Professional Documents

Culture Documents

V1-2 Severe Service Metal Seated Ball Valves

Uploaded by

Sergio Gana GonzalezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

V1-2 Severe Service Metal Seated Ball Valves

Uploaded by

Sergio Gana GonzalezCopyright:

Available Formats

ValvTechnologies’

V1-2 Severe Service Metal Seated Ball Valves

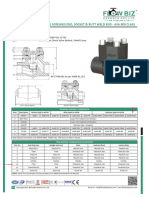

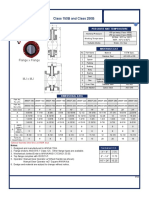

FLANGED BALL VALVES BILL OF MATERIALS

Technical Data Item Description Carbon Steel Std. Trim 316 Stainless Steel Std. Trim Qty

Sizes 1/2 - 36” 1 Ball 4130/RiTech®31 316 S.S/RiTech®31 1

Pressure Classes ASME / ANSI Class 150 - 600 2 Upstream Seat 4130/H.F. A182-F316/H.F. 1

3 Belleville Spring

®

17-4ph 17-4ph 1

Carbon steel (A216 WCB) – standard

Stainless steel (A351 CF8M) – standard 4 Stem 4130/H.F. 316 S.S./H.F. 1

Materials of

Duplex steel 5 Gland 4130/H.F. 316 S.S/H.F. 1

Construction

Exotic alloys

6 Gland Load Spring 302 S.S. 302 S.S. 24

Other materials available upon request

7 Gland Nut A194 Gr. 8M A194 Gr. 8M 4

ASME B16.34

PED 8 Gland Stud A194 Gr. B8M A193 Gr. B8M 4

In Compliance Nuclear ASME III Class 1, 2 and 3 9 End Cap A216-WCB/RiTech®31 A351 GR CF8M/RiTech®31 1

Nuclear Safety Related – 10CFR50 Appendix B 10 Body A216-WCB A351 GR CF8M 1

SIL

11 Body Gasket *Grafoil® *Grafoil® 1

Raised face flange – standard

End Connections 12 Gland Packing Grafoil®/316 S.S. Grafoil®/316 S.S. 3

Other end connections available upon request

13 Body Stud A193 Gr. B7 A193 Gr. B8M 8

Shutoff Absolute zero-leakage shutoff 14 Body Nut A194 Gr. 2H A194 Gr. 8M 8

* For ball sizes below 3”, the body gasket is a pressure seal metal gasket.

** B3 = 150#, B5 = 300#, B6 = 600# RP = Reduced Port; FP = Full Port

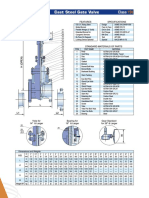

FULL PORT DIMENSIONS (ANSI 150/300/600)

Stem

Size A B C D E(RF) Approximate Weights Cv

Diameter

Pressure All All

150 300 600 150 300 600 150 300 600 150 300 600 150 300 600 150 300 600

Class Classes Classes

1/2 0.63 0.63 0.63 3.50 3.75 3.75 1.25 1.25 1.25 2.00 2.00 2.00 4.25 5.50 6.50 0.50 8 10 14 2

3/4 0.63 0.63 0.63 3.88 4.62 4.62 1.25 1.25 1.25 2.00 2.00 2.00 4.62 6.00 7.50 0.50 9 12 19 28

1 1.06 1.06 1.06 4.25 4.88 4.88 1.88 1.88 1.88 2.90 2.90 2.90 5.00 6.50 8.50 0.75 14 19 25 130

1-1/2 1.50 1.50 1.50 5.00 6.12 6.12 1.88 1.88 1.88 2.90 2.90 2.90 6.50 7.50 9.50 0.75 17 22 30 270

2 2.13 2.13 2.13 6.00 6.50 6.50 3.38 3.38 3.38 5.00 5.00 5.00 7.00 8.50 11.50 1.00 28 31 40 570

3 3.06 3.06 3.06 7.50 8.25 8.25 4.00 4.00 4.00 7.25 7.25 7.25 8.00 11.12 14.00 1.50 95 110 195 1300

4 4.06 4.06 4.06 9.00 10.00 10.75 4.50 4.50 4.50 9.00 9.00 9.00 9.00 12.00 17.00 2.00 140 170 280 2500

6 6.06 6.06 6.06 11.00 12.50 14.00 6.00 6.00 6.50 12.80 12.80 12.80 15.50 15.88 22.00 2.50 410 450 670 5550

8 8.06 8.06 8.06 13.50 15.00 16.50 8.00 8.00 8.50 17.50 17.50 17.50 18.00 19.75 26.00 3.50 690 770 1050 10400

10 10.06 10.06 10.06 16.00 17.50 20.00 10.3 10.30 10.30 19.43 19.43 19.43 21.00 22.38 31.00 4.00 1060 1150 1840 16600

12 12.06 12.06 12.06 19.00 20.50 22.00 12.5 12.50 13.00 22.00 22.00 22.00 24.00 25.50 33.00 5.00 1840 1980 2650 24300

14 12.06 12.06 12.06 21.00 23.00 23.75 12.5 12.50 13.00 22.00 22.00 22.00 27.00 30.00 35.00 5.00 2180 2140 2910 18000

16 15.25 15.25 15.25 23.50 25.50 27.00 14.5 14.50 15.25 30.50 30.50 30.50 30.00 33.00 39.00 7.00 3350 3500 4800 39700

Note: Cv values are based upon Class 150 valves with a Sch. 40 Pipe ID. Consult factory for other configurations.

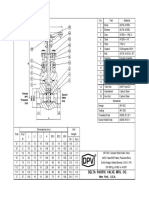

REDUCED PORT DIMENSIONS (ANSI 150/300/600)

Stem

Size A B C D E(RF) Approximate Weights Cv

Diameter

Pressure All 300 &

150 300 600 150 300 600 150 300 600 150 300 600 150 300 600 150 300 600 150

Class Classes 600

1 0.63 0.63 0.63 4.25 4.88 4.88 1.25 1.25 1.25 2.00 2.00 2.00 5.00 6.50 8.50 0.50 10 14 22 19 19

1-1/2 1.06 1.06 1.06 5.00 6.12 6.12 1.88 1.88 1.88 3.00 3.00 3.00 6.50 7.50 9.50 0.75 15 20 28 65 65

2 1.50 1.50 1.50 6.00 6.50 6.50 2.13 2.13 2.13 3.75 3.75 3.75 7.00 8.50 11.50 0.75 25 29 40 160 160

3 2.13 2.13 2.13 7.50 8.25 8.25 3.38 3.38 3.38 5.00 5.00 5.00 8.00 11.12 14.00 1.00 35 41 65 210 210

4 3.06 3.06 3.06 9.00 10.00 10.75 4.00 4.00 4.00 7.25 7.25 7.25 9.00 12.00 17.00 1.50 100 125 140 500 500

6 4.06 4.06 4.06 11.00 12.5 14.00 4.50 4.50 4.50 9.00 9.00 9.00 10.50 15.88 22.00 2.00 180 215 255 750 750

8 5.13 6.06 6.06 13.50 15.00 16.50 5.38 6.00 6.50 11.17 12.80 12.80 11.50 19.75 26.00 2.50 360 610 760 1150 2000

10 7.13 8.06 8.06 16.00 17.50 20.00 7.13 8.00 8.50 13.50 17.50 17.50 13.00 18.00 31.00 3.50* 480 1160 1490 2250 4000

12 8.06 10.06 10.06 19.00 20.50 22.00 8.00 10.30 10.30 19.43 19.43 19.43 14.00 19.75 33.00 4.00* 890 1790 2450 2800 7600

14 10.06 10.06 10.06 21.00 23.00 23.75 10.30 10.30 10.30 19.43 19.43 19.43 15.00 30.00 35.00 4.00 1410 2300 2950 5500 5500

16 10.06 12.06 12.06 23.50 25.50 27.00 10.30 12.50 13.00 22.00 22.00 22.00 16.00 33.00 39.00 5.00* 1740 2550 3300 4400 10900

Note: Cv values are based upon a Sch. 40 Pipe ID. Consult factory for other configurations.

AVAILABLE BODY OPTIONS

Bi-directional sealing Sizes up to 36”

Control trim Elevated temperature options

Special end connections Wafer style

Special hard coatings Forged steel construction

Various materials of construction

©2014-2019 ValvTechnologies, Inc. All rights reserved. 301 V1-2 Data Sheet. March 2019. www.valv.com

®

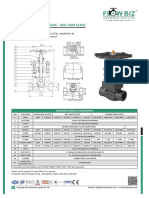

PRESSURE/TEMPERATURE RATINGS

ASME/ANSI 150

FEATURES

Integral metal seat. With our proprietary HVOF RiTech® coating technology,

the integral seat in ValvTechnologies’ valves is resistant to the attack of abra-

sive magnetite and ferrous oxides that may be seen in the steam flow.

Body seal ring. ValvTechnologies employs a field-proven seal ring technology to

ensure sealing under all operating conditions, up to 1400°F. The body seal ring

is loaded at a pressure higher than 20,000 psi. In addition, valves sized 3“

and above contain a secondary Grafoil® seal to further guarantee reliability.

Patented coating process. The sealing surfaces are overlaid with tungsten or ASME/ANSI 300

chromium carbide using our exclusive HVOF RiTech® process. These surfaces

have a hardness of 68 – 72 Rc to allow long periods of operation in the most

severe conditions.

Live-loaded gland area. The V Series’ sealing design features a four stud, live-

loaded assembly designed for heavy industrial applications. The sealing mate-

rial is high purity Grafoil® surrounded by stainless steel wire mesh anti-extru-

sion rings. The six Belleville® springs (per stud) provide constant load pressure

through extreme thermal shocks and prevent wear leaks in high-cycle service.

Blow-out proof stem. The design utilizes a one piece, hard-faced, blow-out

proof stem that is inserted through the inside of the body cavity eliminating

the possibility of blow-out through the gland area.

ASME/ANSI 600

Pressure-temperature ratings are in accordance with ASME/ANSI B16.34 - 2017

©2014-2019 ValvTechnologies, Inc. All rights reserved. 301 V1-2 Data Sheet. March 2019. www.valv.com

You might also like

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Mad-Lib ExerciseDocument2 pagesMad-Lib Exercisejbk23100% (2)

- Grade 6 - HEALTH - Q4 Module 1 - W1Document12 pagesGrade 6 - HEALTH - Q4 Module 1 - W1Love Lei67% (3)

- Fisher Globe Valve Selection Guide PDFDocument12 pagesFisher Globe Valve Selection Guide PDFAmiroucheBenlakehalNo ratings yet

- API602 Forged Steel Gate & Globe ValvesDocument4 pagesAPI602 Forged Steel Gate & Globe ValvesThomasFrenchNo ratings yet

- Pump Foundation Analysis and Design ReportDocument18 pagesPump Foundation Analysis and Design ReportArchana ArchuNo ratings yet

- F Series - Floating Ball ValvesDocument8 pagesF Series - Floating Ball ValvesCarlos Alberto Aguilera MendezNo ratings yet

- VAT Registration Certificate UAEDocument1 pageVAT Registration Certificate UAEMaaz AzadNo ratings yet

- Condominium Concept and Other Types and Other Types of Real Estate HoldingsDocument15 pagesCondominium Concept and Other Types and Other Types of Real Estate HoldingsRhea SunshineNo ratings yet

- 2 - ARM Cotex-M3 - IntroductionDocument124 pages2 - ARM Cotex-M3 - IntroductionNghĩa VũNo ratings yet

- Grinnell Series 8000Document8 pagesGrinnell Series 8000Sergio Gana GonzalezNo ratings yet

- Configuring Functions with CFCsDocument60 pagesConfiguring Functions with CFCsAlu menzikenNo ratings yet

- Valvulas TCIDocument15 pagesValvulas TCIGuillermo de la Fuente SantiagoNo ratings yet

- Ball Valve Full PortDocument2 pagesBall Valve Full PortHardik ShahNo ratings yet

- FlowBiz Forged Steel Gate Valve Flanged End 150 ClassDocument2 pagesFlowBiz Forged Steel Gate Valve Flanged End 150 ClassSHAKIR ANSARINo ratings yet

- FlowBiz Forged Steel Globe ValveDocument14 pagesFlowBiz Forged Steel Globe ValveFlowBiz Exports Pvt. Ltd.No ratings yet

- Tci CHKDocument1 pageTci CHKMiguel Reyes BalcazarNo ratings yet

- Valvulas OS&YDocument1 pageValvulas OS&Ydaniel manuel garces davilaNo ratings yet

- Butterfly Valve Wafer TypeDocument2 pagesButterfly Valve Wafer TypeHardik ShahNo ratings yet

- Cast Steel Globe Valve Pressure Seal Class 1500, 2500Document3 pagesCast Steel Globe Valve Pressure Seal Class 1500, 2500Andri AjaNo ratings yet

- Diaphragm ValveDocument2 pagesDiaphragm ValveHardik ShahNo ratings yet

- DelVal Series 64 3-PC Industrial Ball ValvesDocument2 pagesDelVal Series 64 3-PC Industrial Ball ValvesProcess Controls & ServicesNo ratings yet

- Ball Check ValveDocument2 pagesBall Check ValveHardik ShahNo ratings yet

- FlowBiz Forged Steel Globe Valve Reduced BoreDocument2 pagesFlowBiz Forged Steel Globe Valve Reduced BoreFlowBiz Exports Pvt. Ltd.No ratings yet

- FlowBiz-FORGED-STEEL-CHECK-VALVE 800 ClassDocument2 pagesFlowBiz-FORGED-STEEL-CHECK-VALVE 800 ClassShakir AnsariNo ratings yet

- Gate Valve Drawing and SpecificationsDocument1 pageGate Valve Drawing and SpecificationsismailNo ratings yet

- UL FM OS&Y Gate Valves, AWWA C515 - Water Works - Fire Protection - Model 2030 Series ADocument1 pageUL FM OS&Y Gate Valves, AWWA C515 - Water Works - Fire Protection - Model 2030 Series ASiles LimberdsNo ratings yet

- Valvula Mariposa FlowsealDocument12 pagesValvula Mariposa Flowsealsakura_jNo ratings yet

- Data Sheets Series 155 FloatingDocument4 pagesData Sheets Series 155 Floatingbayarjargal SuwdusNo ratings yet

- Standard Material Specification: Gate Valve - Api 602 / Asme B16.34Document3 pagesStandard Material Specification: Gate Valve - Api 602 / Asme B16.34swatkoolNo ratings yet

- AES BallvalvespecsDocument3 pagesAES Ballvalvespecsclaudio godinezNo ratings yet

- 0sc Wtran 004395 (Bin Mat Qas 000195 00) B Approved With CommentsDocument44 pages0sc Wtran 004395 (Bin Mat Qas 000195 00) B Approved With Commentskhalidusman1984No ratings yet

- CRANE FKX9000 Triple Offset Butterfly How To Order Codes (English) (Nov - 2020)Document1 pageCRANE FKX9000 Triple Offset Butterfly How To Order Codes (English) (Nov - 2020)Cesar CallesNo ratings yet

- High Pressure Multi Stage Blowdown Valve ACT 83 Data Sheet PDFDocument2 pagesHigh Pressure Multi Stage Blowdown Valve ACT 83 Data Sheet PDFjayakumarNo ratings yet

- Val-Comp Z45XDocument1 pageVal-Comp Z45XDaniel04pvNo ratings yet

- Cast Steel Gate Valve Class 150 & 300 SpecificationsDocument4 pagesCast Steel Gate Valve Class 150 & 300 Specificationsarmin heidariNo ratings yet

- Delta Pacific Valve Mfg. Co.: New York, U.S.ADocument1 pageDelta Pacific Valve Mfg. Co.: New York, U.S.ALê Tuấn AnhNo ratings yet

- GLT Gate Valve SW, NPTDocument2 pagesGLT Gate Valve SW, NPTblloewyNo ratings yet

- Plummech Check ValvesDocument1 pagePlummech Check ValvesNguyễn Đăng PhúcNo ratings yet

- Flanged End Connection: Series F Carbon SteelDocument1 pageFlanged End Connection: Series F Carbon SteelBledarNo ratings yet

- FlowBiz Forged Steel Globe Valve Full BoreDocument2 pagesFlowBiz Forged Steel Globe Valve Full BoreFlowBiz Exports Pvt. Ltd.No ratings yet

- A. BALL - FloatingDocument3 pagesA. BALL - FloatingSaputraNo ratings yet

- Class 150 Cast Carbon Steel Gate ValveDocument1 pageClass 150 Cast Carbon Steel Gate Valvearief sugiartoNo ratings yet

- Argus FK 76M Ball Valve Material ListDocument2 pagesArgus FK 76M Ball Valve Material ListFelipe Gamboa Gálvez100% (1)

- Forged High Pressure Ball Valves: SBVF360 SeriesDocument4 pagesForged High Pressure Ball Valves: SBVF360 SeriesToty DzNo ratings yet

- V3-GAN-A125 Gate Valve SpecificationDocument1 pageV3-GAN-A125 Gate Valve SpecificationArthur DeiparineNo ratings yet

- Kamvalok Dry Disconnect Couplings Installation Instructions EnglishDocument10 pagesKamvalok Dry Disconnect Couplings Installation Instructions EnglishAyman64No ratings yet

- FlowBiz Forged Steel Globe Valve 1500 ClassDocument2 pagesFlowBiz Forged Steel Globe Valve 1500 ClassFlowBiz Exports Pvt. Ltd.No ratings yet

- AWWA C-504: Model 3900F & Model 3900MDocument2 pagesAWWA C-504: Model 3900F & Model 3900MPriyanka rajpurohitNo ratings yet

- Argus HK35Document2 pagesArgus HK35Felipe Gamboa GálvezNo ratings yet

- 140 Sheree Blvd. PO Box 566, Exton, PA 19341-0566 US - Web SiteDocument3 pages140 Sheree Blvd. PO Box 566, Exton, PA 19341-0566 US - Web SitegeorgyNo ratings yet

- Flanged Resilient OS&Y Gate Valve (XZ41X), UL/FM ApprovedDocument1 pageFlanged Resilient OS&Y Gate Valve (XZ41X), UL/FM ApprovedRoman UgarteNo ratings yet

- Valvulas de Bola 2Document20 pagesValvulas de Bola 2claudio godinezNo ratings yet

- Inverted Bucket Idh Lf2Document2 pagesInverted Bucket Idh Lf2Roo FaNo ratings yet

- S23-Ss-Ygg-L-015 Flo TiteDocument2 pagesS23-Ss-Ygg-L-015 Flo TiteMichNo ratings yet

- GL 125 150Document1 pageGL 125 150FABIONo ratings yet

- Uploads - Valvulas - Valvulas de Bola - Bola Flotante Aop - Aop CT 3000 Especificacion PDFDocument8 pagesUploads - Valvulas - Valvulas de Bola - Bola Flotante Aop - Aop CT 3000 Especificacion PDFMonica CarrenoNo ratings yet

- Cast Steel Gate Valve: ANSI Class 150 & 300 ANSI Class 150 & 300Document5 pagesCast Steel Gate Valve: ANSI Class 150 & 300 ANSI Class 150 & 300Andri AjaNo ratings yet

- Cast Steel Globe Valve Class: Figure No. Gl1Rcb8 Gl1Bcb8 Gl1Jcb8Document4 pagesCast Steel Globe Valve Class: Figure No. Gl1Rcb8 Gl1Bcb8 Gl1Jcb8Sushil ChauhanNo ratings yet

- Model: Wafer Style Knife Gate ValveDocument16 pagesModel: Wafer Style Knife Gate ValveMohamed RaafatNo ratings yet

- Valve Fittings CataloguexDocument13 pagesValve Fittings CataloguexOPERACIONES TOP OILNo ratings yet

- BUTTERFLY VALVE SPECSDocument18 pagesBUTTERFLY VALVE SPECSRiswanda HimawanNo ratings yet

- 317 Cast Iron PR 3asDocument1 page317 Cast Iron PR 3asAgung YudistiraNo ratings yet

- 15 Threaded Fittings and Weld FittingsDocument12 pages15 Threaded Fittings and Weld FittingsAsmaa MohamedNo ratings yet

- Technical Sheet BSA3TDocument4 pagesTechnical Sheet BSA3TMalik DaniyalNo ratings yet

- Forged High Pressure Ball Valves GuideDocument4 pagesForged High Pressure Ball Valves GuideFabio GiehlNo ratings yet

- InsulatedUnionMeterDocument1 pageInsulatedUnionMetervidaltigres88No ratings yet

- Van bướm thường điều khiển khí nénDocument1 pageVan bướm thường điều khiển khí nénAutoma Viet NamNo ratings yet

- Tdoct1384a EngDocument32 pagesTdoct1384a EngSergio Gana GonzalezNo ratings yet

- TT OpEXL Eccentric Plug Rotary Valve BrochureDocument16 pagesTT OpEXL Eccentric Plug Rotary Valve BrochureSergio Gana GonzalezNo ratings yet

- CVD-5B Metal Hardening BulletinDocument2 pagesCVD-5B Metal Hardening BulletinSergio Gana GonzalezNo ratings yet

- Trimteck Industry Spotlight On Natural GasDocument2 pagesTrimteck Industry Spotlight On Natural GasSergio Gana GonzalezNo ratings yet

- OpTB Product Instruction ManualDocument8 pagesOpTB Product Instruction ManualSergio Gana GonzalezNo ratings yet

- Tdoct0683d EngDocument16 pagesTdoct0683d EngqujunbaoNo ratings yet

- Durco Big Max BX2001 Valve: Product CatalogDocument28 pagesDurco Big Max BX2001 Valve: Product Catalogkagasaw023No ratings yet

- TT OpVEE V-Notch Ball-Valve-BrochureDocument16 pagesTT OpVEE V-Notch Ball-Valve-BrochureSergio Gana GonzalezNo ratings yet

- 701 V Series IOM May 2014Document20 pages701 V Series IOM May 2014arrikanNo ratings yet

- API - Valve StandardsDocument3 pagesAPI - Valve StandardsSergio Gana GonzalezNo ratings yet

- Doosan Diesel Generator 2Document1 pageDoosan Diesel Generator 2Sergio Gana GonzalezNo ratings yet

- MP 2 Enterprises QLDocument36 pagesMP 2 Enterprises QLSergio Gana GonzalezNo ratings yet

- Bulletin A110-4ENDocument12 pagesBulletin A110-4ENSergio Gana GonzalezNo ratings yet

- Westlock Epic Vctds 03243 enDocument12 pagesWestlock Epic Vctds 03243 endreyko77No ratings yet

- Product Overview For SIMATIC S7-1500Document9 pagesProduct Overview For SIMATIC S7-1500alveoyuniarNo ratings yet

- Ico4-Pst Electromagnetic Actuated, Directly ControlledDocument7 pagesIco4-Pst Electromagnetic Actuated, Directly ControlledSergio Gana GonzalezNo ratings yet

- Jamesbury® Wafer-Sphere® Valve: Lugged StyleDocument1 pageJamesbury® Wafer-Sphere® Valve: Lugged StyleSergio Gana GonzalezNo ratings yet

- Handle Handle Screw: The Jamesbury® Flanged Ball ValveDocument1 pageHandle Handle Screw: The Jamesbury® Flanged Ball ValveSergio Gana GonzalezNo ratings yet

- Grinnell Series 1000Document4 pagesGrinnell Series 1000Sergio Gana GonzalezNo ratings yet

- Clarity in An Uncertain World: EIU at 75Document22 pagesClarity in An Uncertain World: EIU at 75Sergio Gana GonzalezNo ratings yet

- 1756 pp001 - en PDocument5 pages1756 pp001 - en Pruso21_2002No ratings yet

- Handle Handle Screw: The Jamesbury® Flanged Ball ValveDocument1 pageHandle Handle Screw: The Jamesbury® Flanged Ball ValveSergio Gana GonzalezNo ratings yet

- Tyco Grinnell Resilient Seat ButterflyDocument8 pagesTyco Grinnell Resilient Seat ButterflySergio Gana GonzalezNo ratings yet

- Handle Handle Screw: The Jamesbury® Flanged Ball ValveDocument1 pageHandle Handle Screw: The Jamesbury® Flanged Ball ValveSergio Gana GonzalezNo ratings yet

- ASUS Motherboard P8Z77-V LXDocument144 pagesASUS Motherboard P8Z77-V LXAnonymous lStpu6o44cNo ratings yet

- PBV 3pc Trunnion 2015 PDFDocument32 pagesPBV 3pc Trunnion 2015 PDFjhair_sanabriaNo ratings yet

- 60 - Controller Fisher 2Document124 pages60 - Controller Fisher 2Sergio Gana GonzalezNo ratings yet

- Magellan 8300Document540 pagesMagellan 8300Fleming AlexanderNo ratings yet

- Ivin Resume Nov 2022Document1 pageIvin Resume Nov 2022Ivin KuriakoseNo ratings yet

- TCS303 Pumping Station ControllerDocument17 pagesTCS303 Pumping Station ControllerNAdreaNo ratings yet

- UNA010F-0-V2: Electrical SpecificationsDocument2 pagesUNA010F-0-V2: Electrical SpecificationsNiko ZabalaNo ratings yet

- HONKON Skin Laser Beauty SolutionsDocument18 pagesHONKON Skin Laser Beauty SolutionsEvolution MedNo ratings yet

- Survey Questionnaire 3 - Student EngagementDocument2 pagesSurvey Questionnaire 3 - Student EngagementDAN MARK CAMINGAWANNo ratings yet

- Leta 2022Document179 pagesLeta 2022Bigovic, MilosNo ratings yet

- ATP Parts Guide-B3Z Mechanical Seal PumpDocument1 pageATP Parts Guide-B3Z Mechanical Seal PumpRony FloresNo ratings yet

- Harper's Illustrated Biochemistry - Hormonal Control in Signal TransductionDocument18 pagesHarper's Illustrated Biochemistry - Hormonal Control in Signal TransductionDr Sanjeeb Kumar Dey BaidyaNo ratings yet

- Levers of Control Analysis of Management Control SDocument17 pagesLevers of Control Analysis of Management Control SApriana RahmawatiNo ratings yet

- 05 N141 31673Document21 pages05 N141 31673priya thakurNo ratings yet

- Aims and Principles of Foreign Language TeachingDocument3 pagesAims and Principles of Foreign Language TeachingresearchparksNo ratings yet

- NDC Format For Billing PADDocument3 pagesNDC Format For Billing PADShantkumar ShingnalliNo ratings yet

- Ms. Louise Lim Mr. Ivan Cyrus DaldeDocument27 pagesMs. Louise Lim Mr. Ivan Cyrus DaldeJazlyn Andria JarafaNo ratings yet

- Essential information checklist for building plan submissionsDocument79 pagesEssential information checklist for building plan submissionsYu chung yinNo ratings yet

- Rubricks For Case StudyDocument2 pagesRubricks For Case StudyMiguelito Aquino RuelanNo ratings yet

- Analy Tisch e Chemie EnglischDocument168 pagesAnaly Tisch e Chemie EnglischHas GomNo ratings yet

- Lesson Plan For Moi AssessmentsDocument3 pagesLesson Plan For Moi Assessmentsapi-321133568No ratings yet

- Hacking Hacktoberfest - SVIT VasadDocument59 pagesHacking Hacktoberfest - SVIT VasadTRISHALA.SWAINNo ratings yet

- AY2017 2018CourseworkFees MOEDocument22 pagesAY2017 2018CourseworkFees MOEYotrisno LangNo ratings yet

- RAB PLTS Hybrid 1kWp-ScheneiderDocument4 pagesRAB PLTS Hybrid 1kWp-ScheneiderilhamNo ratings yet

- Cyber CXDocument2 pagesCyber CXhplzNo ratings yet