Article in

Horizontal expansion of –0.1mm for all of them. This allows Jurnal Teknologi- January 2011.

the parts to have more precise dimensions and fit better with [2] Aliriza Kaleli,Ahmet Dumlu, M. Fatih Corapsiz and Koksal

Erenturk, “ Detailed Analysis of SCARA-Type Serial

other mechanical components such as bearings, rods, and Manipulator on a Moving Base with LabView, Article in

bolts. International Journal of Advanced Robotic Systems- 19th Feb

2013

VIII. CONCLUSION [3] Kurt E. Clothier and Ying Shang, “A Geometric Approach for

Robotic Arm Kinematics with Hardware Design, Electrical

A SCARA manipulator with four degrees of freedom was Design, and Implementation,” Journal of Robotics- 18th August

created, and it now serves as a platform for testing and 2010.

studying a variety of control approaches. The parts [4] Bernhard Mohl and Oskar Von Stryk, “Design and Application of

designed were made available to the online audience so that a 3 DOF Bionic Robot Arm,”-January 2005.

[5] Dr. Amar Nageshwar Rao, Jeevan ,“ Modelling and Analysis of

anyone can 3d print and apply SCARA in actual form for Robotic Arm using Ansys ”, International Journal Of Scientific

further testing of strength, efficiency, economic viability, and Engineering and Technology Research, Vol.04,Issue.33, August-

use in many industrial domains. The morphology chosen for 2015.

the robot's design and execution allowed it to do a variety of [6] R. Jagan , P.Rana Singh , CH .Ashirvadam , K .Navitha “Auto &

Manual Control of Robotic Arm Using PLC”, Vol. 6, Issue 8,

demonstrations and activities, which were easily and quickly August 2017.

programmed using an intuitive graphic interface built [7] Ali Medjebouri and Lamine Mehennaoui, "Active Disturbance

specifically for that purpose. Rejection Control of a SCARA Robot Arm" Vol.8, No.1 (2015)

[8] Ashly Baby, Chinnu Augustine, Chinnu Thampi, Maria George,

The built robotic arm may be used in a variety of ways, and Abhilash A P, Philip C Jose “Pick and Place Robotic Arm

any type of end-effector can be attached to the robot for Implementation Using Arduino” Volume 12, Issue 2 Ver. III

(Mar. – Apr. 2017).

various purposes. For example, we can attach a 3D printer hot [9] Anusha Ronanki, M. Kranthi “Design and Fabrication of Pick and

end to the robot to turn it into a 3D printer or attach a laser Place Robot to be used in Library” Vol. 4, Issue 6, June 2015.

head to turn it into a laser cutter. [10] Rahul Gautam, Ankush Gedam, Ashish Zade, Ajay

Mahawadiwar, “Review on Development of Industrial Robotic

IX. SPECIFICATIONS Arm” Volume: 04 Issue: 03 | Mar -2017.

[11] Abdellatif Baba “ROBOT ARM CONTROL WITH ARDUINO”

1. Degree of Freedom: 4 Technical Report · June 2017.

2. Payload Capacity (Fully Extended): 200-250gm [12] Ksm Sahari and Hong Weng Khor, “Design And Development Of

3. Maximum Reach (Fully Extended): 550cm A 4–Dof Scara Robot For Educational Purposes”, Article in

Jurnal Teknologi · January 2011.

4. Rated speed (Adjustable): 0-80 rpm [13] Md. Anisur Rahman, Alimul Haque Khan , Dr. Tofayel Ahmed ,

5. Hardware interface: USB Md. Mohsin Sajjad, "Design, Analysis and Implementation of a

6. Control Software: Computer interface (GUI) Robotic Arm- The Animator” Volume-02, Issue-10, 2013.

7. Arm 1 spin: 180°

IJERTV10IS060027 www.ijert.org 165

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

You might also like

- Design, Analysis and Manufacturing of Four Degree of Freedom Wireless (Wi-Fi) Controlled Robotic ARMDocument12 pagesDesign, Analysis and Manufacturing of Four Degree of Freedom Wireless (Wi-Fi) Controlled Robotic ARMMasood Akhtar VaheedNo ratings yet

- Pick and Place Robotic ARM Using PLCDocument4 pagesPick and Place Robotic ARM Using PLCDinesh PanickerNo ratings yet

- Thesis Designandfabricationofpickandplace PDFDocument12 pagesThesis Designandfabricationofpickandplace PDFWolderuphael KassahunNo ratings yet

- Pick and Place Robotic ARM Using PLC: Abhiraj Bhalerao Prasad DoifodeDocument4 pagesPick and Place Robotic ARM Using PLC: Abhiraj Bhalerao Prasad DoifodeBilvanadham NNo ratings yet

- What Is A SCARA RobotDocument6 pagesWhat Is A SCARA RobotDeependra TalandiNo ratings yet

- Review On Design and Development of Robotic Arm Generation 1Document3 pagesReview On Design and Development of Robotic Arm Generation 1International Journal of Innovative Science and Research TechnologyNo ratings yet

- FTI 2021 Tech Trends Volume AllDocument504 pagesFTI 2021 Tech Trends Volume AlljapamecNo ratings yet

- Literature Reviewon Designand Simulationof Industrial Robotic Armusing CADCAMSoftwareDocument4 pagesLiterature Reviewon Designand Simulationof Industrial Robotic Armusing CADCAMSoftwareSamuel AbraghamNo ratings yet

- Design and Development of Robotic With 4-Degree of Freedom: Imayam College of EngineeringDocument14 pagesDesign and Development of Robotic With 4-Degree of Freedom: Imayam College of EngineeringvinothkumarNo ratings yet

- Path Planning of Mobile Robot Using ROSDocument8 pagesPath Planning of Mobile Robot Using ROSInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Concept Defense PresentationDocument24 pagesConcept Defense Presentationchris mabantaNo ratings yet

- COPPELIASIMDocument7 pagesCOPPELIASIMRooban SNo ratings yet

- 1 s2.0 S1877050918310548 MainDocument8 pages1 s2.0 S1877050918310548 MainAnonymous 9q5GEfm8INo ratings yet

- Iot Based Hand Gesture Controlled Robotic ArmDocument13 pagesIot Based Hand Gesture Controlled Robotic ArmVivek RahangdaleNo ratings yet

- Design and Development of a 6-DOF Pick and Place Robotic ArmDocument7 pagesDesign and Development of a 6-DOF Pick and Place Robotic ArmAravindNo ratings yet

- Thesis ProjectDocument23 pagesThesis Projecteyoule abdiNo ratings yet

- Irjet V6i31240Document7 pagesIrjet V6i31240Ghanvir SinghNo ratings yet

- Multitasking RobotDocument3 pagesMultitasking RobotJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Pick and Place Robotic ARM Using PLCDocument4 pagesPick and Place Robotic ARM Using PLCBilvanadham NNo ratings yet

- Research Proposal Final - Moradi-1Document4 pagesResearch Proposal Final - Moradi-1api-611744595No ratings yet

- Wirelessroboticarm Vehicle: P. V. Rama Raju, G. Naga Raju, K. Venkat Vinay, M. Anil Kumar, K. Naga Manju, K. ManojDocument4 pagesWirelessroboticarm Vehicle: P. V. Rama Raju, G. Naga Raju, K. Venkat Vinay, M. Anil Kumar, K. Naga Manju, K. ManojNaga Raju GNo ratings yet

- Ijreiss 3094 97729Document13 pagesIjreiss 3094 97729ZEUS GAMINGNo ratings yet

- All Chapter Final ThesisDocument20 pagesAll Chapter Final ThesistayzarlwintunNo ratings yet

- IJRA TemplateDocument9 pagesIJRA TemplateLuis VelascoNo ratings yet

- Design and Analysis of An Articulated Robot ArmDocument8 pagesDesign and Analysis of An Articulated Robot ArmSamuel AbraghamNo ratings yet

- 2015 Design KumarDocument43 pages2015 Design Kumardudde niranjanNo ratings yet

- Jain 2019 IOP Conf. Ser. Mater. Sci. Eng. 691 012010Document9 pagesJain 2019 IOP Conf. Ser. Mater. Sci. Eng. 691 012010Samuel AbraghamNo ratings yet

- Fabricating A Completely Assemblable Robotic ArmDocument19 pagesFabricating A Completely Assemblable Robotic ArmshanthiniNo ratings yet

- Simulation of Pick and Place Robotics System Using Solidworks SoftmotionDocument7 pagesSimulation of Pick and Place Robotics System Using Solidworks SoftmotionSaumya SaxenaNo ratings yet

- Implementation of Line Follower Robot Based Microcontroller Atmega32ADocument5 pagesImplementation of Line Follower Robot Based Microcontroller Atmega32AAhuja ShivamNo ratings yet

- Kinematic Analysis of 6 DOF Articulated Robotic ArmDocument5 pagesKinematic Analysis of 6 DOF Articulated Robotic ArmRoman MorozovNo ratings yet

- Matlab Toolbox For Kinematic Analysis and SimulatiDocument10 pagesMatlab Toolbox For Kinematic Analysis and SimulatiAli GhaffariNo ratings yet

- Design and Implementation of A Wireless Gesture Controlled Robotic Arm With VisionDocument8 pagesDesign and Implementation of A Wireless Gesture Controlled Robotic Arm With VisionAli Najim Al-AskariNo ratings yet

- Robot Control ThesisDocument5 pagesRobot Control Thesisafloaaffbkmmbx100% (1)

- JETIRFA06001Document5 pagesJETIRFA06001Trần ĐạtNo ratings yet

- RBOTICDocument16 pagesRBOTICHus Forth Correnty100% (1)

- Multipurpose Robotic ArmDocument7 pagesMultipurpose Robotic ArmIJRASETPublicationsNo ratings yet

- A Novel Design of A Quadruped Robot For Research PurposesDocument13 pagesA Novel Design of A Quadruped Robot For Research Purposessushreet2754No ratings yet

- Futech2024 03 01 03 +princewillDocument7 pagesFutech2024 03 01 03 +princewillNIKHIL ASNo ratings yet

- Pick and Place Robotic Arm Using Arduino: December 2017Document7 pagesPick and Place Robotic Arm Using Arduino: December 2017visionNo ratings yet

- Line Following Robot ResearchDocument4 pagesLine Following Robot ResearchtherealslimNo ratings yet

- Foreign 2Document8 pagesForeign 2Rhodora A. BorjaNo ratings yet

- MDPN423 Robotics Engineering Mahmoud Sayed Zaghlool 1135487Document11 pagesMDPN423 Robotics Engineering Mahmoud Sayed Zaghlool 1135487Mahmoud Sayed ZaghloolNo ratings yet

- Literature Review Robotic ArmDocument7 pagesLiterature Review Robotic Armafmzeracmdvbfe100% (1)

- Barrier Succeeding Miniature and AutonomousRobotDocument4 pagesBarrier Succeeding Miniature and AutonomousRobotInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Implementation of Ros Navigation Stack On Lego Mindstorms NXT 2.0 RobotDocument6 pagesImplementation of Ros Navigation Stack On Lego Mindstorms NXT 2.0 RobotwendersoncsdepNo ratings yet

- ROBOTIC ARM GIVEN A THREE DEGREE OF FREEDOMDocument28 pagesROBOTIC ARM GIVEN A THREE DEGREE OF FREEDOMEmmanuel OmaleNo ratings yet

- Automated Object Identifing and Sorting RobotDocument8 pagesAutomated Object Identifing and Sorting RobotIJRASETPublicationsNo ratings yet

- PCB DrillingDocument7 pagesPCB Drillingalfonso alvarez garmaNo ratings yet

- SynopsisDocument8 pagesSynopsisSahil RajputNo ratings yet

- A Custom Designed 3D Printed 4 DoF Mobile Robotic Arm For Remote ExplorationDocument6 pagesA Custom Designed 3D Printed 4 DoF Mobile Robotic Arm For Remote ExplorationEditor IJTSRDNo ratings yet

- Exploratory Project Report: Robotic Arm With Learn and Repeat AbilityDocument21 pagesExploratory Project Report: Robotic Arm With Learn and Repeat AbilityDeepak machyaNo ratings yet

- Literature Review of Pick and Place RobotDocument4 pagesLiterature Review of Pick and Place Robotgvzf446w100% (1)

- Smartphone Controlled Robotic Vehicle With Unique Bearing Alignment Mechanism and Robotic Arm For Dangerous Object DisposalDocument6 pagesSmartphone Controlled Robotic Vehicle With Unique Bearing Alignment Mechanism and Robotic Arm For Dangerous Object DisposalEditor IJTSRDNo ratings yet

- Research Paper On Pick and Place RobotDocument7 pagesResearch Paper On Pick and Place Robotgvzwyd4n100% (1)

- Ijsetr Vol 6 Issue 12 1568 1573Document7 pagesIjsetr Vol 6 Issue 12 1568 1573Siddhartha PvpNo ratings yet

- International Journal of Robotics and Automation (IJRA), Volume (1) : IssueDocument24 pagesInternational Journal of Robotics and Automation (IJRA), Volume (1) : IssueAI Coordinator - CSC JournalsNo ratings yet

- A Review On AI Vision Robotic Arm Using Raspberry PiDocument7 pagesA Review On AI Vision Robotic Arm Using Raspberry PiIJRASETPublicationsNo ratings yet

- Teaching and Learning Robotic Arm Model: Kadirimangalam Jahnavi Sivraj PDocument6 pagesTeaching and Learning Robotic Arm Model: Kadirimangalam Jahnavi Sivraj PCătălin PuțoiNo ratings yet

- Integrating Arduino-Based Educational Mobile Robots in ROSDocument6 pagesIntegrating Arduino-Based Educational Mobile Robots in ROSPranjul SinghNo ratings yet

- Robot Operating System (ROS): The Complete Reference (Volume 6)From EverandRobot Operating System (ROS): The Complete Reference (Volume 6)No ratings yet

- Algorithms to calculate, compare, and determine valuesDocument3 pagesAlgorithms to calculate, compare, and determine valuesLee Anne AngelesNo ratings yet

- Year 7 Exam ArtDocument4 pagesYear 7 Exam ArtBarminga KamurenNo ratings yet

- Leadership and Management ModuleDocument6 pagesLeadership and Management ModuleMichael AngelesNo ratings yet

- 11 Axis FormationDocument61 pages11 Axis Formationapi-3800038100% (1)

- Spe 193796 MsDocument22 pagesSpe 193796 MsMurtibaahshe HDNo ratings yet

- FundamentalsDocument39 pagesFundamentalsMoses KibikyaboNo ratings yet

- NBP - Sample Paper - OG - IIIDocument4 pagesNBP - Sample Paper - OG - IIIaqeelanwarnbpNo ratings yet

- A Survey of Control Approaches For Unmanned Underwater Vehicles 19.8.2023 - Ver4.0Document15 pagesA Survey of Control Approaches For Unmanned Underwater Vehicles 19.8.2023 - Ver4.0Dr Agus BudiyonoNo ratings yet

- Apollo / Saturn V: Insert Disk Q and The Fold OverDocument4 pagesApollo / Saturn V: Insert Disk Q and The Fold OverRob ClarkNo ratings yet

- Stellisept - Med - Scrub MSDSDocument10 pagesStellisept - Med - Scrub MSDSChoice OrganoNo ratings yet

- Enthalpy, Spontaneity, EntropyDocument16 pagesEnthalpy, Spontaneity, EntropyJeremy MacalaladNo ratings yet

- Recalling details from stories and visualizing numbersDocument37 pagesRecalling details from stories and visualizing numbersRhea Cherl Ragsag100% (1)

- Central Force Motion/kepler ProblemDocument5 pagesCentral Force Motion/kepler ProblemHel HelNo ratings yet

- Фонетика Тест 1-4Document1 pageФонетика Тест 1-4Карина КамаловаNo ratings yet

- Quadratics Unit Quiz #1Document3 pagesQuadratics Unit Quiz #1hix8073No ratings yet

- Sep. Gravimetrica - CromitaDocument13 pagesSep. Gravimetrica - Cromitaemerson sennaNo ratings yet

- Lab Audit Checklist (PRIDE) - 2014Document12 pagesLab Audit Checklist (PRIDE) - 2014hoanam2009No ratings yet

- Lecture 12 - Mass Balance ApproachDocument18 pagesLecture 12 - Mass Balance ApproachAshhad ShafiqueNo ratings yet

- Bai Giang - CT361 - Chuong 4 (PDF - Io)Document18 pagesBai Giang - CT361 - Chuong 4 (PDF - Io)Nghiệp Nguyễn ThànhNo ratings yet

- Phrasal Verbs ListDocument85 pagesPhrasal Verbs ListVirginia E. C.No ratings yet

- Analysis of Amino AcidsDocument3 pagesAnalysis of Amino AcidsRinaldi SukarnoNo ratings yet

- m2 Arithmetic SequenceDocument9 pagesm2 Arithmetic Sequenceedmund roseteNo ratings yet

- CHEMICAL APPROVAL FORMDocument2 pagesCHEMICAL APPROVAL FORMYosep SasadaNo ratings yet

- Ratio & Proport-WPS OfficeDocument43 pagesRatio & Proport-WPS OfficeRovelyn Sangalang CabreraNo ratings yet

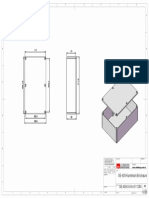

- SE-409 Aluminium Enclosure SE-409-0-0-A-0-11284: RevisionDocument1 pageSE-409 Aluminium Enclosure SE-409-0-0-A-0-11284: RevisionAhmet MehmetNo ratings yet

- JRC127220 01Document74 pagesJRC127220 01GMNo ratings yet

- Guide to designing a strong research proposalDocument11 pagesGuide to designing a strong research proposalmayo ABIOYENo ratings yet

- Quarter 4 - MELC 11: Mathematics Activity SheetDocument9 pagesQuarter 4 - MELC 11: Mathematics Activity SheetSHAIREL GESIMNo ratings yet

- Interpreting SNT TC 1A PDF 2Document1 pageInterpreting SNT TC 1A PDF 2Jagannath SahuNo ratings yet