Professional Documents

Culture Documents

FCC DataSheet

FCC DataSheet

Uploaded by

lorenzoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FCC DataSheet

FCC DataSheet

Uploaded by

lorenzoCopyright:

Available Formats

Flared Cone Connection

For High Pressure Instrument Tube

Applications

No Anti-vibration

Gland Needed!

Parker Autoclave Engineers has taken

a variety of in-house technologies and

has created a patent-pending simple

to make connection using easy-to

use tools that is as safe as a Cone

& Thread connection without any of

the vibration sensitivity. Using just

a hydraulic press and two dies, the

connection is made using a similar

pre-set process as the Parker MPI

(Medium Pressure Inverted) and

Autoclave Engineers QSS (Quick Set

Sleeve) ferrule style connections with

one extra step that flares the tube. This

extra step allows for primary sealing on

the internal diameter of the flare with a

back up secondary seal on the front of

the sleeve.

Contact Information: Product Features:

Parker Hannifin Manufacturing Ltd. • 22,500 psi (2507 SD) or • Wide Temperature Range

Instrumentation Products Division, 20,000 psi (316 SS) working from -100°F (-73°C) to 600°F

Europe

Pottington Business Park pressures (316°C), and -50°F (-45°C) to

Barnstaple 600°F (316°C) for 2507 SD

• Flared Tubing Prevents Tube

phone +44 (0) 1271 313131 Extraction • Single Inconel 718

ipd@parker.com Compression Sleeve

www.parker.com/ipd • Double Metal to Metal Reduces Assembly Errors

Sealing Surfaces (First

Seal is on ID of Tube Flare, • No Anti-vibration gland

Second Seal is Between fitting needed - vibration is

Compression Sleeve and controlled in the standard

Fitting or Valve body) design

Valves, Fittings, Adapters and

Tubing

The process is simple:

1. Cut the tubing square and deburr

2. Slide on Gland Nut

3. Slide on Compression Sleeve

4. Set Compression Sleeve using Die Set “A” to charted hydraulic

pressure

5. Form Flare using Die Set “B” to charted hydraulic pressure

Gland Nut

Instructions are simple, intuitive, and easy to accomplish. One end

can be formed and installed in as little as 2 minutes as compared to Single

15-20 with Cone and Thread type connections. Once formed, only a Compression Sleeve

torque wrench is needed to properly complete the connection in the

fitting or valve. Process Outcome:

Flared Tube End

System Components Flow/Pressure 2507 SD 316 SS

Working Pressure psi/bar** Working Pressure psi/bar**

Connection Orifice Diameter Flow Area Temperature Temperature

in (mm) in2 (mm2) -50 º to 600ºF (-45º to 316ºC) -100º to 600ºF (-73º to 316ºC)

1/4” 0.109 (2.77) 0.009 (5.81) 22,500 (1550) 20,000 (1379)

3/8” 0.203 (5.16) 0.032 (20.65) 22,500 (1550) 20,000 (1379)

9/16” 0.312 (7.92) 0.076 (49.03) 22,500 (1550) 20,000 (1379)

3/4” 0.438 (11.13) 0.151 (97.42) 22,500 (1550) 20,000 (1379)

1” 0.562 (14.27) 0.248 (160.00) 22,500 (1550) 20,000 (1379)

* Flow area is minimum “system” flow area including tubing

** Maximum Working pressure is based on lowest rating of any system component

Connection Sizes

Connection Type FC250 FC375 FC562 FC750 FC1000

Tube O.D. 1/4” 3/8” 9/16” 3/4” 1”

316 SS Pressure Rating PSI 20,000 20,000 20,000 20,000 20,000

2507 SD Pressure Rating PSI 22,500 22,500 22,500 22,500 22,500

For part numbering please refer to the main product catalogue.

© 2016 Parker Hannifin Corporation 4190-FCC January 2016

Parker Hannifin Manufacturing Ltd

Instrumentation Products Division,

Europe

Pottington Business Park

Barnstaple

phone +44 (0) 1271 313131

www.parker.com/ipd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Statica PinDocument2 pagesStatica PinlorenzoNo ratings yet

- Double Block and Bleed (DBB) ValvesDocument36 pagesDouble Block and Bleed (DBB) ValveslorenzoNo ratings yet

- Manuale Dati ParcolDocument44 pagesManuale Dati ParcollorenzoNo ratings yet

- Uniting Geometry For FEA - ForumDocument2 pagesUniting Geometry For FEA - ForumlorenzoNo ratings yet

- Meshing Techniques - ForumDocument5 pagesMeshing Techniques - ForumlorenzoNo ratings yet

- Tips For New Members - ForumDocument8 pagesTips For New Members - ForumlorenzoNo ratings yet

- Salome MeshDocument52 pagesSalome MeshlorenzoNo ratings yet

- RCV-DS-02508-EN - Research Control Valves CV Vs Lift CurveDocument2 pagesRCV-DS-02508-EN - Research Control Valves CV Vs Lift CurvelorenzoNo ratings yet

- Fatigue Analysis of 6300 LT Pressure Vessel by Using Cyclic ServiceDocument7 pagesFatigue Analysis of 6300 LT Pressure Vessel by Using Cyclic ServicelorenzoNo ratings yet

- DT-Sentinel 10MAR2016Document3 pagesDT-Sentinel 10MAR2016lorenzoNo ratings yet

- Stress Linearization - ForumDocument3 pagesStress Linearization - ForumlorenzoNo ratings yet

- Product Data Sheet: Actuator AssemblyDocument2 pagesProduct Data Sheet: Actuator AssemblylorenzoNo ratings yet

- DataSheet Microsart-Manifolds IDocument8 pagesDataSheet Microsart-Manifolds IlorenzoNo ratings yet

- Agilent Site Preparation GuideDocument39 pagesAgilent Site Preparation GuidelorenzoNo ratings yet

- PID Control Tutorial - Yokogawa AmericaDocument3 pagesPID Control Tutorial - Yokogawa AmericalorenzoNo ratings yet

- RCV-UM-00562-EN - Research Control Valves Installation ManualDocument20 pagesRCV-UM-00562-EN - Research Control Valves Installation ManuallorenzoNo ratings yet

- How To Manually Tune A Three-Mode PID ControllerDocument5 pagesHow To Manually Tune A Three-Mode PID ControllerlorenzoNo ratings yet

- RCV-UM-01695-EN - RCVcalc Valve Sizing Software Installation ManualDocument2 pagesRCV-UM-01695-EN - RCVcalc Valve Sizing Software Installation ManuallorenzoNo ratings yet

- Operating Instruction Manual: Mini Bench Top ReactorsDocument28 pagesOperating Instruction Manual: Mini Bench Top ReactorslorenzoNo ratings yet

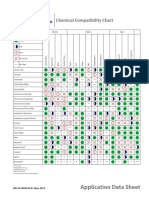

- IND-AS-00899-EN - Chemical Compatibility ChartDocument8 pagesIND-AS-00899-EN - Chemical Compatibility ChartlorenzoNo ratings yet

- MKP - PKP CatalogoDocument12 pagesMKP - PKP CatalogolorenzoNo ratings yet

- Parr Magnetic Drive Shields Installation InstructionsDocument1 pageParr Magnetic Drive Shields Installation InstructionslorenzoNo ratings yet

- E58-CIFQ2: Instruction ManualDocument2 pagesE58-CIFQ2: Instruction ManuallorenzoNo ratings yet

- Liquid Agitation: Bulletin No. 231Document7 pagesLiquid Agitation: Bulletin No. 231lorenzoNo ratings yet

- Zme LQDocument2 pagesZme LQlorenzoNo ratings yet