Professional Documents

Culture Documents

Instruction Manual: 40 Meter Superhet Transceiver Kit

Uploaded by

teconline-1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Instruction Manual: 40 Meter Superhet Transceiver Kit

Uploaded by

teconline-1Copyright:

Available Formats

Instruction Manual

The “Small Wonder - 40+”

40 Meter Superhet Transceiver Kit

Thanks! For purchasing one of the Small Wonder Labs “SW-40+” transceiver kits. This kit is an updated version

of the classic ‘40-40’ transceiver board which originally appeared in the November 1994 issue of QST.

Please take a few moments to look over the section entitled “First Things First”. This is background information

in case you’re fairly new to homebrewing or kit-building.

Please – Be sure to read through the “Building Instructions” portion of this manual before you fire that

soldering iron up! That section contains useful information which is important to your success with this kit.

TABLE OF CONTENTS

First Things First ........................................... 2

Materials........................................................ 4

Parts List........................................................ 4-5

Theory of Operation ...................................... 6

Schematic ...................................................... 7

Pictorial Drawing .......................................... 8

Building Instructions ..................................... 9-11

Wiring the “SW-40+”.................................... 12

Alignment...................................................... 14

Troubleshooting the “SW-40+” .................... 15

Troubleshooting Values ................................ 17

D. Benson, K1SWL Small Wonder Labs 2/9/2007 1

THE FINE PRINT You should be familiar with the standard color-

code markings on resistors. If not, Radio

There are lots of small parts in this kit. With many of us Shack’s Color-Code Guide, #271-1210, will

getting older, this may prove troublesome. I highly help. If you’re not sure, verify the resistor values

recommend a magnifying glass or close-up glasses to with an ohm meter. Resistor color codes are

check all solder joints and component codes. given in the parts list.

THE OTHER FINE PRINT For what it’s worth, approximately 8% of the

male population is red/green colorblind. If

Despite the care I’ve put into this manual, it may contain you’re one of these, you should be verifying all

the occasional error. In the event of a conflict between resistors with a meter before installing them.

portions of this manual, the following order of precedence

applies (most trustworthy first): The SW-40+ board is double-sided, and all holes

Schematic on the board are plated-through. This means that

you do not need to solder on the top side of the

Pictorial

board.

Parts list

Everything else Soldering skills:

By all means, let me know when you catch these – I do Hopefully this isn’t your first experience with a soldering

appreciate hearing about them. I add corrective changes iron. If it is, though, or this is your first solid-state

immediately because it improves the product! project, here are some tips to ensure your success:

TOOLS Use a small iron in the 25-watt class (such as a

Radio Shack #64-2070) and keep the tip clean.

Use a moistened sponge or paper towel and clean

You’ll need the following tools:

the tip periodically as you work.

Soldering iron – 25-40W, solder

Apply only as much heat as is needed to get a

Diagonal cutters good joint. A small vise to hold the printed-

Needle-nose pliers (helpful) circuit board may make soldering easier.

Small slot screwdriver

Touch the soldering iron tip to the PC board

Magnifying glass (recommended)

trace and the component lead simultaneously.

Within a second or two, apply solder and you’ll

TEST EQUIPMENT see the solder flow onto the junction. Withdraw

the solder and then the soldering iron.

You’ll need the following:

Avoid the temptation to load solder onto the joint

DC power source – 12-14V @ 500mA min.

until no more will fit! This is an invitation for

Multimeter trouble, as solder bridges may form across the

Another transceiver (for final adjustment) closer trace separations. Here’s what the correct

Frequency counter (helpful but not essential) and incorrect joint treatments look like:

First Things First

- what you should know -

You don’t need to be an expert in all phases of this craft,

but you should be comfortable with the basics before you

embark on this adventure.

D .Benson, K1SWL 2/9/2007 2

PLEASE READ THE SECTION BELOW BEFORE

REMOVING ANY PARTS FROM THE CIRCUIT

BOARD

Winding Toroids:

Get yourself a roll of desoldering braid (Radio Shack #64- Count as you go. Draw each turn snug against the

2090B). Lay the end of the braid down on the joint to be core to ensure a trim and tight winding. Please

cleaned and press the soldering iron tip over the braid. ensure that none of the turns is wound “over” (on top

Within several seconds you’ll see the braid begin to wick of) its neighbors.

up solder from the joint. Remove the braid and reapply a

new section as needed until the joint is clean. It may be Double-check the turn count when you’re finished.

necessary to pull the component out from the top side of Use your fingernail or a small screwdriver to “bump”

the board while heating the joint. Leave the iron tip on over each turn as you count – this is much easier than

the board only as long as necessary to do the job – the PC counting by eye.

board traces will eventually delaminate (peel off) if

overheated. Trim the excess wire off to about ¼” and strip the

insulation off with a hobby knife.

If that still doesn’t do the trick, it may be necessary to

cut the offending part off on the top side and pull the Counting the turns

remaining leads through with pliers. Contact me for

replacement parts if necessary. If the wire passes through the toroid center hole, it

counts as a turn.

If you need to remove a transistor I’d highly

recommend sacrificing the part by snipping it off on

the top side of the board. The TO-92 pads in

particular are small and the leads are best pulled out

independently to minimize the risk of lifting pads.

After removing a component from the board, the

through-hole will probably still be blocked with

solder. Use a dissecting needle, dental probe

(explorer), or even a large sewing needle, applying

heat to the needle and board trace simultaneously

until the tool pushes through.

D .Benson, K1SWL Small Wonder Labs 2/9/2007 3

Materials

Reference designators:

You’ll find the following items included with your SW-

40+ kit: Each component is uniquely identified by a reference

1 bag of small parts (resistors, caps, etc.) designator. Bypass capacitors are identified as C100 and

1 antistatic bag (semiconductors) up.

1 bag, miscellaneous parts

1 printed circuit board

This manual “C7”:

Capacitor C7 is an assortment of 6 different

Note: The RF chokes for this kit are supplied in the

capacitors designated ‘C7A’ through‘C7F’.

‘miscellaneous’ bag’ to keep them separate from similar-

Selection and installation of this capacitor is

looking resistors.

described later in the text.

(You may want to reproduce the schematic and pictorial Monolithic capacitors:

pages so you can mark them as you work, and still keep

The printing on these parts is tiny! I’d highly

the originals clean.)

recommend using a magnifying glass to verify

component values before installing them.

Special Parts Notes IF Transformers:

• Capacitors: Although not illustrated on the schematic

drawing for reasons of drawing clarity, T1-T3

Here's a general rule for capacitor markings:

contain internal capacitors. Do not remove these

If 3 digits are printed on the capacitor, the first two are capacitors.

significant figures and the third is a multiplier. RF Chokes:

Examples: The order of the color-bands on the RF chokes may

'471' = 47 x 101 = 470 pF vary by manufacturer.

'103' = 10 x 103 = 10,000 pF = .01 uF

Letter suffixes: J=5%, K=10%, M=20%.

Parts List - SW-40+ Transceiver

Qty Ref. Desig. Description Identification

2 C3,9 10 pF ceramic disk '10'

1 C7A 22 pF NPO cer. Disk '22'

9 C2,7B,11,17,18,28,30,32,40 47 pF NPO cer. Disk '47'

3 C1,7C,16 68 pF NPO cer. Disk '68'

2 C7D,8 82 pF NPO cer. Disk '82'

1 C7E 100 pF NPO monolithic cap epoxy, '101J'

1 C7F 120 pF NPO monolithic cap epoxy, '121J'

1 C7G 150 pF NPO monolithic cap epoxy, '151J'

7 C12-15,22,23,29 150 pF ceramic disk '151'

1 C31 220 pF ceramic disk '221'

1 C10 270 pF ceramic disk '271J'

2 C37,39 470 pF ceramic disk '471J'

D .Benson, K1SWL Small Wonder Labs 2/9/2007 4

Parts List (continued)

1 C25 820 pF mylar cap '821J'

1 C38 1000 pF NPO mono. cap epoxy, '102J'

2 C4,5 2700 pF NPO mono. cap epoxy, '272J'

1 C6 3300 pF NPO mono. cap epoxy, '332J'

1 C26 .0022 uF mylar cap '222J'

11 C21,33-35,102-105,108,109,111 .01 uF ceramic disk '103M'

1 C19 .033 uF disk or mono. cap '333J'

7 C20,24,36,101,107,113,114 0.1 uF mono. cap epoxy, '104'

1 C110 3.3 uF 50V radial elec. cap banded end is negative

2 C27,106 47 uF 16V radial elec. cap banded end is negative

1 C112 220 uF 16V or 25V radial elec. cap banded end is negative

1 D1 MV1662 Varicap diode TO-92, 2 leads, stripes only

9 D2-10 1N4148A diode glass body

1 D11 7.5V 0.5W 5% Zener diode 1N5236

1 D12 30V 0.5W 5% Zener diode 1N5256

1 D13 1N4001 diode black case

1 L1 T-50-6, see text, p.10 0.50" dia., yellow

1 L2 FT37-43, 6 turns 0.37" dia., dark grey

2 L3,4 T-37-2, 1.0 uH, 16 turns #26 0.37" dia., red

1 Q1 2N5485 or 2N5486 JFET plastic case (TO-92)

1 Q3 2N3906 PNP plastic case (TO-92)

3 Q2,4,5 2N4401 NPN plastic case (TO-92)

1 Q6 2SC2166 Power transistor

2 RFC1,2 22uH RF choke Red-Red-Blk

1 RFC3 10uH RF choke Brn-Blk-Blk

1 R24 500Ω trim pot Blue plastic, 3 leads

3 R6,14,27 10Ω ¼W 5% resistor Brn-Blk-Blk-Gold

2 R28,29 51Ω ¼W 5% resistor Grn-Brn-Blk-Gold

2 R1,26 470Ω ¼W 5% resistor Yel-Viol-Brn-Gold

1 R19 1KΩ ¼W 5% resistor Brn-Blk-Red-Gold

2 R17,25 2.2KΩ ¼W 5% resistor Red-Red-Red-Gold

4 R2,3,21,22 10KΩ ¼W 5% resistor Brn-Blk-Orange-Gold

4 R10,16,20,23 22KΩ ¼W 5% resistor Red-Red-Orange-Gold

1 R15 47KΩ ¼W 5% resistor Yel-Viol-Orange-Gold

3 R4,7,11 510KΩ ¼W 5% resistor Grn-Brn-Yel-Gold

4 R8,12,13,18 1MΩ ¼W 5% resistor Brn-Blk-Grn-Gold

1 R9 4.7MΩ ¼W 5% resistor Yel-Viol-Grn-Gold

4 S1-S4 8-pin low-profile IC socket

3 T1-3 10.7MHz IF transformer '42IF123'

1 T4 FT37-43, 8 turns :1 turn, see text 0.37" dia., dark grey

1 U2 78L08 voltage regulator plastic case (TO-92)

3 U1,3,5 SA602AN, or SA612AN 8-pin IC

1 U4 NE5532 8-pin IC

5 Y1-5 4.00MHz or 4.032MHz crystal HC-49/U holder, 20pF

D .Benson, K1SWL Small Wonder Labs 2/9/2007 5

centered at 800Hz. The high gain of the two NE5532

stages (64dB total) allows a design with no IF amp stage.

Theory of operation The audio output level is adequate to drive headphones,

but it won’t do the job for loudspeaker applications. The

This transceiver is a single PC-board design measuring AF output stage internally overcurrent-limits on loud

2.8” x 4.0” (7 x 10 cm). It features VFO operation with a signals to provide a ready-made ear protection function.

35-40Hz tuning range, as well as QSK (full break-in) If you’re interested in saving at least 5 milliamps on

operation. Let’s take the 50-cent tour: receive, U4 may be replaced by an LMC662 (available

from Digikey). This suggestion is courtesy of Mitch Lee

The receiver’s RF input is applied to U1 through T1 and and Dennis Monticelli, from their excellent article,

C1, which provide a bandpass filter tuned to 7.0MHz. “Revisiting the 40-40” in the ARRL’s ‘QRP Power’. Use

T1’s secondary winding provides roughly unity gain into good quality low-impedance headphones for best results.

U1 to minimize overload (IMD). U1 provides about “Walkman” headphones are fine, but remember – you get

13dB of gain in this configuration, and converts the RF what you pay for. The 3-dollar bargains are distinctly

input to the IF frequency of 4.0MHz. The L-network inferior!

(C11 and RFC1) following the mixer serve to step the

mixer output impedance down to the crystal filter’s design QSK: The T-R switch function is provided by C40 and

value. Note that C12 and RFC1 appear to be RFC3, which form a series-resonant circuit. Diodes D7-

‘transposed’; this reflects the board’s physical layout. D10 limit during key-down and thereby restrict the signal

levels presented to the receiver front-end during transmit.

The crystal filter itself uses 3 crystals. This works well The double-diode configuration raises the network’s

because of the choice of a low IF frequency. Loss intercept point with respect to W7EL’s original

through the filter is less than 2dB, and with the configuration to improve IMD immunity.

component values as shown, the -6dB bandwidth is about

500Hz. Despite the filter’s low parts count, performance The LO uses the Colpitts configuration. The frequency-

is adequate when combined with the AF section’s determining capacitors are NPO (C0G) monolithic types.

selectivity. The unwanted sideband image is down about These devices are extremely compact and offer good

50dB at the audio chain’s 800Hz peak response temperature stability. C2 and C3 are a voltage divider

frequency. providing proper injection to U1. Note: If you want

broader frequency coverage, the value of C8 may be

The filter output is terminated in a 470Ω resistor at the increased. The useful upper limit for C8 is about 1000pF,

input to U3, the product detector stage. U3 converts the and especially at the larger values, capacitor (and

4.0MHz IF signal to audio and contributes another 13dB varicap diode D1) thermal stability will become crucial.

of gain. BFO crystal Y4 has been selected to match the Use NPO/C0G capacitors if possible, if you tinker with

IF filter frequency, so there’s no BFO frequency trimming this circuit.

needed. The .033 uF capacitor across pins 4 and 5 of U3

provides the first measure of audio low-pass filtering. The design also uses a varicap tuning diode for tuning

coverage. While a smooth ball-bearing tuning cap and

The two sections of U4 each provide roughly 30dB of vernier reduction drive are the preferred approach, that

amplification. The first section is configured as a choice drives the cost and mechanical complexity of a

differential amplifier to make use of U3’s differential transceiver up considerably. The varicap approach

output and rolls off the audio response above 1.5KHz. supports quite a compact package! If you’ve just got to

Diodes D3 and D4 serve to limit the audio swing during have RIT, an outboard circuit that injects an adjustable

transmitter key-down to reasonable values. Without these DC offset into the diode bias network on receive does the

diodes, this stage saturates and upsets the operation of the trick.

following FET switch section.

The transmitter chain is a pretty standard affair. The

The AF mute function is the familiar series FET switch maximum output power is about 2-2.5 watts, and there’s a

popularized by W7EL. Despite its relative simplicity, it’s drive control at the emitter follower stage (Q4) to adjust

hard to beat this circuit for click-free audio switching. In the output level. The diode at the base of Q6 serves to

the “key-up” condition the FET is zero-biased and acts ‘clamp’ the signal to Q6 above ground and thus improves

like a resistance of several hundred ohms. In the “key- drive to the PA by several dB. I don’t feel that the PA

down” condition the FET is in cutoff (because the gate is requires a heat sink at the 1.5-2.5W power level and CW

now 7-8 volts below the source) and acts like an open duty cycles. If you like, there’s room for a ‘compact’-

circuit, preventing audio from getting to U4B, the audio style TO-220 heat sink (Digikey #HS-105 or #HS-106).

final stage. This stage is configured as a bandpass filter

D .Benson, K1SWL Small Wonder Labs 2/9/2007 6

[ IMAGE SCANNED FROM ORIGINAL DOCUMENT

D. Benson, K1SWL Small Wonder Labs 2/9/2007 7

[ SCANNED FROM ORIGINAL DOCUMENT ]

D. Benson, K1SWL Small Wonder Labs 2/9/2007 8

Stuff only a few parts at a time (3-4 pieces). If

you try to add too many parts at once between

Building instructions soldering operations, you may lose track and

wind up with missing solder joints! Once you’ve

All parts installed on the PC board should be fully seated. stuffed the parts on the board, bend the

Do not install the parts in “flying-lead” fashion in the protruding leads slightly outward to keep them

hope that it will improve something-or-other! Minimum in place while the board is inverted for

lead length is important to a successful RF design. soldering.

Diode installation: Some of the disk and monolithic capacitors may

be supplied with a lead spacing of 0.10”

All diodes except D1 are bent for “upright” installation. (2.5mm). The “SW-40+” has generally been

Installation polarity is as shown below. Be sure to note laid out for a 0.20” (5mm) capacitor spacing.

the orientation of the silk-screened circle on the board and The capacitor leads may be gently spread apart

install the diode body over this hole. The cathode near the component bodies and then bent

(banded) end of the diode is oriented at the top. parallel to ease installation.

Recommended Assembly sequence:

I’ve specified the sequence below, but there’s nothing

critical about the order in which the board is populated.

Some parts are best installed in a particular order, as

noted within each group’s instructions.

Directions for winding toroids are found within

each group’s assembly instructions.

Resistor installation:

(The figures which follow are for reference only. See the

All resistors except R4 and R21 are likewise mounted in

pictorial drawing on p. 8 for component values.)

“hairpin” fashion. As with the diodes, try to match the

mounting orientation shown on the drawing. (This

usually has nothing to do with critical dimensions – if

mounted as shown you’ve got better troubleshooting

access to circuit points from the top side of the board.)

Orientation of resistor (and other non-polar devices) color

bands is non-critical.

Installing IC sockets:

The “notch” or dot at one end should be oriented as

shown in the pictorial drawings. Double-check

orientation before soldering. A suggestion: solder down

two opposite corners of each socket, and then go back

and press a fingertip on the socket from underneath while

reheating both connections in turn. You may then solder

the remaining pads. This precaution ensures that the

socket is well seated on the PC board.

Some additional tips:

It’s helpful to work from one end or corner of the

board to the other. This minimizes the “tight

squeeze” cases where the last part in a cluster

has to drop into a tight space.

D. Benson, K1SWL Small Wonder Labs 2/9/2007 9

C14 C15

[ ] Install D13, U2, C102, and C113. If you have the

Y3

Y1

Y2

companion enclosure kit, install connectors J4 (2-pin)

Y4

and J2 (3-pin) as well. This step supplies DC power to

the board and installs the 8 Volt regulator IC. C13 C16

C17

C15

78L08 1N4001 C12 D2

SA

R1

612

C105

U3

C104

(J4) D13 C113

.1 uF

(When these components have been installed, the product

detector/BFO and crystal filter sections of the transceiver

are complete.)

(J2) [ ] Install an 8-pin IC socket at U1.

C102 Group 1 assembly

-reference only- Install the components shown below:

U2

L1 (yellow core) is wound using the larger-

diameter magnet wire from the “Miscellaneous”

[ ] Install an 8-pin IC socket at U4. envelope. Wind with 25 turns (24 turns for

Novice-band operation), prepare lead ends, and

[ ] Install the components shown below: install on the board. All other toroids use the

smaller-diameter wire.

R6 R11

C7 is not installed at this time; see “Alignment”

for installation procedure.

C26 R9 Q1

C24

C106

C25 R10

C10

C23 D3 C27 R8 L1 C4

R14 D5 C8

R7 D4 NE J3 install as

C20 R2 shown here. C9

5532

Silkscreen R17 Q2 C6 C5 R18 C103

C19 U4

C7

C21 is wrong. J1 D1

R4

R3 R15 R16

C22 C107 T1C101 C3

C2

RFC1

C11

C1 U1

(When these components have been installed, the audio

amplifier section of the transceiver is complete.)

[ ] Install an 8-pin IC socket at U3.

(When these components have been installed, the receiver

[ ] Install the components shown below: portion of the transceiver is complete.)

Note: the 5 crystals supplied with this kit have been pre-

selected as a group. They are interchangeable within

this group. Do not, however, substitute replacement

parts – contact me for assistance.

D. Benson, K1SWL Small Wonder Labs 2/9/2007 10

[ ] Install an 8-pin IC socket at U5.

[ ] Install the components shown below:

The following components are polarity-sensitive:

D11, C110, Q3-Q5

Spacing on C31 (between transformers T2 and T3) is

quite tight – install this capacitor prior to installing T2 and

T3.

5) Trim off the free end of the wire so that it has

about ¼” (6mm) more than is needed to reach

pad S1. Repeat the lead preparation as in Step 1

above.

6) Install this lead-end in S1 and solder.

(When these components have been installed, the

transmitter mixer, bandpass filter, and driver sections of

the transceiver are complete.)

[ ] Install the components shown below:

Transformer T4 (grey core) is wound with 4” (10cm) of

magnet wire for the primary winding. The primary

winding is wound first, using 8 turns. Install T4.

[ ] Add a secondary winding to T4 as follows:

1) Strip 1/8” of insulation from one end of the 3”

length of insulated wire. Twist the wire gently

between your fingertips to ensure that all strands

are bundled together. Tin this lead-end with

solder.

2) Install this lead-end in S2 and solder.

3) Take the free end of this wire in the direction of

S1 and then double it back through the whole in

T4.

The following components are polarity-sensitive:

4) Draw the lead snug (not tight!) and proceed

C112, D6-10, D12, Q6

around the toroid material until you’ve formed

one complete turn through the toroid as shown

Q6 (2SC2166) is installed with the metal tab to

below:

the rear (or ‘top’ when viewed from directly

overhead). When viewing the board from the

front edge (U1, U3, and U4 nearest you), Q6’s

labeling must be visible.

D. Benson, K1SWL Small Wonder Labs 2/9/2007 11

L2 is wound using 4” (10cm) of wire on an

FT37-43 (grey) core. Wind 6 turns on this core,

prepare lead ends, and install on the board.

Wiring the SW-40+

L3 and L4 are each wound using 10” (25cm) of

wire on a T37-2 (red) core. Wind each with 16 The figure below shows the schematic interconnect

turns, prepare lead ends, and install each of these between the SW-40+ board and the outside world (more

on the board. on alignment later).

(When these components have been installed, the board Short, direct leads between the SW-40+ board and your

assembly is complete.) connectors and controls are advisable. If you’re going to

run the RF output more than a couple of inches to an

If you have not already done so, install all integrated antenna jack, coax (such as the subminiature RG-174) is

circuits on the board as indicated on page 8. Be sure that recommended. The other interconnect wiring is less

the ICs are oriented properly – the dot or notch is on the critical, but try to avoid routing the wiring over the audio

left side of the 8-pin DIP ICs as shown on the pictorial. (U4) filter section if possible.

CLEAN UP YOUR ACT! Before you install the

finished PC board into an enclosure, grab some cotton

swabs and use acetone (nail polish remover) to remove

solder flux from the foil-side of the PC board. The result

is a much cleaner appearance once you’ve completed this

step.

D. Benson, K1SWL Small Wonder Labs 2/9/2007 12

Wire the connectors and controls to the SW-40+ as shown Before you progress to the next phase of the project, this

pictorially below. Note that the keying return line lacks might be a good time to check out the SW-40+. Add the

its own distinct board connection. This return line is various connectors and controls using temporary leads

shared with the headphones’ return. before you get the project buttoned up in a box. If you

need to do any troubleshooting, you’ll have saved the

aggravation of having to undo all the wiring to get at the

STOP! bottom side of the board!

“SW-40+” Mechanical Details

The pictorial figure below shows some ideas for Enclosures may be found in a variety of styles. Radio

connectors and their accompanying mounting-hole Shack offers several types of metallic enclosures. I’d

diameters. These are merely suggestions and are a matter especially recommend Hosfelt Electronics, Inc., who

of personal preference. carry enclosures offered by a number of companies.

There’s no minimum order, and they can be reached at

The board itself is mounted in an enclosure at the board’s (800) 524-6464 for a catalog. Ten-Tec also offers a

four corners using #4 machine screw hardware. #4 complete line of enclosures, and they support small orders

spacers should be used to separate the PC board from the as well. Call (800) 231-8842 for a free brochure.

enclosure by 3/16” or more. (#4 hex nuts are an

acceptable substitute for spacers.)

D. Benson, K1SWL Small Wonder Labs 2/9/2007 13

[ ] Ground the “Key” (J3-3) input.

Before the “Smoke Test”:

[ ] Tune in your transmitted signal on your “big rig”

Inspect your work to ensure there are no solder receiver. This should be a strong carrier (S9+20

bridges or unsoldered joints. Check to see that or better).

the ICs are mounted in their proper orientations.

Be sure to hunt for the strongest signal over a range of 7.0

to 7.3MHz to ensure that you find the primary signal

Alignment instead of a receiver spurious response.

Alignment is easy with this little rig. For test equipment, Operating frequency adjustment:

you’ll need a main-station rig and multimeter or SWR

bridge. Here’s how: [ ] Note the frequency from the step above.

Remove power and install a value of C7 in

Transmitter alignment:

accordance with one of the tables below.

[ ] Connect a tuning pot to J2. (See page 13 for

interconnect pictorial.) Set the tuning pot to full

For 7-7.05 MHz operation:

counterclockwise (0V on the pot’s center If the frequency Install the following

terminal). was between value for C7

7000-7030 (none)

[ ] Connect a 50Ω dummy load to ‘RF Out’ and its 7030-7060 22pF

adjoining ground return pad. 7060-7090 47pF

7090-7120 68pF

[ ] Set trimmer R24 to the half-scale (‘3 o’clock’) 7120-7140 82pF

position. Do not exceed the half-scale position 7140-7160 100pF

until T2 and T3 have been peaked to

7160-7180 120pF

maximum. Yes…you may have to ‘hunt’ for

7180-7210 150pF

an output power indication!- those two

adjustments peaks are fairly narrow.

For 7.1-7.15 MHz (Novice) operation:

[ ] Using a small slot screwdriver, preset the tuning If the frequency Install the following

slugs in T2 and T3 to the middle of their rotation was between value for C7

range. (This is non-critical; there’s no need to 7100-7130 (none)

count turns.) 7130-7160 22pF

7160-7190 47pF

[ ] Add a clip lead to R29 (see figure below) to 7190-7220 68pF

serve as a short whip antenna. Leave the other 7220-7240 82pF

end of the clip lead unconnected, and ensure that

7240-7260 100pF

this free end is well away from other circuitry.

7260-7280 120pF

7280-7310 150pF

The tables above do not show that more capacitance

moves the frequency higher. It means that more

capacitance compensates for higher frequency. Are we

clear on that?

(The approximate formula for the value of C7 is as

follows:)

[C7] (in pF) = ∆f(KHz) / 1.42

where ∆f is the desired frequency shift

D. Benson, K1SWL Small Wonder Labs 2/9/2007 14

It’s possible to adjust the operating frequency as much as previous page. (For the test circuit above, this

15-20KHz downward by squeezing L1’s turns more corresponds to a DVM measurement of 24V

closely together. If in doubt as to which of two values of DC). Increase drive (turn R24 clockwise) only

C7 to use, install the smaller of the two and compress as needed to get to this level.

L1’s turns as needed.

“Can I set it for more output power?”

Connect the RF output to a wattmeter (if you have one).

You can also use your SWR meter with a dummy load Sure! The component values in the PA stage were

connected and set in the “Forward” metering position. designed for maximum efficiency at 1.5W out. The SW+

will deliver considerably more, but please be aware of the

If you don’t have either of these pieces of equipment, you following:

can ‘haywire’ the test circuit below on a scrap of copper-

clad board. This peak detector circuit furnishes a DC • The higher the output power, the more heat is

voltage to your multimeter. being generated by the PA, and this translates

into ‘driftier’ performance in the local oscillator.

• There’s a possibility of instability in the driver

(Q4/Q5) stage with R24 set to maximum. IF

THE SIDETONE SOUNDS RASPY OR

VANISHES ENTIRELY, reduce the R24

setting.

Receiver alignment:

Adjust T2 and T3 for maximum indicated signal on your [ ] Connect a matched antenna to “RF Out” and its

receiver’s S-meter. The adjustment will be somewhat ground return. Using a small slot screwdriver,

interactive, so alternate between the two for maximum peak T1 for maximum signal (or noise). Once

output. this step is complete, background noise should

be noticeably higher with an antenna connected

[ ] Remove the clip lead. Adjust trimmer R24 as than without.

needed for 1.5 watts of key-down power into a

dummy load or the test circuit shown on the

Troubleshooting the SW-40+ Check once more for solder bridges and missing solder

joints. Probing a suspect section of the circuitry with a

fingertip or insulated tool will sometimes bring a stubborn

The “bugs” you’re most likely to encounter often turn out

circuit to life – if so, check again for a bad connection!

to be caused by the simplest of problems. If your SW-

40+ doesn’t play, the following general suggestions may

be helpful: Of the returns I see, about 85% of problems are caused by

cold solder joints, 5% by solder bridges, and 5% due to

incorrect resistor installation. That leaves only 5% for all

“It works better plugged in!”

the other problems put together! ‘Nuff said.

We’ve all heard that expression before, but unfortunately

Ensure that ICs are installed in the correct location and

it’s true. Ensure that DC power is getting to the SW-40+.

with the right orientation.

A board with no voltage anywhere probably isn’t getting

power.

Likewise, ensure that the transistors and all diodes are

installed with the correct orientation.

“The headphones are silent!”

If you don’t turn up anything with the above steps, see the

It’s probably the same as above – an interconnect

troubleshooting schematic on the last page of this manual.

problem. The 1/8” (3.5mm) jacks in particular are

Using a DVM, check the circuit points noted on the

trouble-prone.

D. Benson, K1SWL Small Wonder Labs 2/9/2007 15

drawing against your SW-40+ to confirm that the DC headphones. Also, a signal source such as your

voltage readings are all in order. main transmitter (on minimum power, please!)

should provide a plainly audible signal when you

Here’s a rule of thumb for the troubleshooting voltages: transmit a string of CW characters just above or

I’ve supplied the nominal voltage readings, but there’s below the 4.000MHz IF frequency. Do not

some unit-to-unit variation. As an overall guideline, a connect the main station transmitter to the SW-

20% variation is an acceptable tolerance. If you’re 40+! Stray leakage is sufficient. Similarly, you

making use of this schematic, “something’s broke”, and should be able to hear the BFO at about

things don’t generally break just a little; you’re looking 4000KHz on your main station receiver. If not,

for the obvious departures from the published values. these steps point to a problem with U3 or its

associated BFO components (Y4 and C17-18).

The troubleshooting schematic also lists AC voltage

readings in case you have access to an oscilloscope or Transmitter

have a high-impedance input RF probe. Readings are

given in Volts p-p. Be sure a load is connected anytime you’re

troubleshooting the transmitter.

The figure below illustrates IC pinout. The “pin

1 at lower left” convention applies to all Dual- Verify that the keying switch Q3 supplies 12V DC to

Inline-Package (DIP) ICs. the transmit mixer (U5) and buffer/driver (Q4-5)

stages when the “Key” input is grounded. Note that

the voltage reading at pin 8 of U5 should be 7.1 to

7.9 volts. No voltage during key-down suggests that

(TOP VIEW) (BOTTOM VIEW)

Q3 is bad or that D11 is installed backward.

8 5 5 8

Touching a screwdriver to Q6’s case (collector)

should yield a distinct (key-down) increase in signal

received on your ‘big rig’ receiver. If not, suspect

4 4

1 1 Q6.

DOT AND/OR NOTCH

If you want to change the sidetone pitch, increasing the

value of C29 raises the sidetone pitch (and Tx offset), and

decreasing that cap lowers it.

“Strange but True” – In general, the ICs themselves

shouldn’t be prime suspects during the troubleshooting

process. Despite their complexity, they’re very reliable, Don’t panic!

and I’ve had to replace these parts at the rate of only 1 … and don’t smash your SW-40+ against a wall! If all

for every thousand or so shipped! else fails, contact me for further technical support:

If those steps don’t turn up anything, here are some Email: dave@smallwonderlabs.com

additional steps to try:

Troubleshooting/alignment is available for a $30 fee ($35

outside the US) . The unit will be returned to you in

Receiver working condition and will include a troubleshooting

report. The price includes return shipping.

Touching either of the 10K resistor leads to the

left of the AF Amp IC (U4) should cause an

Please do not send the unit without contacting me first.

easily-audible hum or buzz in the headphones.

If not, and Vr (the 8V supply) is OK, the [ We’ve moved- twice- …. and counting- since the

NE5532 op amp (U4) is suspect. original edition of these instructions were published. The

work is done off-site in any case, and unsolicited returns

Touching an antenna wire to the 470W resistor tend to end up ‘aging’ under the workbench. ]

to the left of U3 (product detector) should cause

shortwave “crud” to be audible in the

D. Benson, K1SWL Small Wonder Labs 2/9/2007 16

D. Benson, K1SWL Small Wonder Labs 2/9/2007 17

You might also like

- The Ankh African Origin of Electromagnetism by Nur Ankh AmenDocument139 pagesThe Ankh African Origin of Electromagnetism by Nur Ankh AmenHomers Simpson97% (59)

- High Speed Signal Propagation - Advanced Black MagicDocument792 pagesHigh Speed Signal Propagation - Advanced Black MagicVivekanand Kota100% (9)

- MT7613 Optimizes LED PerformanceDocument6 pagesMT7613 Optimizes LED PerformanceVishal dtuNo ratings yet

- Designing Sharp Cut-Off Filters at Very Low FrequenciesDocument12 pagesDesigning Sharp Cut-Off Filters at Very Low Frequencieslizhi0007No ratings yet

- Hal Dkb-2010 ManualDocument101 pagesHal Dkb-2010 Manualteconline-1No ratings yet

- Basic Principles of Fiber Optic CommunicationDocument3 pagesBasic Principles of Fiber Optic CommunicationHumayra Anjumee100% (2)

- List of Radio Stations in Greece PDFDocument69 pagesList of Radio Stations in Greece PDFDimitris EvangeliouNo ratings yet

- The Vacuum-Tube Voltmeter and The Grid-Dip OscillatorDocument4 pagesThe Vacuum-Tube Voltmeter and The Grid-Dip OscillatorJoseGarciaRuizNo ratings yet

- Very Low Phase Noise Vackar VFODocument4 pagesVery Low Phase Noise Vackar VFOShiva Prasad100% (2)

- Ic-7300 WSJT-XDocument6 pagesIc-7300 WSJT-XCostinNo ratings yet

- KEMPER PROFILER Addendum 5.7 (English) PDFDocument145 pagesKEMPER PROFILER Addendum 5.7 (English) PDFAlberto BolocanNo ratings yet

- McMahon, Morgan E. - Vintage RadioDocument265 pagesMcMahon, Morgan E. - Vintage RadioMichael M. StarkeNo ratings yet

- Beitman 1949 TVDocument212 pagesBeitman 1949 TVDirceu RodriguesNo ratings yet

- Kfd2-Stc4-Ex1 P & F BarrierDocument3 pagesKfd2-Stc4-Ex1 P & F Barrierbeig0% (1)

- Deep Learning For Tube Amplifier EmulationDocument7 pagesDeep Learning For Tube Amplifier EmulationVincent RainNo ratings yet

- 09 September 1976Document164 pages09 September 1976Paulo_1970No ratings yet

- Yaesu RadiosDocument17 pagesYaesu RadiosTodd HoferNo ratings yet

- 094-90356 Hallicrafters SR-160 Operating and Service Instructions Dec63Document36 pages094-90356 Hallicrafters SR-160 Operating and Service Instructions Dec63Anonymous AtlmljYFNnNo ratings yet

- How To Build A Slayer ExciterDocument6 pagesHow To Build A Slayer ExciterKevin BinnyNo ratings yet

- Bernards - Sinclair - Clive Sinclair-168 - Transistor Circuits Manual No4-1967Document42 pagesBernards - Sinclair - Clive Sinclair-168 - Transistor Circuits Manual No4-1967David MarchesiNo ratings yet

- Beitman 1950 TVDocument168 pagesBeitman 1950 TVDirceu RodriguesNo ratings yet

- II.2.6 Lysergic Acid Diethylamide (LSD) : by Shinichi SuzukiDocument4 pagesII.2.6 Lysergic Acid Diethylamide (LSD) : by Shinichi SuzukiHasheem AliNo ratings yet

- Build Your Own Basic CW Transceiver for the 1750 Meter BandDocument6 pagesBuild Your Own Basic CW Transceiver for the 1750 Meter Bandsys_64759No ratings yet

- Vacuum Tube - WikipediaDocument33 pagesVacuum Tube - WikipediaHenslsdkgaANo ratings yet

- Remote Behavioral Influence Technology EvidenceDocument20 pagesRemote Behavioral Influence Technology EvidenceGeneration GenerationNo ratings yet

- Multimeter - Wikipedia, The Free EncyclopediaDocument13 pagesMultimeter - Wikipedia, The Free Encyclopediad_richard_dNo ratings yet

- CQ Amateur Radio September 2020Document117 pagesCQ Amateur Radio September 2020SathawitNo ratings yet

- Kemper Profiler Basics EN-DE 2.0 PDFDocument136 pagesKemper Profiler Basics EN-DE 2.0 PDFAlexandre NovaisNo ratings yet

- 70cm Quadruple QuadDocument5 pages70cm Quadruple QuadJosé Antonio Miranda100% (1)

- Jaes V60 9 AllDocument115 pagesJaes V60 9 AllPhilipp Linder100% (1)

- Ameco Amateur Radio Theory CourseDocument304 pagesAmeco Amateur Radio Theory CourseNenad PetrovicNo ratings yet

- Purple MC7Document15 pagesPurple MC7DrixNo ratings yet

- Graphene Field Effect Transistor and Its Application For Electronic SensingDocument24 pagesGraphene Field Effect Transistor and Its Application For Electronic Sensing朱佳芬No ratings yet

- EBU - TECH 3299 HDTV Standards PDFDocument6 pagesEBU - TECH 3299 HDTV Standards PDFAdrian IlieNo ratings yet

- Osd Audio 2020 CatalogDocument37 pagesOsd Audio 2020 CatalogPitarakis NikosNo ratings yet

- Roland Cube 15XL (2010) Service ManualDocument15 pagesRoland Cube 15XL (2010) Service ManualMuhammad KholiliNo ratings yet

- Xk3 ManualDocument114 pagesXk3 ManualmichtalbotNo ratings yet

- Module 3, Cells and How They WorkDocument14 pagesModule 3, Cells and How They WorkMARIA CORAZON CONTANTENo ratings yet

- Trainwreck Express Guitar Amp SchematicDocument15 pagesTrainwreck Express Guitar Amp SchematicDave EastNo ratings yet

- 5 Tone Control Circuits Using Op Amp NE5532Document27 pages5 Tone Control Circuits Using Op Amp NE5532ferdinand100% (1)

- Design Examples: For Use in First Semester Structural Steel Design ClassesDocument125 pagesDesign Examples: For Use in First Semester Structural Steel Design ClassesChika NafiisaNo ratings yet

- Sennheiser 2008Document57 pagesSennheiser 2008Dragan BogdanovicNo ratings yet

- 01-Building A 1929 Style Hartley TransmitterDocument4 pages01-Building A 1929 Style Hartley Transmittermax_orwell100% (1)

- RM Italy KL703 ManualDocument6 pagesRM Italy KL703 ManualpadawerNo ratings yet

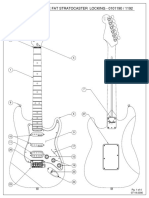

- AMERICAN DELUXE FAT STRATOCASTER LOCKING - TECHNICAL DIAGRAMDocument4 pagesAMERICAN DELUXE FAT STRATOCASTER LOCKING - TECHNICAL DIAGRAMjesus fuentesNo ratings yet

- ABCs of ProbesDocument60 pagesABCs of ProbesAldo VillarNo ratings yet

- MSC Nastran 2021.3: Quick Reference GuideDocument3,392 pagesMSC Nastran 2021.3: Quick Reference GuideCamelia MunteanuNo ratings yet

- Amatur Radio 73 Mag 02 - February - 1974Document132 pagesAmatur Radio 73 Mag 02 - February - 197420AB14No ratings yet

- Data Sheet: 860 MHZ, 34 DB Gain Push-Pull AmplifierDocument10 pagesData Sheet: 860 MHZ, 34 DB Gain Push-Pull AmplifiereddyNo ratings yet

- How to Clean Guitar Strings for Optimal ToneDocument3 pagesHow to Clean Guitar Strings for Optimal ToneJohn Paul FlanciaNo ratings yet

- Hunting Noise SourcesDocument16 pagesHunting Noise Sourceslokesh222No ratings yet

- Experimenter: The Impoverished RadioDocument52 pagesExperimenter: The Impoverished Radiobenra1No ratings yet

- Antenna RFI MonitoringDocument71 pagesAntenna RFI MonitoringmoannaNo ratings yet

- Grid-Stoppers and Miller CapacitanceDocument3 pagesGrid-Stoppers and Miller CapacitanceDiego García MedinaNo ratings yet

- Engr260 Lec5 Op Amps (Ink)Document30 pagesEngr260 Lec5 Op Amps (Ink)Nick RentschNo ratings yet

- A68 RF Hardware Trouble Shooting Guide - WO - SA - A8960 - 1001 PDFDocument56 pagesA68 RF Hardware Trouble Shooting Guide - WO - SA - A8960 - 1001 PDFDnw DigitalprintingNo ratings yet

- RP360-RP360XP Manual 5041674-B OriginalDocument120 pagesRP360-RP360XP Manual 5041674-B OriginalPolivinil Indie RockNo ratings yet

- Implementation Guide Smart - Charging (En)Document56 pagesImplementation Guide Smart - Charging (En)Nico J (TheFantomas)No ratings yet

- Mass Song BookDocument80 pagesMass Song BookRozel Bonaobra IINo ratings yet

- Photosynthesis in Higher Plants - Shobhit NirwanDocument21 pagesPhotosynthesis in Higher Plants - Shobhit NirwanVraj M Barot100% (1)

- Mp3 - Video - DVDDocument46 pagesMp3 - Video - DVDИгорь ИвановNo ratings yet

- MHRD Clarification Dated 16-04-19Document7 pagesMHRD Clarification Dated 16-04-19Subodh KumarNo ratings yet

- Neutrosophic DualityDocument116 pagesNeutrosophic DualityHenry GarrettNo ratings yet

- PSK20 ManualDocument24 pagesPSK20 ManualMehmet YağcıNo ratings yet

- SW20+ ManualDocument17 pagesSW20+ ManualhackmanNo ratings yet

- Molecules: Phenolic Compounds From Allium Schoenoprasum, TragopogonDocument11 pagesMolecules: Phenolic Compounds From Allium Schoenoprasum, Tragopogonteconline-1No ratings yet

- NIH Public Access: Author ManuscriptDocument12 pagesNIH Public Access: Author Manuscriptteconline-1No ratings yet

- 2N5109 Silicon NPN Transistor Broadband RF Amplifier: Absolute Maximum RatingsDocument2 pages2N5109 Silicon NPN Transistor Broadband RF Amplifier: Absolute Maximum Ratingsteconline-1No ratings yet

- TONO Theta-777 ManualDocument49 pagesTONO Theta-777 Manualteconline-1No ratings yet

- PC817 PDFDocument15 pagesPC817 PDFFrancisco SantosNo ratings yet

- M5281-83 Raid096Document39 pagesM5281-83 Raid096teconline-1No ratings yet

- +5V-Powered, Multichannel RS-232 Drivers/Receivers: General Description - FeaturesDocument11 pages+5V-Powered, Multichannel RS-232 Drivers/Receivers: General Description - FeaturesRobert Alexandre GamaNo ratings yet

- 74 Ls 136Document15 pages74 Ls 136teconline-1No ratings yet

- Dwlag530 Manual en UkDocument46 pagesDwlag530 Manual en Ukteconline-1No ratings yet

- Manual Do Airaya 4958NDocument60 pagesManual Do Airaya 4958Nteconline-1No ratings yet

- Cheetah 10K.6 SCSI Disc Drive: ST3146807LW/LC ST373307LW/LC ST336607LW/LCDocument96 pagesCheetah 10K.6 SCSI Disc Drive: ST3146807LW/LC ST373307LW/LC ST336607LW/LCteconline-1No ratings yet

- 7V8X X V KT4Document64 pages7V8X X V KT4matheussartori123No ratings yet

- Tl-wn722n v1 User GuideDocument41 pagesTl-wn722n v1 User GuideSadam LashariNo ratings yet

- Dwlag530 Datasheet en UkDocument2 pagesDwlag530 Datasheet en Ukteconline-1No ratings yet

- Article FernandesDocument6 pagesArticle FernandesHamilton Pereira da SilvaNo ratings yet

- Cell Management (5G RAN3.1 - 01)Document51 pagesCell Management (5G RAN3.1 - 01)VVLNo ratings yet

- Lutron cc-421 Instruction ManualDocument10 pagesLutron cc-421 Instruction ManualБогдан КендзерNo ratings yet

- Minx Xi User Manual EnglishDocument20 pagesMinx Xi User Manual Englishblesson123No ratings yet

- Massive Manual Rev MSMPXXXXDocument33 pagesMassive Manual Rev MSMPXXXXGABRIEL ORTIZNo ratings yet

- TesTer For RemoTe ConTrolCI-03 - Feb08Document1 pageTesTer For RemoTe ConTrolCI-03 - Feb08Alagappan Arunachalam100% (1)

- WT1151 2000 Pressure Transmitter PDFDocument43 pagesWT1151 2000 Pressure Transmitter PDFQuách Ngọc HuyNo ratings yet

- DSA00232856Document2 pagesDSA00232856Profesor RosokNo ratings yet

- Wideband MIMO LPDA Antenna Design for Mobile DevicesDocument2 pagesWideband MIMO LPDA Antenna Design for Mobile DevicesauuuuNo ratings yet

- Lecture Note Chapter 1 & 2Document80 pagesLecture Note Chapter 1 & 2ethiopia ethiopiaNo ratings yet

- Double Stub TuningDocument22 pagesDouble Stub TuningbooksgiveknowledgeNo ratings yet

- Personal Survival TechniquesDocument14 pagesPersonal Survival Techniquesvaldezlouie75100% (1)

- DM-X Programming Guide PDFDocument28 pagesDM-X Programming Guide PDFdany suarezNo ratings yet

- Electronic Distance Measuring Instruments (Edmis)Document12 pagesElectronic Distance Measuring Instruments (Edmis)Arthem VishnuNo ratings yet

- 5G Ready 0.04-12.4 GHZ RF & Microwave Antenna Lab MAT12Document8 pages5G Ready 0.04-12.4 GHZ RF & Microwave Antenna Lab MAT12Amit SharmaNo ratings yet

- Circuits: Elektor ElectronicsDocument333 pagesCircuits: Elektor ElectronicsA Daniel LazarescuNo ratings yet

- Sailor 6090 Navtex User Manual PDFDocument56 pagesSailor 6090 Navtex User Manual PDFJohn QwerNo ratings yet

- Hkcee Physics - Section 3 Waves - P.1Document34 pagesHkcee Physics - Section 3 Waves - P.1Y AdaNo ratings yet

- GDDocument1 pageGDMichelle NuarinNo ratings yet

- Field-Effect Transistors: TypesDocument24 pagesField-Effect Transistors: TypesKhuram Shahzad KhalidNo ratings yet

- MD Series MX Uy Pa Us User GuideDocument4 pagesMD Series MX Uy Pa Us User GuideLuis Matias Carvajal MarigualNo ratings yet

- Polycopié TD Du Module Communications Numériques Avancées (TOME2)Document23 pagesPolycopié TD Du Module Communications Numériques Avancées (TOME2)MOHAMED ABDEL KADER KRIMILNo ratings yet

- Ahmed Elkrewi CV1Document2 pagesAhmed Elkrewi CV1ahmed DgNo ratings yet

- Smith Meter Accuload Iv: Electronic Preset Delivery System Installation and Maintenance ManualDocument64 pagesSmith Meter Accuload Iv: Electronic Preset Delivery System Installation and Maintenance ManualMAIRA ALEJANDRA VNLEZ HERNNNDEZNo ratings yet

- HVT DS AKV 9310 Quadripole V2011Document4 pagesHVT DS AKV 9310 Quadripole V2011sunilNo ratings yet

- BB5216 5cca 160409 120113 041116Document28 pagesBB5216 5cca 160409 120113 041116MarcoNo ratings yet