Professional Documents

Culture Documents

Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 7CV3314B Simotics SD - 315L - Im B3 - 4 P

Uploaded by

HEMANT RAMJIOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 7CV3314B Simotics SD - 315L - Im B3 - 4 P

Uploaded by

HEMANT RAMJICopyright:

Available Formats

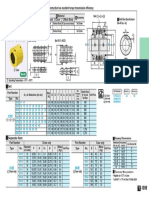

Data sheet for three-phase Squirrel-Cage-Motors SIMOTICS

Motor type: 7CV3314B SIMOTICS SD - 315L - IM B3 - 4 p

Client order no. Item-No. Offer no.

Order no. Consignment no. Project

Remarks

Electrical data

U Δ/Y f P P I n M M η 3) cosφ 3) IA/IN MA/MN MK/MN IE-CL

[V]±10% [Hz]±5% [kW] [hp] [A] [1/min] [kgf.m] [Nm] 4/4 3/4 2/4 4/4 3/4 2/4

Motordaten / Motor Data

415 Δ 50 160.00 -/- 267.00 1489 105.0 1026.0 95.9 96.1 95.8 0.87 0.85 0.78 7.7 3.2 3.3 IE3

IM B3 / IM 1001 FS 315L 1028 kg SF:1 IS 12615 / IEC 60034-1 CE Mark Available

Environmental conditions : -20 °C - +50 °C / 1,000 m Locked rotor time (hot / cold) : 15 s | 25 s

Mechanical data Locked rotor time (hot / cold) : 15 s | 25 s

Yes (standard)

Sound pressure level 50Hz | 60Hz 80 dB(A) 83 dB(A) External earthing terminal

Moment of inertia | Rotor GD² 3.4367 kg m² | 13.7469 kgf.m² Vibration severity grade A (Standard)

155(F) utilized to 130(B)

Bearing DE | NDE 6319 C3 6319 C3 Insulation

bearing lifetime Duty type S1

L10mh FRad max according catalogue 20.000 h 16.000 h Direction of rotation Bidirectional

50|60Hz 1)

L10mh FRad min for coupling operation Cast iron

50.000 h 40.000 h Frame material

50|60Hz 1)

-/-

Type of bearing Locating (fixed) bearing, NDE Forced ventilation motor details

40 g | 40 g

Relubrication interval/quantity DE | NDE Net weight of the motor (IM B3) 1028 kg

6.000 h

Type of construction IM B3 / IM 1001 Rotor weight 305 kg

Degree of protection IP55 Data of anti condensation heating -/- V, -/- W

Lubricants Esso Unirex N3 Coating (paint finish) Standard paint finish

Yes (standard)

Regreasing device Color, paint shade RAL7030

Grease nipple M10x1 DIN 3404 A Motor protection (A) without

Yes

Condensate drainage holes Method of cooling IC411 - Self ventilated, surface cooled

Terminal box

Cable diameter from ... to ...

Terminal box position Top 38.0 mm - 45.0 mm

Material of terminal box Cast iron Cable entry 2xM63x1,5

Type of terminal box TB1 Q01 Cable gland 2 Plugs

Contact screw thread M12

Max. cross-sectional area 185 mm2

Notes:

IA/IN = locked rotor current / current nominal

MA/MN = locked rotor torque / torque nominal

MK/MN = break down torque / nominal torque 1) L10mh according to DIN ISO 281 10/2010

3) Value is valid only for DOL operation with motor design IC411

responsible dep. technical reference created by approved by Technical data are subject to change! There may be discrepancies

between calculated and rating plate values.

DI MC LVM DT Configurator

document type document status customer

datasheet released

MLFB and Order Code document number

1LE7503-3AB43-5AA4

rev. creation date language Page

© Siemens AG 2021 01 2021-09-04 en 1/1

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Install and Time Camshaft and Fuel Injection PumpDocument4 pagesInstall and Time Camshaft and Fuel Injection Pumpjorgedavidgonzalez90% (10)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- F4a51 PDFDocument82 pagesF4a51 PDFJoão Ezer0% (1)

- Certification Record: Customer Class FileDocument2 pagesCertification Record: Customer Class FileSilo LibraNo ratings yet

- MCQ in Machine Design and Shop Practice Part 1 ME Board ExamDocument13 pagesMCQ in Machine Design and Shop Practice Part 1 ME Board Exammarvin villalunaNo ratings yet

- PCC 502 415 Cbpf-Aux.Document5 pagesPCC 502 415 Cbpf-Aux.HEMANT RAMJINo ratings yet

- Formalites For Obtaining New Contracor License Supervisor CertificateDocument15 pagesFormalites For Obtaining New Contracor License Supervisor CertificateHEMANT RAMJINo ratings yet

- PCC221 Recovery BoilerDocument4 pagesPCC221 Recovery BoilerHEMANT RAMJINo ratings yet

- Site Survey Document FilledDocument13 pagesSite Survey Document FilledHEMANT RAMJINo ratings yet

- LT MCC 512.2Document5 pagesLT MCC 512.2HEMANT RAMJINo ratings yet

- LT MCC 511.1Document6 pagesLT MCC 511.1HEMANT RAMJINo ratings yet

- Motor ProtectionDocument17 pagesMotor ProtectionHEMANT RAMJINo ratings yet

- Product Datasheet: Circuit Breaker Compact NSXM F (36 Ka at 415 Vac), 3P, 63 A Rating TMD Trip Unit, Everlink ConnectorsDocument3 pagesProduct Datasheet: Circuit Breaker Compact NSXM F (36 Ka at 415 Vac), 3P, 63 A Rating TMD Trip Unit, Everlink ConnectorsHEMANT RAMJINo ratings yet

- 292 - JK Paper - Technical Offer - Rev 00Document9 pages292 - JK Paper - Technical Offer - Rev 00HEMANT RAMJINo ratings yet

- MSC Sustainability Studies New 08062021Document12 pagesMSC Sustainability Studies New 08062021HEMANT RAMJINo ratings yet

- Protection System & Its ApplicationsDocument27 pagesProtection System & Its ApplicationsHEMANT RAMJINo ratings yet

- Energy Savings With MV Drives - PowerGen 2010 - EN - Frank - RevDocument22 pagesEnergy Savings With MV Drives - PowerGen 2010 - EN - Frank - RevHEMANT RAMJINo ratings yet

- Titration: Parth Hemant Patil Class: XIDocument19 pagesTitration: Parth Hemant Patil Class: XIHEMANT RAMJINo ratings yet

- VFD Fundamentals Copyright 2003 Kilowatt Classroom LLCDocument5 pagesVFD Fundamentals Copyright 2003 Kilowatt Classroom LLCHEMANT RAMJINo ratings yet

- Generator ProtectionDocument17 pagesGenerator ProtectionHEMANT RAMJINo ratings yet

- Rishabh Company ProfileDocument12 pagesRishabh Company ProfileHEMANT RAMJINo ratings yet

- Low Voltage: General Performance IE3 Premium Efficiency Cast Iron MotorsDocument12 pagesLow Voltage: General Performance IE3 Premium Efficiency Cast Iron MotorsHEMANT RAMJINo ratings yet

- Form 10 For Lifting Tools and Tackles Like Crane Chain Pully Block Hoist Sling Belt EtcDocument1 pageForm 10 For Lifting Tools and Tackles Like Crane Chain Pully Block Hoist Sling Belt EtcHEMANT RAMJI100% (1)

- Wap-7 Drawing DrequiredDocument8 pagesWap-7 Drawing DrequiredM PankajNo ratings yet

- DIN Handbook 10 Fasteners 1-Dimensional Standards For Bolts & Screws and Studs - National StandardsDocument2 pagesDIN Handbook 10 Fasteners 1-Dimensional Standards For Bolts & Screws and Studs - National StandardsRollentNo ratings yet

- 777D A-Frame PreloadingDocument3 pages777D A-Frame PreloadingsatyaNo ratings yet

- Ec55b TM - Public382425684Document237 pagesEc55b TM - Public382425684AimHigh100% (4)

- Technical Specification: ConfigurationDocument5 pagesTechnical Specification: ConfigurationKarl ToddNo ratings yet

- Turbine User Manual - Amrit Cement Industries Ltd. PDFDocument202 pagesTurbine User Manual - Amrit Cement Industries Ltd. PDFamit pandeyNo ratings yet

- FG Wilson p180p2 P200e2Document1 pageFG Wilson p180p2 P200e2Angga ClevneztNo ratings yet

- Part 5 MT Drives and Mechanisms 1Document11 pagesPart 5 MT Drives and Mechanisms 1Zayed KhanNo ratings yet

- Chai Couplig Catalogue PDFDocument1 pageChai Couplig Catalogue PDFMinh AnhNo ratings yet

- BIKESTER Assembly Manual MTB - Fr.enDocument23 pagesBIKESTER Assembly Manual MTB - Fr.enfuskjd dsdsdsdsNo ratings yet

- Gas Turbin Mark VIDocument42 pagesGas Turbin Mark VIpradeeps2007_1777402100% (3)

- pp10233-03 - TurbochargerDocument2 pagespp10233-03 - TurbochargerBoBoMilovanovicNo ratings yet

- Empowering Your Life One Generator at A TimeDocument2 pagesEmpowering Your Life One Generator at A TimeRicky AngkawidjajaNo ratings yet

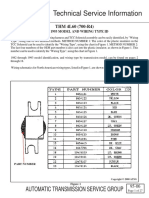

- Technical Service Information: Automatic Transmission Service GroupDocument27 pagesTechnical Service Information: Automatic Transmission Service GroupMario Mastronardi100% (1)

- Gas Turbine Study Material - ch3Document18 pagesGas Turbine Study Material - ch3Mauro MLRNo ratings yet

- C32 MOTOR CAT Electronic Unit Injector - TestDocument2 pagesC32 MOTOR CAT Electronic Unit Injector - TestFreddy Villegas100% (1)

- Parts Catalog - Option Detail: Option Group Graphic Film Card DateDocument3 pagesParts Catalog - Option Detail: Option Group Graphic Film Card DateagvassNo ratings yet

- Normas AplicablesDocument78 pagesNormas AplicablesCarolina GaitanNo ratings yet

- PUHY-P72TNU-A (-BS) 208-230V Product Data SheetDocument2 pagesPUHY-P72TNU-A (-BS) 208-230V Product Data Sheetjuraco20No ratings yet

- Receive ReportDocument28 pagesReceive ReportMihir KumarNo ratings yet

- 4.8. Adjustment of Valve Clearance: DV11 Operation and MaintenanceDocument10 pages4.8. Adjustment of Valve Clearance: DV11 Operation and MaintenanceООО "СК "СМП-708"No ratings yet

- Detail of Maximum Current - ChillersDocument3 pagesDetail of Maximum Current - ChillersMohamed RifanNo ratings yet

- Quo TB Jatty BuyutDocument12 pagesQuo TB Jatty BuyutAgus ainurNo ratings yet

- Type 1035/El-O-Matic Rack-and-Pinion Rotary ActuatorDocument24 pagesType 1035/El-O-Matic Rack-and-Pinion Rotary ActuatorRollyDuqueCampoverdeNo ratings yet

- Cat 775eDocument28 pagesCat 775emattsicsNo ratings yet

- Spare Parts Catalogue 2018/19Document96 pagesSpare Parts Catalogue 2018/19vinu_krishnan91No ratings yet