Professional Documents

Culture Documents

Quick Programming Switch Mode DTS 512 624 1.9 1.3

Quick Programming Switch Mode DTS 512 624 1.9 1.3

Uploaded by

Francois VaaltynOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quick Programming Switch Mode DTS 512 624 1.9 1.3

Quick Programming Switch Mode DTS 512 624 1.9 1.3

Uploaded by

Francois VaaltynCopyright:

Available Formats

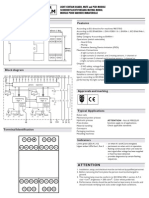

Quick program sheet for DTS 512/624

Dipswitch selections to activate a function.

Dipswitch 1 - Set up.

2 - Motor direction. (Closing left OFF, Closing right ON).

3 - Auto close.

4 - Condominium mode.

5 - P.I.R.A.C. mode

6 - Slow down distance change

PROGRAMING

Run Time Setup (This will automatically happen when triggered after TOTAL power up.)

1) Select and change dipswitch 2 & 6 were applicable.

2) Gate approximately 1metre open.

3) Push and release BT/SET button.

4) Gate will close, open and close again and stop on close limit.

5) Control card will beep twice to confirm end of run time setup.

NOTE: If gate opens first, dipswitch number 2 is wrongly selected.

Auto close (Default 10 seconds) (Infra red beams must be fitted if auto close is activated).

1) Switch Dipswitch 1 and 3 on.

2) Leave dipswitch 2 were it is but put all other dipswitches OFF.

3) Press & hold BT/SET button.

4) PCB will Beep (1 Beep = 1 Sec)

5) Release BT/SET button at required auto close time (Max. 4 minutes).

6) Switch Dipswitch 1 and 3 off.

7) Switch Dipswitch 3 back on to activate the auto close.

Pedestrian Opening (Default 1 meter / 10 seconds auto close).

1) Switch Dipswitch 1 and 4 on.

2) Leave dipswitch 2 were it is but put all other dipswitches OFF.

3) Gate should be in closed position.

4) Press & Release BT/SET Button.

5) Gate will open.

6) Press & release BT/SET button to stop gate at required pedestrian opening distance.

7) Press & Hold BT/SET button to program auto close time required.

8) Control card will Beep (1 Beep = 1 Sec)

9) Release BT/SET button at required pedestrian auto close time (Max. 2 minutes).

10) Switch Dipswitch 1 and 4 off.

11) Gate will close again.

To reset factory default

1) Remove all power.

2) Press and hold BT/SET button, while holding the BT/SET button, re-apply power, AC and DC.

3) With power re-applied, release BT/SET button.

4) PCB will beep to confirm factory default being restored.

Load setting

To adjust the load, turn the provided load pot to determine the load setting (Minimum, anticlockwise and

Maximum clockwise). The control card will beep 1 - 5 beeps on first trigger.

Members L.A Schmidt; M.S Schmidt

ON BOARD RECEIVER PROGRAMING

The onboard receiver is designed to work with most rolling code transmitters.

PROGRAMMING TRANSMITTERS PROGRAMMING TRANSMITTERS

FOR FULL OPENING –BT/Lrn FOR PEDESTRIAN OPENING -PD/Lrn

1. Push the Bt Lrn button, the RX 1. Push the Pd Lrn button, the

led will go on. RX led will go on.

2. Push the required button on the 2. Push the required button on the

transmitter, at arms length from transmitter, at arms length from

PCB once, the Rx led will flash. PCB once, the Rx led will flash.

Press the same button again, Press the same button again, and the

and the PCB will emit 3 beeps PCB will emit 3 beeps for a full

for a full Keelog transmitter or Keelog transmitter or 2 beeps for

2 beeps for other transmitters. other transmitters.

3. Repeat Step 1 and 2 for 3. Repeat Step 1 and 2 for

additional transmitters. Up to 31 additional transmitters. Up to 31

transmitters can be programmed transmitters can be programmed as a

as a joint combination between joint combination between

BT and PD. BT and PD.

The button used for BT Lrn CANNOT be used for Pd Lrn and vice versa.

To erase a button from the receiver, in case of incorrect programming i.e. blue button should be for

BT/Lrn and not PD/Lrn.

Simply push and hold the BT/Lrn or the PD/Lrn for 5 seconds, the board will give 1 beep. Then push

the button you want to erase, the board will give 2 beeps as confirmation. That button is then erased

and can be learned into the correct input.

To master erase:

Push and hold the BT/Lrn or the PD/Lrn button, after 5 seconds the board with give 1 beeps. Keep

holding for another 10 seconds then the board will give 2 beeps.

All transmitters will now be erased.

Members L.A Schmidt; M.S Schmidt

PCB Control card.

Beam option jumper for N/O or N/C beams

500 m/Amp AUX. 2 Amp AC self-resettable fuse.

self-resettable fuse.

NOTE: With the infra-red beam option pins not bridged the PCB operates as N/O beams.

. With the option jumper bridged the PCB operates as N/C beams. (Fail safe mode).

NB – When connecting intercoms to the control card (IT and CMN), please ensure that your

intercom trigger output is potential free (ZERO voltage). If not, a gate relay module

must be fitted.

Members L.A Schmidt; M.S Schmidt

List of audio indications and warnings.

One continuous beep - PCB is damage, replace PCB.

One 1.5 second beep - “Party mode” has been activated.

One 2 second beep - Factory defaults have been set.

One 2 second beep - Beams are incorrectly wired or faulty when

programming the motor. or

Runtime was aborted for whatever reason.

One 3 second beep - Holiday lockout mode has been activated.

One 3 second beep - Gate triggered when motor is in 3 minute overload

lockout.

Two 400 ms beeps - Run time programming (calibrating) has been

successful.

Two 1 second beeps - Pedestrian mode was activated.

or No AC power is present, running battery power only.

Three 200ms beeps - Battery power is too low, or

Override function is open or faulty.

Four 100ms beeps - Motor is in holiday lockout.

Four 200ms beeps - Check motor/load fuse (512/25amp or 624/10amp).

- Check motor brushes and armature.

- PCB reader not picking up Magnet on motor.

Five 1 second beeps - Holiday lockout mode has been de-activated.

Twenty 100ms beeps - Motor has stalled or overloaded, then check the

following points:

1) Gate pulling force (should not exceed 512/12.5kg or

624/15kg)

2) Load pot is set too low (Turn pot completely

clockwise)

3) Battery voltage under load (512/12volt or

624/24volt) (Not connected)

4) Gearbox gearwheel.

List of LED indications.

- LED ON when open limit is activated. (gate open).

- LED OFF when close limit is activated. (gate closed).

- LED flashing SLOW (1 sec. on/1 sec. off) (gate is in motion).

- LED flashes 2 long/3 short continuously (gate is stopped midway).

- LED flashes fast (250ms on/250ms off) continuously. (gate in overload).

- LED flashes 3 fast flashes every 1.5 seconds. (battery low, <11/22VDC).

- LED flashes 1 slow/2 fast continuously. (NO 220 VAC power present).

FOR SAFETY REASONS.

Infra-red beams are recommended for

all gate motor installations.

Members L.A Schmidt; M.S Schmidt

You might also like

- Ignition System Honda CITY IDSIDocument12 pagesIgnition System Honda CITY IDSImuhammad nazir100% (3)

- Funcionamento Dos Motores Volvo Penta D1-2-3-4-6Document90 pagesFuncionamento Dos Motores Volvo Penta D1-2-3-4-6Hugo Soberano100% (8)

- Figure 1: 40A BLDC ESC Form NEX RoboticsDocument9 pagesFigure 1: 40A BLDC ESC Form NEX RoboticsAnonymous NAEIo74FNo ratings yet

- DSE Installation 800+ FE Car Remote Start Keyless Entry AlarmDocument6 pagesDSE Installation 800+ FE Car Remote Start Keyless Entry Alarmi_lov2xlr8100% (2)

- Manual Servei Motor QJDocument166 pagesManual Servei Motor QJJesús García Pérez100% (1)

- Epsilon EP 500 - Medicare Xray MachineDocument10 pagesEpsilon EP 500 - Medicare Xray MachineJoseph SsaliNo ratings yet

- Quick Program Sheet For DTS 500 Expert.: ProgrammingDocument5 pagesQuick Program Sheet For DTS 500 Expert.: ProgrammingFrancois VaaltynNo ratings yet

- Dts Eco 500: Sliding Gate Motor Installation ManualDocument8 pagesDts Eco 500: Sliding Gate Motor Installation ManualFrancois VaaltynNo ratings yet

- Dts Eco 500: Sliding Gate Motor Installation ManualDocument8 pagesDts Eco 500: Sliding Gate Motor Installation ManualFrancois VaaltynNo ratings yet

- Sliding Gate Motor Installation Manual: DTS 500 ExpertDocument15 pagesSliding Gate Motor Installation Manual: DTS 500 ExpertAndrás TóthNo ratings yet

- HW25A30ADocument2 pagesHW25A30AclauderayNo ratings yet

- Manual of RC Timer ESC 30A Brushless Motor Speed Controller: SpecificationDocument6 pagesManual of RC Timer ESC 30A Brushless Motor Speed Controller: SpecificationsempaktelesNo ratings yet

- Powertech Pc160 Manual enDocument8 pagesPowertech Pc160 Manual enenriquevazquez27No ratings yet

- Variador HK 18ADocument3 pagesVariador HK 18AcachitNo ratings yet

- Model C-320Document12 pagesModel C-320carmenlove123No ratings yet

- 30A BLDC ESC Product Manual PDFDocument9 pages30A BLDC ESC Product Manual PDFPePe Eduardo Mendoza EstradaNo ratings yet

- HW 01 V4Document3 pagesHW 01 V4soulotmagic100% (1)

- Musicomlab Lite 6M Manual - Rev10e - 1Document7 pagesMusicomlab Lite 6M Manual - Rev10e - 1albin21No ratings yet

- Manual of RC Timer ESC 30A Brushless Motor Speed Controller: SpecificationDocument6 pagesManual of RC Timer ESC 30A Brushless Motor Speed Controller: SpecificationImran AhmadNo ratings yet

- Controleur QUATRO Not-3 + HUBDocument3 pagesControleur QUATRO Not-3 + HUBPouilly EricNo ratings yet

- Electronic Speed ControlDocument3 pagesElectronic Speed ControlGaneshkumar Krishna ShettyNo ratings yet

- Avionic User Manual For Aircraft Esc Ver2Document2 pagesAvionic User Manual For Aircraft Esc Ver2nopeNo ratings yet

- ICARO InstallDocument7 pagesICARO InstallAdrian MandoleseNo ratings yet

- Assembly Instructions and TipsDocument8 pagesAssembly Instructions and TipsDavid ClrNo ratings yet

- PC160 Merik Home Access Home DepotDocument8 pagesPC160 Merik Home Access Home DepotIsaac SantoyNo ratings yet

- DWB100het en PhpnWwESrDocument2 pagesDWB100het en PhpnWwESrLuis Alberto MayorNo ratings yet

- 30A BLDC ESC Product ManualDocument9 pages30A BLDC ESC Product Manualnguyenanht334No ratings yet

- Ppa Central Facility ConnectDocument15 pagesPpa Central Facility ConnectgustavoNo ratings yet

- ESC - PDF Dot Dash SequenceDocument3 pagesESC - PDF Dot Dash SequenceAl-Hafiz Ahmad FikryNo ratings yet

- Datakom-Dkm0224 Nfpa110Document11 pagesDatakom-Dkm0224 Nfpa110Minn Thet NaingNo ratings yet

- Hornet Airplane ESC User Manual: FeaturesDocument4 pagesHornet Airplane ESC User Manual: FeaturesKurohaRukaNo ratings yet

- Alinco DJ-S41 70cm Transceiver PDFDocument4 pagesAlinco DJ-S41 70cm Transceiver PDFQuasiNo ratings yet

- E606se Om 2Document16 pagesE606se Om 2YéretzianNo ratings yet

- NUX MG-30 Versatile Modeler User Manual: Manuals+Document11 pagesNUX MG-30 Versatile Modeler User Manual: Manuals+JasperMelNo ratings yet

- Orangerx Taranis Manual 4Document6 pagesOrangerx Taranis Manual 4Demon KingNo ratings yet

- Ac1u ControlcardDocument9 pagesAc1u ControlcardJustin'e Christopher RankinNo ratings yet

- Manual ANFIMDocument12 pagesManual ANFIMdiego.fuegotostadoresNo ratings yet

- My TBS - Micro - V2.0 - E - TBS Micro ManualDocument13 pagesMy TBS - Micro - V2.0 - E - TBS Micro ManualAnkh TharaNo ratings yet

- DJ s41Document4 pagesDJ s41mdc2013No ratings yet

- Sony CDP-SP55 PDFDocument28 pagesSony CDP-SP55 PDFvideoson100% (1)

- BMC048 Single RhythmDocument5 pagesBMC048 Single RhythmMaarfy CZNo ratings yet

- Hyt Tc-518 Service ManualDocument59 pagesHyt Tc-518 Service Manualyd2oyd100% (1)

- Solidremote 402uDocument32 pagesSolidremote 402uimagex5No ratings yet

- TC600Document69 pagesTC600kris.kulmannNo ratings yet

- Rct100 Rt601 ManualDocument4 pagesRct100 Rt601 ManualVolintiru ConstantinNo ratings yet

- Kapija BenincaDocument5 pagesKapija BenincaMica Ivanovic100% (1)

- Manual JVC Kd-s6060Document0 pagesManual JVC Kd-s6060Juan José Mazo MercaderNo ratings yet

- AC6 Dual Motor Controller Instruction ManualDocument10 pagesAC6 Dual Motor Controller Instruction ManualderbalijalelNo ratings yet

- LRX 2102R ++ GBDocument5 pagesLRX 2102R ++ GBbrunozoNo ratings yet

- INTELLIswitch993 Instruction SheetDocument2 pagesINTELLIswitch993 Instruction SheetsegasharkNo ratings yet

- A-82 D48UHF Service MannuelDocument42 pagesA-82 D48UHF Service MannuelArnaldo AguilarNo ratings yet

- AudioSonic CL-1482 WekkerradioDocument29 pagesAudioSonic CL-1482 WekkerradiomiraNo ratings yet

- R52.User Manual 1 of 2 1042518Document24 pagesR52.User Manual 1 of 2 1042518DashaTechNo ratings yet

- CPS GRCP-User Manual-Oct 2008Document18 pagesCPS GRCP-User Manual-Oct 2008Nur DiphylleiaNo ratings yet

- TC 21gx20m MalaysiaDocument29 pagesTC 21gx20m MalaysiaChandan Tripathi100% (4)

- Ab MSR22LM PsdiDocument12 pagesAb MSR22LM PsdichnanduNo ratings yet

- D1 Swing Gate Control Board ManualDocument9 pagesD1 Swing Gate Control Board ManualjohnNo ratings yet

- st-045-09 York Utec Furnace BoardsDocument8 pagesst-045-09 York Utec Furnace BoardsMarvin NerioNo ratings yet

- STR WX7Document44 pagesSTR WX7wayne5994No ratings yet

- JVC KD-SX990Document45 pagesJVC KD-SX990stevehamm2No ratings yet

- Mi-8 - Normal Procedures v3Document34 pagesMi-8 - Normal Procedures v3Miles DeiNo ratings yet

- Digital LED Thermometer with Microcontroller AVR ATtiny13From EverandDigital LED Thermometer with Microcontroller AVR ATtiny13Rating: 5 out of 5 stars5/5 (1)

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- Bi-Power Relays LY DatasheetDocument21 pagesBi-Power Relays LY DatasheetcoronaqcNo ratings yet

- Accelerometer: 1 Conical Angle 90°Document2 pagesAccelerometer: 1 Conical Angle 90°dungdhtsNo ratings yet

- 2 Soil Test Result at ParoleumDocument10 pages2 Soil Test Result at ParoleumWinNo ratings yet

- DL Models AccessoriesDocument3 pagesDL Models AccessoriesMarek MarekovicNo ratings yet

- ST121 Over-Temperature TripDocument2 pagesST121 Over-Temperature TripDave Walker100% (1)

- Starting Methods of Induction MotorsDocument8 pagesStarting Methods of Induction MotorsChathuranga Nagasinghe100% (1)

- Halo Lighting Power Trac Lighting Catalog 1977Document40 pagesHalo Lighting Power Trac Lighting Catalog 1977Alan Masters100% (1)

- Notes:-: Structural ConsultantsDocument1 pageNotes:-: Structural ConsultantsHarbhajan SinghNo ratings yet

- RSTEEL RPS Balcony Hinges Brochure ENDocument3 pagesRSTEEL RPS Balcony Hinges Brochure ENBaraa IsmailNo ratings yet

- Siemer Technologies: Pages: 1 of 2Document2 pagesSiemer Technologies: Pages: 1 of 2sivaNo ratings yet

- Topic 4 (Part 1)Document29 pagesTopic 4 (Part 1)Azib HamizanNo ratings yet

- Fountain: Date: 08-Apr-18Document20 pagesFountain: Date: 08-Apr-18MikhaelA.RodriguezNo ratings yet

- Service Bulletin: Fuel Injection PumpDocument14 pagesService Bulletin: Fuel Injection PumpKrunoslav100% (1)

- VATER Elgate Fence & Gate Systems INFO List JULY19Document6 pagesVATER Elgate Fence & Gate Systems INFO List JULY19GarryNo ratings yet

- Electrical Circuit R934C To R954CDocument24 pagesElectrical Circuit R934C To R954CDaniel Vilches100% (1)

- S14 SR20DET ECU PinoutDocument1 pageS14 SR20DET ECU Pinoutpedda meierNo ratings yet

- (Susol Compact ACB) Catalog en 202010Document92 pages(Susol Compact ACB) Catalog en 202010raiNo ratings yet

- Service Manual: Mcculloch Chain Saw - Ms1436NavDocument17 pagesService Manual: Mcculloch Chain Saw - Ms1436NavRobNo ratings yet

- Material For Timber Roof TrussDocument12 pagesMaterial For Timber Roof TrussSitche ZisoNo ratings yet

- FINAL Data 2018-19 20-06-018. FINALDocument350 pagesFINAL Data 2018-19 20-06-018. FINALjeyaramakrishnan ramasubramanian100% (1)

- Circuit Breaker ComponentsDocument14 pagesCircuit Breaker ComponentsShrikant KajaleNo ratings yet

- Hensel Price List 2021Document24 pagesHensel Price List 2021Ashish MahapatraNo ratings yet

- Adapun Analisis Data Pada Pengukuran Multimeter Analog Dan DigitalDocument4 pagesAdapun Analisis Data Pada Pengukuran Multimeter Analog Dan Digitaltuti suoriyantiNo ratings yet

- 1994-1997 Audi A6 (C4) Fuse Box DiagramDocument9 pages1994-1997 Audi A6 (C4) Fuse Box DiagramAlberto MiglinoNo ratings yet

- Rho3 Section7 CommissioningDocument5 pagesRho3 Section7 CommissioningvenkateshbitraNo ratings yet

- Elctricidad Starter AlternaterDocument15 pagesElctricidad Starter AlternaterFredy ReyesNo ratings yet