Professional Documents

Culture Documents

CRCW25123K30JNTG Datasheetz

Uploaded by

Vadim ZorinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CRCW25123K30JNTG Datasheetz

Uploaded by

Vadim ZorinCopyright:

Available Formats

D../CRCW....

Vishay

Lead (Pb)-bearing Thick Film, Rectangular Chip Resistors

FEATURES

• High volume product suitable for commercial and special

applications

• Excellent stability (ΔR/R ≤ ± 1 % for 1000 h at 70 °C)

• Lead (Pb)-bearing solder contacts on Ni barrier layer

• Metal glaze on high quality ceramic

• Protective overglaze

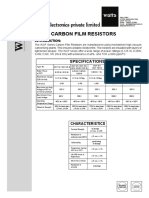

STANDARD ELECTRICAL SPECIFICATIONS

SIZE POWER RATING LIMITING

ELEMENT TEMPERATURE TOLERANCE RESISTANCE

MODEL P70 °C COEFFICIENT RANGE E-SERIES

VOLTAGE ppm/K % Ω

INCH METRIC W MAX. V≅

0.063 50 ± 100 ±1 1R0 - 10M 24 + 96

D10/CRCW0402 0402 1005 ± 200 ±5 24

Zero-Ohm-Resistor: Rmax. = 20 mΩ, Imax. at 70 °C = 1.5 A

0.10 75 ± 100 ±1 1R0 - 10M 24 + 96

D11/CRCW0603 0603 1608 ± 200 ±5 24

Zero-Ohm-Resistor: Rmax. = 20 mΩ, Imax. at 70 °C = 2.0 A

0.125 150 ± 100 ±1 1R0 - 10M 24 + 96

D12/CRCW0805 0805 2012 ± 200 ±5 24

Zero-Ohm-Resistor: Rmax. = 20 mΩ, Imax. at 70 °C = 2.5 A

0.25 200 ± 100 ±1 1R0 - 10M 24 + 96

D25/CRCW1206 1206 3216 ± 200 ±5 24

Zero-Ohm-Resistor: Rmax. = 20 mΩ, Imax. at 70 °C = 3.5 A

0.33 200 ± 100 ±1 1R0 - 10M 24 + 96

CRCW1210 1210 3225 ± 200 ±5 24

Zero-Ohm-Resistor: Rmax. = 20 mΩ, Imax. at 70 °C = 4.0 A

1.0 200 ± 100 ±1 1R0 - 2M2 24 + 96

CRCW1218 1218 3246 ± 200 ±5 24

Zero-Ohm-Resistor: Rmax. = 20 mΩ, Imax. at 70 °C = 7.0 A

0.50 400 ± 100 ±1 1R0 - 10M 24 + 96

CRCW2010 2010 5025 ± 200 ±5 24

Zero-Ohm-Resistor: Rmax. = 20 mΩ, Imax. at 70 °C = 5.0 A

1.0 500 ± 100 ±1 1R0 - 10M 24 + 96

CRCW2512 2512 6332 ± 200 ±5 24

Zero-Ohm-Resistor: Rmax. = 20 mΩ, Imax. at 70 °C = 7.0 A

Notes

• These resistors do not feature a limited lifetime when operated within the permissible limits. However, resistance value drift increasing over

operating time may result in exceeding a limit acceptable to the specific application, thereby establishing a functional lifetime.

• Marking and packaging: see appropriate catalog or web pages

• Power rating depends on the max. temperature at the solder point, the component placement density and the substrate material

www.vishay.com For technical questions, contact: filmresistors.thickfilmchip@vishay.com Document Number: 20008

114 Revision: 13-Oct-08

D../CRCW....

Lead (Pb)-bearing Thick Film, Rectangular Chip Resistors Vishay

TECHNICAL SPECIFICATIONS

PARAMETER D10/

UNIT CRCW0402 D11/ D12/ D25/

CRCW0603 CRCW0805 CRCW1206 CRCW1210 CRCW1218 CRCW2010 CRCW2512

Rated Dissipation at 70 °C (3) W 0.063 0.1 0.125 0.25 0.33 1.0 0.5 1.0

Limiting Element Voltage (2) V≅ 50 75 150 200 200 200 400 500

Insulation Voltage (1 min) Vpeak > 75 > 100 > 200 > 300 > 300 > 300 > 300 > 300

Thermal Resistance (1) K/W ≤ 870 ≤ 550 ≤ 440 ≤ 220 ≤ 140 ≤ 65 ≤ 88 ≤ 65

Insulation Resistance Ω > 109

Category Temperature °C

Range - 55 to + 155

Failure Rate h-1 0.3 x 10-9

Weight/1000 pieces g 0.65 2 5.5 10 16 29.5 25.5 40.5

Notes

(1) For sizes 0402 until 1206 the measuring conditions are in acc. to EN 140401-802. For all other sizes the result depends on the solder pad

dimensions.

(2) Rated voltage: PxR

(3) The power dissipation on the resistor generates a temperature rise against the local ambient, depending on the heat flow support of the

printed-circuit board (thermal resistance). The rated dissipation applies only if the permitted film temperature of 155 °C is not exceeded.

PART NUMBER AND PRODUCT DESCRIPTION

PART NUMBER: CRCW0805562RFKTA (4)

C R C W 0 8 0 5 5 6 2 R F K T A

MODEL VALUE TOLERANCE TCR PACKAGING (5) SPECIAL

CRCW0402 R = Decimal F=±1% K = ± 100 ppm/K TA TB Up to 2 digits

CRCW0603 K = Thousand J=±5% N = ± 200 ppm/K TC TD

CRCW0805 M = Million Z = Zero Ohm Jumper S = Jumper or TE TF

CRCW1206 0000 = Jumper special TG TH

CRCW1210 TI TK

CRCW1218 TL BA

CRCW2010

CRCW2512

PRODUCT DESCRIPTION: CRCW 0805 5620 F 100 RT1

CRCW 0805 5620 F 100 RT1

MODEL SIZE RESISTANCE VALUE TOLERANCE TCR PACKAGING (5)

CRCW 0402 1201 685 = 6.8 MΩ F=±1% ± 100 ppm/K RT1 RT5

0603 1218 224 = 220 kΩ J=±5% ± 200 ppm/K RT6 RT7

0805 2010

1206 2512 ± 1 % = 3 sig.digits, Z = Zero Ohm Jumper RT4 R02

plus multiplier R67 R82

± 5 % = 2 sig.digits, RG1 RT9

plus multiplier R20 B27

Notes

(4) Preferred way for ordering products is by use of the PART NUMBER

(5) Please refer to table PACKAGING, see next page

Document Number: 20008 For technical questions, contact: filmresistors.thickfilmchip@vishay.com www.vishay.com

Revision: 13-Oct-08 115

D../CRCW....

Vishay Lead (Pb)-bearing Thick Film, Rectangular Chip Resistors

PACKAGING

REEL BULK

PACKAGING CODE PACKAGING CODE

MODEL TAPE PIECES/

DIAMETER PITCH PART NUMBER PRODUCT DESC. PIECES PART PRODUCT

WIDTH REEL

PAPER BLISTER PAPER BLISTER NUMBER DESC.

180 mm/7" 2 mm 10 000 TD RT7

D10/CRCW0402 8 mm 50 000 BA B27

330 mm/13" 2 mm 50 000 TE RF4

180 mm/7" 4 mm 5000 TA TI RT1 RG1

D11/CRCW0603 8 mm 285 mm/11.25" 4 mm 10 000 TB RT5 25 000 BA B27

330 mm/13" 4 mm 20 000 TC TL RT6 R20

180 mm/7" 4 mm 5000 TA TI RT1 RG1

D12/CRCW0805 8 mm 285 mm/11.25" 4 mm 10 000 TB RT5 10 000 BA B27

330 mm/13" 4 mm 20 000 TC TL RT6 R20

180 mm/7" 4 mm 5000 TA TI RT1 RG1

285 mm/11.25" 4 mm 10 000 TB RT5

D25/CRCW1206 8 mm

330 mm/13" 4 mm 15 000 TL R20

330 mm/13" 4 mm 20 000 TC RT6

180 mm/7" 4 mm 5000 TA RT1

CRCW1210 12 mm 285 mm/11.25" 4 mm 10 000 TB RT5

330 mm/13" 4 mm 20 000 TC RT6

CRCW1218 12 mm 180 mm/7" 4 mm 4000 TK RT9

CRCW2010 12 mm 180 mm/7" 4 mm 4000 TF R02

8 mm 2000 TG R67

CRCW2512 12 mm 180 mm/7"

4 mm 4000 TH R82

DIMENSIONS

SOLDER PAD DIMENSIONS [in millimeters]

SIZE DIMENSIONS [in millimeters]

REFLOW SOLDERING WAVE SOLDERING

INCH METRIC L W H T1 T2 a b l a b l

0402 1005 1.0 ± 0.05 0.5 ± 0.05 0.35 ± 0.05 0.25 ± 0.05 0.2 ± 0.1 0.4 0.6 0.5

+ 0.10

0603 1608 1.55 - 0.05 0.85 ± 0.1 0.45 ± 0.05 0.3 ± 0.2 0.3 ± 0.2 0.5 0.9 1.0 0.9 0.9 1.0

+ 0.20 + 0.20

0805 2012 2.0 - 0.10 1.25 ± 0.15 0.45 ± 0.05 0.3 - 0.10 0.3 ± 0.2 0.7 1.3 1.2 0.9 1.3 1.3

+ 0.10

1206 3216 3.2 - 0.20 1.6 ± 0.15 0.55 ± 0.05 0.45 ± 0.2 0.4 ± 0.2 0.9 1.7 2.0 1.1 1.7 2.3

1210 3225 3.2 ± 0.2 2.5 ± 0.2 0.55 ± 0.05 0.45 ± 0.2 0.4 ± 0.2 0.9 2.5 2.0 1.1 2.5 2.2

+ 0.10

1218 3246 3.2 - 0.20 4.6 ± 0.15 0.55 ± 0.05 0.45 ± 0.2 0.4 ± 0.2 1.05 4.9 1.9 1.25 4.8 1.9

2010 5025 5.0 ± 0.15 2.5 ± 0.15 0.6 ± 0.1 0.6 ± 0.2 0.6 ± 0.2 1.0 2.5 3.9 1.2 2.5 3.9

2512 6332 6.3 ± 0.2 3.15 ± 0.15 0.6 ± 0.1 0.6 ± 0.2 0.6 ± 0.2 1.0 3.2 5.2 1.2 3.2 5.2

www.vishay.com For technical questions, contact: filmresistors.thickfilmchip@vishay.com Document Number: 20008

116 Revision: 13-Oct-08

D../CRCW....

Lead (Pb)-bearing Thick Film, Rectangular Chip Resistors Vishay

FUNCTIONAL PERFORMANCE

Single Pulse

1000

Pulse Load Pmax (W)

2512

1218

2010

100 1206

0805

0603

0402

10

0.1

0.01-6

10 10-5 10-4 10-3 10-2 10-1 1 10

Pulse Duration ti (s)

Maximum pulse load, single pulse; applicable if P 0 and n ≤ 1000 and U ≤ Umax;

for permissible resistance change equivalent to 8000 h operation

Continuous Pulse

100

Continuous Pulse Load Pmax (W)

1218

1206

0805

10

0603

0402

1

0.10

0.01 -6

10 10-5 10-4 10-3 10-2 10-1 1 10

Pulse Duration ti (s)

Maximum pulse load, continuous pulses; applicable if P ≤ P (ϑamb) and Û ≤ Ûmax;

for permissible resistance change equivalent to 8000 h operation

Pulse Voltage

2000

Pulse Voltage Ûmax (V)

1800 2512

1600

2010

1400

1200

1000

800 1206/1210/1218

600

400 0805

0603

200

0402

0 -6

10 10-5 10-4 10-3 10-2 10-1 1 10

Pulse Duration ti (s)

Maximum pulse voltage, single and continuous pulses; applicable if

P ≤ Pmax; for permissible resistance change equivalent to 8000 h operation

Document Number: 20008 For technical questions, contact: filmresistors.thickfilmchip@vishay.com www.vishay.com

Revision: 13-Oct-08 117

D../CRCW....

Vishay Lead (Pb)-bearing Thick Film, Rectangular Chip Resistors

Temperature Rise in °C

90 120

Rated Power in %

80

0402 0603 0805 1206

1210 100

70

60 80

50

2010 60

40

2512

30 40

1218

20

20

10

0 0

0 0.1 0.2 0.3 0.4 0.5 - 55 - 25 0 25 50 75 100 125 155 175

Power in W 70 Ambient Temperature in °C

Temperature Rise Derating

Current Noise in µV/V

100

Non-Linearity A3 in dB

110

100

90

2

80 10 040

1206

70 0805 3

0603 060

60 0402 5

080

50 6

1 120

40

30

20

10 0.1

100 1K 10K 100K 1M 10M 100 1K 10K 100K 1M 10M

Resistance Value in Ω Current Noise Resistance Value in Ω

Non-Linearity

www.vishay.com For technical questions, contact: filmresistors.thickfilmchip@vishay.com Document Number: 20008

118 Revision: 13-Oct-08

D../CRCW....

Lead (Pb)-bearing Thick Film, Rectangular Chip Resistors Vishay

140 140

Temperature rise ϑr in °C

120 120 ϑs = f [ϑr] C

0°

Parameter: ϑa =2

ϑa

100 100 °C

D1

D1

D

D2 40

1.

12

0..

5.

.A

°C

..

.A 80 80

P 60

AP

P

P

° C

60 60 80

C

0°

10

40 40 C

0°

ϑr = f [P] 12

20 20 C

Parameter: Size 0°

14

0 0

0.5 0.4 0.3 0.2 0.1 0 20 40 60 80 100 120 140 160 180

Load in W Surface temperature ϑs in °C

0.01 0.01

Δ R /R (t) = f [ΔR /R (t = 1000 h)]

Parameter: Time

[Δ R /R ] in % after 1000 h

Resistance change

≤1

0K

≤1

0.1 0.1 M

0h

00 ≤1

0

10 0M

t=

0h

00 0h

0

1 0 0 h Δ R /R [t = 1000 h] = f [ϑs]

5 000 h

2 00 Parameter: Resistance value

10

1 1

10 1 0.1 0.01 20 40 60 80 100 120 140 160 180

Resistance change ΔR /R % Surface temperature ϑs in °C

Stability nomogram typical values (for handling see general explanations)

ϑa = [°C]

120

100

C

0°

=2

ϑa

80 C

0°

=4

ϑa

60 C

0.25 W 0°

=6

ϑa

40 C

0.125 W 0°

=8

ϑa

0.0625 W 20 °C °C

00 20

=1 =1

ϑa ϑa

1 2 3 5 7 10 2 3 5 7 100 2 3 5 7 60 80 100 120 140

Number of mounted resistors [pieces] Surface temperature ϑs [°C]

Power rating as a function of packaging density (guideline)

Document Number: 20008 For technical questions, contact: filmresistors.thickfilmchip@vishay.com www.vishay.com

Revision: 13-Oct-08 119

D../CRCW....

Vishay Lead (Pb)-bearing Thick Film, Rectangular Chip Resistors

TEST PROCEDURES AND REQUIREMENTS

EN 60115-1

REQUIREMENTS

TEST (clause) CONDITIONS OF TEST STABILITY STABILITY

CLASS 1 CLASS 2

OR BETTER OR BETTER

Stability for product types:

1 Ω to 10 MΩ 1 Ω to 10 MΩ

D../CRCW...

Resistance

- ±1% ±5%

(4.5)

Temperature coefficient 20/- 55/20 °C and

± 100 ppm/K ± 200 ppm/K

(4.8.4.2) 20/125/20 °C

U = 2.5 x (P70 x R)1/2

Overload

≤ 2 x Umax.; ± (0.25 % R + 0.05 Ω) ± (0.5 % R + 0.05 Ω)

(4.13)

Duration: according the style

Aging 4 h at 155 °C, dryheat

Solderability Good tinning (≥ 95 % covered)

solder bath method; 235 °C; 2 s

(4.17.5) no visible damage

visual examination

Resistance to soldering heat Solder bath method;

± (0.25 % R + 0.05 Ω) ± (0.5 % R + 0.05 Ω)

(4.18.2) (260 ± 5) °C; (10 ± 1) s

Rapid change of temperature 30 min at LCT = - 55 °C;

± (0.25 % R + 0.05 Ω) ± (0.5 % R + 0.05 Ω)

(4.19) 30 min at UCT = 125 °C; 5 cycles

Damp heat, steady state (40 ± 2) °C; 56 days;

± (1 % R + 0.05 Ω) ± (2 % R + 0.1 Ω)

(4.24) (93 ± 3) % RH

16 h at UCT = 125 °C; 1 cycle at 55 °C;

2 h at LCT = - 55 °C;

Climatic sequence 1 h/1 kPa at 15 °C to 35 °C;

± (1 % R + 0.05 Ω) ± (2 % R + 0.1 Ω)

(4.23) 5 cycles at 55 °C

U = (P70 × R)1/2

U = Umax.; whichever is less severe

U = (P70 × R)1/2

Endurance at 70 °C U = Umax.; whichever is less severe

± (1 % R + 0.05 Ω) ± (2 % R + 0.1 Ω)

(4.25.1) 1.5 h ON; 0.5 h OFF;

70 °C; 1000 h

Extended endurance

Duration extended to 8000 h ± (2 % R + 0.1 Ω) ± (4 % R + 0.1 Ω)

(4.25.1.8)

Endurance at upper category

temperature UCT = 125 °C; 1000 h ± (1 % R + 0.05 Ω) ± (2 % R + 0.1 Ω)

(4.25.3)

APPLICABLE SPECIFICATIONS

• EN 60115-1 Generic specification

• EN 140400 Sectional specification

• EN 140401-802 Detail specification

• IEC 60068-2-X Variety of environmental test procedures

• IEC 60286-3 Packaging of SMD components

www.vishay.com For technical questions, contact: filmresistors.thickfilmchip@vishay.com Document Number: 20008

120 Revision: 13-Oct-08

Legal Disclaimer Notice

Vishay

Disclaimer

All product specifications and data are subject to change without notice.

Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf

(collectively, “Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained herein

or in any other disclosure relating to any product.

Vishay disclaims any and all liability arising out of the use or application of any product described herein or of any

information provided herein to the maximum extent permitted by law. The product specifications do not expand or

otherwise modify Vishay’s terms and conditions of purchase, including but not limited to the warranty expressed

therein, which apply to these products.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this

document or by any conduct of Vishay.

The products shown herein are not designed for use in medical, life-saving, or life-sustaining applications unless

otherwise expressly indicated. Customers using or selling Vishay products not expressly indicated for use in such

applications do so entirely at their own risk and agree to fully indemnify Vishay for any damages arising or resulting

from such use or sale. Please contact authorized Vishay personnel to obtain written terms and conditions regarding

products designed for such applications.

Product names and markings noted herein may be trademarks of their respective owners.

Document Number: 91000 www.vishay.com

Revision: 18-Jul-08 1

You might also like

- SMDDocument6 pagesSMDJose SCNo ratings yet

- CRCW06032431FRT1Document7 pagesCRCW06032431FRT1鄭建銘(小銘)No ratings yet

- Crcw0805390rfkta PDFDocument8 pagesCrcw0805390rfkta PDFManu MathewNo ratings yet

- URC08050Document6 pagesURC08050manuel fernandezNo ratings yet

- Specification: CL 21 F 223 Z B A N N N CDocument3 pagesSpecification: CL 21 F 223 Z B A N N N Csam2976No ratings yet

- SBSM Data SheetDocument4 pagesSBSM Data SheetAlex JonesNo ratings yet

- D/CRCW E3: VishayDocument10 pagesD/CRCW E3: VishayBenyamin Farzaneh AghajarieNo ratings yet

- NIC Components NRSJ SeriesDocument5 pagesNIC Components NRSJ SeriesNICCompNo ratings yet

- Specification: CL 21 A 226 M A Q N N N FDocument3 pagesSpecification: CL 21 A 226 M A Q N N N Felias rangelNo ratings yet

- NIC Components NRE-LW SeriesDocument5 pagesNIC Components NRE-LW SeriesNICCompNo ratings yet

- Specification: CL 21 B 105 K A F N N N EDocument3 pagesSpecification: CL 21 B 105 K A F N N N EcometNo ratings yet

- NIC Components NTR-C SeriesDocument4 pagesNIC Components NTR-C SeriesNICCompNo ratings yet

- Single Metallized Film Pulse Capacitor, Polypropylene Dielectric - According To IEC 60384-16, Grade 1.1Document12 pagesSingle Metallized Film Pulse Capacitor, Polypropylene Dielectric - According To IEC 60384-16, Grade 1.1Hwalam Lee100% (1)

- Carbon Film ResistorsDocument2 pagesCarbon Film ResistorsGopichandNo ratings yet

- Cl05a104ka5nnnc PDFDocument2 pagesCl05a104ka5nnnc PDFdusk dawnNo ratings yet

- DatasheetDocument2 pagesDatasheetOmar LababidiNo ratings yet

- CRT0603 PX 2321elfDocument4 pagesCRT0603 PX 2321elfFernando MarquezNo ratings yet

- CRCW0201 E3: VishayDocument5 pagesCRCW0201 E3: VishaycuperiniNo ratings yet

- PCB Relay: NRP - 17 - C - 12DDocument2 pagesPCB Relay: NRP - 17 - C - 12DZaman SahibNo ratings yet

- 180 Ohm ResistorDocument11 pages180 Ohm ResistorNidhi PanditNo ratings yet

- C3 Catalog CE Miniatura ElraDocument3 pagesC3 Catalog CE Miniatura ElraSneezy DwarfNo ratings yet

- MWR CapsDocument4 pagesMWR CapsMartien BakkerNo ratings yet

- Specification: CL 21 B 105 K B F N N N FDocument2 pagesSpecification: CL 21 B 105 K B F N N N Felias rangelNo ratings yet

- 多圈的 /圓形/綫繞/面板式 (Multiturn/ Round/ Wirewound) 2 種轉軸的樣式 (2 Shaft Style) sDocument1 page多圈的 /圓形/綫繞/面板式 (Multiturn/ Round/ Wirewound) 2 種轉軸的樣式 (2 Shaft Style) sjonatan arangoNo ratings yet

- ATBI2012Document2 pagesATBI2012marina anastasovaNo ratings yet

- NIC Components NRE-WX SeriesDocument1 pageNIC Components NRE-WX SeriesNICCompNo ratings yet

- ABNTC-0201: MSL Level: 2A (This Product Is Packed With Dry Packaging)Document3 pagesABNTC-0201: MSL Level: 2A (This Product Is Packed With Dry Packaging)ricky syandiNo ratings yet

- Sfr16S/25/25H: Vishay BccomponentsDocument11 pagesSfr16S/25/25H: Vishay BccomponentsMuhammad BilalNo ratings yet

- Excel Shortcuts CFIDocument19 pagesExcel Shortcuts CFIRAVICHANDRAN LNo ratings yet

- MP725 Surface Mount Power Film ResistorsDocument1 pageMP725 Surface Mount Power Film ResistorsAroon BhagwandinNo ratings yet

- Relafy 30 Amps T Typfe RelfayDocument2 pagesRelafy 30 Amps T Typfe RelfayMarudhasalamMarudhaNo ratings yet

- RDE Vitrohm PDFDocument2 pagesRDE Vitrohm PDFtecnico4 tecnico4No ratings yet

- RDE Vitrohm PDFDocument2 pagesRDE Vitrohm PDFtecnico4 tecnico4No ratings yet

- Resistor SMD SizesDocument11 pagesResistor SMD Sizescarlos.antouryNo ratings yet

- NIC Component Series NACKADocument4 pagesNIC Component Series NACKANICCompNo ratings yet

- Capacitor 104j63Document4 pagesCapacitor 104j63Peter PeterNo ratings yet

- Series: 105 Miniaturized, Long Life, Low ImpedanceDocument3 pagesSeries: 105 Miniaturized, Long Life, Low ImpedanceAENo ratings yet

- RCS E3: VishayDocument10 pagesRCS E3: VishayMae MegumiNo ratings yet

- Datasheet s1 Pressure TransducerDocument6 pagesDatasheet s1 Pressure TransducerAlexander BerbinNo ratings yet

- PLA M Series RelaysDocument2 pagesPLA M Series RelaysYogesh DetheNo ratings yet

- Surface Mount MLCC CapacitorsDocument6 pagesSurface Mount MLCC CapacitorsmohamedNo ratings yet

- VJ.... W1BC Basic Commodity Series: VishayDocument15 pagesVJ.... W1BC Basic Commodity Series: VishaymmNo ratings yet

- CDE (SMD) AVEZ SeriesDocument4 pagesCDE (SMD) AVEZ Seriesjghjkhgkh87No ratings yet

- RBV1000 - RBV1010: Silicon Bridge Rectifiers PRV: 50 - 1000 Volts Io: 10 AmperesDocument2 pagesRBV1000 - RBV1010: Silicon Bridge Rectifiers PRV: 50 - 1000 Volts Io: 10 AmperesmaheseeeNo ratings yet

- NIC Components NSWC High Voltage SeriesDocument2 pagesNIC Components NSWC High Voltage SeriesNICCompNo ratings yet

- Ponte de Diodo RBV3510Document3 pagesPonte de Diodo RBV3510Allyfranhy Nunes AlvesNo ratings yet

- SMIH NingBoSongleDocument3 pagesSMIH NingBoSongleatlas tajhizNo ratings yet

- Resistor 1k - Vishay - 0.6wDocument3 pagesResistor 1k - Vishay - 0.6wLEDNo ratings yet

- NIC Components NRE-L SeriesDocument5 pagesNIC Components NRE-L SeriesNICCompNo ratings yet

- Surface Mount Aluminum Electrolytic Capacitors: NACE SeriesDocument5 pagesSurface Mount Aluminum Electrolytic Capacitors: NACE SeriesNICCompNo ratings yet

- SFR 25Document9 pagesSFR 25Jose Normando SoaresNo ratings yet

- NIC Components NNR SeriesDocument5 pagesNIC Components NNR SeriesNICCompNo ratings yet

- NIC Components NRE-HW SeriesDocument6 pagesNIC Components NRE-HW SeriesNICCompNo ratings yet

- FNR 05K180 JohansonDielectricsDocument7 pagesFNR 05K180 JohansonDielectricsgulrez1991No ratings yet

- E Uhw 883813Document5 pagesE Uhw 883813Allyfranhy Nunes AlvesNo ratings yet

- K SMDNC03100KB00KP00 0001Document7 pagesK SMDNC03100KB00KP00 0001Pedro LeonNo ratings yet

- Multilayer Ceramic Capacitors Soft Termination High Voltage Series (SH) X7R Dielectric 0805 To 1812 Sizes, 500V To 3Kv Rohs ComplianceDocument9 pagesMultilayer Ceramic Capacitors Soft Termination High Voltage Series (SH) X7R Dielectric 0805 To 1812 Sizes, 500V To 3Kv Rohs CompliancerezaNo ratings yet

- RBV5006Document3 pagesRBV5006Adah BumboneNo ratings yet

- DSAZIHA1000198413Document4 pagesDSAZIHA1000198413Angelica CausNo ratings yet

- Bio Rad Laboratories Catalog Items 9.1.2018Document687 pagesBio Rad Laboratories Catalog Items 9.1.2018Vadim ZorinNo ratings yet

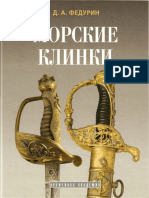

- Федурин - Морские клинкиDocument517 pagesФедурин - Морские клинкиVadim ZorinNo ratings yet

- Available In:: 5 Mengel Court, Salisbury South, South Australia 5106 T: +618 8 8283 0222 F: +618 8 8283 4005Document2 pagesAvailable In:: 5 Mengel Court, Salisbury South, South Australia 5106 T: +618 8 8283 0222 F: +618 8 8283 4005Vadim ZorinNo ratings yet

- NORMEL Technical PassportDocument15 pagesNORMEL Technical PassportVadim ZorinNo ratings yet

- NORMEL Technical PassportDocument15 pagesNORMEL Technical PassportVadim ZorinNo ratings yet

- International Journal of Information Management: Min Yan, Raffaele Filieri, Matthew GortonDocument13 pagesInternational Journal of Information Management: Min Yan, Raffaele Filieri, Matthew GortonmasukujjamanNo ratings yet

- Valaris Exl I: Capacities Primary Rig CharacteristicsDocument1 pageValaris Exl I: Capacities Primary Rig Characteristicsmelody04223No ratings yet

- The Data Science Design ManualDocument456 pagesThe Data Science Design Manualalbgomez100% (4)

- 001 Hydraulics IntroDocument22 pages001 Hydraulics IntroShereen SweissNo ratings yet

- Eq List IEC 60335-2-14 (6.0) 2016-20170814Document3 pagesEq List IEC 60335-2-14 (6.0) 2016-20170814le duc huynhNo ratings yet

- CV Nicolas Duarte Cifuentes InglesDocument2 pagesCV Nicolas Duarte Cifuentes InglesNicolas Duarte CifuentesNo ratings yet

- Learning Remediation-Q3Document11 pagesLearning Remediation-Q3Donna AbenojaNo ratings yet

- Microsoft Exchange Tips and TricksDocument7 pagesMicrosoft Exchange Tips and TricksAditiNo ratings yet

- Computer-3 1st QuarterDocument5 pagesComputer-3 1st QuarterEdmar John SajoNo ratings yet

- SDM MCQ BankDocument87 pagesSDM MCQ BankRamkishan ShindeNo ratings yet

- My Daily Routine UNIT 3Document5 pagesMy Daily Routine UNIT 3Francisco EricesNo ratings yet

- Document From Sfere Electric23 AbcDocument29 pagesDocument From Sfere Electric23 AbcMuhammad SaleemNo ratings yet

- Compact Cylinders ADN - Inch Series, Based On ISO 21287: Product Range OverviewDocument14 pagesCompact Cylinders ADN - Inch Series, Based On ISO 21287: Product Range Overviewyudiar djamaldilliahNo ratings yet

- Penetration Testing (White)Document1 pagePenetration Testing (White)alex mendozaNo ratings yet

- Battery Charger Report 6Document55 pagesBattery Charger Report 6anand.sraju69% (32)

- Specificity and Designing of Multi-Hull Ships and Boats: January 2016Document3 pagesSpecificity and Designing of Multi-Hull Ships and Boats: January 2016Andrés VillarNo ratings yet

- Class 12 Mathematics Project PDFDocument13 pagesClass 12 Mathematics Project PDFsonukum1289No ratings yet

- Lab 2Document10 pagesLab 2waleedNo ratings yet

- Flydat Control Operator'S Manual: Aircraft EnginesDocument16 pagesFlydat Control Operator'S Manual: Aircraft EnginesNickNo ratings yet

- Nanna MESCOM Payment Receipt-2110405DMCL2787-1949541Document1 pageNanna MESCOM Payment Receipt-2110405DMCL2787-1949541Lijesh MathewNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 7CV3314B Simotics SD - 315L - Im B3 - 4 PDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 7CV3314B Simotics SD - 315L - Im B3 - 4 PHEMANT RAMJINo ratings yet

- Case Summary - Apple Inc: Syndicate 5Document2 pagesCase Summary - Apple Inc: Syndicate 5Diasty Widar HapsariNo ratings yet

- NF - Apple EUADocument2 pagesNF - Apple EUAgustavogko01100% (1)

- UGC Net StatisticsDocument47 pagesUGC Net StatisticsSumant SharmaNo ratings yet

- Wbcs 2022 AdmitDocument2 pagesWbcs 2022 AdmitChandra SudipNo ratings yet

- Tri Lok Metal Seated Valve: Summary SpecificationDocument1 pageTri Lok Metal Seated Valve: Summary SpecificationBHARGAVNo ratings yet

- 2.2 Resume Action Words TipsDocument3 pages2.2 Resume Action Words TipsMichelle SavanneNo ratings yet

- Dear Mr. PinkDocument7 pagesDear Mr. PinkK59 Nguyễn Tiến DũngNo ratings yet

- Evolving Business Models of Online Food Delivery Industry in Indian ContextDocument8 pagesEvolving Business Models of Online Food Delivery Industry in Indian ContextDeepak TyagiNo ratings yet

- LIBRARIES Cataloging Correctly For Kids An Introduction To The ToolsDocument147 pagesLIBRARIES Cataloging Correctly For Kids An Introduction To The ToolsJosé AliagaNo ratings yet