Professional Documents

Culture Documents

Planning Points 11.03.22

Uploaded by

ravitejatalatamOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Planning Points 11.03.22

Uploaded by

ravitejatalatamCopyright:

Available Formats

CHENNAI PETROLEUM CORPORATION LIMITED

PRODUCTION PLANNING 11-Mar-22

CRUDE RECEIPT PLAN

TANKER GRADE QTY ( MT ) L/C CARGO START TIME STOP TIME

S GANGA BOM 50,800 119 118 ,116 , 11-Mar 02:OO 12-Mar 02:OO

A POLARIS ARB 1,35,000 116 120 ,121 ,108 ,110 , 15-Mar 05:OO 16-Mar 18:OO

MARATHI BAM 1,35,400 110 110 ,105 ,109 ,111 , 17-Mar 06:OO 18-Mar 16:OO

FEEDING PLAN

REFINERY FEED SPIKE Rate/hr REMARKS START TIME STOP TIME

121 400 When 121 is low,c/o 11-Mar 06:OO 14-Mar 06:OO

105 400 When 105 is req for receipt,c/o 14-Mar 06:OO 17-Mar 10:OO

CDU1

120 400 When 120 is low,c/o 17-Mar 10:OO 18-Mar 10:OO

110 120 300 / 100 18-Mar 10:OO 21-Mar 06:OO

LS 107 620 When 107 is low,c/o 11-Mar 06:OO 11-Mar 21:OO

LS 114 620 When 118 is ready,c/o 11-Mar 21:OO 12-Mar 14:OO

CDU2 BH 118 620 When 118 is low,c/o 12-Mar 14:OO 15-Mar 19:OO

HS LS 113 115 420 / 200 When 113 is low,c/o 15-Mar 19:OO 19-Mar 01:OO

HS LS 111 115 500 / 120 19-Mar 01:OO 21-Mar 06:OO

HS LS 111 114 450 / 150 When 111 is low,c/o 11-Mar 06:OO 12-Mar 15:OO

HS LS 112 114 450 / 150 When 112 is low,c/o 12-Mar 15:OO 16-Mar 11:OO

CDU3

HS LS 113 115 400 / 200 When 113 is low,c/o 16-Mar 11:OO 18-Mar 16:OO

HS LS 109 119 500 / 100 18-Mar 16:OO 21-Mar 06:OO

GENERAL

Crude Tank Composition

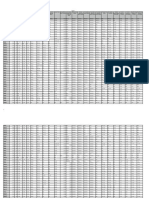

11-Mar High Sulphur Crude s Low Sulphur Crude s HS UNIT ETP Total

Dip

TANK ARB DAS UPP BAM BAL BAH ARL % BOM RAV NMN BSR SAP NEM NKO % RCO SLOP SLOP %

T105 961 60 7 2 2 1 28 100 0 100

T107 702 10 4 5 7 70 1 98 2 100

T108 188 84 2 4 10 100 100

T109 663 17 81 1 99 1 100

T110 287 1 2 95 0 2 100 100

T111 508 2 98 100 100

T112 1092 17 80 3 100 100

T113 1207 0 22 78 100 100

T114 1173 6 11 83 100 100

T115 1182 1 5 92 0 99 1 100

T116 277 14 7 52 12 11 1 97 3 100

T118 181 100 100 100

T119 644 7 2 31 52 1 93 7 100

T120 235 85 2 13 100 100

T121 1157 85 3 0 12 100 0 100

Tank unde r M&I:117,106

Production Planning 11-Mar-22

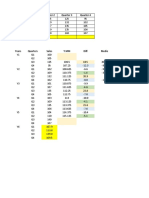

Lube Units - Plan Fri

Feed rate Ext/ Indicative Target

Plant Grade Feed tk R/D tk Remarks Dist Routing

m3/hr Wax time of c/o Visc

71 VR 80* Spindle DHDT/DS 2.8

LN 302 5.1

LN 65 302 320 303/ASP Next change 13-Mar 20:OO IN 304/311 /309 8.8

73

IN 68 304/311/309 321 303/ASP Next change 14-Mar 20:OO 500N 305 14.5-15

BN 55 308/310 306 307/ASP Next change 17-Mar 20:OO HN OHCU 23.5

BN 38 306 342 OHCU Next change 11-Mar 18:OO DAO 308/310 33-35

IN 50 321 340 Wax Next change 12-Mar 08:OO Wax Feed (KL) 1200

9

LN Match Pt-73 r/d 320 341 Wax Next change 15-Mar 08:OO

IN 50 321 340 Wax Next change 15-Mar 18:OO Wax - feed days 4

BN Match Pt-9 342 362/363 307/ASP Next change 11-Mar 18:OO

IN Max T'put 340 361/365/368 303/ASP Next change 12-Mar 08:OO

10 LOBS Tanker Loading -16/03/22

LN Match Pt-9 341 367 303/ASP Next change 15-Mar 08:OO

IN Max T'put 340 361/365/368 303/ASP Next change 15-Mar 18:OO Grade Qty in KL Tank Remarks

* PDA T'put is based on Asphalt ullage. LN 1500 T367

# Pt-73 500N / BN extract to be routed to respective tanks at the earliest after stabilization IN 8000 T365/368

BN 2500 T363

Total 12000

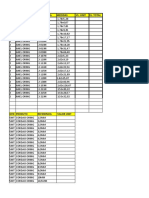

Product Tanker Plan

Tanker Name Product Laycan Qty (TMT) +/- 10 % Destination Remarks

MT Hari Aradhana MS / HSD 11-13/03/22 5/6 Ennore IOCL

MT Crimson Jade Naphtha (C: +22 / P: 60 % / FBP: 170°C) 17-19/03/22 35 Export CPCL

TBN Naphtha (C: +22 / P: 60 % / FBP: 170°C) 29-31/03/22 35 Export CPCL

TBN Naphtha (C: +22 / P: 65 % / FBP: 170°C) 05-07/04/22 35 Export CPCL

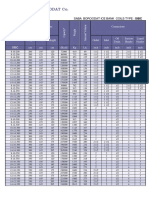

CTMPL Plan (TKL) Stream Routing Plan

Date Product Quantity Remarks MS Raw Diesel

28-Feb-22 MS 30.0 Over FCCU MS UCO (FBP < 200°C) Pt-1 / 15 / 201 (HS) DHDT / DHDS

03-Mar-22 PCK 0.4 Over Naphtha Pt-1 / 15 / 201 (LS) DHDS / DHDT

03-Mar-22 HSD 75.0 Over Pt-1 Hy Nap DHDT / DHDS DCU HCN / LCGO DHDT / DHDS

09-Mar-22 PCK 0.3 Over Pt-15 Hy Nap DHDT / DHDS / HSD BS-VI FCCU TCO HSD BS-VI / DHDT / DHDS

09-Mar-22 MS 36.0 On Pt-201 Hy Nap DHDT / DHDS / CCR VGO

13-Mar-22 PCK 0.3 Pt-201 LSRG ISOM / HGU / LPN Pt- 15 / 201 VGO OHCU

13-Mar-22 HSD 74.0 Pt-1 Stab Nap ISOM / CCR / HGU / LPN LS VGO to FCCU -

19-Mar-22 PCK 0.3 Pt-201 LSRN CCR / LPN UCO to FCCU Maximum (143+)

19-Mar-22 SKO 3.5 Pt-15 Stab Nap ISOM / CCR / HGU / LPN Pt- 15 / 201 Slop Dist (LS) RFO / DCU / FO

19-Mar-22 PCK 0.3 Pt-74 Bal Nap Sp I Top - ISOM / Sp II Btm - CCR Pt- 15 /201 Slop Dist (HS) DCU / FO

19-Mar-22 MS 36.0 207 Light Nap Pt-74 / ISOM / HGU DCU HCGO OHCU / FO

23-Mar-22 PCK 0.3 207 Hy Nap CCR / HSD BS-VI / MS Lube Slop Tk- 312 / 313 / 325 / FO

23-Mar-22 HSD 75.0 DHDS Syn Nap CCR / MS / FCCU / LPN OHCU Conversion 62 % Min

CBPL Plan (TKL) DHDT Syn Nap CCR / MS / FCCU / LPN 207 Filter Backwash Tk- 312 / 313 / 325

Date Product Quantity Remarks 206 NHT LN Pt-74 / ISOM Pt- 15 / 201 HS EGO DHDT / DHDS / OHCU

24-Feb-22 HSD 56.8 Over 212 NHDT C7+ CCR / HGU Pt- 15 / 201 LS EGO DHDS / DHDT / OHCU

04-Mar-22 PCK 0.2 Over 212 NHDT C5- MS / HGU VBU VGO -

04-Mar-22 MS 16.6 (CPCL-15.2) Over 212 DIHR Pt-74 (8 m3/hr) VR

07-Mar-22 PCK 0.2 Over DCU LCN ISOM / DHDT Pt-1 PDA / ABB / DCU / FO

07-Mar-22 ZSKO 0.3 Over VBU Naphtha - Pt- 15 / 201 (HS) DCU / ABB / PDA / FO

07-Mar-22 ATF 14.0 Over ATF MODE Pt- 15 / 201 (LS) RFO / DCU / FO

08-Mar-22 ZSKO 0.1 Over Pt-1 TPL SK VBU Tar -

08-Mar-22 PCK 0.2 Over Pt-15 Pt-17 (75 m3/hr), rest to TPL SK Extracts Bitumen / DCU / FO

08-Mar-22 HSD 48.0 On Pt-201 Pt-203 (55 m3/hr), rest to TPL SK Pitch Bitumen

14-Mar-22 PCK 0.2 OHCU HSD Slop to DCU 30 m3/hr

14-Mar-22 MS 22.0 Pt-4 60 m3/hr (TPL Rtn SK) Slop to CDU-1 / CDU-2 -

17-Mar-22 LSATF 0.4 HSD Recovery Target (at 360°C)

17-Mar-22 ATF 13.5 CDU 1 15 Atm 15 Vac 201 Atm 201 Vac DCU LCGO OHCU

18-Mar-22 LSATF 0.3 90 97 97 98 98 90 90

18-Mar-22 HSD 48.0 Unit Tput Requirement (m3/hr)

24-Mar-22 PCK 0.2 Pt-4 DHDS DHDT OHCU FCCU ISOM CCRU Pt-74 Pt-14 DCU PDA VBU

24-Mar-22 MS 10.6 60 300 370 330 146 50 70 20 14 275 80 -

Standing Instructions: Sulphur Target (ppm)

1) FCCU to be operated in MS maximisation mode (Cracked Gasoline FBP to be targeted at 200°C). DHDS 5

2) Heavy Naphthas to be fully absorbed in Diesel pool, routing to naphtha pool to be avoided. DHDT 5

3) Excess SK after meeting Pt-4 feed requirement to be continuously pumped to DHDT and DHDS. OHCU HSD 10

4) TPL Low Sulphur Return SK to be continuously received in product diesel tanks. LCO -

5) LCO and HCO to be absorbed in HSD BS-VI header based on sulphur and recovery. HCO -

6) To increase MS production, ISOM C5- to be kept routed to MS pool based on header RVP. Cr Gasoline 13

7) CDU-1 VR to be fully absorbed in PDA to meet DAO quality. Naphtha Pool FBP (°C)

8) CDU-2 Stabilised Naphtha FBP to be aimed below 125°C to reduce Naphtha make. Hy Naphtha 170

9) Syn Naphthas FBP to be optimised based on product HSD flash to reduce Naphtha make. Syn Naphtha 170

Today's Instructions: Operating Mode

1) SK and Raw Diesel ullages are critical, DHDS and DHDT to be operated at combined T'puts of 670 m3/hr. FCCU MS

2) To reduce SK spill over to Raw Diesel pool, ATF units to be operated at combined T'puts of 190 m3/hr.

3) OHCU to run in LSATF Mode and r/d to be routed to Tk-422.

4) CDU-2 Stab Naphtha and Syn Naphtha makes are high, Naphtha make to be optimised.

5) Excess SK available in Tank 503 to be absorbed in DHDS and DHDT at 60 m3/hr.

6) Heavy Naphthas to be fully absorbed in Diesel pool, routing to naphtha pool and ISOM / CCR feed pool to be avoided.

DGM (PP) 11-03-2022

You might also like

- Planning Points - 070122Document2 pagesPlanning Points - 070122ravitejatalatamNo ratings yet

- Fisa Xbar R SDocument1 pageFisa Xbar R SCristi BragaNo ratings yet

- PerformanceDocument10 pagesPerformancecsl1600No ratings yet

- TBN TrendDocument8 pagesTBN TrendNaveed Ul Qamar MughalNo ratings yet

- Caterpillar 32B9400010 - Overhaul Gasket KitDocument3 pagesCaterpillar 32B9400010 - Overhaul Gasket KitFernando PadillaNo ratings yet

- Frenos Af50Document2 pagesFrenos Af50Emilio CortesNo ratings yet

- 02-04-02 Tilt Cylinder (R.H.) (6 Degrees - 10 Degrees, 6 Degrees - 6 Degrees)Document2 pages02-04-02 Tilt Cylinder (R.H.) (6 Degrees - 10 Degrees, 6 Degrees - 6 Degrees)Gustavo RodriguezNo ratings yet

- Turakhia Polymers Pvt. LTD.: DCA Cum CS of Indian Oil Corporation Ltd. For PP / HDPE / LLDPEDocument4 pagesTurakhia Polymers Pvt. LTD.: DCA Cum CS of Indian Oil Corporation Ltd. For PP / HDPE / LLDPEdiadam07No ratings yet

- Audio FT 950 Config.Document2 pagesAudio FT 950 Config.CarlosNo ratings yet

- Impedancias de Transformadores de Dos DevanadosDocument7 pagesImpedancias de Transformadores de Dos DevanadosEDUARDO SALINAS LOPEZNo ratings yet

- JFB Metallized Polyester Film CapacitorDocument2 pagesJFB Metallized Polyester Film CapacitorJuan Manuel JorqueraNo ratings yet

- Production Nonstaff-3Document3 pagesProduction Nonstaff-3latawan komdanNo ratings yet

- DP 0900Document4 pagesDP 0900sarah.sergioengandconNo ratings yet

- Pizza DemandDocument3 pagesPizza DemandAnkit Kumar SinghNo ratings yet

- SREDNJA GOSPODARSKA ŠKOLA KRIŽEVCI UkratkoDocument5 pagesSREDNJA GOSPODARSKA ŠKOLA KRIŽEVCI UkratkoMislav DrokanNo ratings yet

- Produtos Pós Contagem: 2) Diferenca NegativaDocument7 pagesProdutos Pós Contagem: 2) Diferenca NegativaIrving ArrudaNo ratings yet

- Techlibrary Carb Numerical ListingDocument14 pagesTechlibrary Carb Numerical Listingv8chargeNo ratings yet

- Kediri Ilham 01Document2 pagesKediri Ilham 01Nurcahyadin WorkNo ratings yet

- Total: O V E R TI M E P A Y Cash AdvancesDocument6 pagesTotal: O V E R TI M E P A Y Cash AdvancesJohn SaavedraNo ratings yet

- Yamaha EF6600A GeneratorDocument44 pagesYamaha EF6600A GeneratortimmckennaNo ratings yet

- 2021-07-02 - 13-09-31 - Soy Gluten 70.30 - B9r2r9qvme4rDocument5 pages2021-07-02 - 13-09-31 - Soy Gluten 70.30 - B9r2r9qvme4rGagan SvNo ratings yet

- Client Symbol Series Netqty Netprice MTM Optionty Pe Strikepric E Marketpri Ce Mtmvpo SDocument3 pagesClient Symbol Series Netqty Netprice MTM Optionty Pe Strikepric E Marketpri Ce Mtmvpo SRounak ChowdhuryNo ratings yet

- JC011 T-Nagar Ring Details BackupDocument21 pagesJC011 T-Nagar Ring Details BackupAshok KumarNo ratings yet

- Tank Volume CalcDocument3 pagesTank Volume CalcSachinl PatelNo ratings yet

- Saba IceBankColisDocument3 pagesSaba IceBankColissukamtoNo ratings yet

- AA1050Document3 pagesAA1050designNo ratings yet

- High-Rep Bench Press Program: W# Sets Reps Weight W# Sets 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Explanations: RO-FDocument3 pagesHigh-Rep Bench Press Program: W# Sets Reps Weight W# Sets 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Explanations: RO-FDen KongNo ratings yet

- Boom Swing Cylinder Inner PartDocument2 pagesBoom Swing Cylinder Inner PartOecox Cah DjadoelNo ratings yet

- Adhe PPMDocument15 pagesAdhe PPMAdhe R ebeka PardosiNo ratings yet

- Low Cement Dense Castables / Calcestruzzi Densi A Basso Cemento / Betons Denses A Basse Teneur en Ciment / Dichte Lc-BetoneDocument2 pagesLow Cement Dense Castables / Calcestruzzi Densi A Basso Cemento / Betons Denses A Basse Teneur en Ciment / Dichte Lc-Betoneasad razaNo ratings yet

- Tabla Dodge Roming 2 HojasDocument2 pagesTabla Dodge Roming 2 HojasVicente VazquezNo ratings yet

- RS1 RS2 RS3 RS4 RS5 RS6 RS7 RS8 RS9 RS10 RS11 RS12 RS13 RS14 RS15 RS16 RS17 RS18 RS19 RS20Document4 pagesRS1 RS2 RS3 RS4 RS5 RS6 RS7 RS8 RS9 RS10 RS11 RS12 RS13 RS14 RS15 RS16 RS17 RS18 RS19 RS20Munish GaurNo ratings yet

- New Mailam MinesDocument12 pagesNew Mailam MinesparameswarikumarNo ratings yet

- William H Greene-Econometric Analysis-PrenticeDocument5 pagesWilliam H Greene-Econometric Analysis-PrenticeAbdel Lee Moomine TraoréNo ratings yet

- REE - Plot MachineDocument5 pagesREE - Plot MachineDaniel SandovalNo ratings yet

- Physics - Puc - 1 - 2020Document1 pagePhysics - Puc - 1 - 2020PranalNo ratings yet

- Client Symbol Series Netqty Netprice MTM Optionty Pe Strikepric E Marketpri Ce Mtmvpo SDocument3 pagesClient Symbol Series Netqty Netprice MTM Optionty Pe Strikepric E Marketpri Ce Mtmvpo SRounak ChowdhuryNo ratings yet

- Rot 15 AprilDocument2 pagesRot 15 AprilMuhammad Zainal HafizNo ratings yet

- Aplicatie 4Document35 pagesAplicatie 4AndreeaPopescuNo ratings yet

- 6air Intake For 15a AlternatorDocument1 page6air Intake For 15a AlternatorSri hartatiNo ratings yet

- Inna 2Document2 pagesInna 2Eydis BirtaNo ratings yet

- Tetragonal MX2 LanthanidesDocument3 pagesTetragonal MX2 LanthanidesLaxman ChyNo ratings yet

- Demanda - At-Ft - At-Ft - At-Ft - At-Ft Promedio Movil 3M Promedio Movil Ponderad O3MDocument3 pagesDemanda - At-Ft - At-Ft - At-Ft - At-Ft Promedio Movil 3M Promedio Movil Ponderad O3MJESSICA NATALIA VARGAS GOMEZNo ratings yet

- Employee'S Provident Fund Organisation: Electronic Challan Cum Return (Ecr)Document5 pagesEmployee'S Provident Fund Organisation: Electronic Challan Cum Return (Ecr)Mainak MitraNo ratings yet

- For PoDocument5 pagesFor Pomotorcentral balayanNo ratings yet

- Sodexo Perú S.A - Contractor: Week 05-06Document4 pagesSodexo Perú S.A - Contractor: Week 05-06Juan SanjinezNo ratings yet

- Tabela Tubos HidráulicosDocument1 pageTabela Tubos HidráulicosJPJFNo ratings yet

- Perfiles de CallesDocument6 pagesPerfiles de CallesEDUAR SANCHEZ CIEZANo ratings yet

- Registro de Temperatura Cuartos de Secado # Cuartos 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Set Point HorasDocument1 pageRegistro de Temperatura Cuartos de Secado # Cuartos 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Set Point HoraskarenNo ratings yet

- Fase Acercam Carril Volumen So N FW FHV A 1316 1564 B 1398 2602 B 1509 1660Document3 pagesFase Acercam Carril Volumen So N FW FHV A 1316 1564 B 1398 2602 B 1509 1660Davila Yalli JhonNo ratings yet

- Rekap Absen Ds Siantarsidempuan Agustus 2017Document5 pagesRekap Absen Ds Siantarsidempuan Agustus 2017BillyNo ratings yet

- Delivery Line Clamp 1001 227Document2 pagesDelivery Line Clamp 1001 227Oecox Cah DjadoelNo ratings yet

- QTD Produto Referencia Medidas Vl. Unit Vl. TotalDocument3 pagesQTD Produto Referencia Medidas Vl. Unit Vl. TotalGleyson SousaNo ratings yet

- 1ra Diferencias Cjardin Sep19Document10 pages1ra Diferencias Cjardin Sep19Laura GiraldoNo ratings yet

- HKH 1106 2022-07-22 SD 2022-07-28 8821Document16 pagesHKH 1106 2022-07-22 SD 2022-07-28 8821Nurcahyadin WorkNo ratings yet

- Grafik Peningkatan Detak Jantungkecepatan (20-25) Dan Beban RinganDocument6 pagesGrafik Peningkatan Detak Jantungkecepatan (20-25) Dan Beban RinganwahyufadjarNo ratings yet

- DSMC Quan Tum Miramar01132a201702061109Document2 pagesDSMC Quan Tum Miramar01132a201702061109Jorge IbacetaNo ratings yet

- 7air Intake For 13a 25a AlternDocument1 page7air Intake For 13a 25a AlternEm sulistioNo ratings yet

- Computation NewDocument3 pagesComputation NewJhony MahinayNo ratings yet

- Fluid Catalytic Cracking - Wikipedia PDFDocument9 pagesFluid Catalytic Cracking - Wikipedia PDFSauptik DattaNo ratings yet

- 5 Membrane Function PogilDocument5 pages5 Membrane Function PogilEmma75% (8)

- GB EJ StorageDocument3 pagesGB EJ StorageAndres BeltranNo ratings yet

- 2-033400-Section Lightweight ConcreteDocument4 pages2-033400-Section Lightweight ConcreteAhmad SaadeldinNo ratings yet

- Astm E-1417-PtDocument11 pagesAstm E-1417-PtRamadhan AdityaNo ratings yet

- Ssac 111 S N412345Document14 pagesSsac 111 S N412345Shubham WakarekarNo ratings yet

- 22PAM0062 - INTERMEDIATE ACADEMIC ENGLISH - Part1Document17 pages22PAM0062 - INTERMEDIATE ACADEMIC ENGLISH - Part1Dwi Nurvidi PriliaNo ratings yet

- 1.1 Cell Structure 2 MSDocument11 pages1.1 Cell Structure 2 MSF JNo ratings yet

- Determining The Plastic I Index of Soils Imit and PlasticityDocument5 pagesDetermining The Plastic I Index of Soils Imit and PlasticitysitrakiniavoNo ratings yet

- List of Substandard Drugs-2010Document6 pagesList of Substandard Drugs-2010Mohammad Shahbaz AlamNo ratings yet

- Annex 1 Qualification of HPLC EquipmentDocument17 pagesAnnex 1 Qualification of HPLC EquipmentAbhilash NarayananNo ratings yet

- GCSE Edexcel Biology Self-Studying TextbookDocument89 pagesGCSE Edexcel Biology Self-Studying TextbookDhuhaa YusufNo ratings yet

- Chemistry Lab Report 1Document9 pagesChemistry Lab Report 1Imazahra Badaruddin25% (4)

- Chem 3Document3 pagesChem 3phkavinNo ratings yet

- Eucalyptus Pulp Fibres As Alternative ReDocument8 pagesEucalyptus Pulp Fibres As Alternative ReDiego JavierNo ratings yet

- 5 6176732192253674928Document14 pages5 6176732192253674928Manu ShreeNo ratings yet

- MTE PDS MS 13X DS1 Rev03Document2 pagesMTE PDS MS 13X DS1 Rev03Javier Regueiro ListeNo ratings yet

- Periodic Table by Khan SirDocument9 pagesPeriodic Table by Khan Sirbabulstar98No ratings yet

- Final Lesson PlanDocument10 pagesFinal Lesson PlanMary Grace Jerna Artazo Nozal-Cuadra100% (1)

- Masterglenium Sky 504: Description Features and BenefitsDocument2 pagesMasterglenium Sky 504: Description Features and BenefitsvikasNo ratings yet

- Table of Product Types For Halal Certification PDFDocument18 pagesTable of Product Types For Halal Certification PDFAryo Gilang Yusa MaulanaNo ratings yet

- Sample 31302Document16 pagesSample 31302sriniNo ratings yet

- 3 Welding ImperfectionsDocument44 pages3 Welding ImperfectionsAdhanom G.No ratings yet

- Agaroses For Molecular Biology: Clonaje Y Expresión de Proteínas RecombinantesDocument3 pagesAgaroses For Molecular Biology: Clonaje Y Expresión de Proteínas RecombinantesKATHENo ratings yet

- Biolab Activity 8 2Document3 pagesBiolab Activity 8 2Radylyn CuaresmaNo ratings yet

- Protein Structure and FunctionDocument35 pagesProtein Structure and FunctionPRAJWAL SHYAM BHOSALENo ratings yet

- ZP PadDocument7 pagesZP PadbaktiperkasaNo ratings yet

- Landmark - Halliburton Well Design SoftwareDocument10 pagesLandmark - Halliburton Well Design SoftwareAli AlakariNo ratings yet

- Tea Test ResultsDocument3 pagesTea Test ResultsMarketplace86% (7)

- General Biology 1 Unit 1Document45 pagesGeneral Biology 1 Unit 1lc camposoNo ratings yet