Professional Documents

Culture Documents

2 P I e C e S B A L L V A L V e C L A S S 8 0 0

Uploaded by

raulOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2 P I e C e S B A L L V A L V e C L A S S 8 0 0

Uploaded by

raulCopyright:

Available Formats

REF.

716-717

2 PIECES BALL VALVE CLASS 800

Size : DN 1/4“ to DN 2“

Ends : Threaded female BSP, NPT or S.W.

Min Temperature : - 30°C in S.S. and - 20°C in carbon steel

Max Temperature : + 180°C

Max Pressure : 138 Bars (Class 800)

Specifications : Anti blow-out stem

Fire safe

Full bore

Materials : Carbon steel or Stainless steel

Date : 10/15 Rev.09

Page 1 of 6

Information provided as an indication and subject to possible modification

REF. 716-717

2 PIECES BALL VALVE CLASS 800

SPECIFICATIONS :

Full bore

Anti blow-out stem

Class 800

Fire safe according to BS 6755 part.2

Atex

Antistatic device

2 pieces type

Galvanization treatment of zinc anti-corrosion coating, 8µ thickness (for ref.717)

USE :

Chemical and pharmaceutical industries, petrochemical industries, hydraulic installation, compressed air

Min and max Temperature Ts : - 30°C to + 180°C for stainless steel type Ref.716

Min and max Temperature Ts : - 20°C to + 180°C for carbon steel type Ref.717

Max Pressure Ps : 138 bars

Steam : 10 bars maximum

RANGE :

Ball valve class 800 forged carbon steel ASTM A105N body Ref. 717 DN 1/4“ to DN 2“

Ball valve class 800 forged stainless steel body ASTM A182 F316L Ref. 716 DN 1/4“ to DN 2“

Stainless steel 304 with red cover handle Ref. 9830316-9830318

Locking device Ref. 9830301-9830315

Galvanized steel handwheel Ref.9830571-9830574

ENDS :

Female / female threaded cylindrical BSP Ref. 716 and 717

Female / female threaded NPT Ref. 7161 and 7171

Socket Welding ends Ref. 7162 and 7172

Date : 10/15 Rev.09

Page 2 of 6

Information provided as an indication and subject to possible modification

REF. 716-717

2 PIECES BALL VALVE CLASS 800

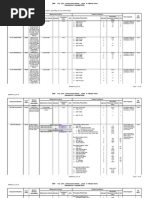

MATERIALS :

Item Designation Materials 717 Materials 716

1 Body ASTM A105N ASTM A182 F316L

2 Ball ASTM A182 F316L

3 Stem ASTM A182 F316L

4 Ends ASTM A105N ASTM A182 F316L

5 Body gasket Carbongraphite

6 Seat PTFE + carbongraphite

7 Stem gasket Carbongraphite

8 Disc springs Steel

9 Packing gland ASTM A105 F304

10 Stop FE P11 ( UNI 5867 )

11 Nut Steel 6S

12 Handle FE P11 ( UNI 5867 )

Date : 10/15 Rev.09

Page 3 of 6

Information provided as an indication and subject to possible modification

REF. 716-717

2 PIECES BALL VALVE CLASS 800

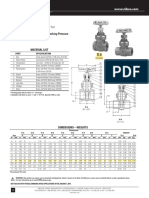

SIZE ( in mm ) :

Stem size : SW ends size ( Ref.7162 and 7172 ) :

Ref. DN 8 10 15 20 25 32 40 50

Ø Bore 10 10 15 20 25 30 38 48

L 67 67 75 90 105 120 135 155

E 148 148 148 180 180 240 240 280

H 72 72 75 85 95 100 105 115

716 / 717 C 5 5 5.5 7.5 7.5 9 9 9

ØY 8 8 10 12 12 14 14 14

Ø SW 14.3 17.8 21.8 27.3 34 42.6 48.7 61.3

L1 9.5 9.5 9.5 11.5 13 14 16 17

Weight ( Kg ) 0.6 0.6 0.8 1.5 2 3.3 4.5 6

Date : 10/15 Rev.09

Page 4 of 6

Information provided as an indication and subject to possible modification

REF. 716-717

2 PIECES BALL VALVE CLASS 800

HANDWHEEL SIZE ( in mm ) :

DN 1/4" 3/8" 1/2" 3/4" 1" 1"1/4 1"1/2 2"

H 70 70 70 64 64 80 80 80

L 128 128 128 130 130 205 205 205

L1 63 63 63 82 82 105 105 105

Ref. 9830571 9830571 9830572 9830573 9830573 9830574 9830574 9830574

Weight (Kg) 0.300 0.300 0.380 0.420 0.420 0.460 0.460 0.460

Date : 10/15 Rev.09

Page 5 of 6

Information provided as an indication and subject to possible modification

REF. 716-717

2 PIECES BALL VALVE CLASS 800

STANDARDS :

Fabrication according to ISO 9001 : 2008

DIRECTIVE 97/23/CE : CE N° 0948

Risk category III Module B+C1

Pressure tests according to API 598, table 6

Fire safe according to B.S. 6755 part.2

Threaded female BSP cylindrical ends according to ISO 228/1

Threaded female NPT ends according to ANSI B2.1

Materials according to NACE MR 01-75

ATEX Group II Category 2 G/2D Zone 1 & 21 Zone 2 &22 ( optional marking )

INSTALLATION AND MAINTENANCE

BEFORE INSTALLATION :

Pipe-line must be cleaned and free from residual of weldings,rubbish,shaving and every kind of extraneous materials.

Pipe-line must be perfectly aligned and their support properly dimensioned so that there’s no external constraint.

Please use the right product according to the services conditions to seal the valve.

Use the right bolt tightening so that the ends won’t be damaged.

During welding operation, for S.W. types half open the valve and weld the valves according to special procedures (like in

water) to protect the seat because it could burn.

CLEANING AND TESTS

Keep closed the valves during the cleaning operation so that there’s no impurities between the ball and the body.

Tests under pressure must be done with a cleaned pipe-line.

Open partially the valve for tests. Pressure test do not exceed the valve specifications according to API 598.

MAITENANCE

It’s recommended to operate the valve ( open and close ) 1 to 2 times per year.

When intervention on the valve, be sure there’s no pressure in the pipe-line, there’s no fluid in it,and that it is isolated.

The temperature must be low enough to operate without risks.

If there’s a corrosive fluid,inert installation before intervention.

Date : 10/15 Rev.09

Page 6 of 6

Information provided as an indication and subject to possible modification

You might also like

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Data Sheet UbsvDocument6 pagesData Sheet UbsvMeet JaniNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- technical_datasheet_forged_carbon_steel_a105n_gate_valve_trim8_class800_bspDocument5 pagestechnical_datasheet_forged_carbon_steel_a105n_gate_valve_trim8_class800_bspBenny 37No ratings yet

- Check Ranurado RH84X MechDocument1 pageCheck Ranurado RH84X MechFLOW INDUSTRIAL SACNo ratings yet

- AWWA C-504: Model 3900F & Model 3900MDocument2 pagesAWWA C-504: Model 3900F & Model 3900MPriyanka rajpurohitNo ratings yet

- technical_datasheet_forged_carbon_steel_a105n_gate_valve_trim8_class800_nptDocument5 pagestechnical_datasheet_forged_carbon_steel_a105n_gate_valve_trim8_class800_nptBenny 37No ratings yet

- FTS62Document6 pagesFTS62Mauro Sebastian ViganottiNo ratings yet

- Ecoline Est 150-600Document21 pagesEcoline Est 150-600Yosses Sang NahkodaNo ratings yet

- Butterfly ValvesDocument27 pagesButterfly ValvesИгорьNo ratings yet

- technical_datasheet_forged_carbon_steel_a105n_gate_valve_trim8_class800_swDocument5 pagestechnical_datasheet_forged_carbon_steel_a105n_gate_valve_trim8_class800_swBenny 37No ratings yet

- technical_datasheet_2_pieces_forged_carbon_steel_ball_valve_800lbsDocument7 pagestechnical_datasheet_2_pieces_forged_carbon_steel_ball_valve_800lbsBenny 37No ratings yet

- Forged Steel A105 Class 150 Mod. XXXXX: Pressure Temperature RatingsDocument2 pagesForged Steel A105 Class 150 Mod. XXXXX: Pressure Temperature Ratingsanthony RodriguezNo ratings yet

- Filtro DuplexDocument8 pagesFiltro DuplexGuillermo ArandaNo ratings yet

- Plummech Check ValvesDocument1 pagePlummech Check ValvesNguyễn Đăng PhúcNo ratings yet

- 2309+QT04 - Gala-Motorized Butterfly ValveDocument4 pages2309+QT04 - Gala-Motorized Butterfly ValveNam Đỗ100% (1)

- BUTTERFLY VALVE SPECSDocument18 pagesBUTTERFLY VALVE SPECSRiswanda HimawanNo ratings yet

- Valve Cat-Seats, Offsets Etc..Document12 pagesValve Cat-Seats, Offsets Etc..PRASANTH PRASANTHNo ratings yet

- Butterfly Valves GuideDocument28 pagesButterfly Valves GuideLAWRENCENo ratings yet

- Floating Ball 715,730Document4 pagesFloating Ball 715,730Danielle JohnsonNo ratings yet

- 170 172 176 RegadaDocument8 pages170 172 176 RegadaOreavu BuzauNo ratings yet

- SY Y StranerDocument2 pagesSY Y StranerPhú Song LongNo ratings yet

- CORROSION COUPON AT AR 701 Project Description ADocument2 pagesCORROSION COUPON AT AR 701 Project Description AKian GancangNo ratings yet

- technical_datasheet_2_pieces_forged_carbon_steel_ball_valve_800lbs_wedling_endsDocument11 pagestechnical_datasheet_2_pieces_forged_carbon_steel_ball_valve_800lbs_wedling_endsBenny 37No ratings yet

- Keystone K-Lok 360-370 Data SheetDocument12 pagesKeystone K-Lok 360-370 Data SheetMnttoMecNo ratings yet

- Stainless Steel Ball Valve SpecsDocument6 pagesStainless Steel Ball Valve SpecsTelmo EstrelaNo ratings yet

- FT Valvula Compuerta Clase 800 SWDocument1 pageFT Valvula Compuerta Clase 800 SWFernando CarreñoNo ratings yet

- Unprice Quotation - Forged Steel ValveDocument3 pagesUnprice Quotation - Forged Steel ValveTommy ArjanggiNo ratings yet

- Technical Sheet BSA3TDocument4 pagesTechnical Sheet BSA3TMalik DaniyalNo ratings yet

- Swing Check Valve - Flanged: Technical FeaturesDocument1 pageSwing Check Valve - Flanged: Technical FeaturesAhmed El MorsyNo ratings yet

- Flanged Ball ValveDocument20 pagesFlanged Ball ValveToty DzNo ratings yet

- 783 784 785 786Document8 pages783 784 785 786lesonspkNo ratings yet

- 600scjs#cy 2-12 - 15Document2 pages600scjs#cy 2-12 - 15MohamadIbnuHassanNo ratings yet

- 12 Valves SpecificationsDocument19 pages12 Valves Specificationsshaliq28100% (1)

- Forged High Pressure Ball Valves: SBVF360 SeriesDocument4 pagesForged High Pressure Ball Valves: SBVF360 SeriesToty DzNo ratings yet

- A51L-6438-250-PNID - Rev 5Document1 pageA51L-6438-250-PNID - Rev 5Manuel SerranoNo ratings yet

- Filtro Tipo yDocument5 pagesFiltro Tipo yKaren BasoaltoNo ratings yet

- Steam Trap: P46SRN/P46SRM/P46SRWDocument2 pagesSteam Trap: P46SRN/P46SRM/P46SRWGina FelyaNo ratings yet

- Ball Three Pieces Steel A105 / A216 WCB 1000 PSIG: Pressure Temperature RatingsDocument2 pagesBall Three Pieces Steel A105 / A216 WCB 1000 PSIG: Pressure Temperature RatingsAlicia MartinezNo ratings yet

- RV/RR - DETAIL DRAWING OF RESILIENT SEATED AND BUTTERFLY VALVESDocument64 pagesRV/RR - DETAIL DRAWING OF RESILIENT SEATED AND BUTTERFLY VALVESduc22198No ratings yet

- FlowBiz Forged Steel Globe Valve Reduced BoreDocument2 pagesFlowBiz Forged Steel Globe Valve Reduced BoreFlowBiz Exports Pvt. Ltd.No ratings yet

- Cast Steel Swing Check Valves-Bs 1868, Api-6D, Asme B16.34: M.M.K. Engineering Co. Pvt. LTDDocument3 pagesCast Steel Swing Check Valves-Bs 1868, Api-6D, Asme B16.34: M.M.K. Engineering Co. Pvt. LTDAnonymous 6ZWS6IG2J9No ratings yet

- UL FM OS&Y Gate Valves, AWWA C515 - Water Works - Fire Protection - Model 2030 Series ADocument1 pageUL FM OS&Y Gate Valves, AWWA C515 - Water Works - Fire Protection - Model 2030 Series ASiles LimberdsNo ratings yet

- Needle Valves Screwed Bonnet Design Double Ferrule Tube EndsDocument1 pageNeedle Valves Screwed Bonnet Design Double Ferrule Tube Endsponmanikandan1No ratings yet

- Fdez. Jove - Valvula 3 Vías - (SFERACO)Document12 pagesFdez. Jove - Valvula 3 Vías - (SFERACO)Pedro VarelaNo ratings yet

- Brass Gate Valve: Brass Body - Non-Rising Stem - Full PortDocument1 pageBrass Gate Valve: Brass Body - Non-Rising Stem - Full PortBrayan CJNo ratings yet

- CLASS 150: AWWA C504 Double Flanged Butterfly ValveDocument1 pageCLASS 150: AWWA C504 Double Flanged Butterfly ValveAnnie De WildeNo ratings yet

- Series Cast Iron Full Port Class 125 Flanged Ball Valve: DescriptionDocument2 pagesSeries Cast Iron Full Port Class 125 Flanged Ball Valve: DescriptionLuisPortorelliZambranoNo ratings yet

- 1 110 Gauge Shutoff ValveDocument2 pages1 110 Gauge Shutoff ValveAinayya alfatimahNo ratings yet

- Temp. Control ValveDocument7 pagesTemp. Control Valvesaurabh kumarNo ratings yet

- Shinyi Catalogue 2017Document64 pagesShinyi Catalogue 2017Huy NguyễnNo ratings yet

- Spirax Sarco Piston Valve RP31Document2 pagesSpirax Sarco Piston Valve RP31PaulNo ratings yet

- Swing Check Valve 900 Class SpecDocument1 pageSwing Check Valve 900 Class SpecMunishTrichyNo ratings yet

- Bellow Seal Valves: AN ISO 9001:2000 COMPANYDocument20 pagesBellow Seal Valves: AN ISO 9001:2000 COMPANYDeepak HishikarNo ratings yet

- technical_datasheet_forged_carbon_steel_a105n_gate_valve_trim16_class800_nptDocument5 pagestechnical_datasheet_forged_carbon_steel_a105n_gate_valve_trim16_class800_nptBenny 37No ratings yet

- Cast Iron Ball Valve PN 16 Length DINDocument8 pagesCast Iron Ball Valve PN 16 Length DINKarolNo ratings yet

- DelVal Series 64 3-PC Industrial Ball ValvesDocument2 pagesDelVal Series 64 3-PC Industrial Ball ValvesProcess Controls & ServicesNo ratings yet

- 08.25 Victaulic® Knife Gate ValveDocument8 pages08.25 Victaulic® Knife Gate ValveMichał KisielewskiNo ratings yet

- Valvula Mariposa FlowsealDocument12 pagesValvula Mariposa Flowsealsakura_jNo ratings yet

- Ball and Roller Bearing SteelsDocument18 pagesBall and Roller Bearing SteelsraulNo ratings yet

- Study of Meta-Dynamic Recrystallization Behavior of GH5188 SuperalloyDocument11 pagesStudy of Meta-Dynamic Recrystallization Behavior of GH5188 SuperalloyraulNo ratings yet

- Standard Specification For: Designation: B574 17Document6 pagesStandard Specification For: Designation: B574 17raulNo ratings yet

- Electrochemical DeburringDocument8 pagesElectrochemical DeburringraulNo ratings yet

- Conservation and Segregation OF Critical Alloy and Precious Metal Bearing Parts and ScrapDocument18 pagesConservation and Segregation OF Critical Alloy and Precious Metal Bearing Parts and ScrapraulNo ratings yet

- Astm A351 - A351m - 13Document5 pagesAstm A351 - A351m - 13raulNo ratings yet

- Castings, Austenitic, For Pressure-Containing PartsDocument7 pagesCastings, Austenitic, For Pressure-Containing PartsraulNo ratings yet

- A216a216m 38465 PDFDocument4 pagesA216a216m 38465 PDFraulNo ratings yet

- Castings, Austenitic, For Pressure-Containing PartsDocument7 pagesCastings, Austenitic, For Pressure-Containing PartsraulNo ratings yet

- Mobin Data Sheet Sample-14000405Document12 pagesMobin Data Sheet Sample-14000405raulNo ratings yet

- Astm e 186 2015Document4 pagesAstm e 186 2015Husen TaufiqNo ratings yet

- Astm A105Document5 pagesAstm A105ahmad0% (1)

- Steel Castings, Ferritic and Martensitic, For Pressure-Containing Parts, Suitable For Low-Temperature ServiceDocument7 pagesSteel Castings, Ferritic and Martensitic, For Pressure-Containing Parts, Suitable For Low-Temperature Serviceist93993No ratings yet

- Steam or Valve Bronze Castings: Standard Specification ForDocument3 pagesSteam or Valve Bronze Castings: Standard Specification ForAhmed BilalNo ratings yet

- Fisher ED, EAD, and EDR Sliding - Stem Control Valves: The Easy - e Valve FamilyDocument28 pagesFisher ED, EAD, and EDR Sliding - Stem Control Valves: The Easy - e Valve FamilyraulNo ratings yet

- Fisher ValvesDocument12 pagesFisher ValvesmohamedkhalifehNo ratings yet

- General Requirements For Copper Alloy CastingsDocument6 pagesGeneral Requirements For Copper Alloy CastingsLC Chong100% (1)

- Steel Castings, Welding, Qualifications of Procedures and PersonnelDocument19 pagesSteel Castings, Welding, Qualifications of Procedures and PersonnelDavidNo ratings yet

- SUSTARIN C EN-pomDocument1 pageSUSTARIN C EN-pomraulNo ratings yet

- ASTM A703 - 2018aDocument13 pagesASTM A703 - 2018aahmad100% (2)

- Ansi b36.10 Pipe SizeDocument9 pagesAnsi b36.10 Pipe SizeSpoonful BurnsideNo ratings yet

- Preparation and Characterization of Polyaluminum Chloride Containing High Content of Al and Active ChlorineDocument9 pagesPreparation and Characterization of Polyaluminum Chloride Containing High Content of Al and Active ChlorineraulNo ratings yet

- DS BA Double Flanged Butterfly ValveDocument5 pagesDS BA Double Flanged Butterfly ValveraulNo ratings yet

- CLPL 11 09Document30 pagesCLPL 11 09Ilham SipalaNo ratings yet

- Acetal (POM) Molding and Extrusion Materials: Standard Classification ForDocument9 pagesAcetal (POM) Molding and Extrusion Materials: Standard Classification ForraulNo ratings yet

- SUSTARIN C EN-pomDocument1 pageSUSTARIN C EN-pomraulNo ratings yet

- Aerospace Science and Technology: Julien Caillet, Franck Marrot, Yannick Unia, Pierre-Antoine AubourgDocument9 pagesAerospace Science and Technology: Julien Caillet, Franck Marrot, Yannick Unia, Pierre-Antoine AubourgraulNo ratings yet

- The Electrochemical Production of Highly Effective Polyaluminum ChlorideDocument7 pagesThe Electrochemical Production of Highly Effective Polyaluminum ChlorideraulNo ratings yet

- Nondestructive Rapid Identification of Metals and Alloys by Spot TestDocument58 pagesNondestructive Rapid Identification of Metals and Alloys by Spot TestraulNo ratings yet

- Four Pillars of EducationDocument42 pagesFour Pillars of EducationWinter BacalsoNo ratings yet

- Using Previous Years AlmanacDocument1 pageUsing Previous Years AlmanacbhabhasunilNo ratings yet

- Remote Control Panel (RCP) User'S GuideDocument13 pagesRemote Control Panel (RCP) User'S GuideAdrian PuscasNo ratings yet

- Flavors Supplies BudgetDocument6 pagesFlavors Supplies BudgetJomarie EmilianoNo ratings yet

- WET - AT - AT - 003 - ENG - Manuale Di Istruzione Tenute LubrificateDocument15 pagesWET - AT - AT - 003 - ENG - Manuale Di Istruzione Tenute LubrificateNadia WilsonNo ratings yet

- Sharp Sharp Cash Register Xe A207 Users Manual 284068Document1 pageSharp Sharp Cash Register Xe A207 Users Manual 284068Zeila CordeiroNo ratings yet

- Holy Week Labyrinth GuideDocument4 pagesHoly Week Labyrinth GuideEileen Campbell-Reed100% (1)

- Vocabulary Practice 1Document3 pagesVocabulary Practice 1Phuong AnhNo ratings yet

- B.O Blog 6 (Benefits and Hacks of Using Turmeric)Document6 pagesB.O Blog 6 (Benefits and Hacks of Using Turmeric)sanaNo ratings yet

- Database AwsDocument15 pagesDatabase AwsHareesha N GNo ratings yet

- 1675.does Concrete Lighten or Change Color As It DriesDocument5 pages1675.does Concrete Lighten or Change Color As It DriestvrNo ratings yet

- Project management software enables collaborationDocument4 pagesProject management software enables collaborationNoman AliNo ratings yet

- Julia Henzler - Resume 2 27Document1 pageJulia Henzler - Resume 2 27api-491391730No ratings yet

- GRP 10 JV'sDocument43 pagesGRP 10 JV'sManas ChaturvediNo ratings yet

- Agile Spotify - Team - HomeworkDocument8 pagesAgile Spotify - Team - Homeworksp76rjm7dhNo ratings yet

- Ethylene Yield From Pyrolysis Cracking in Olefin PDocument6 pagesEthylene Yield From Pyrolysis Cracking in Olefin PALL2WINNo ratings yet

- Nord Stage Factory Patches v3 v4 v5Document18 pagesNord Stage Factory Patches v3 v4 v5Danilo Giuliani DobermannNo ratings yet

- MMC Fiori Cheat Sheet PDFDocument2 pagesMMC Fiori Cheat Sheet PDFAleksandar KNo ratings yet

- Master in Public Management: Application PacketDocument6 pagesMaster in Public Management: Application PacketMark GironNo ratings yet

- Monologue Speech in A Foreign Language LessonDocument3 pagesMonologue Speech in A Foreign Language LessonResearch ParkNo ratings yet

- Pediatrics Study ScheduleDocument2 pagesPediatrics Study ScheduleNatnaelNo ratings yet

- My CV - Rose ChebetDocument5 pagesMy CV - Rose ChebetSammy WatimaNo ratings yet

- wizBRAINeng20 2Document4 pageswizBRAINeng20 2Deepika AgrawalNo ratings yet

- Cooler Ok El8sDocument11 pagesCooler Ok El8sIBRAHIM ALMANLANo ratings yet

- Consumer Notebook Price List For September 2010Document4 pagesConsumer Notebook Price List For September 2010Anand AryaNo ratings yet

- Strategic Marketing Plan for British American TobaccoDocument31 pagesStrategic Marketing Plan for British American TobaccoAli Abbas50% (2)

- DownloadDocument2 pagesDownloadAmit KumarNo ratings yet

- 2006fileaveo MTDocument63 pages2006fileaveo MTeurospeed2100% (1)

- Berkowitz Et Al (2010) - Skills For Psychological Recovery - Field Operations GuideDocument154 pagesBerkowitz Et Al (2010) - Skills For Psychological Recovery - Field Operations GuideRita CamiloNo ratings yet

- Jurnal Mira FixDocument16 pagesJurnal Mira Fixarisanto micoNo ratings yet