Professional Documents

Culture Documents

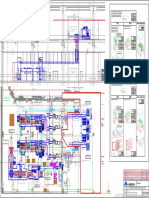

Światło Otworu 285x267cm: 0,00 100,90m N.P.M. 0,00 100,90m N.P.M

Uploaded by

Raffaele ConternoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Światło Otworu 285x267cm: 0,00 100,90m N.P.M. 0,00 100,90m N.P.M

Uploaded by

Raffaele ConternoCopyright:

Available Formats

+16,47

+15,91 +15,91

565

565

275

275

Tarczyński Naturalnie Parówki 160g

Tarczyński Naturalnie Parówki 200g

5

NamePlastic Tray 160g

80

80

Tarczyński Parówki Szynka 220g SK

I

Packaging Type Plastic Tray

ZYN

Tarczyński Parówki Kurczak 180g TA

RC H= 19 mm Nominal Speed (ppm)

Max Speed (ppm) 168.0

180 0 Orientation Flat

+13,62 16 Side Leading Short

Facing UP

+13,32 F01 F02

Customer format ref. 1 Customer format ref. 6

607

607

Customer format ref. 2 Customer format ref. 7

Customer format ref. 3

Customer format ref. 4

4000

Światło otworu

285x267cm

OUTER FOLDED AND GLUED FLAP

L 10 L 3

37 1 1855 25 4 773

Configuration W 1 Configuration W 2

H 1 H 8

+8,75 +8,75 TOT 10 TOT 48

Orientation Standing Orientation Flat

TA

H=1790

RC

ZY

61

Name C01 Name C02

62

NS

KI

200

Packaging Type Tray+Lid (outer) Packaging Type Tray+Lid (outer)

Nominal Speed (ppm) Nominal Speed (ppm)

73

+8,14 +8,14 0

Max Speed each machine 400 60 Max Speed each machine 3,5

(ppm) 16.8 (ppm)

Orientation Flat Orientation Flat

Side Leading Short Side Leading Short

+7,40 +7,40 +7,40 Facing UP

PLASTIC BOXES WITHOUT

SEPARATOR INSIDE

Facing UP

+7,18

+6,12 +6,12

NO GLUE APPLICATION BETWEEN TRAY/LID

+6,00 +6,00

197 E.D.

BA

FRO CK

NT S IDE

SID

814

740

.D.

17

9E 7E

.D. 23

LABEL APPLICATION

6000

3178

INTERLAYER (6/7)

3943

Światło otworu

285x260cm

2850

1600

37 1 815 1 483 10 574

1750

INTERLAYER (2/3)

1576

1726

37 3 298 10 INTERLAYER (0/1)

765

±0,00=100,90m n.p.m. ±0,00=100,90m n.p.m.

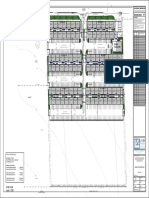

X Series seireS X

L 5

H=1790

L 2

W 4

110

110

110

Configuration Configuration W 2

-1,10 -1,10 -1,10 -1,10 H 8 H 8

TOT 160 TOT 32

MAXIMUM TOTAL PRODUCTION: 12.6 pallet/h Orientation FLAT MAXIMUM TOTAL PRODUCTION: 13 pallet/h

Orientation Flat

24695 Tarczyński Parówki FamilyPack 440g

Plastic Tray

Name 400g

Marke

I Packaging Type Plastic Tray

SK H= 37 mm

YN

CZ

T AR Nominal Speed (ppm)

Max Speed (ppm) 100.0

450

180 ,4

158 Orientation Flat

Side Leading Short

Facing UP

3240

3562

MANUAL INFEED FOR

±0,00

COMPLETE PALLET OF

EMPTY PLASTIC BOXES F03 F04

REI 240

EMPTY PLASTIC BOXES

EMPTY PLASTIC BOXES 160 DESCENDING COLUMN Customer format ref. 5 Customer format ref. 8

2600

DESCENDING COLUMN

230

900

HMI

LIVE-TECH

TRAY FLAT BLANK

H=TBD

LID FLAT BLANK

OUTER FOLDED AND GLUED FLAP

L 5 L 3

Configuration W 1 Configuration W 2

H 1 H 4

4685

STRETCHING FILM

MANUAL OUTFEED TOT 5 TOT 24

H=TBD

PALLET LABEL

FOR EMPTY PLASTIC Orientation Standing Orientation Flat

LABEL CHECKING UNIT AND REJECT SYSTEM LIVE-TECH

BOXES 1470 810 TA

RC

ZYN

SKI Name C01 Name C02

200

Packaging Type Tray+Lid (outer) Packaging Type Tray+Lid (outer)

160

Nominal Speed (ppm) Nominal Speed (ppm)

230 Max Speed each machine 20 60

0 Max Speed each machine 4,2

1270

40

8836

(ppm) 0 (ppm)

H=3950

Orientation Flat Orientation Flat

HMI

4980 1480 Side Leading Short

PLASTIC BOXES WITHOUT

Side Leading Short

Facing UP Facing UP

SEPARATOR INSIDE

EMPTY PLASTIC BOXES 1750

860

H=3950 DESCENDING COLUMN 700

BOXES/PLASTIC BOXES

1580

REJECT SYSTEM

150

NO GLUE APPLICATION BETWEEN TRAY/LID

FULL PLASTIC BOXES/CARTON BOXES MANUAL INFEED FOR

820

ELEVATOR COMPLETE PLASTIC

1740

BOXES

2170

HMI

MANUAL OUTFEED FOR

COMPLETE PALLET OF

CARTON BOXES

197 E.D.

H=500

2600 FRO

NT

BA

CK

S IDE

SID

E

970

.D.

17

9E 7E

23

LIVE-TECH

LIVE-TECH

.D.

LABEL APPLICATION

1590 LABEL CHECKING UNIT AND REJECT SYSTEM LIVE-TECH

H=TBD

H=3950

INTERLAYER (6/7)

MANUAL OUTFEED FOR

COMPLETE PALLET OF

1600

1750

H=3950 FULL PLASTIC BOXES INTERLAYER (2/3)

1576

1726

H=TBD

1700

HMI

LABEL CHECKING UNIT

LIVE-TECH

(ONLY PRESENCE) INTERLAYER (0/1)

1300

FULL PLASTIC BOXES/CARTON BOXES

REI 240

LID FLAT BLANK BOXES/PLASTIC BOXES

TRAY FLAT BLANK REJECT SYSTEM ELEVATOR

BOX LABEL

FULL PLASTIC BOXES/CARTON BOXES

ELEVATOR

80

PANNELLO 1000

PANNELLO 1000

L 5 L 2

13

H=2850 Configuration W 4 W 2

PANNELLO 700

Configuration

TE 800

TEN

BAT

OLO

H 8

SING

TA

POR

H 8

TOT 160 TOT 32

PANNELLO 1200

H=3950 MAXIMUM TOTAL PRODUCTION: 15 pallet/h Orientation FLAT MAXIMUM TOTAL PRODUCTION: 15.8 pallet/h

PANNELLO 200

Orientation Flat

9340

CHECK WEIGHER SYSTEM 2500

4 Format scheme update enrico.promio 18/06/2021

3 Layout Upgrade enrico.promio 14/06/2021

2 Layout Upgrade enrico.promio 09/06/2021

MANUAL INFEED FOR 1 Layout Upgrade enrico.promio 03/06/2021

STACKED PALLET 0 Emissione Layout enrico.promio 22/02/2021

otwór ULTIMA MODIFICA / LAST MODIFICATION enrico.promio 18/06/2021

PANNELLO 300

PANNELLO 1500 PANNELLO 1500 PANNELLO 1500

INTERLAYER ok REV. DESCRIZIONE / DESCRIPTION SIGNATURE DATE

4000 COMMITTENTE

90 CUSTOMER

D11

EI120

LABEL APPLICATION UNIT FOR PALLET LABEL APPLICATION UNIT

EWA

200 TARCZYNSKI

2100

FOR BOXES

2620

MANUAL INFEED FOR

STACKED INTERLAYER

otwór OFF./ JOB N°

PROGETTO

ok

L210068 PROJECT SECONDARY PACKAGING LINE FOR PLASTIC TRAYS

DATA/DATE OGGETTO DIS N°

18/06/2021 DRAWING TITLE DWG N° LTA01763D_REV04

SECONDARY PACKAGING SYSTEM SCALA/SCALE DRAWING REVISION 0 4

PRELIMINARY LAYOUT A0 1:50 COMPLETE PALLETTIZING SYSTEM DISEGNATORE

AUTHOR E.PROMIO

DIMENSIONS NOT BINDING Live-Tech s.r.l. si riserva ai termini di legge la proprietà del presente disegno con divieto di riprodurlo o comunicarlo a terzi senza autorizzazione.

This drawing is property of Live-Tech s.r.l. and cannot be reproduced or given to third parties without our written authorization

You might also like

- Carlos Gardel - La CumparsitaDocument9 pagesCarlos Gardel - La CumparsitaPriscila Saccone0% (1)

- Asaykake No Starmine-2Document2 pagesAsaykake No Starmine-2BonoNo ratings yet

- Orange - 7!! (Your Lie in April ED 2)Document4 pagesOrange - 7!! (Your Lie in April ED 2)jgarjar100% (1)

- Jesus Bleibet Meine Freude (Extended)Document5 pagesJesus Bleibet Meine Freude (Extended)Quintus VetrixNo ratings yet

- If I Had A ChickenDocument6 pagesIf I Had A ChickenElena BogachevaNo ratings yet

- Complete Forex Trading Guide - Forex - Doc-1Document228 pagesComplete Forex Trading Guide - Forex - Doc-1Raph Sun87% (46)

- Austin Farwell - TogetherDocument3 pagesAustin Farwell - TogetherJustin D'souza100% (1)

- 2 - Special IssuesDocument18 pages2 - Special IssuesMoe AdelNo ratings yet

- Art Tatum - Tea For Two 1953Document3 pagesArt Tatum - Tea For Two 1953E S50% (2)

- 14e GNB ch01 SMDocument7 pages14e GNB ch01 SMOmerGull100% (1)

- Gilberto Santa Rosa - Perdoname (Karaoplay - Com) 2Document20 pagesGilberto Santa Rosa - Perdoname (Karaoplay - Com) 2zeus33No ratings yet

- Bank Transfer2Document180 pagesBank Transfer2Imc TeknoNo ratings yet

- Hotels in CoimbatoreDocument4 pagesHotels in CoimbatoreSoma Nathan100% (1)

- Max. Boxes Size: Światło Otworu 285x267cmDocument1 pageMax. Boxes Size: Światło Otworu 285x267cmRaffaele ConternoNo ratings yet

- Upper Floor Entrance: Max. Boxes SizeDocument1 pageUpper Floor Entrance: Max. Boxes SizeRaffaele ConternoNo ratings yet

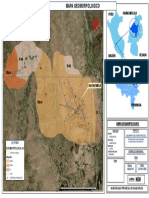

- Mapa de Capacidad de Uso MayorDocument1 pageMapa de Capacidad de Uso Mayorlionel hansNo ratings yet

- Mapa de EcorregionesDocument1 pageMapa de Ecorregioneslionel hansNo ratings yet

- Mapa de GeomorfologicoDocument1 pageMapa de Geomorfologicolionel hansNo ratings yet

- Boogie Woogie2Document1 pageBoogie Woogie2Guillaume VilliersNo ratings yet

- AndanteDocument1 pageAndanteABNo ratings yet

- ArpeggiaDocument2 pagesArpeggiaGabeNo ratings yet

- IC800 STR - W6253 TRF - Smps - 15 - Lips TR801: Inverter SupplyDocument2 pagesIC800 STR - W6253 TRF - Smps - 15 - Lips TR801: Inverter SupplyGabriel LatiuNo ratings yet

- Σαν ναυαγόςDocument6 pagesΣαν ναυαγόςArgiris MaipasNo ratings yet

- Final Fantasy XV - HellfireDocument16 pagesFinal Fantasy XV - HellfireBen LiNo ratings yet

- Projeto Arquitetônico 2Document1 pageProjeto Arquitetônico 2Bruno KolokovskiNo ratings yet

- Dau Site Dev Plan-ModelDocument1 pageDau Site Dev Plan-ModelJhn Cbllr BqngNo ratings yet

- Pokemon Intro Theme SongDocument5 pagesPokemon Intro Theme SongBogdan ProfirNo ratings yet

- The Melrose Rag: Dedicated To Miss Elfie Keith, Hillsboro, IllDocument3 pagesThe Melrose Rag: Dedicated To Miss Elfie Keith, Hillsboro, Ill홍정기No ratings yet

- Print FullDocument14 pagesPrint FullЮ супчикNo ratings yet

- Shouting 4Document1 pageShouting 4Masc SanhuezaNo ratings yet

- Timekeeper Cookie's Trial Theme Arrangement: Yurjae's Music NoteDocument4 pagesTimekeeper Cookie's Trial Theme Arrangement: Yurjae's Music NotellIllIlIllIlNo ratings yet

- Reason LivingDocument8 pagesReason LivingNguyen NgocNo ratings yet

- Chainsaw Man ED 1 - Chainsaw BloodDocument2 pagesChainsaw Man ED 1 - Chainsaw Bloodbarti koksNo ratings yet

- VahaDocument2 pagesVahaSabri Tulug TirpanNo ratings yet

- AOST - Aimer - Brave ShineDocument9 pagesAOST - Aimer - Brave Shine불꽃길No ratings yet

- Minera Santa Elena/Gemcom Software: Plano Geologico-Estructural El CerradoDocument1 pageMinera Santa Elena/Gemcom Software: Plano Geologico-Estructural El CerradoFrancisco Guido Fuentes GreeneNo ratings yet

- Shouting 2Document1 pageShouting 2Masc SanhuezaNo ratings yet

- Maple Leaf Rag: Maik Philipp PaulsenDocument5 pagesMaple Leaf Rag: Maik Philipp Paulsenja123No ratings yet

- Ramp Up Ramp Up: Ground Floor PlanDocument1 pageRamp Up Ramp Up: Ground Floor PlanISHA SINGHNo ratings yet

- Hitorigoto - Eromanga-Sensei OP - TheishterDocument4 pagesHitorigoto - Eromanga-Sensei OP - TheishterHuy NguyễnNo ratings yet

- Trabajo RagtimeDocument6 pagesTrabajo Ragtimesebastian alvarezNo ratings yet

- Orange - 7!! (Easier Ver.)Document4 pagesOrange - 7!! (Easier Ver.)jgarjarNo ratings yet

- Uso (Lie) : Full Metal Alchemist: Brotherhood ED-1Document8 pagesUso (Lie) : Full Metal Alchemist: Brotherhood ED-1Enzo FenizaNo ratings yet

- Let All Mortal Flesh Keep SilenceDocument3 pagesLet All Mortal Flesh Keep Silencehj905bgmrNo ratings yet

- Kirameki - Shigatsu Wa Kimi No Uso ED1Document8 pagesKirameki - Shigatsu Wa Kimi No Uso ED1Huy NguyễnNo ratings yet

- Chainsaw Man Ed8 - First Death (Kesseki Piano)Document4 pagesChainsaw Man Ed8 - First Death (Kesseki Piano)nabstyblook2No ratings yet

- Joe Hisaishi - NostalgiaDocument4 pagesJoe Hisaishi - NostalgiaErnest CheungNo ratings yet

- God Bless KeyboardDocument3 pagesGod Bless KeyboardmassimosgargiNo ratings yet

- Swordland SAO Animenz ArrDocument9 pagesSwordland SAO Animenz Arrhenry.jklingerNo ratings yet

- DUET PB (Spartitp) - ConvertitoDocument4 pagesDUET PB (Spartitp) - ConvertitoMaxNo ratings yet

- GateofsteinerpianoDocument10 pagesGateofsteinerpianoDániel KrebszNo ratings yet

- Kenaston Chilly GonzalesDocument3 pagesKenaston Chilly GonzalesAarón HuancahuariNo ratings yet

- Im A Believer PianoDocument4 pagesIm A Believer PianoJocey DufordNo ratings yet

- Ado - 夜のピエロDocument7 pagesAdo - 夜のピエロraymondthe49No ratings yet

- Chiisana Koi No Uta - C MajorDocument1 pageChiisana Koi No Uta - C MajorDuy Thien VuNo ratings yet

- Bling-Bang-Bang-Born Creepy Nuts MASHLE Season 2 OP Fonzi M VersionDocument5 pagesBling-Bang-Bang-Born Creepy Nuts MASHLE Season 2 OP Fonzi M Versionkendralam227No ratings yet

- Block A Block B: Site Plan Scale 1: 250Document1 pageBlock A Block B: Site Plan Scale 1: 250MikeNo ratings yet

- 恨别 Hen Bie: Arrangement by: Ing78764 = 84Document3 pages恨别 Hen Bie: Arrangement by: Ing78764 = 84SYCNo ratings yet

- The Baddest: Piano Sheet MusicDocument5 pagesThe Baddest: Piano Sheet MusicPablo NievaNo ratings yet

- Greensleeves ValseDocument1 pageGreensleeves ValseDorie NemoNo ratings yet

- ¿Donde Hallo El SolazDocument2 pages¿Donde Hallo El Solazmanuel ulloa torresNo ratings yet

- Kyouran Hey Kids - THE ORAL CIGARETTES Noragami Aragoto OP Animenzs ArrangementDocument6 pagesKyouran Hey Kids - THE ORAL CIGARETTES Noragami Aragoto OP Animenzs ArrangementMikaela Juliana FrancoNo ratings yet

- Above All - MSCZ OrigiDocument3 pagesAbove All - MSCZ OrigiProf. Felipe CantãoNo ratings yet

- Advanced NPV ProblemsDocument3 pagesAdvanced NPV ProblemsjimjoneNo ratings yet

- Cobecon - Market Reviewer.3.2022 23Document14 pagesCobecon - Market Reviewer.3.2022 23Inigo CruzNo ratings yet

- Rera Report6919 PDFDocument78 pagesRera Report6919 PDFPawan RanjanNo ratings yet

- References FINALDocument6 pagesReferences FINALRaul MartinNo ratings yet

- Steel BusinessDocument10 pagesSteel BusinessEricge PSB TradingNo ratings yet

- Motshelo - Phase 2Document32 pagesMotshelo - Phase 2Mohh50% (2)

- Adam Smith Wealth NationsDocument3 pagesAdam Smith Wealth NationsDarryl Jeethesh D'souza100% (1)

- Lalit Narayan Mithila University, DarbhangaDocument1 pageLalit Narayan Mithila University, DarbhangaBad BoyNo ratings yet

- Answer Key VIDocument1 pageAnswer Key VIParmesh GuptaNo ratings yet

- Auto UpdatedDocument8 pagesAuto UpdatedAmitesh AgrawalNo ratings yet

- Pak Steel MillDocument31 pagesPak Steel Millwasiq Ahmed0% (1)

- The Investment Function.2Document12 pagesThe Investment Function.2Angelica T. GenovaNo ratings yet

- 2022 Global Outlook: Thriving in A New Market RegimeDocument16 pages2022 Global Outlook: Thriving in A New Market RegimeRubens HenriquesNo ratings yet

- Assignment in Tax 102 What Is Transfer?Document5 pagesAssignment in Tax 102 What Is Transfer?JenniferFajutnaoArcosNo ratings yet

- EUR Statement: 30 September 2023 (GMT+01:00) - 22 January 2024 (GMT+01:00)Document4 pagesEUR Statement: 30 September 2023 (GMT+01:00) - 22 January 2024 (GMT+01:00)Mohammed laid BoutalebNo ratings yet

- 1949 Report Operations Facilities Organization Financial Status Modernization Pacific ElectricDocument323 pages1949 Report Operations Facilities Organization Financial Status Modernization Pacific ElectricJason BentleyNo ratings yet

- Unified TC 1.3Document2 pagesUnified TC 1.3wahab ahamedNo ratings yet

- Este Documento Es Aceptado Tributariamente Por SunatDocument2 pagesEste Documento Es Aceptado Tributariamente Por SunatMelissa CongonaNo ratings yet

- Comair AnnualReportDocument76 pagesComair AnnualReportJanus CoetzeeNo ratings yet

- Local Resources Available in Tarrant County - 2 PDFDocument15 pagesLocal Resources Available in Tarrant County - 2 PDFJoshua ClickNo ratings yet

- Investing in Africa SDI ModelDocument36 pagesInvesting in Africa SDI ModelRita CoomaNo ratings yet

- Detailed Guidelines On Use of Framework AgreementsDocument7 pagesDetailed Guidelines On Use of Framework AgreementsFreddy VargasNo ratings yet

- Corporate Ownership and Dominance of Indonesia's Palm Oil Supply ChainsDocument7 pagesCorporate Ownership and Dominance of Indonesia's Palm Oil Supply Chainssakul lukaskusNo ratings yet

- ClearDocument3 pagesClearOleg DaffNo ratings yet

- Revision5 Variance2Document4 pagesRevision5 Variance2adamNo ratings yet