Professional Documents

Culture Documents

AWWA C-504: Model 3900F & Model 3900M

Uploaded by

Priyanka rajpurohitOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AWWA C-504: Model 3900F & Model 3900M

Uploaded by

Priyanka rajpurohitCopyright:

Available Formats

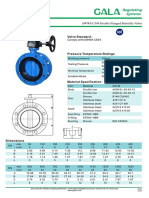

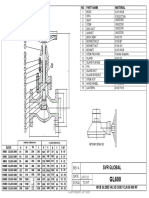

AWWA C-504 Model 3900F & Model 3900M

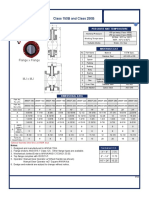

BUTTERFLY VALVE Class 150B and Class 250B

PRESSURE AND TEMPERATURE

150 psi wwp (Class 150B)

Nominal Pressure

250 psi wwp (Class 250B)

EPDM: -10°C to 120°C

Working Temperature

NBR: -10°C to 82°C

Suitable Media Water, Oil, Gas

MATERIALS LIST

No. Part Name Material ASTM Spec.

1 Shaft Stainless Steel AISI 420 or 630

Flange x Flange 2 Spacer Brass ASTM B16 C36000

3 Packing EPDM -

4 Bushing Brass ASTM B16 C36000

5 Body Ductile Iron ASTM A536 65-45-12

6 Bearing Teflon -

7 Seat EPDM -

MJ x MJ 8 Disc

Ductile Iron(with SS316 Edge)

ASTM A536 65-45-12

Optional: Stainless Steel 316

9 Cover Plate Stainless Steel AISI 420

10 Lock Washer Carbon Steel AISI 1045

DIMENSIONAL DATA

Part No.

3900F-130 3900F-140 3900F-160 3900F-180 3900F-200 3900F-220 3900F-240 3900F-260 3900F-280 3900F-300 3900F-340

FL x FL

Part No.

3900M-130 3900M-140 3900M-160 3900M-180 3900M-200 3900M-220 3900M-240 3900M-260 3900M-280 3900M-300 3900M-340

MJ x MJ

Valve Size 3” 4” 6” 8” 10” 12” 14” 16” 18” 20” 24”

A 6-5/16 7-1/16 8-3/8 9-5/8 10-15/16 12-1/2 14-1/16 16-1/16 17-1/4 18-9/16 22-9/16

B 3-11/16 5-1/2 6-13/16 8 9-5/16 10-13/16 12-1/8 12-3/8 13 14-5/16 16-3/4

C 1-3/16 1-3/16 1-3/16 1-3/16 1-3/16 1-3/16 1-3/4 1-3/4 1-3/4 1-3/4 1-3/4

D 3-9/16 3-9/16 4-15/16 4-15/16 4-15/16 4-15/16 5-15/16 6-7/8 6-7/8 8-5/16 8-5/16

ANSI

5 5 5 6 8 8 8 8 8 8 8

125# FL

E ANSI

5 5 5 6 8 8 8 8 8 8 10

250# FL

MJ x MJ 8-1/2 8-1/2 8-1/2 8-5/8 9-1/4 9-1/4 11-1/2 12 12-1/4 12-1/2 13-1/4

Turns to

6 6 8 8 8 13 13 20 20 18 18

Open/Close

Optional Stainless Steel Disc and NBR Seat

Notes:

1. Designed and manufactured to AWWA C504. Handwheel O.D.

2. Flange ends to ANSI B16.1 Class 125. Other flange types are available. 3” ~ 4” 7.75

3. Mechanical-Jointed Ends to AWWA/ANSI C153/A21.53.00.

4. Top flange complies with ISO5211/1. 6” ~ 14” 11.75

5. Operator: Manual Gear Operator w/ Wheel Handle (as shown)

Manual Gear Operator w/2” Square AWWA Nut 16” ~ 24” 15.25

6. Design and material are subject to change without notice.

WARNING: This product can expose you to chemicals including lead, which is known to the State of California to

cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov.

United Water Products 0120

5355 Ramona Blvd., Jacksonville, FL 32205

TEL. 877-766-4459 FAX: 877-766-4458

Website: www.unitedwaterproducts.com

AWWA C-504 Model 3900F & Model 3900M

BUTTERFLY VALVE Class 150B and Class 250B

APPLICATIONS:

Butterfly Valves can be used in any installation where

throttling is desired in relatively clean liquid services. The

valve is bubble tight at full rated pressure allowing for dead

end service. Being a fully rubber lined valve allows this

valve to be used in rough service applications.

FEATURES:

Ductile Iron Body

Full Rubber Lining on flanged valves

AISI 420 or 630 Stainless Steel shaft

Fusion Bonded Epoxy Coating in accordance with AWWA

C550

ISO 5211 Mounting Plate

250 PSI Operating Pressure

Ductile Iron disc with 316 Stainless Steel disc edge

BENEFITS:

Ductile Iron bodies translate into pure strength achieving

three times that of Cast Iron alone. After Fusion Bonding,

the seat is vulcanized to the body making a very corrosion

resistant valve. The single piece 420 Stainless Steel shaft

is capable of high torques and will handle any actuator on

the market via the 5211 mounting plate. The polished 316

*Materials List and Dimensions on reverse side Stainless Steel edge of the Ductile Iron disc assures users

of a perfect seal every time.

SPECIFICATIONS:

All butterfly valves shall be bubble-tight in either direction at rated valve pressure with rubber seating confirming to

design standards of AWWA C-504 latest revision. Manufacturer shall have a minimum of ten years manufacturing

butterfly valves.

All butterfly valves bodies shall be constructed of Ductile Iron ASTM A536 Grade 65-45-12 and cast iron bodies will

not be permitted. The disc shall be constructed of ductile iron and have a polished 316 Stainless Steel edge

permanently welded to the disc. Cast Iron disc’s will not be permitted. The (NSF- 61) fusion bonded epoxy coated

body shall have a vulcanized rubber lining throughout the interior of the body extending beyond the waterway of the

valve to the outside of the valve. Standard epoxy paints and rubber seats attached to the disc will not be permitted.

The valve shaft will be constructed of AISI 420 or 630 Stainless Steel. All valves 24” and smaller shall have a single

piece shaft.

United Water Products 0120

5355 Ramona Blvd., Jacksonville, FL 32205

TEL. 877-766-4459 FAX: 877-766-4458

Website: www.unitedwaterproducts.com

You might also like

- Project Report On Unsaturated Polyester Resin (20 MT Per Day Output)Document7 pagesProject Report On Unsaturated Polyester Resin (20 MT Per Day Output)EIRI Board of Consultants and PublishersNo ratings yet

- Ecoline Est 150-600Document21 pagesEcoline Est 150-600Yosses Sang NahkodaNo ratings yet

- RV/RR - DETAIL DRAWING OF RESILIENT SEATED AND BUTTERFLY VALVESDocument64 pagesRV/RR - DETAIL DRAWING OF RESILIENT SEATED AND BUTTERFLY VALVESduc22198No ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Precast Concrete ReportDocument28 pagesPrecast Concrete ReportAchyutam Khajuria50% (2)

- 2309+QT04 - Gala-Motorized Butterfly ValveDocument4 pages2309+QT04 - Gala-Motorized Butterfly ValveNam Đỗ100% (1)

- Butterfly ValvesDocument27 pagesButterfly ValvesИгорьNo ratings yet

- Nutron TM Trunnion Mounted Ball Valve FlyerDocument2 pagesNutron TM Trunnion Mounted Ball Valve FlyerAlbert RubianoNo ratings yet

- V5-GRS-A125: Gate ValveDocument1 pageV5-GRS-A125: Gate ValveChristian oliverosNo ratings yet

- Butterfly Valves GuideDocument28 pagesButterfly Valves GuideLAWRENCENo ratings yet

- Forged High Pressure Ball Valves: SBVF360 SeriesDocument4 pagesForged High Pressure Ball Valves: SBVF360 SeriesToty DzNo ratings yet

- CLASS 150: AWWA C504 Double Flanged Butterfly ValveDocument1 pageCLASS 150: AWWA C504 Double Flanged Butterfly ValveAnnie De WildeNo ratings yet

- Flanged Ball ValveDocument20 pagesFlanged Ball ValveToty DzNo ratings yet

- Valve Cat-Seats, Offsets Etc..Document12 pagesValve Cat-Seats, Offsets Etc..PRASANTH PRASANTHNo ratings yet

- Lead Free Valves: Catalogue2018Document11 pagesLead Free Valves: Catalogue2018Ratheesh KumarNo ratings yet

- Data Sheet UbsvDocument6 pagesData Sheet UbsvMeet JaniNo ratings yet

- MSA Ball Valves enDocument20 pagesMSA Ball Valves enBiswajit DeyNo ratings yet

- MSA Ball Valves PDFDocument20 pagesMSA Ball Valves PDFAli FardidNo ratings yet

- CI Wafer / DI Lug Butterfly Valves: Series 0160Document2 pagesCI Wafer / DI Lug Butterfly Valves: Series 0160Vignesh NadimuthuNo ratings yet

- Keystone K-Lok 360-370 Data SheetDocument12 pagesKeystone K-Lok 360-370 Data SheetMnttoMecNo ratings yet

- Model 2400-L: Lug WaferDocument1 pageModel 2400-L: Lug WaferNicolás FriasNo ratings yet

- Newco Cast Carbon Steel Bolted Bonnet Valves Technical DataDocument1 pageNewco Cast Carbon Steel Bolted Bonnet Valves Technical DataOceanexNo ratings yet

- Valvulas Mariposas DorotDocument4 pagesValvulas Mariposas DorotVicenteRojasLeonNo ratings yet

- V3-GAN-A125 Gate Valve SpecificationDocument1 pageV3-GAN-A125 Gate Valve SpecificationArthur DeiparineNo ratings yet

- API 6D Wafer Style Dual Plate Check Valves: Fig No: MV-1220Document15 pagesAPI 6D Wafer Style Dual Plate Check Valves: Fig No: MV-1220VIVEK TIWARINo ratings yet

- HidraulicaDocument4 pagesHidraulicaAntonio Anatoly Viamont PintoNo ratings yet

- Fox ™ Triple Effect Air Vent + Anti Water Hammer: FeaturesDocument5 pagesFox ™ Triple Effect Air Vent + Anti Water Hammer: FeaturesNicolás Polito MuñozNo ratings yet

- Cast Steel Swing Check Valves-Bs 1868, Api-6D, Asme B16.34: M.M.K. Engineering Co. Pvt. LTDDocument3 pagesCast Steel Swing Check Valves-Bs 1868, Api-6D, Asme B16.34: M.M.K. Engineering Co. Pvt. LTDAnonymous 6ZWS6IG2J9No ratings yet

- 600scjs#cy 2-12 - 15Document2 pages600scjs#cy 2-12 - 15MohamadIbnuHassanNo ratings yet

- 140 Sheree Blvd. PO Box 566, Exton, PA 19341-0566 US - Web SiteDocument3 pages140 Sheree Blvd. PO Box 566, Exton, PA 19341-0566 US - Web SitegeorgyNo ratings yet

- UL FM OS&Y Gate Valves, AWWA C515 - Water Works - Fire Protection - Model 2030 Series ADocument1 pageUL FM OS&Y Gate Valves, AWWA C515 - Water Works - Fire Protection - Model 2030 Series ASiles LimberdsNo ratings yet

- REL-BFW-300 FM & UL Wafer Butterfly Valve: Material List Component MaterialDocument2 pagesREL-BFW-300 FM & UL Wafer Butterfly Valve: Material List Component MaterialSavy PhanethNo ratings yet

- DPCVDocument4 pagesDPCVjamil voraNo ratings yet

- Model: Wafer Style Knife Gate ValveDocument16 pagesModel: Wafer Style Knife Gate ValveMohamed RaafatNo ratings yet

- Rsgv-As: Resilient Seated Gate Valve Approved To As2638.2Document3 pagesRsgv-As: Resilient Seated Gate Valve Approved To As2638.2MaloneNo ratings yet

- Wheatley Series 822 Check Valves FlyerDocument2 pagesWheatley Series 822 Check Valves FlyerLorena DávilaNo ratings yet

- FT - F0233-300 - v. Compuerta NRS PDFDocument1 pageFT - F0233-300 - v. Compuerta NRS PDFDaniel AlvarezNo ratings yet

- Shinyi Catalogue 2017Document64 pagesShinyi Catalogue 2017Huy NguyễnNo ratings yet

- 3CM2S Piping Material Class Specification: 000-SP-PI02-0070Document5 pages3CM2S Piping Material Class Specification: 000-SP-PI02-0070Oswaldo GuerraNo ratings yet

- Gala Valve Fire Fighting Catalogue 2018 V#5 - A4 - BDocument7 pagesGala Valve Fire Fighting Catalogue 2018 V#5 - A4 - BChhomNo ratings yet

- Cast Steel Gate Valve: ANSI Class 150 & 300 ANSI Class 150 & 300Document5 pagesCast Steel Gate Valve: ANSI Class 150 & 300 ANSI Class 150 & 300Andri AjaNo ratings yet

- Valvulas OS&YDocument1 pageValvulas OS&Ydaniel manuel garces davilaNo ratings yet

- Series Cast Iron Full Port Class 125 Flanged Ball Valve: DescriptionDocument2 pagesSeries Cast Iron Full Port Class 125 Flanged Ball Valve: DescriptionLuisPortorelliZambranoNo ratings yet

- V4-CWD-A200: Double Door Check ValveDocument1 pageV4-CWD-A200: Double Door Check ValveArthur DeiparineNo ratings yet

- Cast Carbon Steel Check Valve: Class 150Document1 pageCast Carbon Steel Check Valve: Class 150Mina MagdyNo ratings yet

- Bellows Sealed Globe Valve, Flanged Ends 11.3-G-Fl: 1/2" - 2" Asme 150 - 600 LBDocument4 pagesBellows Sealed Globe Valve, Flanged Ends 11.3-G-Fl: 1/2" - 2" Asme 150 - 600 LBfranznelsonNo ratings yet

- Cast Steel Globe Valve Pressure Seal Class 1500, 2500Document3 pagesCast Steel Globe Valve Pressure Seal Class 1500, 2500Andri AjaNo ratings yet

- DelVal Series 64 3-PC Industrial Ball ValvesDocument2 pagesDelVal Series 64 3-PC Industrial Ball ValvesProcess Controls & ServicesNo ratings yet

- 88A-200 SERIES: Carbon Steel ASME Class 150 Flanged Full Port Ball Valve - 1/2" Through 1"Document9 pages88A-200 SERIES: Carbon Steel ASME Class 150 Flanged Full Port Ball Valve - 1/2" Through 1"alan quispe coronelNo ratings yet

- Technical Sheet BSA3TDocument4 pagesTechnical Sheet BSA3TMalik DaniyalNo ratings yet

- UL Listed Y Strainer - 300 Psi - Fire Protection - Model 3800Document1 pageUL Listed Y Strainer - 300 Psi - Fire Protection - Model 3800Nicolás Fernández CanepaNo ratings yet

- Valvula WaferDocument1 pageValvula Waferingenieria.proyectos.ipalcorNo ratings yet

- Union Bonnet Globe Valve: Submittal SheetDocument1 pageUnion Bonnet Globe Valve: Submittal SheetRajesh ChoudharyNo ratings yet

- 88A-200 Series: Standards Compliance Standard Features Variations AvailableDocument5 pages88A-200 Series: Standards Compliance Standard Features Variations AvailableEdgar Vilca HuanacuniNo ratings yet

- Argus FK 76M Ball Valve Material ListDocument2 pagesArgus FK 76M Ball Valve Material ListFelipe Gamboa Gálvez100% (1)

- Steam Trap Datasheet TLV Type P65SRNDocument2 pagesSteam Trap Datasheet TLV Type P65SRNAnonymous ThzA9zNo ratings yet

- 2 P I e C e S B A L L V A L V e C L A S S 8 0 0Document6 pages2 P I e C e S B A L L V A L V e C L A S S 8 0 0raulNo ratings yet

- Threaded End Connection: Series S Ductile IronDocument1 pageThreaded End Connection: Series S Ductile IronptnusadharmafNo ratings yet

- Butterfly Valves Gd-381: SpecificationDocument2 pagesButterfly Valves Gd-381: SpecificationJOSE GABRIELNo ratings yet

- AWWA C-504: Model 3900F & Model 3900MDocument2 pagesAWWA C-504: Model 3900F & Model 3900MPriyanka rajpurohitNo ratings yet

- Dn80 Pressure Reducing ValveDocument1 pageDn80 Pressure Reducing ValvePriyanka rajpurohitNo ratings yet

- Class 125 Iron Body Check ValvesDocument1 pageClass 125 Iron Body Check ValvesPriyanka rajpurohitNo ratings yet

- dn15 To dn50 PRVDocument2 pagesdn15 To dn50 PRVPriyanka rajpurohitNo ratings yet

- Lead-Free Bronze Check ValvesDocument1 pageLead-Free Bronze Check ValvesPriyanka rajpurohitNo ratings yet

- Monoflange AstavaDocument12 pagesMonoflange AstavaPriyanka rajpurohitNo ratings yet

- Trunnion Ball Valve DubaiDocument4 pagesTrunnion Ball Valve DubaiPriyanka rajpurohitNo ratings yet

- Ba BM: Backflow Preventer With Verifiable Reduced Pressure Zone With Funnel IncorporatedDocument4 pagesBa BM: Backflow Preventer With Verifiable Reduced Pressure Zone With Funnel IncorporatedPriyanka rajpurohitNo ratings yet

- Air 1500 PDFDocument24 pagesAir 1500 PDFPriyanka rajpurohitNo ratings yet

- Fully-Lugged Lever Operated Butterfly Valves PN16Document1 pageFully-Lugged Lever Operated Butterfly Valves PN16Priyanka rajpurohitNo ratings yet

- Pneumatic Heavy-Duty Quarter Turn ActautorDocument14 pagesPneumatic Heavy-Duty Quarter Turn ActautorPriyanka rajpurohitNo ratings yet

- TrunnionBallValveBrochure 6D EBROCHURE 091514Document40 pagesTrunnionBallValveBrochure 6D EBROCHURE 091514Marlon TurnerNo ratings yet

- Cryogenic Valve BrochureDocument30 pagesCryogenic Valve BrochurePriyanka rajpurohitNo ratings yet

- Control+Valve ProfileDocument12 pagesControl+Valve ProfilePriyanka rajpurohitNo ratings yet

- Swing Check DrawDocument1 pageSwing Check DrawPriyanka rajpurohitNo ratings yet

- 02 +trunnion+pipeline+ball+valveDocument10 pages02 +trunnion+pipeline+ball+valvePriyanka rajpurohitNo ratings yet

- Metal Seated GV DN350 PDFDocument1 pageMetal Seated GV DN350 PDFPriyanka rajpurohitNo ratings yet

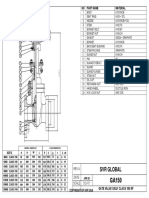

- GA150 CAST STEEL GA Specs 15-200Document1 pageGA150 CAST STEEL GA Specs 15-200Priyanka rajpurohitNo ratings yet

- 316SS globe valve technical data sheetDocument1 page316SS globe valve technical data sheetPriyanka rajpurohitNo ratings yet

- Double Flanged Butterfly Valve PDFDocument1 pageDouble Flanged Butterfly Valve PDFPriyanka rajpurohitNo ratings yet

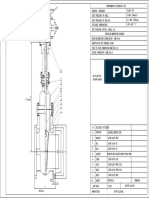

- Motor Controlled Gate Valve Z941H-16C DN150 DN200 PDFDocument1 pageMotor Controlled Gate Valve Z941H-16C DN150 DN200 PDFPriyanka rajpurohitNo ratings yet

- Range: Rack & Pinion ActuatorsDocument12 pagesRange: Rack & Pinion ActuatorsPriyanka rajpurohitNo ratings yet

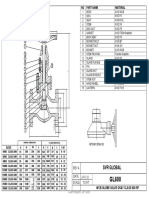

- GL300 CAST STEEL GL SpecsDocument1 pageGL300 CAST STEEL GL SpecsPriyanka rajpurohitNo ratings yet

- Av-Tek DEX Double EccentricDocument12 pagesAv-Tek DEX Double Eccentrickbc404No ratings yet

- GL600 CAST STEEL GL SpecsDocument1 pageGL600 CAST STEEL GL SpecsPriyanka rajpurohitNo ratings yet

- Double Eccentric Butterfly Valve With Manual Gear Operator - AWWA C504 - Water Works PDFDocument1 pageDouble Eccentric Butterfly Valve With Manual Gear Operator - AWWA C504 - Water Works PDFPriyanka rajpurohitNo ratings yet

- GL300 CAST STEEL GL SpecsDocument1 pageGL300 CAST STEEL GL SpecsPriyanka rajpurohitNo ratings yet

- GL600 CAST STEEL GL SpecsDocument1 pageGL600 CAST STEEL GL SpecsPriyanka rajpurohitNo ratings yet

- GL600 - CAST - STEEL - GL - Specs Uns TrimDocument1 pageGL600 - CAST - STEEL - GL - Specs Uns TrimPriyanka rajpurohitNo ratings yet

- Graphite Structures in Cast Irons ELKEMDocument1 pageGraphite Structures in Cast Irons ELKEMVishal NangareNo ratings yet

- Prestressed Beam Design for Conventional HallDocument12 pagesPrestressed Beam Design for Conventional HallHaymanAHMEDNo ratings yet

- Wood Plastic Composites - A PrimerDocument11 pagesWood Plastic Composites - A PrimerParchuri PraveenNo ratings yet

- A Simple Small Metalworking ShaperDocument7 pagesA Simple Small Metalworking ShaperAxel DominiqueNo ratings yet

- Sheet Piles: There Are 3 Main Types of Sheet Pile WallsDocument7 pagesSheet Piles: There Are 3 Main Types of Sheet Pile WallsniyatiNo ratings yet

- Mass Housing Using GFRG Panels A Sustainable RapidDocument7 pagesMass Housing Using GFRG Panels A Sustainable RapidGanesh SuryawashiNo ratings yet

- Who's Who in Polymers Natural Plastics Timeline: Year Discovered byDocument10 pagesWho's Who in Polymers Natural Plastics Timeline: Year Discovered byelsobkiNo ratings yet

- Fiberstrong Product InformationDocument80 pagesFiberstrong Product InformationpradeepNo ratings yet

- 01 - Different Types of Metal Joining ProcessesDocument44 pages01 - Different Types of Metal Joining ProcessesMetwally NaserNo ratings yet

- Reformulated SoR 2016-17Document54 pagesReformulated SoR 2016-17Muncipal Engineer EluruNo ratings yet

- How To Install Wall Angle For A Drop CeilingDocument5 pagesHow To Install Wall Angle For A Drop CeilingcoyzNo ratings yet

- Section 078200 - Board FireproofingDocument5 pagesSection 078200 - Board FireproofingWENDING HUNo ratings yet

- Working Principle of FSPDocument5 pagesWorking Principle of FSPjames_raj_7No ratings yet

- Mil e 5400TDocument71 pagesMil e 5400TNikola GrgićNo ratings yet

- KEI BRAND CABLE PRICE LIST MARCH 2019Document15 pagesKEI BRAND CABLE PRICE LIST MARCH 2019tejaswi1700No ratings yet

- Iso Important DocumentDocument6 pagesIso Important DocumentKDTNo ratings yet

- AVA-Alms Valve Agency Info Sheet (2013)Document26 pagesAVA-Alms Valve Agency Info Sheet (2013)MeanRatNo ratings yet

- Consolidated Commerical Form 1Document71 pagesConsolidated Commerical Form 1Mathias OnosemuodeNo ratings yet

- LECTURE ON MATERIALS FOR UREA PLANTSDocument19 pagesLECTURE ON MATERIALS FOR UREA PLANTSdeepankar kumarNo ratings yet

- Application 6 Kasım Design of The Building Envelope Related To Thermal ComfortDocument10 pagesApplication 6 Kasım Design of The Building Envelope Related To Thermal ComfortMukhammadjonNo ratings yet

- Fireproof Insulated Metal Wall PanelDocument2 pagesFireproof Insulated Metal Wall Panelliviu_dovaNo ratings yet

- Masterseal 501 Wa TdsDocument2 pagesMasterseal 501 Wa TdsStephen Ogalo100% (1)

- ACI 530 QuestionsDocument3 pagesACI 530 QuestionsEduardo De Castro Cruz Jr.100% (1)

- Dr. Fixit Pidicrete MPB acrylic concrete binderDocument3 pagesDr. Fixit Pidicrete MPB acrylic concrete binderamandeepsuperanNo ratings yet

- Final Presentation - Corrected (1) .PPTX RaviDocument15 pagesFinal Presentation - Corrected (1) .PPTX RavisudamNo ratings yet

- GalvInfoNote 1 9Document4 pagesGalvInfoNote 1 9Sajib Chandra RoyNo ratings yet

- Unit 7Document25 pagesUnit 7rameshbabu_1979No ratings yet

- SikaGrout - 212Document4 pagesSikaGrout - 212Frans van der MerweNo ratings yet