Professional Documents

Culture Documents

Create Elec Safety Program

Uploaded by

geraleao208Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Create Elec Safety Program

Uploaded by

geraleao208Copyright:

Available Formats

Creating an electrical

safety program

Protecting employees from

electrical dangers on the job Application Note

As dangerous jobs go, the Syntech Enerflex, one of the

world of working with elec- largest electrical and instru-

tricity might not seem the mentation open shop contrac-

most romantic. Unlike fire- tors in western Canada, has

fighting or law enforcement, developed a brand new safety

electricians aren’t often program targeted at reduc-

featured in blockbuster movies ing the likelihood of an arc

as heroic, brave saviors of the flash incident and in doing

street. But working with elec- so, is leading the way toward

tricity can be comparatively increased awareness of the

dangerous and the injury rate phenomenon in Canada.

for electricians is high. People The program hinges on the

who work on or near electrical adoption of a new minimum

Safety sources have to be extremely standard for digital multimeters

Program careful to avoid electrocution or (DMMs). The DMMs, purchased

arc flash incidents. by Syntech Enerflex but owned

Case An arc flash is a devastat- by the individual workers, are

Study ing outburst of energy that the Fluke 179 CAT IV 600 V/

can range in temperature CAT III 1000 V. Their previous

from 2,800 to 19,000 degrees DMMs were not as high qual-

Celsius. It sends a concen- ity as the company needed,

trated wave of radiant energy, says Syntech Enerflex health,

hot gases and melting metal safety and environment (south)

outwards from its source. The coordinator Larry Johnson, so

effects on those nearby can they sought out new products

Product: Fluke 179 Digital Multimeter include: death, radiation burns, that came with comprehen-

brain damage, hearing and sive educational tools. Most

vision loss. It impacts every- importantly, says Johnson, they

one in the immediate zone wanted a tool that was proven

Profile: Syntech Enerflex and flying shrapnel from the to be safe and effective in the

blast can even harm those at a workplace.

distance.

Applications: CSA approval, arc flash In order to prevent such a

training, protocols tragedy, more and more compa-

nies are working to prevent arc

flash incidents. In Canada the

efforts are still quite new, as

the awareness of the dangers of

arc flash is not as widespread

as it is in the U.S. But one

company, Syntech Enerflex in

Alberta, is taking the initiative

to protect its employees from

arc flash now.

Electrical safety programs are a key component in

avoiding electrical accidents and protecting employees

from arc flash and other electrical dangers.

“One of the key reasons we dards,” says Johnson, “we personal protective equipment

went with Fluke was Canadian learned more about arc flash or PPE, such as an arc flash

Standards Association (CSA) and National Fire Protection face shield, eye and hearing

approval. Our previous meters Association (NFPA) 70E Stan- protection, insulated hand tools,

were not CSA approved, and dard for Electrical Safety in insulated gloves, and fire resis-

even though the tool was built the Workplace. It’s a standard tant clothing.

to standards, it was not tested in the States that talks about Johnson says the feedback

and we felt this was one of how to mitigate the risk around about the program from the

the most important aspects to arc flash. We put it to practice employees has been good.

consider when purchasing a around here.” “Most of the employees have

meter.” Johnson adds that it Together with the meter always checked their meters

was also important that CSA training tools and the infor- before they use them, but the

independently verifies that the mation in NFPA 70E, Syntech new procedure lays it out better

test tools meet the requirements Enerflex’s safety program was for them,” he explains. “It’s

of International Electro-Tech- devised. The center of the their own meter and they look

nical Commission (IEC) 61010, policy is the DMM pre-use after it as an important tool.

which itself is the basis for inspection procedure. It has They use these ideas to kick it

CSA C22.2 No 61010-1-04. 10 steps and focuses on making up a notch.”

But finding and buying the sure the test tool is in good One of the most important

new meters was only the first condition, is right for the job elements of this new training is

step. A meter is only as good and that the meter and leads promoting respect and aware-

as the person operating it, so are functioning properly (see ness of the dangers arc flash

Johnson and his team set forth next page). poses to electrical workers.

investigating everything they The third component to They form the critical bridge

could about arc flash. Fluke Syntech Enerflex’s multimeter between electrical power and

provided part of the research safety program is called Ener- the society and businesses that

materials in the form of training gized Work Authorization. It depend on it. Their safety is

seminars and training videos. outlines the protocol employ- not just important to Syntech

The other half of the research ees have to follow when test- Enerflex, but for the trade as a

delved into the standards set ing energized equipment. The whole. Electricians do not need

in the United States specific to protocol was based on NFPA glamour; they need a safe and

arc flash. 70E as well, which requires the healthy workplace in which to

“Once we determined there calculation of a flash protection perform their jobs.

was an existing meter that boundary inside which work-

was tested and met CSA stan- ers must be protected with

Equipment approved by independent organizations like CSA can help protect Pre-use inspection procedures employed at Syntech Enerflex can help

users even in the event of operator error. avoid equipment damage.

2 Fluke Education Partnership Program Creating an electrical safety program

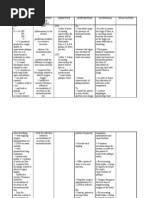

Syntech Enerflex Safe Work Practice:

Multimeter Pre-Use Inspection

1. Check meter for date of last calibration; if the 8. Test leads; turn meter to OHMs and short

calibration is past due date, do not use meter tests leads together. Meter should show

and send in for calibration. continuity. While still shorted, jiggle leads to

2. Check rating of meter to ensure meter specs check for loose connections or breaks in the

meet job requirements and a minimum of Cat leads. Good leads are 0.1 ohms to 0.3 ohms.

III double insulated. 9. On Fluke meters, to test the fuse, plug test

3. Check meter for CSA or equivalent approval. lead into V/Ohm input, select OHMs, insert

probe tip into mA input read value, or insert

4. Check fuses for continuity. probe into A input and read value. A good

5. Check to ensure ohm and voltage protection fuse should read close to zero.

are at the same level (may require checking 10. If the meter has had any mishaps or blown

operators manual). fuses, the meter should be inspected before

6. Check condition of meter case and general using.

condition.

7. Check leads, visual inspection for cracks,

bare spots, finger guards, double insulated

and category rating.

Fluke Corporation

PO Box 9090, Everett, WA USA 98206

©2007 Fluke Corporation. Printed in U.S.A.

12/2007 3213017 A-EN-N Rev A

Web access: http://www.fluke.com

3 Fluke Education Partnership Program Creating an electrical safety program

You might also like

- 101 Creative Problem Solving Techniques by James M. HigginsDocument241 pages101 Creative Problem Solving Techniques by James M. HigginsJacostorius96% (56)

- C 099EB I Gard ManualDocument18 pagesC 099EB I Gard ManualSejahtra AbadiNo ratings yet

- ĐỀ THI THỬ ĐH - Mã 129 (Smartie)Document6 pagesĐỀ THI THỬ ĐH - Mã 129 (Smartie)Hoang Huy NguyenNo ratings yet

- Document 2 PDFDocument5 pagesDocument 2 PDFLuis Miguel Esquivel SequeiraNo ratings yet

- Appendixe 1 STR 1386 TestsDocument7 pagesAppendixe 1 STR 1386 TestshansamvNo ratings yet

- Bruns InjuriesDocument7 pagesBruns InjuriesJasmin JesenkovicNo ratings yet

- Surge Stopper IC Simplifies Design of Intrinsic Safety Barrier For Electronics Destined For Hazardous EnvironmentsDocument7 pagesSurge Stopper IC Simplifies Design of Intrinsic Safety Barrier For Electronics Destined For Hazardous Environmentscnrk777inNo ratings yet

- Seguridad Choque ElectricoDocument12 pagesSeguridad Choque ElectricoMiguel Alfonso Ruiz MendezNo ratings yet

- ArcFlash-eGuide-Final EATONDocument24 pagesArcFlash-eGuide-Final EATONRafael AlemanNo ratings yet

- 10 THINGS ABOUT ARC FLASH SAFETYDocument1 page10 THINGS ABOUT ARC FLASH SAFETYAlejandro Salas VásquezNo ratings yet

- Practical Approaches To Mitigating Arc Flash ExposureDocument9 pagesPractical Approaches To Mitigating Arc Flash ExposureE.ANANDANNo ratings yet

- Mitigating Arc Flash Injuries Through Remote Wireless CuttingDocument6 pagesMitigating Arc Flash Injuries Through Remote Wireless CuttingAlexis ibarraNo ratings yet

- Arc Flash Safety ProgramDocument6 pagesArc Flash Safety Programlimkokchiang809No ratings yet

- Presentation - Eaton - Arc Flash SolutionsDocument57 pagesPresentation - Eaton - Arc Flash SolutionsJamesNo ratings yet

- Six Strategies To Mitigate Arc Flash Incidents: OlutionsDocument2 pagesSix Strategies To Mitigate Arc Flash Incidents: OlutionsCyrix.OneNo ratings yet

- GE Arc Flash GuideDocument26 pagesGE Arc Flash GuideJOSE LUIS FALCON CHAVEZNo ratings yet

- What You Need To Know About Arc Flash: White Paper WP083033ENDocument6 pagesWhat You Need To Know About Arc Flash: White Paper WP083033ENVigneshwaran KandaswamyNo ratings yet

- ERICO Grounding Products and SystemsDocument84 pagesERICO Grounding Products and SystemsHatem OmerNo ratings yet

- Research Paper On Electrical SafetyDocument6 pagesResearch Paper On Electrical Safetygz45tyye100% (1)

- Arc Flash NFPA 20101215Document2 pagesArc Flash NFPA 20101215John Fredy Martínez CardonaNo ratings yet

- Arc Flash ThesisDocument6 pagesArc Flash Thesistheresasinghseattle100% (1)

- Arc Flash Mitigation: Executive SummaryDocument13 pagesArc Flash Mitigation: Executive Summaryheriberhuerta100% (1)

- Arc Flash Hazards and Electrical Safety Program ImplementationDocument5 pagesArc Flash Hazards and Electrical Safety Program Implementationgirish19No ratings yet

- Electrical Safety Research PaperDocument4 pagesElectrical Safety Research Paperadyjzcund100% (1)

- Material Handling & AutomationDocument35 pagesMaterial Handling & AutomationrogerioNo ratings yet

- Paper - Innovative Techniques For Mitigating Arc Flash ExposureDocument9 pagesPaper - Innovative Techniques For Mitigating Arc Flash ExposurehenriquezrsNo ratings yet

- The 4P's Approach To Arc Flash Risk AssessmentDocument9 pagesThe 4P's Approach To Arc Flash Risk AssessmentJohn BihagNo ratings yet

- Protection From LightningDocument3 pagesProtection From Lightninguser123No ratings yet

- Dehn Catalogo General Interna Dps Externa 2023Document380 pagesDehn Catalogo General Interna Dps Externa 2023Toti.No ratings yet

- Arc FlashDocument7 pagesArc FlashGhulam MustaqeemNo ratings yet

- Arc Flash StudyDocument2 pagesArc Flash Studychampion2007100% (1)

- Electrical Workplace Safety TrainingDocument3 pagesElectrical Workplace Safety TrainingOsvaldo MolinaNo ratings yet

- Lightning ProtectionDocument8 pagesLightning ProtectionLalo PatoNo ratings yet

- HVM Arcflashfaq 331251 0Document4 pagesHVM Arcflashfaq 331251 0Waleed ElzanatiNo ratings yet

- Understanding Arc Flash Hazards in MiningDocument8 pagesUnderstanding Arc Flash Hazards in MiningwillytNo ratings yet

- An Overview of ESD Process Control ProblemsDocument6 pagesAn Overview of ESD Process Control Problemstl xNo ratings yet

- Slup 224Document191 pagesSlup 224marcosscaratoNo ratings yet

- ArcFlash FAQDocument13 pagesArcFlash FAQravilabier100% (1)

- Arc Flash Mitigation TechniquesDocument4 pagesArc Flash Mitigation Techniquesger80No ratings yet

- Arc Flash: Technical Advisory BulletinDocument5 pagesArc Flash: Technical Advisory BulletinAhmad YaseenNo ratings yet

- Arc Flash: Technical Advisory BulletinDocument5 pagesArc Flash: Technical Advisory BulletinDiki AriNo ratings yet

- Developing A Consumer-Oriented Guide On Surge ProtectionDocument10 pagesDeveloping A Consumer-Oriented Guide On Surge ProtectionJohn Philip BuntalesNo ratings yet

- ArcFlash Handbook FINAL-onlineDocument80 pagesArcFlash Handbook FINAL-onlineMichael CincoNo ratings yet

- Research Paper Electrical SafetyDocument6 pagesResearch Paper Electrical Safetyisuehjulg100% (1)

- Lightning Surge Protection GuideDocument8 pagesLightning Surge Protection Guidemarissa LovaNo ratings yet

- Plant Floor Safety Spring 2024Document49 pagesPlant Floor Safety Spring 2024ssolvera32No ratings yet

- 7358-07 VeriSafe WP2 VF PDFDocument7 pages7358-07 VeriSafe WP2 VF PDFmaykee01No ratings yet

- 1.1. DEHN Surge Protector Catalogs PDFDocument339 pages1.1. DEHN Surge Protector Catalogs PDFGan SAIK NGAINo ratings yet

- Understanding The Hazard: Electrical Equipment in Hazardous (Classified) LocationsDocument4 pagesUnderstanding The Hazard: Electrical Equipment in Hazardous (Classified) LocationsVivianNo ratings yet

- Littelfuse Arc-Flash Hazards White PaperDocument8 pagesLittelfuse Arc-Flash Hazards White PaperVigneshwaran KandaswamyNo ratings yet

- Arc Flash and Coordination Study Conflict in An Older Industrial PlantDocument6 pagesArc Flash and Coordination Study Conflict in An Older Industrial PlantSamara FahiraNo ratings yet

- ARC Flash ARCON DeviceDocument12 pagesARC Flash ARCON DeviceGustavo GamezNo ratings yet

- Arc FlashDocument6 pagesArc Flashrajap2737No ratings yet

- Arc Flash Risk ManagementDocument20 pagesArc Flash Risk ManagementmikexanderNo ratings yet

- Arc Flash BasicsDocument5 pagesArc Flash BasicsabenitechNo ratings yet

- Surge Protection Made As Simple As A Circuit BreakerDocument8 pagesSurge Protection Made As Simple As A Circuit BreakerSchalter ElectricNo ratings yet

- Lightning Protection According NFC 17 102Document6 pagesLightning Protection According NFC 17 102FerryNo ratings yet

- Lightning Protection According To IEC 62305Document10 pagesLightning Protection According To IEC 62305Ahmed Shoaib100% (1)

- WHITE PAPER: Arc Flash and How To Prevent ItDocument4 pagesWHITE PAPER: Arc Flash and How To Prevent ItRajiv ChaudhariNo ratings yet

- Arc Flash Energy Reduction Techniques Zone Selective Interlocking & Energy-Reducing Maintenance SwitchingDocument13 pagesArc Flash Energy Reduction Techniques Zone Selective Interlocking & Energy-Reducing Maintenance SwitchingBuelvas NicanorNo ratings yet

- A Survey of Arc Flash Computation Methods and Mitigation StrategiesDocument11 pagesA Survey of Arc Flash Computation Methods and Mitigation StrategiesLuis Miguel Esquivel SequeiraNo ratings yet

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- Infineon FS450R17KE3 DS v02 - 03 ENDocument8 pagesInfineon FS450R17KE3 DS v02 - 03 ENgeraleao208No ratings yet

- EL CID Iris Qualitrol Brochure V6 8 20Document4 pagesEL CID Iris Qualitrol Brochure V6 8 20geraleao208No ratings yet

- Differences in Voltage Testers Can Be Shocking: Application NoteDocument3 pagesDifferences in Voltage Testers Can Be Shocking: Application Notegeraleao208No ratings yet

- S-T MaintenanceManualDocument34 pagesS-T MaintenanceManualgeraleao208No ratings yet

- Does Your Meter Measure Up?Document1 pageDoes Your Meter Measure Up?geraleao208No ratings yet

- ABCs of SafetyDocument7 pagesABCs of Safetygeraleao208No ratings yet

- Validation and Reception of Electric Arc Furnace TransformersDocument6 pagesValidation and Reception of Electric Arc Furnace Transformersgeraleao208No ratings yet

- Cmos Logic DataDocument450 pagesCmos Logic DataseleneedithNo ratings yet

- Choosing The Correct Fuse For Your Tester: Application NoteDocument2 pagesChoosing The Correct Fuse For Your Tester: Application Notegeraleao208No ratings yet

- Power Electronics and Its Challenges - RashidDocument3 pagesPower Electronics and Its Challenges - Rashidgeraleao208No ratings yet

- Abb - The Motor GuideDocument118 pagesAbb - The Motor GuideRolando DaclanNo ratings yet

- Module 1 BrowserDocument9 pagesModule 1 Browsergeraleao208No ratings yet

- Input Current Harmonic Reduction in AC-DC RectifiersDocument7 pagesInput Current Harmonic Reduction in AC-DC Rectifiersgeraleao208No ratings yet

- Information and Measuring System For Electric Arc Furnace Transformer MonitoringDocument7 pagesInformation and Measuring System For Electric Arc Furnace Transformer Monitoringgeraleao208No ratings yet

- The Past, Present, and Future of Power ElectronicsDocument6 pagesThe Past, Present, and Future of Power Electronicsgeraleao208No ratings yet

- SGP9 Practices For Long Service Lifeof Transformers CBIPConfon Large Power Transformers 2013Document11 pagesSGP9 Practices For Long Service Lifeof Transformers CBIPConfon Large Power Transformers 2013geraleao208No ratings yet

- Drives ABCReferenceDocument96 pagesDrives ABCReferenceRicardo SilvaNo ratings yet

- Teaching Power Electronics - RashidDocument7 pagesTeaching Power Electronics - Rashidgeraleao208No ratings yet

- Vacon Engineered AC Drives ManualDocument166 pagesVacon Engineered AC Drives Manualdario_es100% (4)

- Power Electronics For Very High Power ApplicationsDocument6 pagesPower Electronics For Very High Power Applicationsgeraleao208No ratings yet

- Power Electronics-An Emerging Technology - B.K.BoseDocument8 pagesPower Electronics-An Emerging Technology - B.K.Bosegeraleao208No ratings yet

- Guide of Methods For Determining The Condition of Stator Winding Insulation and Their Effectiveness in Large MotorsDocument36 pagesGuide of Methods For Determining The Condition of Stator Winding Insulation and Their Effectiveness in Large MotorsNilav KumarNo ratings yet

- Drives ABCReferenceDocument96 pagesDrives ABCReferenceRicardo SilvaNo ratings yet

- Artikel Wechselrichterkippen-Abhilfe-durch-CCP V07 76Document17 pagesArtikel Wechselrichterkippen-Abhilfe-durch-CCP V07 76geraleao208No ratings yet

- Classification of Fault DiagnosisDocument6 pagesClassification of Fault Diagnosisgeraleao208No ratings yet

- Life Assessment of Electric Arc Furnace TransformersDocument11 pagesLife Assessment of Electric Arc Furnace Transformersgeraleao208No ratings yet

- Operation and Maintenance Practices Extend Transformer LifespanDocument11 pagesOperation and Maintenance Practices Extend Transformer Lifespangeraleao208No ratings yet

- CPSC5125 - Assignment 3 - Fall 2014 Drawing Polygons: DescriptionDocument2 pagesCPSC5125 - Assignment 3 - Fall 2014 Drawing Polygons: DescriptionJo KingNo ratings yet

- BuellRetailCatalog en USDocument76 pagesBuellRetailCatalog en USErcüment Kayacık100% (2)

- 1969 Viyana Andlaşmalar Hukuku SözleşmesiDocument4 pages1969 Viyana Andlaşmalar Hukuku SözleşmesiZeynep MadenNo ratings yet

- Juice in PakistanDocument9 pagesJuice in Pakistanrize1159100% (1)

- Human Rights EducationDocument149 pagesHuman Rights EducationLeonard MamergaNo ratings yet

- Bankruptcy Judge Imposes Sanctions On CounselDocument17 pagesBankruptcy Judge Imposes Sanctions On Counsel83jjmackNo ratings yet

- 03 IoT Technical Sales Training Industrial Wireless Deep DiveDocument35 pages03 IoT Technical Sales Training Industrial Wireless Deep Divechindi.comNo ratings yet

- FSN Lullaby Warmer Resus Plus&PrimeDocument4 pagesFSN Lullaby Warmer Resus Plus&PrimemohdkhidirNo ratings yet

- SWOT ANALYSIS - Docx Sime DarbyDocument9 pagesSWOT ANALYSIS - Docx Sime Darbynur azfarinie ruzliNo ratings yet

- Processed oDocument2 pagesProcessed oHemanth KumarNo ratings yet

- Kundalini Reiki Manual: Paul CrickDocument17 pagesKundalini Reiki Manual: Paul CrickKkkk100% (1)

- Black Industries Lost Files - Terror in The DarknessDocument14 pagesBlack Industries Lost Files - Terror in The Darknessjadrax100% (8)

- Document PDFDocument16 pagesDocument PDFnelson_herreraNo ratings yet

- Chapter 4 Designing Your SolutionDocument22 pagesChapter 4 Designing Your SolutionRamona Isabel UrsaisNo ratings yet

- NCP For Ineffective Airway ClearanceDocument3 pagesNCP For Ineffective Airway ClearanceJennelyn BayleNo ratings yet

- 411 PS1 2018 AnsDocument3 pages411 PS1 2018 AnsAlbertus MuheuaNo ratings yet

- 小學四年級 Primary 4: W I M O F 2018Document7 pages小學四年級 Primary 4: W I M O F 2018Do Yun100% (2)

- Lirik LaguDocument34 pagesLirik LaguAdjie SatryoNo ratings yet

- Resignation LetterDocument7 pagesResignation LetterMichael San LuisNo ratings yet

- Design Portfolio (Priyal)Document30 pagesDesign Portfolio (Priyal)PRIYAL SINGHALNo ratings yet

- TULIP ChartDocument1 pageTULIP ChartMiguel DavillaNo ratings yet

- TQM Implementation in ToyotaDocument15 pagesTQM Implementation in ToyotaSaikat GhoshNo ratings yet

- Final Order in The Matter of M/s Alchemist Capital LTDDocument61 pagesFinal Order in The Matter of M/s Alchemist Capital LTDShyam SunderNo ratings yet

- Human Rights DefinitionDocument2 pagesHuman Rights DefinitionFathiah MhNo ratings yet

- Sensory Evaluation of FoodDocument38 pagesSensory Evaluation of FoodKHOZA SBUSISIWENo ratings yet

- Decision Criteria For Ethical ReasoningDocument14 pagesDecision Criteria For Ethical ReasoningZara ImranNo ratings yet

- q2 Wk1 Worksheet1 Music8Document10 pagesq2 Wk1 Worksheet1 Music8Michie Maniego - GumanganNo ratings yet

- Maceda Vs Energy Reg BoardDocument4 pagesMaceda Vs Energy Reg BoardJay Mark Esconde100% (1)

- Antianginal Student222Document69 pagesAntianginal Student222MoonAIRNo ratings yet