Professional Documents

Culture Documents

Seleccion Chaveteros Norma JIS

Seleccion Chaveteros Norma JIS

Uploaded by

alanv8Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Seleccion Chaveteros Norma JIS

Seleccion Chaveteros Norma JIS

Uploaded by

alanv8Copyright:

Available Formats

[Technical Data]

Machine Keys and Key Grooves Excerpts from JIS B 1301(1996)

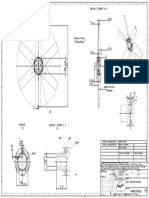

1. Parallel Keys and Key Grooves 2. Slope Key, Gib Head Key and Key Groove

Gib Head Key Section of Key(A-A)

− S1 1.6 Section of Key Section of Key Groove − S1

Slope Key 6.3

b

b

b

(Code T)

b

1

1.6 S1=Tolerance of b× r2

2

c

− S1 ℓ

25

25

6.3 6.3

h

c

ℓ

h

A

b

6.3 b2 C c

− S2 1.6 6.3 30° f

25

25

1 c 6.3 ℓ

S2=Tolerance of h× 1.6 − S2 3.2 Slope 1

h

1

2 3.2 100 ± 1000

h1

b1 1

6.3 6.3 S1=Tolerance of b×

h

h

2 A

h2

t2

1.6

r1 1.6 h2=h, f=h, e≈b − S2 Section of Key Groove

1

h

S2=Tolerance of h× h2=h, f≈h, e=b

2 r2

t1

d

t2

b2 1.6

6.3

1.6

t 12

d b1

6.3

r1

Unit:mm

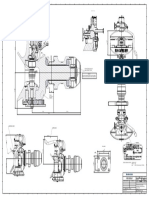

Dimension of Key Groove Reference Unit:mm

Key Nominal (Sliding Type) Standard Precision Class Dimension of Key Groove Dimension of Key Groove Reference

Reference Reference Reference Reference Applicable Key Nominal

Dimension b1 b2 b1 b2 b1 and b2 b h b1 and b2

Dimension r1 and r2 Dimension Dimension Dimension Shaft Dia.(1) Dimension Reference Reference Reference Applicable

b×h

of b1, b2 Tolerance Tolerance Tolerance Tolerance Tolerance ℓ(1) 2

of t1 of t2 of t2, t1 d Reference Tolerance Reference h1 c Reference Tolerance r1 and r2 Dimension Dimension Dimension Shaft Dia.( )

b×h Tolerance of t1 of t2 of t2, t1 d

(H9) (D10) (N9) (Js9) (P9) Dimension (h9) Dimension Dimension (D10)

2×2 2 + 0.025 +0.060 −0.004 −0.006 1.2 1.0 6~8 2×2 2 0 2 0 − 6~30 2 +0.060 1.2 0.5 + 0.05 6~8

±0.0125 0.16 0.08

3×3 3 0 +0.020 −0.029 −0.031 0.08~0.16 1.8 1.4 8~10 3×3 3 − 0.025 3 − 0.025 − 6~36 3 +0.020 1.8 0.9 0 8~10

+ 0.1 ~0.25 ~0.16

4×4 4 2.5 1.8 10~12 4×4 4 4 7 8~45 4 2.5 1.2 10~12

+ 0.030 +0.078 0 −0.012 0 h9

5×5 5 ±0.0150 3.0 2.3 12~17 0 0 +0.078

0 +0.030 − 0.030 −0.042 5×5 5 5 8 10~56 5 3.0 1.7 + 0.1 12~17

− 0.030 − 0.030 +0.030

6×6 6 3.5 2.8 17~22 6×6 6 6 10 0.25 14~70 6 0.16 3.5 2.2 0 17~22

0.16~0.25

(7×7) 7 4.0 3.0 20~25 (7×7) 7 7.2 0 10 ~0.40 16~80 7 ~0.25 4.0 3.0 20~25

+ 0.036 +0.098 0 −0.015 − 0.036

8×7 8 ±0.0180 4.0 3.3 22~30 0 +0.098

0 +0.040 − 0.036 −0.051 8×7 8 7 11 18~90 8 4.0 2.4 22~30

− 0.036 +0.040

10×8 10 5.0 3.3 30~38 10×8 10 8 0 12 22~110 10 5.0 2.4 + 0.2 30~38

h11

12×8 12 5.0 3.3 38~44 12×8 12 8 − 0.090 12 28~140 12 5.0 2.4 0 38~44

14×9 14 5.5 3.8 44~50 14×9 14 9 14 0.40 36~160 14 0.25 5.5 2.9 44~50

+ 0.043 +0.120 0 −0.018 0.25~0.40 0 +0.120

(15×10) 15 ±0.0215 5.0 5.0 50~55 (15×10) 15 10.2 0 h10 15 ~0.60 40~180 15 ~0.40 5.0 5.0 + 0.1 50~55

0 +0.050 − 0.043 −0.061 − 0.043 − 0.070 +0.050 0

16×10 16 6.0 4.3 + 0.2 50~58 16×10 16 10 0 16 45~180 16 6.0 3.4 50~58

− 0.090

18×11 18 7.0 4.4 0 58~65 18×11 18 11 18 50~200 18 7.0 3.4 58~65

+ 0.2

0 h11

20×12 20 7.5 4.9 65~75 20×12 20 12 20 56~220 20 7.5 3.9 0 65~75

− 0.110

22×14 22 9.0 5.4 75~85 22×14 22 14 22 63~250 22 9.0 4.4 75~85

+ 0.052 +0.149 0 −0.022 0 0 +0.149 + 0.1

(24×16) 24 ±0.0260 8.0 8.0 80~90 (24×16) 24 16.2 − 0.070 h10 24 0.60 70~280 24 0.40 8.0 8.0 0 80~90

0 +0.065 − 0.052 −0.074 0.40~0.60 − 0.052 +0.065

25×14 25 9.0 5.4 85~95 25×14 25 14 22 ~0.80 70~280 25 ~0.60 9.0 4.4 85~95

28×16 28 10.0 6.4 95~110 0 + 0.2

28×16 28 16 h11 25 80~320 28 10.0 5.4 95~110

− 0.110 0

32×18 32 11.0 7.4 110~130 32×18 32 18 28 90~360 32 11.0 6.4 110~130

(35×22) 35 11.0 11.0 125~140 (35×22) 35 22.3 0 h10 100~400 35 11.0 11.0 + 0.15 125~140

− 0.084 0

0 32 + 0.3

36×20 36 12.0 8.4 130~150 36×20 36 20 − 0.130 h11 − 36 12.0 7.1 0 130~150

(38×24) 38 + 0.062 +0.180 0 −0.026 12.0 12.0 140~160 (38×24) 38 24.3 0 h10 36 − 38 12.0 12.0 + 0.15 140~160

±0.0310 0 − 0.084 +0.180 0

40×22 40 0 +0.080 − 0.062 −0.088 0.70~1.00 13.0 9.4 150~170 − 0.062 0 1.00 +0.080 0.70 + 0.3

40×22 40 22 − 0.130 h11 36 − 40 13.0 8.1 0 150~170

~1.20 ~1.00

(42×26) 42 13.0 13.0 160~180 (42×26) 42 26.3 0 h10 40 − 42 13.0 13.0 + 0.15 160~180

− 0.084 0

45×25 45 15.0 10.4 170~200 45×25 45 25 0 40 − 45 15.0 9.1 170~200

+ 0.3

50×28 50 17.0 11.4 200~230 50×28 50 28 − 0.130 45 − 50 17.0 10.1 200~230

0

56×32 56 20.0 12.4 230~260 56×32 56 32 50 − 56 20.0 11.1 230~260

63×32 63 + 0.074 +0.220 0 −0.032 1.20~1.60 20.0 12.4 260~290 1.60 1.20

63×32 63 0 32 50 − 63 +0.220 20.0 11.1 + 0.3 260~290

±0.0370 h11 ~2.00 ~1.60

70×36 70 0 +0.100 − 0.074 −0.106 22.0 14.4 290~330 70×36 70 − 0.074 36 56 − 70 +0.100 22.0 13.1 0 290~330

0

80×40 80 25.0 15.4 330~380 80×40 80 40 − 0.160 63 − 80 25.0 14.1 330~380

90×45 90 + 0.087 +0.260 0 −0.037 2.00~2.50 28.0 17.4 380~440 2.50 2.00

90×45 90 0 45 70 − 90 +0.260 28.0 16.1 380~440

±0.0435 ~3.00 ~2.50

100×50 100 0 +0.120 − 0.087 −0.124 31.0 19.5 440~500 100×50 100 − 0.087 50 80 − 100 +0.120 31.0 18.1 440~500

Note(1) The applicable shaft diameter is calculated from the torque corresponding to the strength of the key, for presentation as 1

Note( ) From the values for ℓ given below, which are in the appropriate range in the table, one should be selected.

referential data for general-purpose use. When the key is of an appropriate size relative to the torque to be transmitted, a

The tolerance for l should be h12 under JIS B0401(dimension tolerance and fitting), in principle.

shaft thicker than the applicable shaft diameter may be used. In some cases, t1 and t2 should be adjusted so that a side

6,8,10,12,14,16,18,20,22,25,28,32,36,40,45,50,56,63,70,80,90,100,110,125,140,160,180,200,220,250,280,320,360,400

of the key will come into uniform contact with the shaft and the hub. A shaft narrower than the applicable shaft diameter

Note(2) The appropriate shaft diameter should be matched with the torque corresponding to the strength of the key.

should not be used.

Reference The nominal sizes given in( )should not be used unless they are absolutely necessary.

Reference The nominal sizes given in( )do not conform to the relevant international standard and must not be used in new design.

2857 The groove for the boss should be slanted to 1/100, in principle. 2858

You might also like

- Pages From Toyota Hilux Wiring DiagramsDocument6 pagesPages From Toyota Hilux Wiring DiagramsPoon Electronic Training CentreNo ratings yet

- Uic 505 Rolling StockDocument122 pagesUic 505 Rolling StockJose Saravia75% (4)

- Blind Flange 1,2, Hinge, Handlen & Plug PDFDocument1 pageBlind Flange 1,2, Hinge, Handlen & Plug PDFArief MaulanaNo ratings yet

- JIS B 1301-1996 - Chavetero PDFDocument1 pageJIS B 1301-1996 - Chavetero PDFPablo PasqualiniNo ratings yet

- 010 - Key and Their Corresponding Keyways PDFDocument1 page010 - Key and Their Corresponding Keyways PDFBaguz SaputraNo ratings yet

- Chaveta Norma JISDocument1 pageChaveta Norma JISADP RovalNo ratings yet

- WFBR22F00382-0 - 860 - 6-6 - P5ZL - 35 - Pa - 38 - 10 - ADocument1 pageWFBR22F00382-0 - 860 - 6-6 - P5ZL - 35 - Pa - 38 - 10 - AAlan Miguel PuffNo ratings yet

- Tapcon 230 Expert 6655746 ENDocument2 pagesTapcon 230 Expert 6655746 ENParthiban.PNo ratings yet

- Tapcon 230 Basic 6655745 ENDocument1 pageTapcon 230 Basic 6655745 ENPalash DahakeNo ratings yet

- Blind Flange 1,2, Hinge, Handlen & PlugDocument1 pageBlind Flange 1,2, Hinge, Handlen & PlugArief MaulanaNo ratings yet

- Prestressed Girder Elevation: Bar Bending DiagramDocument1 pagePrestressed Girder Elevation: Bar Bending DiagramMelrose LaforgaNo ratings yet

- Onder Den TorenDocument1 pageOnder Den TorenHarry van LunenburgNo ratings yet

- Braced Cuts: Q Q CN G H1q2 CH B9 CN g1 Q H C B9 HDocument1 pageBraced Cuts: Q Q CN G H1q2 CH B9 CN g1 Q H C B9 HjcvalenciaNo ratings yet

- Ball Rollers (For Upward Facing) : Milled Stainless SteelDocument1 pageBall Rollers (For Upward Facing) : Milled Stainless SteelLộcLộcNo ratings yet

- 0BZ Bosa Britalia 10Document1 page0BZ Bosa Britalia 10genesisbarrockNo ratings yet

- Crankshaft NutDocument1 pageCrankshaft Nutmavas88069No ratings yet

- Razvan 4 AcoperisDocument1 pageRazvan 4 AcoperisMaria MateiNo ratings yet

- Ficha Tecnica Valvula Prueba y DrenajeDocument1 pageFicha Tecnica Valvula Prueba y DrenajeGabino CRNo ratings yet

- Drawing 5 112120141754838Document1 pageDrawing 5 112120141754838k koradiaNo ratings yet

- Pedoman Obat EmergencyDocument10 pagesPedoman Obat EmergencyPOKJA PKPONo ratings yet

- Estructuras Cimientacion: Aula Aprestamiento S.H.V. S.H.MDocument1 pageEstructuras Cimientacion: Aula Aprestamiento S.H.V. S.H.MCarlos MezaNo ratings yet

- Schematic - Regen Radio Experimenal - 2022-07-30Document1 pageSchematic - Regen Radio Experimenal - 2022-07-30nestor.escala7666No ratings yet

- Parallel Keys Parallel Keys: Selectable Dimensions Configurable DimensionsDocument1 pageParallel Keys Parallel Keys: Selectable Dimensions Configurable DimensionsFrandika PrimayogaNo ratings yet

- Kusen Pintu Kayu Type 51 & 61Document3 pagesKusen Pintu Kayu Type 51 & 61Glen SangariNo ratings yet

- Kusen Pintu Kayu Type 51 & 61Document3 pagesKusen Pintu Kayu Type 51 & 61Glen SangariNo ratings yet

- En AX22u-4Document2 pagesEn AX22u-4YakupovNo ratings yet

- Detail Drawing Pipe Vise AzriDocument1 pageDetail Drawing Pipe Vise AzriAdam FitriNo ratings yet

- Tapcon 230 Pro 6787371 ESDocument2 pagesTapcon 230 Pro 6787371 ESHoward LamonNo ratings yet

- Tapcon 230 Basic 6787368 ESDocument1 pageTapcon 230 Basic 6787368 ESMaximiliano SanchezNo ratings yet

- Tapcon 230 Expert 6787385 ESDocument2 pagesTapcon 230 Expert 6787385 ESCristhian SaízNo ratings yet

- This Drawing Is The Property of MIKANO International Limited. and Must Not Be Re Issued, Copied or Reproduced Without Their Consent in WritingDocument2 pagesThis Drawing Is The Property of MIKANO International Limited. and Must Not Be Re Issued, Copied or Reproduced Without Their Consent in WritingXamiPati50% (2)

- Ej Plate A 0420Document1 pageEj Plate A 0420Stefan MilojevicNo ratings yet

- 519-18-TR-2A - 20240405 - 0001 (Commented)Document2 pages519-18-TR-2A - 20240405 - 0001 (Commented)Harish KumarNo ratings yet

- Scanner Infrared 2Document1 pageScanner Infrared 2achil de troyNo ratings yet

- Incidence Map 1111Document1 pageIncidence Map 1111WBKONo ratings yet

- Dimension Tables: Speed Reducer CHH - 613 DA To 618 DADocument1 pageDimension Tables: Speed Reducer CHH - 613 DA To 618 DAsalpa nugrahaNo ratings yet

- Ringfeder Coupling 303 Aus - Info Drawing - 15990007Document1 pageRingfeder Coupling 303 Aus - Info Drawing - 15990007fahrul amirNo ratings yet

- Mas Que Tu Amigo Trombone IDocument2 pagesMas Que Tu Amigo Trombone IEdgardo Mendez GuzmanNo ratings yet

- Đế Vương 1Document4 pagesĐế Vương 1Duy Tính TrầnNo ratings yet

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocument1 pageYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterVictor Ingol LozanoNo ratings yet

- Key Plan:: Symbols & AbbreviationsDocument1 pageKey Plan:: Symbols & Abbreviationsmahmudulalam konokNo ratings yet

- Sigra Sirkuit DiagramDocument147 pagesSigra Sirkuit DiagramKhilmi Ainur Rifqi0% (1)

- Tangent Amp-50-Service-ManualDocument4 pagesTangent Amp-50-Service-ManualRaika ZamboniniNo ratings yet

- 8DJH-427061 SwgGra 20230619134846Document3 pages8DJH-427061 SwgGra 20230619134846Tomislav ProtićNo ratings yet

- Steel Structure Connection DrawingsDocument1 pageSteel Structure Connection DrawingsKavi Arasan0% (1)

- DZX-1051 ADocument2 pagesDZX-1051 AZain UddinNo ratings yet

- Give Thanks FingerstyleDocument1 pageGive Thanks FingerstyleAli SuryaNo ratings yet

- Inventorwizard: Miniature Steam Engine Vertical Steam Engine With Reverse Gear (Anno 1830) Steam Chest 000.010Document1 pageInventorwizard: Miniature Steam Engine Vertical Steam Engine With Reverse Gear (Anno 1830) Steam Chest 000.010Lucas MaccagnanNo ratings yet

- Colibri-Alto SaxDocument1 pageColibri-Alto SaxStephen RiceNo ratings yet

- Connecting RodDocument1 pageConnecting RodCốGắngNàoNo ratings yet

- Post-Classical Review Crossword 2017Document4 pagesPost-Classical Review Crossword 2017api-439999505No ratings yet

- Incidence Map 10182021Document1 pageIncidence Map 10182021Debbie HarbsmeierNo ratings yet

- Ge2100309.Pg017-Pg018 E01.3+r1 132kv Line Tie Bay Protection PanelDocument40 pagesGe2100309.Pg017-Pg018 E01.3+r1 132kv Line Tie Bay Protection PanelFrancis KoomsonNo ratings yet

- BM1-664-M-2013-01 General LayoutDocument1 pageBM1-664-M-2013-01 General LayoutMulia R'n RNo ratings yet

- Teras Elemen: Ervi Dn8HdDocument3 pagesTeras Elemen: Ervi Dn8HdjoegempakNo ratings yet

- Ba - 100 SeriesDocument21 pagesBa - 100 SeriesArtamei WestriNo ratings yet

- Dilermando Reis Noite de Lua1Document7 pagesDilermando Reis Noite de Lua1daniel nogaraNo ratings yet

- CylinderHead RightDocument1 pageCylinderHead RightAlbert AshokNo ratings yet

- Profil Make New Gland Cylinder Boom PC1250SP-8Document1 pageProfil Make New Gland Cylinder Boom PC1250SP-8Ahmad RhamdaniNo ratings yet

- Toyota 3FGC Specs 200 DpiDocument4 pagesToyota 3FGC Specs 200 Dpialanv8No ratings yet

- Toyota 4P PartsDocument51 pagesToyota 4P Partsalanv8No ratings yet

- Same Laser 110 130 150 Workshop ManualDocument420 pagesSame Laser 110 130 150 Workshop Manualalanv8No ratings yet

- Seleccion Chaveteros Norma JIS PDFDocument1 pageSeleccion Chaveteros Norma JIS PDFalanv8No ratings yet

- Catalog Pneumatics Series Power Clamps Arms Asco en 4687134Document56 pagesCatalog Pneumatics Series Power Clamps Arms Asco en 4687134Jorge Luis Reyes VerduzcoNo ratings yet

- ElbDocument5 pagesElbjcunha4740No ratings yet

- Measurement and Instrumentation Theory and Application 2nd Edition Morris Solutions ManualDocument36 pagesMeasurement and Instrumentation Theory and Application 2nd Edition Morris Solutions Manualraymondferguson5259h100% (31)

- Fender SystemsDocument52 pagesFender SystemsMuhammad YasserNo ratings yet

- Astm A0453 PDFDocument8 pagesAstm A0453 PDFndt_inspectorNo ratings yet

- ASTM A416-A416M 17a - Steel StrandDocument5 pagesASTM A416-A416M 17a - Steel StrandEfrain SueldoNo ratings yet

- Overhaul: 1. Inspect Connecting Rod Thrust ClearanceDocument22 pagesOverhaul: 1. Inspect Connecting Rod Thrust ClearanceIslam AttiaNo ratings yet

- EMD 645 Service Manual Sec. 11Document12 pagesEMD 645 Service Manual Sec. 11Elliot CapsonNo ratings yet

- Sylvac Catalogue 2014 en WebDocument221 pagesSylvac Catalogue 2014 en Websava88No ratings yet

- Elevator en PDFDocument11 pagesElevator en PDFMichael FordwuoNo ratings yet

- Carbon Steel Billets, Blooms, Slabs and Bars For Forgings - Specification (Fifth Revision)Document12 pagesCarbon Steel Billets, Blooms, Slabs and Bars For Forgings - Specification (Fifth Revision)SreenathaNo ratings yet

- Is 5986-2011Document14 pagesIs 5986-2011oneakshay100% (1)

- BS 5892-3 1992 Railway Rolling Stock Materials - Part 3 Specification For Monobloc Wheels For Traction and Trailing Stock PDFDocument30 pagesBS 5892-3 1992 Railway Rolling Stock Materials - Part 3 Specification For Monobloc Wheels For Traction and Trailing Stock PDFPhillip Miller100% (1)

- Designing With Rolling Bearings:part1Document52 pagesDesigning With Rolling Bearings:part1Vanessa GomesNo ratings yet

- Deva - Glide enDocument24 pagesDeva - Glide enSavin TimofteNo ratings yet

- Tech Data PDFDocument35 pagesTech Data PDFymsyaseenNo ratings yet

- En 10029Document5 pagesEn 10029manuela vilas boasNo ratings yet

- Stotz - Air-Probes-And-RingsDocument8 pagesStotz - Air-Probes-And-Ringszeybek_144649143No ratings yet

- C170 90 (Reapproved1999) PDFDocument3 pagesC170 90 (Reapproved1999) PDFGie Mak100% (1)

- E1221Document20 pagesE1221LLNo ratings yet

- Is-2048 - Specification For Parallel Keys and KeywaysDocument7 pagesIs-2048 - Specification For Parallel Keys and Keywayssrtools1980y100% (1)

- JIS B 2702 1987, Hot Coiled Helical SpringsDocument9 pagesJIS B 2702 1987, Hot Coiled Helical SpringsMuhammad Zainal MahfudNo ratings yet

- Clampex KTR 603Document9 pagesClampex KTR 603Dario LežaićNo ratings yet

- Formline en 10037927Document20 pagesFormline en 10037927sreenam225254No ratings yet

- IS 4503 (1967) - Shell and Tube Type Heat Exchangers PDFDocument72 pagesIS 4503 (1967) - Shell and Tube Type Heat Exchangers PDFNunoFelipe100% (2)

- Chapter 07 Dimensioning and TolerancingDocument29 pagesChapter 07 Dimensioning and TolerancingThếBãoNo ratings yet

- How To Make Setting Parameter PDFDocument67 pagesHow To Make Setting Parameter PDFanggaNo ratings yet

- CH 5 Casting FundamentalsDocument14 pagesCH 5 Casting FundamentalsSumeet SainiNo ratings yet

- Instruction Manual - Alfa Laval Agitator - Alt - Altb Ese03504en PDFDocument108 pagesInstruction Manual - Alfa Laval Agitator - Alt - Altb Ese03504en PDFMuhammad SyawalNo ratings yet