Professional Documents

Culture Documents

A Smart-Gun-EN

A Smart-Gun-EN

Uploaded by

shubham yadav0 ratings0% found this document useful (0 votes)

1 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

1 views2 pagesA Smart-Gun-EN

A Smart-Gun-EN

Uploaded by

shubham yadavCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Smart-Gun®

Three dispense points on single applicator, allowing smarter dispensing

The Smart-Gun® has three individually selected

dispense tips to dispense any comination of

spray, stream or ribbon apply material.

The Smart-Gun provides three individually controlled

valves to manipulate specific nozzle tips. This precise

control allows for three different nozzle patterns or

orientations to be utilized by the same robot with limited

robot manipulation.

Nozzle blocks are application specific, ensuring the

orientation of each nozzle is optimized for the vehicles

access and the application need. Designed for PVC

seam sealing applications in interior seam seal, (ISS)

and underbody seam sealer (UBS) applications.

Features and benefits

• Slim design allows for great reach into part

without extensive cautionary robot programming.

• No external valves or square corners.

• Material inlet on Smart-Gun is in rear, ensuring

material hoses do not interfere with part.

• Capable of dispensing two separate one-part

materials, limiting valve changes or needs.

Rotating Smart-Gun Stationary Smart-Gun

Rotary vs stationary

• Stationary units commonly used in UBS applications

and keep moving parts to a minimum.

• Rotating units include a material swivel and stationary

hose inlet, allowing the SG to be roated without

wrapping material or air hoses around the robot or tool.

Typical applications

• One-part sprayable materials

• Heat-cure PVC sealer

Fixed

• Vehicle seam sealing

• Underbody sealing

• Roof ditch seam sealing

Three Carbide Tips

Rotary Smart-Gun product specifications

Rotation Infinite rotation capability (rotating models only)

Mounting Fastens directly to robot wrist plate (J6)

Dimensions 21.9" (555 mm) long x 4" (100 mm) dia.

Tip Orientation Model dependent

Fluid Valves (3) internal No-Drip valves with spring sssist

(3) “valve open” tube fittings – (1) per

Air Ports (Rotary) 360° + Infinite

nozzle (1) “close all valves” tube fitting

Rotation

Air Ports (Stationary) (1) per valve open, (1) per valve close

Lubrication (1) grease fitting and (1) outlet tube fitting

Max. inlet pressure 1,900 Psi (131 bar) fluid pressure

Min. air pressure 80 Psi (5.5 Bar) air pressure

Single- or dual- material inlet manifolds,

Accessories

carbide dispense tips

Available carbide dispense tips: (order separately)

Slot Ribbon Medium-Fan

Medium fan Heavy-Fan Narrow-Fan Round-Stream

Medium- and Deep- Airless

airlessSpray

spray Airless Spray Airless Spray

Cut Options

© 2019 Nordson Corporation l All Rights Reserved l AUL-19- 6110 l Revised 12/19

Why choose Nordson

In highly competitive manufacturing markets, productivity is Nordson Industrial Coating Systems

vital and performance is essential. That’s why we apply both

to everything we do, whether it’s our products, expertise 100 Nordson Drive Phone: +1.440.985.4000

or outstanding customer service. We’ll always be there to Amherst, OH, 44001 www.nordson.com/ics

help maintain the new standards you’ve set, with expert USA

service and support delivered through our teams working

/Nordson_Coating /NordsonICS

across the globe.

This unique Nordson approach helps you reach new levels /company/nordson-industrial-coating-systems

of production, while working more accurately, efficiently and

Find your local Nordson office:

competitively than ever. Precisely why manufacturers who

www.nordson.com/icslocations

demand quality, can rely on Nordson.

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Rights and Liabilities of PartnersDocument8 pagesRights and Liabilities of PartnersEzaz Khan100% (1)

- Dutch Bangla Bank, Bangladeshi BankDocument1 pageDutch Bangla Bank, Bangladeshi BankShakil50% (2)

- Fanuc Profibus ManualDocument109 pagesFanuc Profibus Manualshubham yadavNo ratings yet

- Deck of Worlds GuidebookDocument8 pagesDeck of Worlds GuidebookHans LuytenNo ratings yet

- Lac Session RationaleDocument3 pagesLac Session Rationalepebles ann caguitquit100% (10)

- Principle of Management Elton MayoDocument15 pagesPrinciple of Management Elton MayoJoanna LoNo ratings yet

- 2010 Bar Exam QuestionsDocument6 pages2010 Bar Exam QuestionsKatherine AplacadorNo ratings yet

- Dean Riano Lectures On Remedial Laws: The Review Center at TwilightDocument27 pagesDean Riano Lectures On Remedial Laws: The Review Center at TwilightSeventh HokageNo ratings yet

- UTIITSL-PBV-Terms and ConditionsDocument3 pagesUTIITSL-PBV-Terms and Conditionsshubham yadavNo ratings yet

- IMG-7426 MergedDocument2 pagesIMG-7426 Mergedshubham yadavNo ratings yet

- Pallavi ProjectDocument81 pagesPallavi Projectshubham yadavNo ratings yet

- 9sMhtE-name Change Correction FormDocument1 page9sMhtE-name Change Correction Formshubham yadavNo ratings yet

- FcyvDocument1 pageFcyvshubham yadavNo ratings yet

- Bottle Orientation Interface System (Boris) : December 3, 2014Document72 pagesBottle Orientation Interface System (Boris) : December 3, 2014shubham yadavNo ratings yet

- Cooper Crouse Hinds LED Family PresentationDocument36 pagesCooper Crouse Hinds LED Family Presentationshubham yadavNo ratings yet

- Shubham Yadav 1Document1 pageShubham Yadav 1shubham yadavNo ratings yet

- Mutual Fund Risk & ReturnDocument27 pagesMutual Fund Risk & Returnshubham yadavNo ratings yet

- Questionaire (Pre Test) Name:: Page 1 of 2Document2 pagesQuestionaire (Pre Test) Name:: Page 1 of 2shubham yadavNo ratings yet

- Chapter - Iv Emergence of Kapus in Andhra PoliticsDocument66 pagesChapter - Iv Emergence of Kapus in Andhra PoliticsMurali GurajalaNo ratings yet

- House and Senate GOP Letter To Sal Pace, Brandon Shaffer, John Hickenlooper On Prop 103Document5 pagesHouse and Senate GOP Letter To Sal Pace, Brandon Shaffer, John Hickenlooper On Prop 103ColoradoPeakPoliticsNo ratings yet

- CSW - Workshop Instructions - RevisedDocument13 pagesCSW - Workshop Instructions - RevisedDARLENENo ratings yet

- Sample ExcelDocument6 pagesSample ExcelAbdulrauf MacatampoNo ratings yet

- Yishak MaereguDocument66 pagesYishak MaereguHebron DawitNo ratings yet

- Regular Verbs ListDocument9 pagesRegular Verbs ListLanestonyNo ratings yet

- The Reality of Celebrating Eid Milad Un Nabi (Pbuh)Document5 pagesThe Reality of Celebrating Eid Milad Un Nabi (Pbuh)Mohammed SachaNo ratings yet

- Characteristics Ofthe 21ST Century AssessmentDocument2 pagesCharacteristics Ofthe 21ST Century AssessmentJanjan S SarominesNo ratings yet

- Introduction To Linear Algebra For Science and Engineering 3Rd Edition Daniel Norman Full ChapterDocument67 pagesIntroduction To Linear Algebra For Science and Engineering 3Rd Edition Daniel Norman Full Chapterflorence.beebe430100% (5)

- Communication Between Delta HMI and Siemens PLC S7-1200 - Delta Industrial AutomationDocument5 pagesCommunication Between Delta HMI and Siemens PLC S7-1200 - Delta Industrial AutomationAlonso AutomationNo ratings yet

- Code Switching AssignmentDocument5 pagesCode Switching AssignmentLennson CHIKOMONo ratings yet

- Religious Tolerance in IslamDocument6 pagesReligious Tolerance in IslamAdegbola IbrahimNo ratings yet

- QB-DPPDocument54 pagesQB-DPPd anjilappa100% (1)

- Graduate School of International Relations ValedictorianDocument3 pagesGraduate School of International Relations ValedictorianJen RiveraNo ratings yet

- Consumer BehaviorDocument45 pagesConsumer BehaviorSravaniChariNo ratings yet

- 12685/mas Maq SF Exp Sleeper Class (SL)Document2 pages12685/mas Maq SF Exp Sleeper Class (SL)Vishnu KollarethNo ratings yet

- Human Resource Strategy: Atar Thaung HtetDocument16 pagesHuman Resource Strategy: Atar Thaung HtetaungnainglattNo ratings yet

- TheNineWorlds 10015803Document178 pagesTheNineWorlds 10015803jurebieNo ratings yet

- Screaming Gummie Bear C12-1-12 and C11-3-6Document5 pagesScreaming Gummie Bear C12-1-12 and C11-3-6fikdanial02No ratings yet

- Lesson Plan in Community OrganizingDocument15 pagesLesson Plan in Community OrganizingJustine Price Danielle BunalesNo ratings yet

- SCHWALBE-Bicycle-Tires 2020 ENDocument100 pagesSCHWALBE-Bicycle-Tires 2020 ENpetarlNo ratings yet

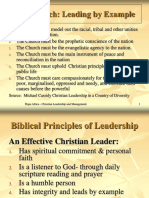

- The Church: Leading by Example: Source: Michael Cassidy Christian Leadership in A Country of DiversityDocument44 pagesThe Church: Leading by Example: Source: Michael Cassidy Christian Leadership in A Country of DiversityAlen John PinheiroNo ratings yet

- Ibt Prelim ReviewerDocument8 pagesIbt Prelim ReviewerApril Mae LomboyNo ratings yet