Professional Documents

Culture Documents

Version 1 Plan: Subject To Updates!: Icon A5 Sport R/C Model

Uploaded by

temich312Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Version 1 Plan: Subject To Updates!: Icon A5 Sport R/C Model

Uploaded by

temich312Copyright:

Available Formats

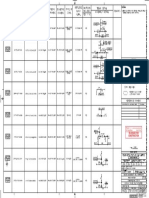

VERSION 1 PLAN: SUBJECT TO UPDATES!

ENGINE COVER TOP

MAKE 1

FUSE MAIN BASE WING TOP PANEL

MAKE 1 MAKE 2

E.C. BASE

MAKE 2

ELEV. SERVO

PLACEMENT

RUDD. SERVO

PLACEMENT

WINGTIP BOTTOM ENGINE COVER SIDE

MAKE 4 MAKE 2

WING

CARBON SPAR PLACEMENT (ARROW SHAFT)-attach to upper side of MAIN WING PANEL - WING TOP PANEL bends over to create airfoil

CG

HULL WING PT.C POINT

WING MAIN PANEL

MAKE 4

MAKE 2

HULL WING PT.B

MAKE 6

FUSE FORMERS

MAKE 2 EACH WING PLATE

HULL WING PART A MAKE 2

F4A F5A

F1A F2A

F3A MAKE 2 ***SECOND WILL BE USED

TO TEST MOTOR THRUST ANGLE

NOSE HATCH COVER TOP SKIN

F1B F2B F3B F4B WHEEL WELL SKIN MAKE 1

F5B F6 AILERON

MAKE 2

FLAP SERVO

SERVO

MAKE 1

PLACEMENT

PLACEMENT

*** TRIM & SAND TO SHAPE

*** TRIM & SAND TO SHAPE

BOTTOM

DOUBLERS D2 D3 D4 D5 D6 HORIZ. STAB SUPPORT

MAKE 2 EA. MOTOR MOUNT MAKE 2

LIGHT PLY

HATCH COVER BOTTOM

MAKE 1

MAKE 3

- 5mm foam (Depapered Dollar Store Foam)

- Wingspan: 40" *** TRIM AND SAND

- Length: 27" (approx) FRONT WING DOWEL REAR WING DOWEL

FOR SNUG FIT INTO FUSE

- Flying Weight: 15-17.5oz

- Motor: 30g 1800KV or similar

- Speed Control: 20A+

M. MOUNT BASE APPROX. LOCATION APPROX. LOCATION

MAKE 1

- Battery: 3s 1300mah

INNER FUSE

- Servos: 4 x 5g (or 9g)

- Carbon Arrow Shaft (0.3" OD

ENGINE POD

- Bamboo Skewers

- 0.125" Light PLY

- Micro flex pushrods

SIDE WALL

SUPPORT BAMBOO SKEWER

OUTTER SIDE FUSE

MAKE 2 FOAM OR BALSA PLACEMENT

MAIN MAKE 2 MAKE 2

SCALE FUSE WALL

THIS SQUARE

SHOULD MAKE 2

MEASURE

2" X 2"

REAR FIN

MAKE 2 BOTTOM HULL CENTER

HULL CENTER SPACER MAKE 2

MAKE 1

BOTTOM HULL SIDE

MAKE 2

ICON A5 SPORT R/C MODEL

HORIZ. STABILIZER DESIGNER: S.WESLEY (SNice)

SNICE's NOTES:

These plans are based on the prototype model which flew (and floated) successfully. They may be updated in the future! MAKE 1 ***build & fly at your own risk***

***for personal use only***

Model flies best when "overpowered". Airframe needs lots of thrust and acceleration to overcome friction/drag on water and sliding takeoffs.

A thrust to weight ratio greater than one gives the best flight performance. Flaps are not necessary but are highly reccomended.

They allow the wing to generate lots o' lift at slower speeds - trust me, you will want it!

About 0.125" of up deflection on each aileron is recommended to ward off tip stalls.

Overall, this model performs beautifully and was much more aerobatic, fast, and fun than I had anticipated!

I hope you have a successful build and I hope you have as much fun with yours as I am having with mine!

Check out WWW.SNICERC.COM for pics, videos, and additional info about this model!

WATERPROOFING THE MODEL:

Still trying to determine the best method, but here is how I did mine. It added

extra weight but resulted in a waterproof hull. Finished model was painted with

FOR BUILD INFO AND MORE FREE PLANS VISIT:

WWW.SNICERC.COM

several coats of acrylic paint. Acrylic clear coat was then applied to entire model.

2 coats on the Hull and nose of the plane. Finally, several LIGHT coats of RUSTOLEUM

CLEAR coat were sprayed on. DO NOT apply to bare foam as it will melt it away!

You might also like

- The Art of RevengeDocument5 pagesThe Art of RevengePricilla SaulsNo ratings yet

- Fan walkthrough covers story updatesDocument5 pagesFan walkthrough covers story updatesJamal Kazmi100% (2)

- Produced by An Autodesk Student Version: Front Elevation Cottage 4Document1 pageProduced by An Autodesk Student Version: Front Elevation Cottage 4JOSEPHNo ratings yet

- P4 Gad 1Document1 pageP4 Gad 1yogendraNo ratings yet

- Shalini Dosaj LandscapeDocument21 pagesShalini Dosaj Landscapehamayoun_mNo ratings yet

- Lighting Plan 1ST FloorDocument1 pageLighting Plan 1ST FloorFauzi Imam HidayatNo ratings yet

- Replace Runway Airfield Lighting: Construction PlansDocument51 pagesReplace Runway Airfield Lighting: Construction PlansYosef ChabudNo ratings yet

- Storm Drainage DetailsDocument1 pageStorm Drainage DetailsCivil Design EngineerNo ratings yet

- Room FinishDocument1 pageRoom FinishAneeq MustafaNo ratings yet

- 092-26-0002-3-08 - Utilities Pipe Bridge Plan & ElevationDocument1 page092-26-0002-3-08 - Utilities Pipe Bridge Plan & ElevationDon Joseph Rene OmandacNo ratings yet

- Access Control and CCTV Equipment LegendDocument1 pageAccess Control and CCTV Equipment LegendHardiNo ratings yet

- DFC-LWD-DC059-SJ-DRG - 230203 Rev.01Document1 pageDFC-LWD-DC059-SJ-DRG - 230203 Rev.01amrNo ratings yet

- Akai MPC4000 Service ManualDocument54 pagesAkai MPC4000 Service ManualPatricio PintoNo ratings yet

- LoveDocument1 pageLoveImee Kassandra Estomo CachoNo ratings yet

- Lift Controller: Digital DisplayDocument20 pagesLift Controller: Digital DisplayNazar AbbasNo ratings yet

- 1Document1 page1Jen AgabinNo ratings yet

- Section 1.0 Typical AMF PANEL Application WiringDocument2 pagesSection 1.0 Typical AMF PANEL Application WiringMAYUR GENSET100% (4)

- 4z2up-Ps-0067 A3 02Document1 page4z2up-Ps-0067 A3 02nguyen hai vanNo ratings yet

- Engine Controls (Powertrain Management)Document4 pagesEngine Controls (Powertrain Management)Alejandro Quiñones VelazquezNo ratings yet

- Pioneer VSX 517 K S SMDocument92 pagesPioneer VSX 517 K S SMSaulvcr64 PorleyNo ratings yet

- SITE PLAN-mergedDocument12 pagesSITE PLAN-mergedMeet MakwanaNo ratings yet

- Toggle Select Wire Mode Hide All Non Selected Wires Clear Selection Select Color Search Text PrintDocument2 pagesToggle Select Wire Mode Hide All Non Selected Wires Clear Selection Select Color Search Text PrintFelix Velasquez100% (2)

- MTK4110-1509- PM-1 SIDE VIEW GENERAL ASSEMBLY( FINAL) upd 24 july 2018Document1 pageMTK4110-1509- PM-1 SIDE VIEW GENERAL ASSEMBLY( FINAL) upd 24 july 2018delvi.panjaitan097No ratings yet

- Gecko203v WiringDocument1 pageGecko203v WiringKenny HebertNo ratings yet

- 4-5Document1 page4-5Jen AgabinNo ratings yet

- LG TV 32lc7d-AbDocument98 pagesLG TV 32lc7d-AbJamesnov70No ratings yet

- MiG-23 Flogger Plans v1.0 in PDFDocument2 pagesMiG-23 Flogger Plans v1.0 in PDFFahim Le MajesticNo ratings yet

- Techwood ManualDocument31 pagesTechwood ManualStacy CamarataNo ratings yet

- YSS SUSPENSION UPGRADES FOR APRILIA SCOOTERSDocument22 pagesYSS SUSPENSION UPGRADES FOR APRILIA SCOOTERSRt OpNo ratings yet

- 2007 Lefty Speed dlr2 SL rp23 Headshok 2007 Setup Guide enDocument2 pages2007 Lefty Speed dlr2 SL rp23 Headshok 2007 Setup Guide enJosé BerenguerNo ratings yet

- Lundin Street: Parking AreaDocument1 pageLundin Street: Parking Arearizki rosidiNo ratings yet

- WELD MAP ATAD 03 11 2021 (Chuan) - For 21250415 (Recovered)Document1 pageWELD MAP ATAD 03 11 2021 (Chuan) - For 21250415 (Recovered)Tâm TrầnNo ratings yet

- Contrast Music Production Center ManualDocument54 pagesContrast Music Production Center ManualFrancisco Rodriguez MartinezNo ratings yet

- A B C D E: Model: em 349 Description: TV CabinetDocument1 pageA B C D E: Model: em 349 Description: TV CabinetPana ChriNo ratings yet

- 1999 System Wiring Diagrams. Chevrolet - SuburbanDocument1 page1999 System Wiring Diagrams. Chevrolet - SuburbanJimmy Perera BurgosNo ratings yet

- Lighting Layout Plan 083 106Document23 pagesLighting Layout Plan 083 106Kyaw Myo ThetNo ratings yet

- TB135483 008 00F1Document1 pageTB135483 008 00F1Rene HebaNo ratings yet

- Hospital Block: Key PlanDocument1 pageHospital Block: Key PlanKripa SriramNo ratings yet

- Bertyl-7 PDFDocument1 pageBertyl-7 PDFKripa SriramNo ratings yet

- Opt Nissan 3Document4 pagesOpt Nissan 3YduR ZurCNo ratings yet

- 2Document1 page2Jen AgabinNo ratings yet

- Floor Plans For New Reading Fire Station in The 900 Block of Penn StreetDocument2 pagesFloor Plans For New Reading Fire Station in The 900 Block of Penn StreetReading EagleNo ratings yet

- Location of BoardDocument1 pageLocation of BoardjeffreyinfantedulayNo ratings yet

- M Ặt Bằng Sàn Hoàn Thi Ện Tầng Thượng: Penthhouse 02Document1 pageM Ặt Bằng Sàn Hoàn Thi Ện Tầng Thượng: Penthhouse 02Hoàng NamNo ratings yet

- Lay Out ProduksiDocument1 pageLay Out ProduksiMuhammad FaizalNo ratings yet

- Site Modification: Bill of MaterialDocument1 pageSite Modification: Bill of MaterialRaziKhanNo ratings yet

- ROOFTOPDocument1 pageROOFTOPJen AgabinNo ratings yet

- Hold Class 2: 102B15 - W21X68 - 29'-10 1/2" - ONE REQ'D CAMBER 3/4"Document1 pageHold Class 2: 102B15 - W21X68 - 29'-10 1/2" - ONE REQ'D CAMBER 3/4"ai ambaraNo ratings yet

- Combine PDFDocument6 pagesCombine PDFJake BenliroNo ratings yet

- Proposed two-storey commercial building and warehouse floor plansDocument1 pageProposed two-storey commercial building and warehouse floor plansJan GarciaNo ratings yet

- Mitra: Front View (Door Removed) Front View Front View (Cover Removed)Document15 pagesMitra: Front View (Door Removed) Front View Front View (Cover Removed)Denzo RyugaNo ratings yet

- Yak-130 MJ 5-inch model plane assembly guideDocument1 pageYak-130 MJ 5-inch model plane assembly guideAlejandro Lablée0% (2)

- Yak-130 MJ 5-inch model plane assembly guideDocument1 pageYak-130 MJ 5-inch model plane assembly guideHuascar CandiaNo ratings yet

- Toaz - Info Yak 130 PRDocument1 pageToaz - Info Yak 130 PRPaul DanielNo ratings yet

- Planning FPT CHC 06 Juli 2023 DayDocument1 pagePlanning FPT CHC 06 Juli 2023 DayDoniNo ratings yet

- 1 Front Elevation 2 Left Side Elevation 5 Longitudinal SectionDocument1 page1 Front Elevation 2 Left Side Elevation 5 Longitudinal SectionJan Emilyn Chavez CatindigNo ratings yet

- On Rollbar: Sun DeckDocument1 pageOn Rollbar: Sun DeckMamdouh SalahNo ratings yet

- 11 181000 4800000121 RGF SRV DRG 100220 - 02Document1 page11 181000 4800000121 RGF SRV DRG 100220 - 02ahmad.suliman.saeedNo ratings yet

- Power plant site layout and detailsDocument1 pagePower plant site layout and detailsJohn Phillip Lopez MasagcaNo ratings yet

- P - 1 - Musngi Res - BPDocument1 pageP - 1 - Musngi Res - BPJanine PalecNo ratings yet

- THC124 - Lesson 1. The Impacts of TourismDocument50 pagesTHC124 - Lesson 1. The Impacts of TourismAnne Letrondo Bajarias100% (1)

- A History of Linear Electric MotorsDocument400 pagesA History of Linear Electric MotorseowlNo ratings yet

- 02 Lightning Rods and AccessoriesDocument78 pages02 Lightning Rods and Accessoriesmoosuhaib100% (1)

- Maam Approve Na Pls HuhuDocument28 pagesMaam Approve Na Pls HuhuErica Joy Escopete100% (1)

- Goethe Zertifikat b1 HorenDocument2 pagesGoethe Zertifikat b1 HorenLevent75% (4)

- Kütahya between the Lines: Uncovering Historical Insights from Post-Medieval CeramicsDocument24 pagesKütahya between the Lines: Uncovering Historical Insights from Post-Medieval Ceramicslatinist1No ratings yet

- Christopher Westra - Laws of Attraction PDFDocument3 pagesChristopher Westra - Laws of Attraction PDFZachary LeeNo ratings yet

- PRESSURE VESSEL Handbook - Eugene F. Megyesy 12th 2001Document501 pagesPRESSURE VESSEL Handbook - Eugene F. Megyesy 12th 2001vamcodong71% (7)

- Meluha-The Fern Hotel Sustainability ProgramDocument7 pagesMeluha-The Fern Hotel Sustainability Programbushra sayyadNo ratings yet

- Secu Gen Hamster Pro 20Document2 pagesSecu Gen Hamster Pro 20Ashish GusainNo ratings yet

- WMS INFINEON PROJECT TOWER (11Kv VCB INSTALLATION) - REV-1Document5 pagesWMS INFINEON PROJECT TOWER (11Kv VCB INSTALLATION) - REV-1tana100% (1)

- ID26Document21 pagesID26Ashish BaidyanathanNo ratings yet

- Four Pillars of EducationDocument42 pagesFour Pillars of EducationWinter BacalsoNo ratings yet

- The Secret Science of Shaktipat - Guide To Initiation 13 September 2020Document77 pagesThe Secret Science of Shaktipat - Guide To Initiation 13 September 2020Patrick JenksNo ratings yet

- How To Critique A Photograph - Facebook PDFDocument1 pageHow To Critique A Photograph - Facebook PDFpeterNo ratings yet

- Trisomy 21 An Understanding of The DiseaseDocument28 pagesTrisomy 21 An Understanding of The DiseaseHannahjane YbanezNo ratings yet

- Bharathidasan University UG/PG Exam ApplicationDocument2 pagesBharathidasan University UG/PG Exam ApplicationOppili yappanNo ratings yet

- CBSE Class 10 Science Revision Notes Chapter - 2 Acids, Bases and SaltsDocument11 pagesCBSE Class 10 Science Revision Notes Chapter - 2 Acids, Bases and Saltsmilind dhamaniyaNo ratings yet

- Project management software enables collaborationDocument4 pagesProject management software enables collaborationNoman AliNo ratings yet

- PDA Technical Documents on Sterilization ProcessesDocument3 pagesPDA Technical Documents on Sterilization ProcessesManas MishraNo ratings yet

- MPMC All Questions and AnswerDocument6 pagesMPMC All Questions and AnswerMODERN TELUGAMMAYINo ratings yet

- 1866 Lee Animal Magnetism and Magnet Lucid SomnambulismDocument354 pages1866 Lee Animal Magnetism and Magnet Lucid SomnambulismtvosNo ratings yet

- Acer Aspire 4535 (Compal LA-4921P) PDFDocument57 pagesAcer Aspire 4535 (Compal LA-4921P) PDFMustafa AkanNo ratings yet

- Enscape Tutorial GuideDocument27 pagesEnscape Tutorial GuideDoroty CastroNo ratings yet

- Mobile Assisted Language Learning (MALL) Describes An Approach To Language LearningDocument7 pagesMobile Assisted Language Learning (MALL) Describes An Approach To Language Learninggusria ningsihNo ratings yet

- German Companies in RwandaDocument6 pagesGerman Companies in RwandaTabitha KaraniNo ratings yet

- Economics Principles and Policy 13th Edition Baumol Solutions ManualDocument2 pagesEconomics Principles and Policy 13th Edition Baumol Solutions ManualCraigGonzalezaxzgd100% (17)

- Strategic Marketing Plan for British American TobaccoDocument31 pagesStrategic Marketing Plan for British American TobaccoAli Abbas50% (2)

- Cell Organelles 11Document32 pagesCell Organelles 11Mamalumpong NnekaNo ratings yet

- Fundamentals of Computer Hardware NotesDocument7 pagesFundamentals of Computer Hardware NotesSreemoyee RoyNo ratings yet