Professional Documents

Culture Documents

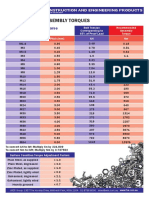

Recommended Assembly Torques 2016

Uploaded by

Mohamed Elkady0 ratings0% found this document useful (0 votes)

31 views9 pagesOriginal Title

Recommended_Assembly_Torques_2016

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

31 views9 pagesRecommended Assembly Torques 2016

Uploaded by

Mohamed ElkadyCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 9

Recommended Assembly Torques

Class 4.6 ISO Metric Coarse Pitch Bolts & Screws

Bolt Tension Recommended

Corresponding to Assembly

65% of Proof Load Torque

Diameter Pitch (mm) kN Nm

M1.6 0.35 0.19 0.06

M2 0.40 0.31 0.12

M2.5 0.45 0.50 0.25

M3 0.50 0.73 0.44

M4 0.70 1.29 1

M5 0.80 2.08 2.1

M6 1.00 2.94 3.5

M8 1.25 5.34 8.5

M10 1.50 8.45 17

M12 1.75 12.4 30

M14 2.00 16.8 47

M16 2.00 22.9 73

M18 2.50 28.1 101

M20 2.50 35.8 143

M22 2.50 44.3 195

M24 3.00 51.6 248

M27 3.00 67 362

M30 3.50 81.9 491

M33 3.50 101 669

M36 4.00 120 864

M39 4.00 143 1115

M42 4.50 164 1378

M48 5.00 215 2064

M56 5.50 298 3338

M64 6.00 393 5030

To convert kN to lbf; Multiply Kn by 224.809

To convert Nm to lbft: Multiply Nm by 0.737562

Surface Condition Torque Adjustment Factors

Plain Steel, as supplied x 1.0

Plain Steel, degreased x 2.0

Zinc Plated, as supplied x 1.0

Zinc Plated, lightly oiled x 0.9

Galvanised, degreased x 2.1

Galvanised, lightly oiled x 1.1

Heavily greased x 0.7

Recommended Assembly Torques

BSW Mild Steel Bolts & Screws

Bolt Tension Recommended

Corresponding to Assembly

65% of Proof Load Torque

Diameter Threads Per Inch lbf lbft

(TPI)

1/4” 20 736 3

5/16” 18 1208 6

3/8” 16 1786 11

7/16” 14 2451 18

1/2” 12 3176 26

5/8” 11 5206 54

3/4” 10 7705 96

7/8” 9 10641 155

1” 8 13943 232

1.1/8” 7 17566 329

1.1/4” 7 22473 468

1.1/2” 6 32334 808

To convert kN to lbf; Multiply Kn by 224.809

To convert Nm to lbft: Multiply Nm by 0.737562

Surface Condition Torque Adjustment Factors

Plain Steel, as supplied x 1.0

Plain Steel, degreased x 2.0

Zinc Plated, as supplied x 1.0

Zinc Plated, lightly oiled x 0.9

Galvanised, degreased x 2.1

Galvanised, lightly oiled x 1.1

Heavily greased x 0.7

Recommended Assembly Torques

Class 8.8 ISO Metric Coarse Pitch Bolts & Screws

Bolt Tension Recommended

Corresponding to Assembly

65% of Proof Load Torque

Diameter Pitch (mm) kN Nm

M1.6 0.35 0.48 0.15

M2 0.40 0.78 0.31

M2.5 0.45 1.28 0.64

M3 0.50 1.9 1.1

M4 0.70 3.32 2.7

M5 0.80 5.35 5

M6 1.00 7.54 9

M8 1.25 13.8 22

M10 1.50 21.9 44

M12 1.75 31.8 77

M14 2.00 43.4 122

M16 2.00 59.2 190

M18 2.50 74.8 269

M20 2.50 95.6 372

M22 2.50 118 519

M24 3.00 138 640

M27 3.00 179 967

M30 3.50 219 1314

M33 3.50 270 1782

M36 4.00 319 2297

M39 4.00 380 2970

M42 4.50 437 3671

M48 5.00 573 5500

M56 5.50 792 8870

M64 6.00 1045 13376

To convert kN to lbf; Multiply Kn by 224.809

To convert Nm to lbft: Multiply Nm by 0.737562

Surface Condition Torque Adjustment Factors

Plain Steel, as supplied x 1.0

Plain Steel, degreased x 2.0

Zinc Plated, as supplied x 1.0

Zinc Plated, lightly oiled x 0.9

Galvanised, degreased x 2.1

Galvanised, lightly oiled x 1.1

Heavily greased x 0.7

Recommended Assembly Torques

Class 10.9 ISO Metric Coarse Pitch Bolts & Screws

Bolt Tension Recommended

Corresponding to Assembly

65% of Proof Load Torque

Diameter Pitch (mm) kN Nm

M5 0.80 7.67 8

M6 1.00 10.9 13

M8 1.25 19.8 32

M10 1.50 31.3 63

M12 1.75 45.5 109

M14 2.00 62.1 174

M16 2.00 84.5 270

M18 2.50 103 371

M20 2.50 132 528

M22 2.50 164 722

M24 3.00 190 914

M27 3.00 248 1339

M30 3.50 303 1817

M33 3.50 371 2449

M36 4.00 441 3173

M39 4.00 527 4110

To convert kN to lbf; Multiply Kn by 224.809

To convert Nm to lbft: Multiply Nm by 0.737562

Surface Condition Torque Adjustment Factors

Plain Steel, as supplied x 1.0

Plain Steel, degreased x 2.0

Zinc Plated, as supplied x 1.0

Zinc Plated, lightly oiled x 0.9

Galvanised, degreased x 2.1

Galvanised, lightly oiled x 1.1

Heavily greased x 0.7

Recommended Assembly Torques

Class 12.9 ISO Metric Coarse Pitch Bolts & Screws

Bolt Tension Recommended

Corresponding to Assembly

65% of Proof Load Torque

Diameter Pitch (mm) kN Nm

M3 0.50 3.17 1.9

M4 0.70 5.54 4.4

M5 0.80 8.97 8.9

M6 1.00 12.7 15

M8 1.25 23.1 37

M10 1.50 36.6 73

M12 1.75 53.2 128

M14 2.00 72.8 203

M16 2.00 98.8 316

M18 2.50 121 436

M20 2.50 155 620

M22 2.50 191 840

M24 3.00 222 1066

M27 3.00 289 1561

M30 3.50 354 2124

M33 3.50 437 2884

M36 4.00 515 3708

To convert kN to lbf; Multiply Kn by 224.809

To convert Nm to lbft: Multiply Nm by 0.737562

Surface Condition Torque Adjustment Factors

Plain Steel, as supplied x 1.0

Plain Steel, degreased x 2.0

Zinc Plated, as supplied x 1.0

Zinc Plated, lightly oiled x 0.9

Galvanised, degreased x 2.1

Galvanised, lightly oiled x 1.1

Heavily greased x 0.7

Recommended Assembly Torques

SAE Grade 5 Bolts & Screws – UNF Thread

Bolt Tension Recommended

Corresponding to Assembly

65% of Proof Load Torque

Diameter Threads Per Inch lbf lbft

(TPI)

1/4 28 2010 8

5/16 24 3180 17

3/8 24 4840 30

7/16 20 6560 48

1/2 20 8840 74

9/16 18 11240 105

5/8 18 14170 148

3/4 16 20600 258

7/8 14 28100 410

1 12 36600 610

1.1/8 12 41100 771

1.1/4 12 51600 1075

1.3/8 12 63200 1448

1.1/2 12 76000 1900

To convert kN to lbf; Multiply Kn by 224.809

To convert Nm to lbft: Multiply Nm by 0.737562

Surface Condition Torque Adjustment Factors

Plain Steel, as supplied x 1.0

Plain Steel, degreased x 2.0

Zinc Plated, as supplied x 1.0

Zinc Plated, lightly oiled x 0.9

Galvanised, degreased x 2.1

Galvanised, lightly oiled x 1.1

Heavily greased x 0.7

Recommended Assembly Torques

SAE Grade 8 Bolts & Screws – UNF Thread

Bolt Tension Recommended

Corresponding to Assembly

65% of Proof Load Torque

Diameter Threads Per Inch lbf lbft

(TPI)

1/4 28 2820 12

5/16 24 4510 23

3/8 24 6820 43

7/16 20 9230 67

1/2 20 12480 104

9/16 18 15860 149

5/8 18 19950 208

3/4 16 29120 364

7/8 14 39700 549

1 12 51700 862

1.1/8 12 66700 1241

1.1/4 12 83700 1744

1.3/8 12 102500 2349

1.1/2 12 123300 3083

SAE Grade 5 & 8 Bolts & Screws – 1” SAE

Bolt Tension Recommended

Corresponding to Assembly

65% of Proof Load Torque

Diameter 1” SAE Threads Per Inch lbf lbft

(TPI)

Grade 5 14 37500 625

Grade 8 14 53000 883

To convert kN to lbf; Multiply Kn by 224.809

To convert Nm to lbft: Multiply Nm by 0.737562

Surface Condition Torque Adjustment Factors

Plain Steel, as supplied x 1.0

Plain Steel, degreased x 2.0

Zinc Plated, as supplied x 1.0

Zinc Plated, lightly oiled x 0.9

Galvanised, degreased x 2.1

Galvanised, lightly oiled x 1.1

Heavily greased x 0.7

Recommended Assembly Torques

SAE Grade 5 Bolts & Screws – UNC Thread

Bolt Tension Recommended

Corresponding to Assembly

65% of Proof Load Torque

Diameter Thread Per Inch lbf lbft

(TPI)

1/4 20 1760 7

5/16 18 2890 15

3/8 16 4290 27

7/16 14 5880 43

1/2 13 7860 66

9/16 12 10070 94

5/8 11 12480 130

3/4 10 18460 231

7/8 9 25550 373

1 8 33470 558

1.1/8 7 36700 688

1.1/4 7 46600 971

1.3/8 6 55500 1272

1.1/2 6 67600 1690

1.3/4 5 91300 2663

2 4.5 120200 4007

2.1/4 4.5 156300 5861

2.1/2 4 192400 8017

2.3/4 4 237100 10867

3 4 287100 14355

3.1/4 4 341500 18498

3.1/2 4 400600 23368

3.3/4 4 464600 29038

4 4 532900 35527

To convert kN to lbf; Multiply Kn by 224.809

To convert Nm to lbft: Multiply Nm by 0.737562

Surface Condition Torque Adjustment Factors

Plain Steel, as supplied x 1.0

Plain Steel, degreased x 2.0

Zinc Plated, as supplied x 1.0

Zinc Plated, lightly oiled x 0.9

Galvanised, degreased x 2.1

Galvanised, lightly oiled x 1.1

Heavily greased x 0.7

Recommended Assembly Torques

SAE Grade 8 Bolts & Screws – UNC Thread

Bolt Tension Recommended

Corresponding to Assembly

65% of Proof Load Torque

Diameter Thread Per Inch lbf lbft

(TPI)

1/4 20 2470 10

5/16 18 4090 21

3/8 16 6040 38

7/16 14 8320 61

1/2 13 11050 92

9/16 12 14170 133

5/8 11 17610 183

3/4 10 26060 326

7/8 9 36000 525

1 8 47200 787

1.1/8 7 59500 1116

1.1/4 7 75500 1573

1.3/8 6 90000 2063

1.1/2 6 109500 2738

1.3/4 5 148200 4323

2 4.5 195000 6500

2.1/4 4.5 253500 9506

2.1/2 4 312000 13000

2.3/4 4 384500 17623

3 4 465600 23280

3.1/4 4 553800 29998

3.1/2 4 649700 37899

3.3/4 4 753400 47088

4 4 864200 57613

To convert kN to lbf; Multiply Kn by 224.809

To convert Nm to lbft: Multiply Nm by 0.737562

Surface Condition Torque Adjustment Factors

Plain Steel, as supplied x 1.0

Plain Steel, degreased x 2.0

Zinc Plated, as supplied x 1.0

Zinc Plated, lightly oiled x 0.9

Galvanised, degreased x 2.1

Galvanised, lightly oiled x 1.1

Heavily greased x 0.7

You might also like

- Steelmasters Torque TableDocument6 pagesSteelmasters Torque TableIbrahim SaidNo ratings yet

- WDS Torque ChartDocument9 pagesWDS Torque ChartThaharNo ratings yet

- WDS Construction Engineering Torque SpecsDocument1 pageWDS Construction Engineering Torque SpecsKawsar AlamNo ratings yet

- RATV - Socket Head Fasteners - MetricDocument1 pageRATV - Socket Head Fasteners - MetricGustavo CarvalhoNo ratings yet

- HTD HXB cl10.9 Tight TorqDocument1 pageHTD HXB cl10.9 Tight Torqaegean227No ratings yet

- HTD Ss HXB Tight TorqDocument1 pageHTD Ss HXB Tight TorqTony CefaiNo ratings yet

- SOCKET HEAD CAP SCREW TIGHTENING TORQUE GUIDEDocument1 pageSOCKET HEAD CAP SCREW TIGHTENING TORQUE GUIDEChandru Vel100% (1)

- ES-PM-FW0009-2016Document5 pagesES-PM-FW0009-2016陳相如No ratings yet

- Stainless Steel Pre-Load and Tightening TorquesDocument4 pagesStainless Steel Pre-Load and Tightening TorquesPrasetyaHutamaNo ratings yet

- RITZ Screw Specification PDFDocument12 pagesRITZ Screw Specification PDFThawatchai DanwangkhawNo ratings yet

- Boltmasters Pty LTD Recommended Assembly TorquesDocument9 pagesBoltmasters Pty LTD Recommended Assembly TorquesNavneet SunilNo ratings yet

- Bolt Torque Cl4.6-Tight-TorqDocument1 pageBolt Torque Cl4.6-Tight-TorqMir AsifNo ratings yet

- Master CatalogDocument114 pagesMaster CatalogFINNING CATNo ratings yet

- Socket Head Cap Screws Dimensions and Torque SpecsDocument4 pagesSocket Head Cap Screws Dimensions and Torque SpecssarbiniNo ratings yet

- Hex Bolts: Tensile / Yield / Shear Strength Tightening TorqueDocument1 pageHex Bolts: Tensile / Yield / Shear Strength Tightening TorqueVivekNo ratings yet

- Max Rec Tightening Torque PDFDocument1 pageMax Rec Tightening Torque PDFReginald D. De GuzmanNo ratings yet

- Metric Hex Bolt DimensionsDocument7 pagesMetric Hex Bolt DimensionsVishal MistryNo ratings yet

- Torquing Specification Inch & Metric Fastener Chart: Socket Head Cap ScrewsDocument2 pagesTorquing Specification Inch & Metric Fastener Chart: Socket Head Cap ScrewsgielNo ratings yet

- Service DataDocument12 pagesService DataGianni DaBolognaNo ratings yet

- Katalog AnkeraDocument20 pagesKatalog AnkeraBosko MiljevicNo ratings yet

- NIS Bearing Units Catalogue PDFDocument162 pagesNIS Bearing Units Catalogue PDFMunkhnasan MonaNo ratings yet

- WSA 109 - 2011 Flange Gaskets Working SheetDocument1 pageWSA 109 - 2011 Flange Gaskets Working SheetAbit BronjaNo ratings yet

- Metric DIN 433 Flat Washer Dimensions and SpecificationsDocument4 pagesMetric DIN 433 Flat Washer Dimensions and SpecificationsChris StefanouNo ratings yet

- Metric Thread Dimensions - Bolt Sizes Chart For M1.6 To M69 Screws - AccuDocument3 pagesMetric Thread Dimensions - Bolt Sizes Chart For M1.6 To M69 Screws - AccuGaurav VatsNo ratings yet

- Metric Fastener Dimensions and SpecificationsDocument1 pageMetric Fastener Dimensions and SpecificationsDerekNo ratings yet

- High Tensile Bolts TechnicalDocument6 pagesHigh Tensile Bolts Technicalventhan_kalaiNo ratings yet

- 1000x800 Column DesignDocument10 pages1000x800 Column DesigneOzdemir1No ratings yet

- Metric DIN 137 SpecDocument5 pagesMetric DIN 137 Specpradipbhosale81No ratings yet

- Metric Bolt Torque Table NM - CNCexpoDocument1 pageMetric Bolt Torque Table NM - CNCexpoNepoleon KaruppiahNo ratings yet

- CBR soil penetration test data analysis and graphsDocument14 pagesCBR soil penetration test data analysis and graphsDaniel AbelloNo ratings yet

- Din 933Document2 pagesDin 933Sugumar0% (1)

- Torque SettingsDocument3 pagesTorque Settingsgamedbk002No ratings yet

- Complete Fastener Solutions Hexagon BoltsDocument2 pagesComplete Fastener Solutions Hexagon Boltscoolkaisy100% (2)

- Torque Chart NormetDocument1 pageTorque Chart NormetvmrvdnvNo ratings yet

- PT. SWADAYA GRAHA Engineering TablesDocument9 pagesPT. SWADAYA GRAHA Engineering TablesAndri EkoNo ratings yet

- Blind Nuts Semi Hex RHDocument1 pageBlind Nuts Semi Hex RHSagar KumarNo ratings yet

- Roofdek D32S: Ultimate Section Properties To EurocodeDocument1 pageRoofdek D32S: Ultimate Section Properties To EurocodeVolodymyr ShchurNo ratings yet

- Metric DIN 439 Spec PDFDocument4 pagesMetric DIN 439 Spec PDFHasib SejdinovicNo ratings yet

- Z M A A B (MM) N H (Hours) : Gear Design (Is-4460) (Spur or Helical)Document14 pagesZ M A A B (MM) N H (Hours) : Gear Design (Is-4460) (Spur or Helical)Dhirender KapoorNo ratings yet

- S06&12 CBR 04 August 20161.odsDocument6 pagesS06&12 CBR 04 August 20161.odsAnonymous 0VmQRqfNNo ratings yet

- Din 934Document1 pageDin 934Chuan ChuNo ratings yet

- Drive Technology: Couplings Torque Limiters Clamping Elements Torque Measuring SystemsDocument3 pagesDrive Technology: Couplings Torque Limiters Clamping Elements Torque Measuring SystemsELİF ORTANo ratings yet

- S06&12 CBR 04 August 20161Document24 pagesS06&12 CBR 04 August 20161Anonymous 0VmQRqfNNo ratings yet

- Conversion TablesDocument4 pagesConversion TablesdeokarnitinpNo ratings yet

- Prestressing Thread Steel BarDocument3 pagesPrestressing Thread Steel BarIsmantoTaufikNo ratings yet

- Fasten BoltDocument1 pageFasten BoltSara BookerNo ratings yet

- Screw DimensionDocument2 pagesScrew DimensionAbhijeet SinghNo ratings yet

- Metric Bolt Torque Table NmDocument1 pageMetric Bolt Torque Table NmninatenaNo ratings yet

- Metric Bolt Torque Table NM - CNCexpoDocument1 pageMetric Bolt Torque Table NM - CNCexponate anantathat100% (1)

- Appendix 5. Standard Screen Scales PDFDocument3 pagesAppendix 5. Standard Screen Scales PDFJorell PaguioNo ratings yet

- Nutsert 9468 MMDocument1 pageNutsert 9468 MMAJITHNo ratings yet

- Rubber Sheet MRDocument4 pagesRubber Sheet MRES KNNo ratings yet

- Screws CapacitiesDocument1 pageScrews CapacitiesZaido Al HalabiNo ratings yet

- High Tensile: Hexagon Head Setscrews Fine Pitch EN ISO 8676 (DIN 961)Document2 pagesHigh Tensile: Hexagon Head Setscrews Fine Pitch EN ISO 8676 (DIN 961)jaison jacobNo ratings yet

- Bolt Din 933Document2 pagesBolt Din 933anNo ratings yet

- MICC Cable Data SheetDocument2 pagesMICC Cable Data SheetMarc IvoNo ratings yet

- Dimensiuni NPTDocument2 pagesDimensiuni NPTGrosu CosminNo ratings yet

- SS Bolt Properties STD: Din STD ISO 4017 B.S. DIN933 DIN931 DIN931 GB5783 DIN DIN912 Astm DIN603 Ansi DIN6923 JIS EN ASDocument5 pagesSS Bolt Properties STD: Din STD ISO 4017 B.S. DIN933 DIN931 DIN931 GB5783 DIN DIN912 Astm DIN603 Ansi DIN6923 JIS EN ASHithish ReddyNo ratings yet

- Installation and Operating Guide: Photovoltaik Module Production Series ACDocument10 pagesInstallation and Operating Guide: Photovoltaik Module Production Series ACClyde FairbanksNo ratings yet

- STJLR.50.5058 Issue 2 20190805Document6 pagesSTJLR.50.5058 Issue 2 20190805Shu FuNo ratings yet

- Excavator RepairDocument320 pagesExcavator Repairlub007No ratings yet

- Hex and Hex Washer Head DimensionsDocument4 pagesHex and Hex Washer Head DimensionsanhthoNo ratings yet

- BW141 151 161 AC AD-4 Operation-MaintenanceDocument110 pagesBW141 151 161 AC AD-4 Operation-MaintenanceРуденко Роман100% (1)

- Self Drilling Anchors SUPANCHORDocument3 pagesSelf Drilling Anchors SUPANCHORMohd AftabNo ratings yet

- Technical English 1 CBDocument129 pagesTechnical English 1 CBelena86% (14)

- Lesson-1-3 (CE 321C)Document81 pagesLesson-1-3 (CE 321C)Andjie LeeNo ratings yet

- Ancon QwikFoot and QwikFix Threaded Inserts Design GuideDocument36 pagesAncon QwikFoot and QwikFix Threaded Inserts Design GuideDan MoldoveanuNo ratings yet

- Python 2Document28 pagesPython 2Rosemary J SmithNo ratings yet

- Drawer Slides Guide with Drilling Diagrams and SpecificationsDocument48 pagesDrawer Slides Guide with Drilling Diagrams and SpecificationsvadivelNo ratings yet

- ASME B18.31.3-2009 - Threaded Rods - Inch SeriesDocument14 pagesASME B18.31.3-2009 - Threaded Rods - Inch SeriesSandeep Kumar JaiswalNo ratings yet

- Promat PFPH Chapter 8 Smoke Barriers DoorsDocument17 pagesPromat PFPH Chapter 8 Smoke Barriers DoorsRamiAl-fuqahaNo ratings yet

- Jonsored LT2213 ReservedeleDocument19 pagesJonsored LT2213 ReservedeleArne NielsenNo ratings yet

- Installing, Maintaining, and Verifying Your Charpy Impact MachineDocument26 pagesInstalling, Maintaining, and Verifying Your Charpy Impact MachineTurgay DeryaNo ratings yet

- SMD, SMG, SFG Mixers and Flowmakers: Installation and Operating InstructionsDocument46 pagesSMD, SMG, SFG Mixers and Flowmakers: Installation and Operating InstructionsAlexis ElíasNo ratings yet

- 2007 Maxxforce 5 Engine Manual-3Document94 pages2007 Maxxforce 5 Engine Manual-3Harlinton descalziNo ratings yet

- Electric Actuator User ManualDocument32 pagesElectric Actuator User Manualrizky efrinaldoNo ratings yet

- Welding Procedure Specification's (WPS) : Presented by John Lucas Welding Engineer UTI CorporationDocument30 pagesWelding Procedure Specification's (WPS) : Presented by John Lucas Welding Engineer UTI CorporationCris VillapanaNo ratings yet

- Standard Specifications SRA-01-FD11 SRA-01A-FD11 SRA-L-01-FD11 SRA-EL-01-FD11Document42 pagesStandard Specifications SRA-01-FD11 SRA-01A-FD11 SRA-L-01-FD11 SRA-EL-01-FD11Gonzalo CánepaNo ratings yet

- 10V1600G20F 16601001304Document102 pages10V1600G20F 16601001304Toan Vo100% (2)

- MST - 1500VD #154501 UP Parts ManualDocument122 pagesMST - 1500VD #154501 UP Parts ManualJohn Fredy Palacio G.100% (1)

- File n5Document77 pagesFile n5eyasuabreha05No ratings yet

- Elastic FasteningsDocument74 pagesElastic FasteningsMohamad SaquibNo ratings yet

- Nammsyra 000011Document704 pagesNammsyra 000011Dalia MuraddNo ratings yet

- Introduction To E.D&G Siginificance of E.D&G Engineering Drawing of Some Machine Parts Connecting Rod & It'S Significance Bolt and It'S SignificanceDocument12 pagesIntroduction To E.D&G Siginificance of E.D&G Engineering Drawing of Some Machine Parts Connecting Rod & It'S Significance Bolt and It'S SignificanceAbu Huraira Atta UllahNo ratings yet

- Catalogo de Partes ORBIT-125Document63 pagesCatalogo de Partes ORBIT-125lainer chauxNo ratings yet

- BA LIFTKET 2019 09 EnglischDocument40 pagesBA LIFTKET 2019 09 Englischjølle jølle100% (1)

- Model 66500A-66510A - Air Hydraulic Floor Jack ManualDocument8 pagesModel 66500A-66510A - Air Hydraulic Floor Jack ManualAlain DefoeNo ratings yet

- Manual ETANK2000Document73 pagesManual ETANK2000Ever BriceñoNo ratings yet