Professional Documents

Culture Documents

Using Green Cold Pressing To Produce High Quality Fish Oil From Industrial Salmon Waste

Using Green Cold Pressing To Produce High Quality Fish Oil From Industrial Salmon Waste

Uploaded by

Rifqi Fathul ArroisiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Using Green Cold Pressing To Produce High Quality Fish Oil From Industrial Salmon Waste

Using Green Cold Pressing To Produce High Quality Fish Oil From Industrial Salmon Waste

Uploaded by

Rifqi Fathul ArroisiCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/342659001

Using Green Cold Pressing to Produce High Quality Fish Oil From Industrial

Salmon Waste

Article · July 2020

DOI: 10.30564/jzr.v2i1.2021

CITATIONS READS

2 396

1 author:

Tarek Fouda

Tanta University

150 PUBLICATIONS 104 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

IMPACT OF THE FOURTH INDUSTRIAL REVOLUTION ON THE DEVELOPMENT OF SCIENTIFIC RESEARCH IN THE FIELD OF AGRICULTURAL ENGINEERING IN EGYPT AND

ARAB WORLD View project

Manufacture and evaluation unit to produce hydrogen gas from water. View project

All content following this page was uploaded by Tarek Fouda on 04 July 2020.

The user has requested enhancement of the downloaded file.

Journal of Zoological Research | Volume 02 | Issue 01 | January 2020

Journal of Zoological Research

http://ojs.bilpublishing.com/index.php/jzr

ARTICLE

Using Green Cold Pressing to Produce High Quality Fish Oil From In-

dustrial Salmon Waste

Tarek Fouda*

Department of Agricultural Engineering, Faculty of Agriculture, Tanta University, Egypt

ARTICLE INFO ABSTRACT

Article history The main objective of this research was to determine the amount of oil

Received: 18 June 2020 fish were extracted from fish west resulted from butchering, cutting and

splitting processes before salmon smoking by using cold pressing meth-

Accepted: 27 June 2019 ods. The amount and the characteristics of extracted of oil were tested

Published Online: 30 June 2020 at Regional Centre for food and feed the USDA Agricultural Research

Center laboratory. The samples were used from fresh Salmon waste

Keywords: about 1000g from each of the (head, skin, viscera, backbone, frames

Salmon and cuts off). This waste recorded more than 22% of the total mass from

salmon fish with used modern extract machine. in this experiment the

Waste extract results revealed the fresh salmon waste have more than 16% of oil fish

Efficiency per one kg of salmon waste. The oil weight from Salmon waste for (head,

Yield skin, viscera, backbone, frames and cuts off). was increased with press-

ing time increase as well as oil productivity increased. The optimum

Smoking

conditions at pressing time was 200 min, for all salmon waste compo-

Fish oil nents . Oil productivity fluctuated according to waste sources was 190,

Cold pressing 210, 86, 188, 178 and 90 g.oil/1000 g. by head, skin, off cuts, terming,,

viscera, and backbone frames, Salmon by-products, oil productivity was

Wet rendering

ranged between 8.60 to 21.00% at constant pressure. High contents of

functional EPA (20:5 ω 3) and DHA (22:6 ω 3) for oil fish.

1. Introduction retard spoilage. If the moisture content of fresh fish is

F

reduced during drying to around 25%, bacteria cannot

ish is one of the most perishable of all staple com- survive and autolytic activity will be greatly reduced, but

modities. Spoilage occurs as the result of the action to prevent mould growth, the moisture content must be

of enzymes (autolysis) and bacteria present in the reduced to 15%. Also the presence of salt retards bacterial

fish and also chemical oxidation of the fat which causes action and, in addition, it aids the removal of water by os-

rancidity. At the high temperatures prevalent in tropical mosis [5].

countries, bacterial and enzymic actions are enhanced. Cold press is preferred due to its wide usage areas,

Fish invariably become putrid within a few hours of cap- simple use, lack of manpower, low cost, environmentally

ture unless they are preserved or processed in some way friendly, lack of harmful organic solvents and high-quality

to reduce this microbial and autolytic activity and, hence, production possibilities. In addition, generally the product

*Corresponding Author:

Tarek Fouda,

Department of Agricultural Engineering, Faculty of Agriculture, Tanta University, Egypt;

Email: tfouda628@gmail.com; tfouda@yahoo.com

14 Distributed under creative commons license 4.0 DOI: https://doi.org/10.30564/jzr.v2i1.2021

Journal of Zoological Research | Volume 02 | Issue 01 | January 2020

is not applied to heat treatment (cold press), therefore, as functional EPA (20:5n-3) and DHA (22:6n-3) in the oil;

mentioned in the study, high-quality oils are obtained. In however, the application of fish oil has been limited by its

the cold pressed process oil extraction relies solely on the high susceptibility to oxidation. This review reports the

pressure. No, or very little, heat is added to the paste to characteristics of EPA and DHA oxidation compared with

assist in the extraction. Cold presses are usually mechan- those of other fatty acids such as linoleic acid (18:2n-6).

ically operated and often consist of a screw device that is In addition, effective approaches to protect against oxi-

tightened against the paste to extract the oils. Cold press- dation are discussed, focusing on the unique antioxidant

ing usually produces a lower-yield, but higher quality of potential of amine compounds. Finally, the exceptionally

oil [11]. high oxidative stability of EPA and DHA in biological

Primary and secondary processes using to prepare systems is discussed. Understanding the protective mech-

salmon fish for handling and smoking the waste rustling anism against EPA and DHA oxidation in such systems

from gutting & deheading, grading - whole fish, deslim- may be useful for the development of an effective antioxi-

ing and weighing as primary processes and filleting, dant procedure for fish oil that is rich in EPA and DHA [4].

trimming, pin bone removal, skinning, fillet washing and So the main objective to determine the amount of oil

grading fillets as secondary processes varied to have head, fish were extracted from fish west resulted from butcher-

skin, viscera, backbone, frames and cuts off. Management ing, cutting and splitting processes before salmon smok-

and handling of fish waste is an environmental, social pri- ing by using cold pressing `methods. Also avoid potential

ority for many countries and is more problematic because effects to the environment and human health.

of rising production volumes. The fish processing industry

causes a large quantity of tissue waste and by-products 2. Materials and Methods

which tend to be either discarded or retailed at low value

Experiments were designed to extract fish oil from salmon

for fertilizer or animal feed [6].

waste befor and after preparing for industrial processes

The fish by product is nearly (skin 6%, viscer-

and detremined thr oil extractions percntage from all

a7%,off-cuts10%, head 18% - backbone frames10%) [10].

By-products. The amount and the characteristics of ex-

The fish processing industries produce large quantities

tracted of oil were tested at Regional Centre for food and

of fish waste which often represent about 20-50% of the

feed the USDA Agricultural Research Center laboratory.

total fish weight [3].

The samples were used from fresh Salmon waste about

Fish by-products included viscera, head and skin,

1000g from each of the (head, skin, viscera, backbone,

which had a lot of unexploited potential for value adding

frames and cuts off).

and some of them were being utilized at present. Fish oil

could be produced by several methods which included 2.1 Salmon Sampling

hydraulic pressing, vacuum distillation, urea crystalliza-

tion, supercritical fluid extraction, which all require high Five salmon components group A, B, C, D and G accord-

temperature or high pressure in processing or reduction of ing to weight 1.2, 1.5, 1, 7, 2.1 and 2.7 kg.

moisture content in sample prior to extraction [7].

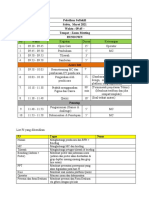

Table 1. salmon components groups.

Fouda using cold pressing, oil extraction yield in-

creased and characterization of quality. The optimum Salmon group

conditions at pressing time was 180 min., oil productivity Component A B C D G

was 18.00%, and extraction efficiency were 98.46% at

Head, 15 17 18.60 20.15 22

constant pressure [2].

Skin 5 3.6 5.6 4.8 5

Fish oils are a rich natural source of omega-3 polyun-

saturated fatty acids (PUFAs), mainly Eicosapentaenoic Off cuts 2 3 3.4 2.9 3

acid (EPA) and Docosahexaenoic acid (DHA), which re- Trimming 10 9 7.2 8.7 8

ceived great interest in the scientific community because Viscera 6 11 9 10.3 11

of their positive roles on human health and nutrition [10]. Backbone 8 7.6 11 9.6 9

Beneficial health effects of ω-3 PUFAs were well

Slice 54 48.8 45.2 43.55 42

demonstrated and included the prevention of a number of

diseases, such as coronary heart diseases, hypertension, Source: Author determination from Bentleys Egypt company

arthritis, autoimmune disorders, cancer [1].

2.2 Salmon By-products

Kazuo Miyashita The benefit of fish oil to health has

been widely recognized because of the high contents of By-products are parts of the fish that are removed before

Distributed under creative commons license 4.0 DOI: https://doi.org/10.30564/jzr.v2i1.2021 15

Journal of Zoological Research | Volume 02 | Issue 01 | January 2020

the fish reaches the final consumer in order to improve

their keeping qualities, reduce the shipping weight or

increase the value of the main fish product. They include

blood, viscera, heads, bones, skin, trimmings and fins.

[8]

. The salmon fish components include water lose and

fish by product percentage about 43.65%. edible portion

nearly from 56.35% . While the fish waste percentage Figure 5. backbone frames

include (skin 5% - viscera 6% trimmings, 10% - off-cuts

2% - head 15% - backbone 8%). and salmon slice, 54%.

The salmon fish samples were collected from Bent-

leys Egypt company one from Egyptian industrial group,

the by-products of befor and after salmon smoking,

weighted 1000 grams for all component (head, off cuts,

viscera, backbone frames, skin, and termning), separated

and package under vacuum, as showing in Figure (1 to 5).

Figure 6. The salmon slice

Source: Author determination Figure(1 to 5) from Bentleys Egypt com-

pany.

2.3 Cold Press Extraction

Cold press extraction were used required less energy also

environmental friendly. High-quality oils can be obtained

by performing production. It is used to extract oil from

Figure 1. The salmon fish salmon waste samples waste samples prepared with using

plastic bag under vacuum with 1 kg, from fish waste were

processed to keep the waste material and put one bag in

the pressing box have about 3 cm in deep, 30 cm in long,

15 cm in wide and two plate with the same dimensions

one of them acting load on the sample’s as a small pro-

totype for cold pressing methods. Different compressed

times from 20 to 200 min. at constant pressure were ap-

Figure 2. The salmon skin proximately.

2.4 Measurements

Oil weight (g) = Extract oil from fish by product sample

(1000,g.)

Oil percentage recovery = the weight of oil recovered

(g)/ the weight of the initial waste sample (g). *100

Oil productivity,% = Extract oil /Weight of fish by

product × Average weight of fish.

Figure 3. The salmon viscera and trimmings Oil mass in sample determined three times

for 1000 g. of Salmon by-products by cold pressing

(cold pressing after 200 min.)

3. Results and Discussions

3.1 Salmon Components

The salmon components include salmon slice as edible

portion and fish by product percentage as a industrial

Figure 4. The salmon head waste the results of edible portion and fish by product

ranged from 42 to 54% and 46 to 56% respectively as

16 Distributed under creative commons license 4.0 DOI: https://doi.org/10.30564/jzr.v2i1.2021

Journal of Zoological Research | Volume 02 | Issue 01 | January 2020

showing in Figure 7.

Figure 7. Salmon fish components

Source: Author determination

3.2 By-products Percentage

The fish waste percentage include head, skin, off-cuts,

trimmings, viscera and backbone additional to salmon

slice resultes in five salmon group A,B,C,D and G fluc- Figure 8. Five salmon components group A, B, C, D and

tuated with differences for all components as showing in G

Figure 8 and Figure 9. Source: Author determination

The head ranged between 15 to 22%, skin ranged

between 3 to 5.6%, off-cuts, ranged between 2 to 3.4%

trimmings ranged between 7.2 to 10%, viscera ranged be-

tween 6 to 11% and backbone ranged between 7.6 to 11%.

Also salmon slice ranged between 42 to 54%, this results

recorded from different batches and result fluctuation ac-

crued to fish preparing processes.

Figure 9. fluctuation in Salmon slice and by product com-

ponents (cold pressing after 200 min.)

Source: Author determination

3.3 Oil percentage Recovery from By-products

Figure 10 Showed the oil percentage recovery from skin,

ranged from 18.10 to 21%, head ranged from 17 to 19%

viscera from 15.2 to 17.8% and terming from 16.0 to

18.8% this accumulated to fat percentage in salmon by

product.

Distributed under creative commons license 4.0 DOI: https://doi.org/10.30564/jzr.v2i1.2021 17

Journal of Zoological Research | Volume 02 | Issue 01 | January 2020

Table 2. Oil extracted components from salmon by prod-

ucts

Estimated uncertainty

Fatty acid % of Total fatty acids

(U)

Palmitic Acid C16:0 9.08 ±0.31

Stearic Acid C18:0 2.51 ±0.22

Oleic Acid C18:0 41.75 ±1.66

Linoleic Acid C18:1n9 13.62 ±2.43

Linolenic Acid C18:3n3 5.64 ±0.24

Source: Author determination by Regional Centre for food and feed the

USDA Agricultural Research Center laboratory.

Figure 10. Oil percentage recovery from salmon by prod-

ucts (cold pressing after 200 min.) Table 3. Oil extracted characteristics from salmon by

products

Source: Author determination

Relative distribu-

Fatty acids Name

3.4 Oil productivity from by products tions

C14:0 Myristic acid 2.36%

Figure 11. Showed the oil productivity extracted from C15:0 Pentaenoic acid 0.18%

skin, the amount of oil ranged from 181 to 210 g. C16:1ω9 Palmatolic acid 0.28%

oil/1000g skin, the amount of oil from head ranged from C16:1ω7 2.68%

170 to 190 g. oil/1000g head, viscera from 152 to 178 g.

C16:2ω4 0.38%

oil/1000g viscera and terming from 160 to 188 g. oil/1000g

C17:0 Heptadecanoic acid 0.15%

terming according to fat percentage in by product, also the

C16:3ω4 Hexadecatrienoic acid 0.28%

methods of extract and extract efficiency work as import-

ant factor. C18:1ω7 Vaccinic acid 3.14%

C18:3ω4 0.16%

C18:4ω3 Octadecatetraenoic acid 0.58%

C20:0 Arachidic acid 0.32%

C20:1ω11 Octadecatetraenoic acid 0.29%

C20:1ω9 Gadoleic acid 4.16%

C20:1ω7 Eicosaenoic acid 0.13%

C20:2ω6 Eicosadienoic acid 1.16%

C20:3ω6 Eicosatrienoic acid 0.17%

C20:4ω6 Eicosatrienoic acid 0.19%

C20:3ω3 Eicosatrienoic acid 0.52%

C20:4ω3 Eicosatrienoic acid 0.78%

Figure 11. The amount of oil extracted from by products Eicosapentaenoic acid(E-

(cold pressing after 200 min.) C20:5ω3 2.46%

PA)

Source: Author determination C22:1ω11 Cetoliec acid 2.52%

C22:1ω9 Erucic acid 0.40%

3.5 Oil extracted Characteristics from Salmon by C22:5ω3 Clupandonic acid(DPA) 1.12%

Products Docosahexaenoic

C22:6ω3 2.97%

acid(DHA)

Salmon by products were extracted by cold pressing its None identified fatty acid 0.02%

content of long chain omega-3 polyunsaturated fatty

acids (PUFA), such as (DHA), (DPA) and eicosapen- Source: Author determination by Regional Centre for

taenoic acid (EPA), which are currently highly valued food and feed the USDA Agricultural Research Center

for their prophylactic and therapeutic properties in nu- laboratory.

tritional and health fields. High contents of functional

3.6 Fatty Acids Composition

EPA (20:5 ω 3) and DHA (22:6 ω 3) in the oil as show-

ing in Table 2 and 3. The results in Table 2 and 3 indicated that, total saturated

18 Distributed under creative commons license 4.0 DOI: https://doi.org/10.30564/jzr.v2i1.2021

Journal of Zoological Research | Volume 02 | Issue 01 | January 2020

fatty acids (TSFA) in from salmon by products were 44% References

of total fatty acids (TFA). The major saturated fatty acids

is polmetic acids (C16:0) which represented about 9.08% [1] Eslick G. D., Howe P. R., Smith C., Priest R.. Ben-

of TFA and about 58.51% of TSFA . the second ons is soussan A. Benefits of fish oil supplementation in hy-

myristic acid (C14:0) 3.26% followed by stearic acids perlipidemia: a systematic review and meta-analysis.

International Journal of Cardiology, 2009, 136: 4-16.

(C16:0) 2.51% of TFA. Monoumsotmroted fatty acids

[2] Fouda, T.Z. Waste Management For Smoking Salmon

(MUSFA) of oil extracted from salmon is 55.35% of TFA

By- Products To Extract Omega-3 Fish Oil Scientific

and the predominant MUSFA is oleic acids (C18:1mg)

Papers Series Management, Economic Engineering

which is represented 41.75% of TFA and about 75.43%

in Agriculture and Rural Development, 2018, 18(3).

of MUSFA, followed by godoleic acids (C20:1wg) 4.61%

Print ISSN: 284-7995, E-ISSN: 2285-3952.

TFA and 7.52% of MUSFA and vaccinic acid( C18:1wg)

[3] Ghaly, A. E., Dave, D., Brooks, M. S., Budge, S. M..

3.14% of TFA and 5.67% of MUSFA . Polumsoturated

Production of biodieselby enzymatic transesterifica-

fatty acids PUSFA represent about 30% of TFA . The

tion: A critical review. American Journal of Biochem-

predominant PUSFA is linoleic acid (C18:3n6) which

istry and Biotechnology, 2010, 6: 54-76.

represent 13.62% of TFA and about 45.40% of PUSFA

[4] Kazuo Miyashita. Prevention of Fish Oil Oxidation

followed by five fatty acids represent more than 1.0%

Journal of Oleo ScienceCopyright ©2019 by Japan

of TFA and between 1.12 – 5.64% of TFA, nomely le- Oil Chemists’ Society doi: 10.5650/jos.ess18144J.

nolenic acids (C18:3n3) 5.6490, do cosahexaenoic acid Oleo Sci., 2019, 68(1): 1-11.

(C22:6w3, DHA) 2.97% eicosapentenoic acid ( C20:5w3. [5] Khoshmanesh, S.. Design of Solar Dehydrator, Cou-

EPA) 2.46%, eicosadienoic acid ( C22:2w6) 1.16% and pled with Energy Storage in Rock Bed Reservoir for

clupandonic acid ( C22:5w3) 1.12% of TFA Other PUSFA Fish Drying Process. International Conference on

reprent less than, the oil extracted from salmon had ahigh Energy and Environment (ICEE), Universiti Tenaga

amoumts of MUSFA and PUSFA, these types of FA repre- Nasional, Bangi, Selangor, Malaysia, 2006, 28-30:

sented more than 85% of TFA, also this oil contant 0 high 1-8.

amounts of w3,w6 and wg fatty acids . these fatty acid [6] Lin, C. Y., Li, R. J.. Fuel properties of biodiesel pro-

playing very important jobs in healthy nutrition . duced from the crude fish oil from the soapstock of

marine fish. Fuel processing technology, 2009, 90(1):

4. Conclusions 130-136.

The main results of the present research can be summa- [7] Mbatia B., Adlercreutz D., Adlercreutz P., Mahadhy

rized as follows: A., Mulaa F., Mattiasson B.. Enzymatic oil extraction

(1) The results of edible portion and fish by product and positional analysis of ω-3 fatty acids in Nile

ranged from 42 to 54% and 46 to 56% respectively. perch and salmon heads. Process Biochemistry, 2010,

(2) The salmon by product percentage classified to 45: 815-819.

head ranged between 15 to 22%, skin ranged between 3 [8] Ramírez, A.. Salmon by-product proteins FAO Fish-

to 5.6%, off-cuts, ranged between 2 to 3.4% trimmings eries Circular. 2017, 1027: 1-6.

[9] Rustad, T.. Physical and Chemical Properties of Pro-

ranged between 7.2 to 10%, viscera ranged between 6 to

tein Seafood by-products. CRC Press, 2007.

11% and backbone ranged between 7.6 to 11%.

[10] Saldanha L. G., Salem Jr. N., Brenna J. T.. Workshop

(3) The oil fish salmon extracted from by product were

on DHA as a required nutrient: overview. Prostaglan-

oil percentage recovery from skin, ranged from 18.10 to

dins, Leukotrienes and Essential Fatty Acids, 2009,

21%, head ranged from 17 to 19% viscera from 15.2 to

81: 233-236.

17.8% and terming from 16.0 to 18.8%.

[11] Uitterhaegen E., Evon P.. Twin–cold extrusion tech-

(4) Oil extracted characteristics

nology for vegetable oil extraction: A review, Journal

Oil were extracted by cold pressing have high contents

of Food Engineering, 2017, 212: 190–200.

of functional EPA (20:5 ω 3) and DHA (22:6 ω 3) in the

[12] Rome, FAO. 2007: 31. ISSN: 0429-9329.

oil

http://www.fao.org/3/a-a1394e.pdf

Distributed under creative commons license 4.0 DOI: https://doi.org/10.30564/jzr.v2i1.2021 19

View publication stats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Characterization of Cognitive Deficits in Rats Overexpressing Human Alpha-Synuclein in The Ventral Tegmental Area and Medial Septum Using Recombinant Adeno-Associated Viral Vectors (2013)Document12 pagesCharacterization of Cognitive Deficits in Rats Overexpressing Human Alpha-Synuclein in The Ventral Tegmental Area and Medial Septum Using Recombinant Adeno-Associated Viral Vectors (2013)Rifqi Fathul ArroisiNo ratings yet

- s40071 019 0221 1Document13 pagess40071 019 0221 1Rifqi Fathul ArroisiNo ratings yet

- Comparative Study of The Antioxidant and Enzyme inDocument21 pagesComparative Study of The Antioxidant and Enzyme inRifqi Fathul ArroisiNo ratings yet

- Extraction and Microencapsulation of Tuna Virgin FDocument11 pagesExtraction and Microencapsulation of Tuna Virgin FRifqi Fathul ArroisiNo ratings yet

- Animal Behaviour: Alice Bouchard, Klaus ZuberbühlerDocument15 pagesAnimal Behaviour: Alice Bouchard, Klaus ZuberbühlerRifqi Fathul ArroisiNo ratings yet

- Reppert and Roode 2018 - HighlightDocument14 pagesReppert and Roode 2018 - HighlightRifqi Fathul ArroisiNo ratings yet

- Hypoxic Conditioned Medium From Mesenchymal Stem C.en - IdDocument12 pagesHypoxic Conditioned Medium From Mesenchymal Stem C.en - IdRifqi Fathul ArroisiNo ratings yet

- Asian Weaver Ants, Oecophylla Smaragdina, and Their Repelling of PollinatorsDocument6 pagesAsian Weaver Ants, Oecophylla Smaragdina, and Their Repelling of PollinatorsRifqi Fathul ArroisiNo ratings yet

- Soil Microbial Resources For Improving Fertilizers Efficiency in An Integrated Plant Nutrient Management SystemDocument25 pagesSoil Microbial Resources For Improving Fertilizers Efficiency in An Integrated Plant Nutrient Management SystemRifqi Fathul ArroisiNo ratings yet

- Healthcare 09 01536Document11 pagesHealthcare 09 01536Rifqi Fathul ArroisiNo ratings yet

- Microsatellite Loci For The Weaver Ant Oecophylla SmaragdinaDocument4 pagesMicrosatellite Loci For The Weaver Ant Oecophylla SmaragdinaRifqi Fathul ArroisiNo ratings yet

- Shigella Pathogenesis: Molecular and Computational Insights: ReviewDocument23 pagesShigella Pathogenesis: Molecular and Computational Insights: ReviewRifqi Fathul ArroisiNo ratings yet

- Genome-Scale Metabolic Modeling Reveals Sars-Cov-2-Induced Metabolic Changes and Antiviral TargetsDocument19 pagesGenome-Scale Metabolic Modeling Reveals Sars-Cov-2-Induced Metabolic Changes and Antiviral TargetsRifqi Fathul ArroisiNo ratings yet

- Molecular Pathogenesis of Shigella SPP.: Controlling Host Cell Signaling, Invasion, and Death by Type III SecretionDocument23 pagesMolecular Pathogenesis of Shigella SPP.: Controlling Host Cell Signaling, Invasion, and Death by Type III SecretionRifqi Fathul ArroisiNo ratings yet

- Grismer Et Al 2016 Ansonia KhaochangensisDocument26 pagesGrismer Et Al 2016 Ansonia KhaochangensisRifqi Fathul ArroisiNo ratings yet

- Comparative Morphology of Bornean Species of Ansonia (Amphibia Anura Bufonidae) (24pgs)Document24 pagesComparative Morphology of Bornean Species of Ansonia (Amphibia Anura Bufonidae) (24pgs)Rifqi Fathul ArroisiNo ratings yet

- Sl2021-Monitoring2-Kel.28-Rifqi Fathul ArroisiDocument2 pagesSl2021-Monitoring2-Kel.28-Rifqi Fathul ArroisiRifqi Fathul ArroisiNo ratings yet

- Ansonia Spinulifer,: Assessment By: IUCN SSC Amphibian Specialist GroupDocument9 pagesAnsonia Spinulifer,: Assessment By: IUCN SSC Amphibian Specialist GroupRifqi Fathul ArroisiNo ratings yet

- Crispr Cas9 Nobel Chemistry November 2020Document34 pagesCrispr Cas9 Nobel Chemistry November 2020Rifqi Fathul ArroisiNo ratings yet

- Sertifikat Best of The MonthDocument1 pageSertifikat Best of The MonthRifqi Fathul ArroisiNo ratings yet

- 3730 9730 3 PBDocument16 pages3730 9730 3 PBRifqi Fathul ArroisiNo ratings yet

- Species Diversity, Elevational Distribution and Reproductive Modes in An Amphibian Community at The Matang Range, Sarawak (Borneo)Document35 pagesSpecies Diversity, Elevational Distribution and Reproductive Modes in An Amphibian Community at The Matang Range, Sarawak (Borneo)Rifqi Fathul ArroisiNo ratings yet

- RD Kasar Level UPDocument1 pageRD Kasar Level UPRifqi Fathul ArroisiNo ratings yet

- Foods 09 00073Document12 pagesFoods 09 00073Rifqi Fathul ArroisiNo ratings yet

- Praktikum Minggu Ke 6Document2 pagesPraktikum Minggu Ke 6Rifqi Fathul ArroisiNo ratings yet

- Aquatic Ecosystem and Biodiversity A ReviewDocument13 pagesAquatic Ecosystem and Biodiversity A ReviewRifqi Fathul ArroisiNo ratings yet

- STB 1Document45 pagesSTB 1Rifqi Fathul ArroisiNo ratings yet