Professional Documents

Culture Documents

CORROSION COUPON AT AR 701 Project Description A

Uploaded by

Kian GancangOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CORROSION COUPON AT AR 701 Project Description A

Uploaded by

Kian GancangCopyright:

Available Formats

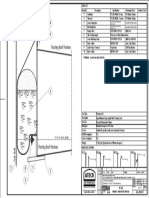

CORROSION COUPON AT AR-701 INSTALLATION

Introduction

The RBI (Risk Base Inspection) inspection program was initiated to determine internal

inspection due date requirements for the FFAR (Fixed Film Anaerobic Reactor) tanks,

and also determine risks driving the required internal inspection interval. As outcome of

this RBI assessment work it is recommended that Acoustic Emission (AE) test are used to

monitor floor conditions, allowing future operations and inspection, repair, replacement

plans to be managed using results from these tests. To confirm corrosion rate by biogas

corrosion coupon shall be install before conduct Acoustic Emission (AE) in year 2012.

Project Description

Install 3 duplicate sets of Coupons, for remove the coupon after 6 month, 1 year, and 2

years. The ideal location would be to insert the corrosion coupon rack through the T1, T2,

or T3 roof inspection nozzle Tank AR-701 with a 2" ball valve on each the three T1, T2,

T3 nozzle, so the coupon rack diameter would have to slide through a 2" ball valve.

Corrosion coupon should be placed at vapor space of reactor.

Design Data

AR-701 Tank

Design Pressure : 600 (max) – 50 (min) mm H2O

Operation Pressure : 200 mm H2O

o

Temperature : 37 C

Content : Water, packing biomass

Capacity Nominal : 6872 M3

Dimension :

- Diameter 25000 mm

- Height T-T 14000 mm

Tank Material : CS with coating epoxy phenolic

Material List AR-701

No Description Material Width/Thickness Welding Type

1 Roof A283C - / 8,0 Dbl Lap

2 Shell

#1 A283C 2800 / 9,6 Dbl Butt

#2 A283C 2800 / 9,6 Dbl Butt

#3 A253C 2800 / 11,0 Dbl Butt

#4 A131B 2800 / 12,5 Dbl Butt

#5 A131B 2800 / 14,9 Dbl Butt

3 Annular Plate A131B - / 9,6 Dbl Butt

4 Bottom Plate A283C 2285 / 9,6 Sgl Lap

5 Compression Bar A283C 310 / 35 Dbl Butt

6 Stiffener SS 400 L 150 x 100 x 9 Sgl Butt w/ B.U.Bar

7 Roof framing SS 400

8 Nozzle Flange A105

9 Nozzle Neck A106

10 Support Structure SS 400

11 Support Grid SS 400

You might also like

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- 110 00 Training Guide Rev 1Document30 pages110 00 Training Guide Rev 1vilegual1No ratings yet

- Data Sheet UbsvDocument6 pagesData Sheet UbsvMeet JaniNo ratings yet

- HEAT EXCHANGER DESIGN CALCULATIONSDocument8 pagesHEAT EXCHANGER DESIGN CALCULATIONSanishNo ratings yet

- Earthing & Lightning Protection Technical Spec - Nghi Son 2 Thermal PowerDocument46 pagesEarthing & Lightning Protection Technical Spec - Nghi Son 2 Thermal PowerQuang LuongNo ratings yet

- A. BALL - FloatingDocument3 pagesA. BALL - FloatingSaputraNo ratings yet

- Globe Rev. A SHT 2Document1 pageGlobe Rev. A SHT 2Agus SupriadiNo ratings yet

- PT. (PERSERO) Bill of Quantity for 5 Tube BundlesDocument3 pagesPT. (PERSERO) Bill of Quantity for 5 Tube BundlesmoddysNo ratings yet

- 11d Pms Rev00a Ongc 27jul15Document3 pages11d Pms Rev00a Ongc 27jul15abhiNo ratings yet

- Datasheet For Ball ValveDocument1 pageDatasheet For Ball ValvevalveNo ratings yet

- Att 2 - EdsDocument30 pagesAtt 2 - Eds정동현No ratings yet

- Cast Steel Swing Check Valves-Bs 1868, Api-6D, Asme B16.34: M.M.K. Engineering Co. Pvt. LTDDocument3 pagesCast Steel Swing Check Valves-Bs 1868, Api-6D, Asme B16.34: M.M.K. Engineering Co. Pvt. LTDAnonymous 6ZWS6IG2J9No ratings yet

- Bill of Quantity: Fabrikasi 4 (Empat) Unit Tube Bundle 11-E-106, 11-E-118B, 11-E-119, 11-E-127, Tahun 2013Document3 pagesBill of Quantity: Fabrikasi 4 (Empat) Unit Tube Bundle 11-E-106, 11-E-118B, 11-E-119, 11-E-127, Tahun 2013moddysNo ratings yet

- Bectel ASME Process Cal R2Document21 pagesBectel ASME Process Cal R2Sivakumar SelvarajNo ratings yet

- Drilling Engineering: PETE 203Document48 pagesDrilling Engineering: PETE 203nicessg@gmail.comNo ratings yet

- Drilling Engineering: PETE 203Document48 pagesDrilling Engineering: PETE 203AbdullahNo ratings yet

- Tbe For Osbl (SBS)Document5 pagesTbe For Osbl (SBS)benidbb100% (3)

- 5 Catalogue Winway DBB Valve-MinDocument19 pages5 Catalogue Winway DBB Valve-MinAsyadullah Al-FatihNo ratings yet

- NPT Sop Pde 004 f08 Bom Globe ValveDocument18 pagesNPT Sop Pde 004 f08 Bom Globe ValveMohamed SelimNo ratings yet

- Expansion Bellow SpecificationDocument1 pageExpansion Bellow SpecificationASHWINI BHOSALENo ratings yet

- Type C: Hopper Shape Knife Gate ValveDocument13 pagesType C: Hopper Shape Knife Gate ValveAbdur Rohman Al BaabNo ratings yet

- Fox ™ Triple Effect Air Vent + Anti Water Hammer: FeaturesDocument5 pagesFox ™ Triple Effect Air Vent + Anti Water Hammer: FeaturesNicolás Polito MuñozNo ratings yet

- Needle Valves Screwed Bonnet Design Double Ferrule Tube EndsDocument1 pageNeedle Valves Screwed Bonnet Design Double Ferrule Tube Endsponmanikandan1No ratings yet

- Design Calculation-Spacer SpoolDocument8 pagesDesign Calculation-Spacer SpoolHasmukh Dave100% (1)

- Nozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim GalalaDocument5 pagesNozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim Galalapaary100% (2)

- Api 650 Data Sheet (BWT-01)Document4 pagesApi 650 Data Sheet (BWT-01)Rajesh K PillaiNo ratings yet

- Specification For Fire Pump - Part 10Document5 pagesSpecification For Fire Pump - Part 10Melisa MackNo ratings yet

- Needle ValvesDocument8 pagesNeedle Valvesleopoldo cobosNo ratings yet

- Material Take Off List (MTO) : Project: Construction of Chemical Storage Shelter at Gas Treat & Utilities AreaDocument8 pagesMaterial Take Off List (MTO) : Project: Construction of Chemical Storage Shelter at Gas Treat & Utilities AreaMadhan KannanNo ratings yet

- 2 P I e C e S B A L L V A L V e C L A S S 8 0 0Document6 pages2 P I e C e S B A L L V A L V e C L A S S 8 0 0raulNo ratings yet

- Datasheet TankDocument1 pageDatasheet TankAnonymous lQiANQusxiNo ratings yet

- Pentair 4003038 Industrial M88 LDocument4 pagesPentair 4003038 Industrial M88 LcatderNo ratings yet

- XCT-B 400w: Top Class High Performance and Unique, Extremely Compact TIG Torch DesignDocument2 pagesXCT-B 400w: Top Class High Performance and Unique, Extremely Compact TIG Torch Designkismikloshun55No ratings yet

- ES - Model B5002, B5002NDocument1 pageES - Model B5002, B5002NSANRAJ TECHNONo ratings yet

- Tdi 50000 Tpy, GNFCDocument6 pagesTdi 50000 Tpy, GNFCkrunal panchalNo ratings yet

- Schem DrawingDocument2 pagesSchem DrawingMohamed ArafaNo ratings yet

- ADMA-OPCO Strainer Data SheetDocument7 pagesADMA-OPCO Strainer Data Sheetvinoj chandranNo ratings yet

- Piping Flame ArrestorsrsDocument1 pagePiping Flame ArrestorsrsMadhavMitruNo ratings yet

- Bill of Quantity: Fabrikasi 4 (Empat) Unit Tube Bundle 11-E-106, 11-E-118B, 11-E-119, 11-E-127 Tahun 2013Document3 pagesBill of Quantity: Fabrikasi 4 (Empat) Unit Tube Bundle 11-E-106, 11-E-118B, 11-E-119, 11-E-127 Tahun 2013moddysNo ratings yet

- Solenoid Valve 2/2 Way N.O. Direct Acting - Dampness-Proof IP 67Document2 pagesSolenoid Valve 2/2 Way N.O. Direct Acting - Dampness-Proof IP 67Ramius HamdaniNo ratings yet

- Pressure Vessel Data Sheet for Residue Gas ScrubberDocument2 pagesPressure Vessel Data Sheet for Residue Gas ScrubberElias EliasNo ratings yet

- SAP FILTER-May-2020-1200Dia-Rev - PDocument4 pagesSAP FILTER-May-2020-1200Dia-Rev - PHasmukh DaveNo ratings yet

- 10BFFRM2D0Document4 pages10BFFRM2D0Diego BarriosNo ratings yet

- Filtro Tipo yDocument5 pagesFiltro Tipo yKaren BasoaltoNo ratings yet

- Drawing 80AQ15-60 Non CodedDocument2 pagesDrawing 80AQ15-60 Non Codeddaus nasNo ratings yet

- Tube Seal Liquid FilledDocument1 pageTube Seal Liquid Filledmota1960No ratings yet

- Globe Rev. A SHT 1Document1 pageGlobe Rev. A SHT 1Agus SupriadiNo ratings yet

- Sweeper (Brushes With Convoluted Sections) (Two Piece End Caps) (72 - ) - (S - N 435400101 & Above, 783700101 & Above) - SweeperDocument3 pagesSweeper (Brushes With Convoluted Sections) (Two Piece End Caps) (72 - ) - (S - N 435400101 & Above, 783700101 & Above) - SweeperJhon Atencio LopezNo ratings yet

- 25 7731564081 PDFDocument2 pages25 7731564081 PDFbsnegi111No ratings yet

- Class 125 Iron Body Gate Valves: Bolted Bonnet - Outside Screw and Yoke - Solid Wedge - Bronze MountedDocument1 pageClass 125 Iron Body Gate Valves: Bolted Bonnet - Outside Screw and Yoke - Solid Wedge - Bronze MountedJOSE GABRIELNo ratings yet

- KT-403-WFP Bronze Check ValveDocument1 pageKT-403-WFP Bronze Check ValveIlyas sagriNo ratings yet

- Ecoline Est 150-600Document21 pagesEcoline Est 150-600Yosses Sang NahkodaNo ratings yet

- Datasheet For Ball Valve123Document1 pageDatasheet For Ball Valve123valveNo ratings yet

- DS - DRG - 300 PSI - 8320Document2 pagesDS - DRG - 300 PSI - 8320Shasin SolankiNo ratings yet

- Liquid Pitch and Pitch Fume Piping SpecificationDocument3 pagesLiquid Pitch and Pitch Fume Piping SpecificationAnonymous FoHj39G8CNo ratings yet

- Chand Rakant Salunk HeDocument2 pagesChand Rakant Salunk HesalunkheclNo ratings yet

- Sweeper (Brushes With Convoluted Sections) (Two Piece End Caps) (60 - ) - (S - N 434700101 & Above, 714400101 & Above) - SweeperDocument3 pagesSweeper (Brushes With Convoluted Sections) (Two Piece End Caps) (60 - ) - (S - N 434700101 & Above, 714400101 & Above) - SweeperLeidys ORTIZ CONEONo ratings yet

- HD 282 Butterfly ValveDocument4 pagesHD 282 Butterfly ValveBhavin lodayaNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Chapter-11 CRYOSTATSDocument17 pagesChapter-11 CRYOSTATSKian GancangNo ratings yet

- Study of Welding & Cathodic-Protection of Gas-PipelinesDocument94 pagesStudy of Welding & Cathodic-Protection of Gas-PipelinesKian GancangNo ratings yet

- Safety Data Sheet - Natural GasDocument5 pagesSafety Data Sheet - Natural GasKian GancangNo ratings yet

- Slide Set 3 - Role of LNG, GTL, CNGDocument71 pagesSlide Set 3 - Role of LNG, GTL, CNGPhuong NguyenNo ratings yet

- Gas Bussiness ManagementDocument1 pageGas Bussiness ManagementFrank MosesNo ratings yet

- Lined Pipes & Fittings GuideDocument68 pagesLined Pipes & Fittings Guidegilbert4285No ratings yet

- Welding Lecture1 2Document34 pagesWelding Lecture1 2Dr Abhijeet GangulyNo ratings yet

- Ip - Project - of - Chemistry Form of SoapsDocument18 pagesIp - Project - of - Chemistry Form of Soapsshanti singh100% (1)

- Curing MethodsDocument16 pagesCuring Methodsaloys NdzieNo ratings yet

- Conceps of RCC-PCCDocument63 pagesConceps of RCC-PCCurhenNo ratings yet

- Cronicon: Research Article An Investigation of Blast Performance of Mine Protective Military BootsDocument15 pagesCronicon: Research Article An Investigation of Blast Performance of Mine Protective Military BootsJOSE FREDY BARRETO FRANCONo ratings yet

- Ce Aim-JeDocument64 pagesCe Aim-JeKutty DhanushNo ratings yet

- Activity Sheet 1Document11 pagesActivity Sheet 1Ayan ShaikhNo ratings yet

- Material PropertiesDocument20 pagesMaterial Propertieskhalid ahmedNo ratings yet

- Design and Fabrication of a Die for Compacting Aluminum PowderDocument69 pagesDesign and Fabrication of a Die for Compacting Aluminum PowderPartth VachhaniNo ratings yet

- Push Button XAL - B324Document4 pagesPush Button XAL - B324Swaran Kumar SNo ratings yet

- What Is Shoring - What Is Reshoring - EFCO CorpDocument4 pagesWhat Is Shoring - What Is Reshoring - EFCO Corpmohamed.s.elsayedNo ratings yet

- A 391 - A 391M - 98 Qtm5ms9bmzkxts1sruqDocument6 pagesA 391 - A 391M - 98 Qtm5ms9bmzkxts1sruqClaudia Patricia Magaña RabanalesNo ratings yet

- R 152a Diagrama de Refrigerante P-HDocument1 pageR 152a Diagrama de Refrigerante P-HJose LuisNo ratings yet

- Analysis Geological Minerals Using ARL EQUINOX 41102Document2 pagesAnalysis Geological Minerals Using ARL EQUINOX 41102Daniel AguifNo ratings yet

- CNG MsdsDocument2 pagesCNG MsdssamypalNo ratings yet

- "Hot Topics": Effect of Carbon in Ductile IronDocument4 pages"Hot Topics": Effect of Carbon in Ductile IronAdeel BhattiNo ratings yet

- PRESTRESSED CONCRETE 03 Rev00Document4 pagesPRESTRESSED CONCRETE 03 Rev00Hussein MuslihNo ratings yet

- Winters Productoverview2Document12 pagesWinters Productoverview2JOSE DEL CARMEN TOLEDONo ratings yet

- CBSE Class 8 Science Sample Paper Set 4: General InstructionsDocument3 pagesCBSE Class 8 Science Sample Paper Set 4: General InstructionsPahul GehaniNo ratings yet

- Gear MaterialDocument14 pagesGear MaterialShounak DasNo ratings yet

- Ch19 Sample ExerciseDocument25 pagesCh19 Sample ExerciseWardah FaizahNo ratings yet

- Design of Two Way Slab: 2nd/3rd Floor Slab S1Document14 pagesDesign of Two Way Slab: 2nd/3rd Floor Slab S1John Paul Hilary EspejoNo ratings yet

- Balancing Chemical Equations 1Document4 pagesBalancing Chemical Equations 1luis martinezNo ratings yet

- Welder Job Clearance Card for Ali QurbanDocument43 pagesWelder Job Clearance Card for Ali QurbanDhanush NairNo ratings yet

- 190102-DC10.5-Expansive and Stable Soils-Public ReviewDocument66 pages190102-DC10.5-Expansive and Stable Soils-Public Reviewvõ hoàng thái100% (1)

- Tos Science 7 1st Quater ExamDocument2 pagesTos Science 7 1st Quater Examlaydee claveria0% (1)

- Use of Waste Tyres in Road ConstructionDocument11 pagesUse of Waste Tyres in Road Constructionvotetorecieve 1100% (1)

- BiopolymersDocument39 pagesBiopolymersbm OUREMNo ratings yet

- Hydrogen BarbequeDocument5 pagesHydrogen BarbequepanchoganchoNo ratings yet