Professional Documents

Culture Documents

Program calculates vapor pipe pressure drop

Uploaded by

westewr0 ratings0% found this document useful (0 votes)

14 views4 pagesOriginal Title

Vap.line Pre. drop

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views4 pagesProgram calculates vapor pipe pressure drop

Uploaded by

westewrCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 4

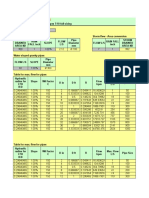

PROGRAM TO CALCULATE THE PRESSURE DROP ACROSS VAPOR PIPE

( PREPARED BY : K.S.SINGH-->DOMB.DESIGN DEPT.)

PROCEDURE : A = COMMERCIAL PIPE

B = SMOOTH PIPE

This program is mainly developed for sizing of vapor pipe for distillation.The program is self

explanatery. For a given fluid insert the name,liq.density,mol.wt,vapor viscosity.Calculate the

effective length & insert.Insert the vapor temp.of operation.For a given vapor pipe size certain

pressure drop is calculated for certain collection rate & vice versa. Based on the results decide

whether vapor pipe size is o.k ?

IMP.NOTE :

Vapor pipe sizing is very critical for vacuum operation due to drastic increase in the volumetric

flow rate of the vapor which is due to very low vapor density at low pressure.

SO FOR VAPOR PIPE SIZING FOR VACUUM OPERATION SPECIAL CARE SHOULD BE

TAKEN

A : COMMERCIAL PIPE ( CS,SS ETC )

INPUT DATA REQUIRED OUTPUT RESULTS

NAME OF THE LIQ. = HCl DENSITY OF VAPOR = 0.00142 gm/cc

DENSITY OF LIQUID = 1.16 gm/cc VELOCITY = 25.44 m/sec

PRESS OF OPERN = 760 mm Hg PRESSURE DROP = 45.99 mm Hg

VAPOR TEMP. = 40 °C

MOL WT = 36.5

VAPOR PIPE DIA = 50 mm

VISCOSITY OF VAP.= 0.008 CP

EFF.LENGTH OF PIPE= 30 m = STRAIGHT LENGTH + EQUIVALENT LENGTH.

COLL.RATE REQD(LIQ.) = 220 Lit/Hr (Considering Density of pure Liq. HCl as 1.36 gm./cc)

PRESS OF TEMP.OF VAPOR VAPOR PR.DROP

COLLN RATE OPER. OPER °C DENSITY VELOCITY mm Hg

LIT/HR mm Hg GM/CC CM/SEC

1250 750 80 0.00123384 16633.9451 1294.14227

1000 250 70 0.00042327 38790.5485 2502.12078

1000 200 70 0.00033862 48488.1856 3127.65097

800 200 70 0.00033862 38790.5485 2074.45423

700 200 70 0.00033862 33941.7299 1622.55219

600 200 70 0.00033862 29092.9114 1221.84631

500 200 70 0.00033862 24244.0928 873.62105

500 150 70 0.00025396 32325.4571 1164.82807

500 100 70 0.00016931 48488.1856 1747.2421

500 50 70 8.4654E-05 96976.3712 3494.4842

500 40 70 6.7724E-05 121220.464 4368.10525

400 30 80 4.9354E-05 133071.561 3975.55707

300 20 80 3.2903E-05 149705.506 3512.38389

250 20 80 3.2903E-05 124754.588 2511.35717

200 20 80 3.2903E-05 99803.6707 1665.68954

200 20 90 3.1996E-05 102630.97 1712.87622

200 20 100 3.1138E-05 105458.27 1760.06289

200 20 110 3.0325E-05 108285.569 1807.24956

150 20 110 3.0325E-05 81214.1768 1064.46369

150 15 110 2.2744E-05 108285.569 1419.28492

100 10 110 1.5163E-05 108285.569 1009.60834

80 10 110 1.5163E-05 86628.4552 669.635559

70 10 110 1.5163E-05 75799.8983 523.761203

60 10 110 1.5163E-05 64971.3414 394.41301

50 8 110 1.213E-05 67678.4806 352.507006

50 7 110 1.0614E-05 77346.835 402.865149

50 6 115 8.9804E-06 91416.0156 476.145233

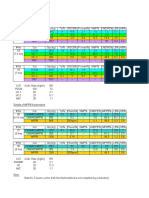

B : SMOOTH PIPE ( MS/PP,MS/PTFE,MS/PVDF ETC )

INPUT DATA REQUIRED OUTPUT RESULTS

NAME OF THE LIQ. = TOLUENE DENSITY OF VAPOR = 0.00310996 gm/cc

DENSITY OF LIQUID = 0.866 gm/cc VELOCITY = 1924.51029 cm/sec

PRESS OF OPERN = 750 mm Hg PRESSURE DROP = 30.6919754 mm Hg

VAPOR TEMP. = 80 °C

MOL WT = 92

VAPOR PIPE DIA = 80 mm

VISCOSITY OF VAP.= 0.008 CP

EFF.LENGTH OF PIPE= 50 m = STRAIGHT LENGTH + EQUIVALENT LENGTH.

COLL.RATE REQD = 1250 Lit/Hr

PRESS OF TEMP.OF VAPOR VAPOR PR.DROP

COLLN RATE OPER. OPER °C DENSITY VELOCITY mm Hg

LIT/HR mm Hg GM/CC CM/SEC

1250 750 80 0.00310996 1924.51029 30.6919754

1000 250 80 0.00103665 4618.82471 62.3094006

1000 200 80 0.00082932 5773.53088 77.8867507

800 200 80 0.00082932 4618.82471 52.7073357

700 200 80 0.00082932 4041.47162 41.723925

600 200 80 0.00082932 3464.11853 31.8587165

500 200 80 0.00082932 2886.76544 23.1558695

500 150 80 0.00062199 3849.02059 30.8744927

500 100 80 0.00041466 5773.53088 46.3117391

500 50 80 0.00020733 11547.0618 92.6234782

500 40 80 0.00016586 14433.8272 115.779348

400 30 80 0.0001244 15396.0824 104.466564

300 20 80 8.2932E-05 17320.5927 94.7165307

250 20 80 8.2932E-05 14433.8272 68.842812

200 20 80 8.2932E-05 11547.0618 46.5871431

200 20 80 8.2932E-05 11547.0618 46.5871431

200 20 80 8.2932E-05 11547.0618 46.5871431

200 20 80 8.2932E-05 11547.0618 46.5871431

150 20 80 8.2932E-05 8660.29633 28.1593931

150 15 80 6.2199E-05 11547.0618 37.5458574

100 10 80 4.1466E-05 11547.0618 27.700881

80 10 80 4.1466E-05 9237.64942 18.745674

70 10 80 4.1466E-05 8082.94324 14.8393594

60 10 80 4.1466E-05 6928.23706 11.3307399

50 8 80 3.3173E-05 7216.91361 10.2944015

50 7 80 2.9026E-05 8247.90126 11.7650303

50 6 80 2.488E-05 9622.55147 13.7258687

PRESSURE DROP CALCULATIONS FOR VAPOURS AND GASES.

Flowrate of fluid 500 Kg/hr = 1102.4 lb/hr

Inside pressure 50 mm Hg

Operatig temperature 20

Mavg 127.0

And density 0.3475 Kg/m3 0.0217 lb/ft3

Friction factor 0.02

line size 6 inch

Length of line 30 m 98.43 ft

So total persure drop 2.46 mm Hg

So pressure on downstream required 47.54 mm Hg

You might also like

- Pressure Drop Calculations - BC Solver6 - MacroFree Version (Inspect)Document53 pagesPressure Drop Calculations - BC Solver6 - MacroFree Version (Inspect)Jerome IlaoNo ratings yet

- Analise MPDocument9 pagesAnalise MPPCP EzataNo ratings yet

- UPVC Pipe DimensionDocument1 pageUPVC Pipe Dimensionajeet gulatiNo ratings yet

- Aquarius+ UPVC Industrial Pipe & FittingsDocument16 pagesAquarius+ UPVC Industrial Pipe & Fittingspanchal harnishNo ratings yet

- Abaco ModyDocument195 pagesAbaco ModyDo IsidroNo ratings yet

- HETP calculations and packing sizingDocument16 pagesHETP calculations and packing sizingAriesNo ratings yet

- Packed Stripper SizingDocument16 pagesPacked Stripper SizingAriesNo ratings yet

- Test Report CP16-210 - Y5K23F2515 PSIDocument1 pageTest Report CP16-210 - Y5K23F2515 PSIDieguin SuárezNo ratings yet

- DBR ChecklistDocument9 pagesDBR ChecklistJai ThakkarNo ratings yet

- Perhitungan Aliran Fluida: Menentukan Densitas Dan Viskositas AirDocument26 pagesPerhitungan Aliran Fluida: Menentukan Densitas Dan Viskositas AirHandika Muhammad PrabuNo ratings yet

- Thermodynamic properties of hydrocarbons combustion reactionsDocument24 pagesThermodynamic properties of hydrocarbons combustion reactionsDiana LaitonNo ratings yet

- William Hazen Sloped Pipe SizingcDocument3 pagesWilliam Hazen Sloped Pipe Sizingcadel rihanaNo ratings yet

- Tuberias ManningDocument6 pagesTuberias ManningDaniel Gil GtzNo ratings yet

- 2BE1 Liquid Ring Vacuum Pump - Guomei PumpDocument7 pages2BE1 Liquid Ring Vacuum Pump - Guomei PumpOscarNo ratings yet

- Fluid Flow Pressure Drop in Packed ColumnDocument14 pagesFluid Flow Pressure Drop in Packed Columnmohammed kadhimNo ratings yet

- Technical Data of Black and Hot Dip Galvanized Steel Pipes Conforming To Astm A 53 Grade A & B Sch-40Document5 pagesTechnical Data of Black and Hot Dip Galvanized Steel Pipes Conforming To Astm A 53 Grade A & B Sch-40mechmohsin4745No ratings yet

- H1C114074 Arifuddin NurDocument11 pagesH1C114074 Arifuddin NurArhy ArifuddinNo ratings yet

- Sewer Design On Excel 2009Document117 pagesSewer Design On Excel 2009ashe zinabNo ratings yet

- Nitrogen Spreadsheet JR EditDocument20 pagesNitrogen Spreadsheet JR EditОлександр ЛетюкNo ratings yet

- RTD Thermistor Z202030 0NDocument1 pageRTD Thermistor Z202030 0NcesarNo ratings yet

- C:/Users/carre/Desktop/Simulacion Produccion de Caprolactama, HSC MainDocument22 pagesC:/Users/carre/Desktop/Simulacion Produccion de Caprolactama, HSC MainCamila Florencia ScarlatoNo ratings yet

- C:/Users/carre/Desktop/Simulacion Produccion de Caprolactama, HSC MainDocument22 pagesC:/Users/carre/Desktop/Simulacion Produccion de Caprolactama, HSC MainCamila Florencia ScarlatoNo ratings yet

- Catalogue Mondea 2023 Fix (2) XDocument38 pagesCatalogue Mondea 2023 Fix (2) XyanurulNo ratings yet

- Calculo de Erosion UsleDocument10 pagesCalculo de Erosion UsleJose Luis EstupiñanNo ratings yet

- Tablas de Bombeo ElectrosumergibleDocument8 pagesTablas de Bombeo ElectrosumergibleDiana RubioNo ratings yet

- Headloss Table RawanduzDocument12 pagesHeadloss Table Rawanduznaseer lateeNo ratings yet

- Sound AttenuatorDocument4 pagesSound AttenuatorFareethAbdullahNo ratings yet

- Aplisens PEM-1000Document4 pagesAplisens PEM-1000CalcRodVerNo ratings yet

- Lab 5 - BombasDocument12 pagesLab 5 - BombasDavid Paez GonzalezNo ratings yet

- Aceite Réplica 2Document7 pagesAceite Réplica 2Alejandra HolguinNo ratings yet

- Mechanical Properties: QT-900 Technical Data SheetDocument2 pagesMechanical Properties: QT-900 Technical Data SheetIshmael WoolooNo ratings yet

- Pressure To VacuumDocument1 pagePressure To Vacuumjesus_manrique2753No ratings yet

- Hsap BombasDocument4 pagesHsap Bombasjeanpaul mesa perezNo ratings yet

- Tuberia PVC y CPVC SCH 80Document1 pageTuberia PVC y CPVC SCH 80Ramón PortocarreroNo ratings yet

- Ghosh (130) Amp SweepDocument4 pagesGhosh (130) Amp SweepKUMAR GHOSHNo ratings yet

- Sz300a4aaaDocument8 pagesSz300a4aaah1234bNo ratings yet

- Stranded Overhead Shield Wire (Ground Wire) : Product DescriptionDocument1 pageStranded Overhead Shield Wire (Ground Wire) : Product DescriptionNguyen KhoaNo ratings yet

- Design Analysis For Palm Beach Marg For Ch:1250: Time (T) in Months in Seconds TV U (%)Document33 pagesDesign Analysis For Palm Beach Marg For Ch:1250: Time (T) in Months in Seconds TV U (%)sushil deshmukhNo ratings yet

- Palm Beach Marg RevisedDocument33 pagesPalm Beach Marg Revisedsushil deshmukhNo ratings yet

- Extra High Hazard Sample Hydraulic CalculationsDocument15 pagesExtra High Hazard Sample Hydraulic CalculationszaszaNo ratings yet

- Technical information on tensile strength, tightening torque and stainless steelDocument13 pagesTechnical information on tensile strength, tightening torque and stainless steelAngelo PereiraNo ratings yet

- C:/Users/carre/Desktop/hysys Giu, HSC Main: Case: Flowsheet: Main Current Flowsheet EnvironmentDocument28 pagesC:/Users/carre/Desktop/hysys Giu, HSC Main: Case: Flowsheet: Main Current Flowsheet EnvironmentCamila Florencia ScarlatoNo ratings yet

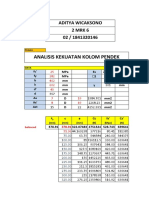

- Aditya Wicaksono 02-2MRK6 SBTDocument8 pagesAditya Wicaksono 02-2MRK6 SBTADITYA WICAKSONONo ratings yet

- Flow Meter Orifice CalculationDocument27 pagesFlow Meter Orifice CalculationLaksono BudiNo ratings yet

- Diseño - Cone Meter Sizing Nov30 09 - Beta 0.8Document1 pageDiseño - Cone Meter Sizing Nov30 09 - Beta 0.8IngKarasuma1No ratings yet

- SANLAU1 Mong Coc Thanh UyDocument20 pagesSANLAU1 Mong Coc Thanh Uylam phuNo ratings yet

- Palm Beach Marg Revised 1Document39 pagesPalm Beach Marg Revised 1sushil deshmukhNo ratings yet

- SAE 100 R2AT Hose Data SheetDocument1 pageSAE 100 R2AT Hose Data SheetNagarjunSHNo ratings yet

- Cable Properties # Properties Voltage Drop Size For Each TotalDocument5 pagesCable Properties # Properties Voltage Drop Size For Each Totalss787No ratings yet

- Tabel Percobaan Flow MeasuringDocument5 pagesTabel Percobaan Flow MeasuringLutfhi HanafiNo ratings yet

- Bare Overhead Conductors-2015Document63 pagesBare Overhead Conductors-2015Weber HahnNo ratings yet

- Experiment #1 Raynold Number Flow CharacteristicsDocument7 pagesExperiment #1 Raynold Number Flow CharacteristicsMir Masood ShahNo ratings yet

- Alekss P Kursa DarbsDocument19 pagesAlekss P Kursa Darbsalex.pugejs28No ratings yet

- Experiment 3,4Document9 pagesExperiment 3,4AsifMutahirNo ratings yet

- Butterfly Valves: PROGEF Standard Butterfly Valve Type 567 Hand Lever With Ratchet SettingsDocument2 pagesButterfly Valves: PROGEF Standard Butterfly Valve Type 567 Hand Lever With Ratchet SettingskasvikrajNo ratings yet

- Dtubing and flowline pressure drop analysisDocument9 pagesDtubing and flowline pressure drop analysiskỳ tâm nguyễn võNo ratings yet

- BUL 4462 Product Overview Hose Bulletin UK MainDocument4 pagesBUL 4462 Product Overview Hose Bulletin UK MainTuan buivietNo ratings yet

- COND-TERMOF1000 (Dimensionare Cond AF)Document10 pagesCOND-TERMOF1000 (Dimensionare Cond AF)pbutucNo ratings yet

- Gost 839-1980 PDFDocument1 pageGost 839-1980 PDFDejanNo ratings yet

- United States Census Figures Back to 1630From EverandUnited States Census Figures Back to 1630No ratings yet

- U Cal For ReactorDocument5 pagesU Cal For ReactorwestewrNo ratings yet

- Chilled Brine Requirement in Pl. 5 & Pl. 4Document1 pageChilled Brine Requirement in Pl. 5 & Pl. 4westewrNo ratings yet

- EvapDocument7 pagesEvapwestewrNo ratings yet

- Vacuum Science and TechnologyDocument7 pagesVacuum Science and TechnologywestewrNo ratings yet

- Fract. DetailsDocument1 pageFract. DetailswestewrNo ratings yet

- Shell & Tube Condenser Design MethodDocument4 pagesShell & Tube Condenser Design MethodwestewrNo ratings yet

- Programme To Calculate The Corrosion Rate Using Test PieceDocument2 pagesProgramme To Calculate The Corrosion Rate Using Test PiecewestewrNo ratings yet

- DLL All Subjects 2 q4 w8 d2Document8 pagesDLL All Subjects 2 q4 w8 d2Kinder DarpingNo ratings yet

- Data Sheet: PhotodiodesDocument22 pagesData Sheet: PhotodiodesDavid Nasael VERGARANo ratings yet

- Perret Mahindra SeminarDocument32 pagesPerret Mahindra SeminarBeowulf StarkNo ratings yet

- RIYAGUPTA MidSemDocument14 pagesRIYAGUPTA MidSemanaya jianaNo ratings yet

- Hiwin Gen Ballscrew Catalogue EngDocument178 pagesHiwin Gen Ballscrew Catalogue EngValeriy KobaNo ratings yet

- Sets ProbabilityDocument33 pagesSets ProbabilityGaithNo ratings yet

- PGDM-IIPR Final Research Based ReportDocument9 pagesPGDM-IIPR Final Research Based Reportnavneet dubeyNo ratings yet

- Mathematics Reference Books: No. Name Author PublisherDocument1 pageMathematics Reference Books: No. Name Author PublisherDelicateDogNo ratings yet

- ECG Synthtetic - Cloudias - 07311840000004Document8 pagesECG Synthtetic - Cloudias - 07311840000004Wheel ChairNo ratings yet

- Auveco HNI 490Document1 pageAuveco HNI 490BillNo ratings yet

- 107 - Low Stretch Rope - 2018Document5 pages107 - Low Stretch Rope - 2018Dusan CincarNo ratings yet

- Ipc TM 650Document10 pagesIpc TM 650Jose Pablo VenegasNo ratings yet

- Determine Crop Water Stress Using Deep Learning ModelsDocument22 pagesDetermine Crop Water Stress Using Deep Learning ModelsY19ec151No ratings yet

- Automatic Optimization and Elastic ConstantsDocument15 pagesAutomatic Optimization and Elastic ConstantsFebriman ZendratoNo ratings yet

- Further Mathematics: University of Cambridge International Examinations General Certificate of Education Advanced LevelDocument8 pagesFurther Mathematics: University of Cambridge International Examinations General Certificate of Education Advanced LevelPelatihan MatematikaNo ratings yet

- CorpusRembrandt 3Document819 pagesCorpusRembrandt 3Yuliya UdotNo ratings yet

- Overview of Medicine - Its Importance and ImpactDocument9 pagesOverview of Medicine - Its Importance and ImpactDuffosNo ratings yet

- EIA Case Study of Highway Project WideningDocument10 pagesEIA Case Study of Highway Project WideningSRUTHI FRANCIS M.Tech Environmental Engineering 2020-2022No ratings yet

- BSBADM502 Assessment Task 1 Global V1.1 Jan 21Document5 pagesBSBADM502 Assessment Task 1 Global V1.1 Jan 21Gorkhali GamingNo ratings yet

- Goldspink & Kay, 2007 PDFDocument15 pagesGoldspink & Kay, 2007 PDFPantelis TsavalasNo ratings yet

- I. Objectives: Detailed Science Lesson Plan Grade Level 10 Quarter/Dom AIN 4 Quarter Week & Day NO. Page NoDocument3 pagesI. Objectives: Detailed Science Lesson Plan Grade Level 10 Quarter/Dom AIN 4 Quarter Week & Day NO. Page NoDinz Guanzon TayactacNo ratings yet

- 5th Weekly Exam - Plumbing ArithmeticDocument11 pages5th Weekly Exam - Plumbing ArithmeticArchie Gomocag0% (1)

- Joints, Bones & Healthy SkeletonsDocument2 pagesJoints, Bones & Healthy Skeletonsسكمي نعمة الكرمهNo ratings yet

- AD IBS Assignment-1Document6 pagesAD IBS Assignment-1anvesha raoNo ratings yet

- EE129 Answers 724Document12 pagesEE129 Answers 724gma.roseangelikaNo ratings yet

- Avian 48 Guide PDFDocument8 pagesAvian 48 Guide PDFEng-Mohamed Zakria ElbadryNo ratings yet

- Garlic As Mosquito RepellentDocument18 pagesGarlic As Mosquito Repellentagnes80% (5)

- SDT Pipedrive Sales Dashboard TemplateDocument10 pagesSDT Pipedrive Sales Dashboard TemplateMANEESH SINGHNo ratings yet

- Armstrong ANFDocument2 pagesArmstrong ANFBramandito DamarNo ratings yet

- LectureNotes8 PDFDocument8 pagesLectureNotes8 PDFGuoXuanChanNo ratings yet