Professional Documents

Culture Documents

Arch Spec Part 1

Uploaded by

شاهنوازحيدرCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Arch Spec Part 1

Uploaded by

شاهنوازحيدرCopyright:

Available Formats

HOSPITAL IN TENBAK AREA

1.3.9 The field sample, when accepted by the Engineer, shall be used as basis for comparison

with the remainder of the installation of the work of this Section for the purpose of

acceptance or rejection

1.3.10 Quality Control Submittals: In accordance with the provisions of Division 01Section”

Submittals Procedure”, submit the following:

1.3.10.1 Design Data: When and as directed by the Engineer, engineering design calculations

confirming the structural stability of the mockups.

1.4 QUALITY ASSURANCE

1.4.1 Qualifications:

1.4.1.1 Fabricators' and Installers' Qualifications: In accordance with the provisions of the

specification Sections for products and materials incorporated into the mockups.

1.4.1.2 In constructing mockups, take measures to ensure the safety of Project personnel and the

public.

1.4.1.3 Field Representation: During construction of mockup, representatives of the manufacturers

shall be present on site to coordinate installation.

1.5 SCHEDULING

1.5.1 The Engineer shall be notified at the start of construction of mockups and shall receive

progress reports to allow the Engineer to schedule his inspections.

1.5.2 Visual examination of the mockups during construction will be made by the Engineer and

other entities representing incorporated materials.

1.5.3 Obtain the Engineer's acceptance of visual qualities of mockups before commencing the

corresponding work for the Project, revise the updated Construction Schedule to reflect

required revisions to mockups.

1.5.4 All systems to be installed in the mockup shall have been tested and their correspondent

Certificates submitted following QCS requirements, and contract conditions.

1.5.5 Should mockups fail to meet the Engineer's approval or performance testing, partially or

completely, they shall be taken down or dismantled, and reconstructed to the extent

necessary, until acceptance has been obtained.

1.5.6 Time the completion and reworking of mockups necessary to obtain acceptance to avoid

delay in the construction schedule of the Project. Update the Construction Schedule to

reflect required revisions to mockups.

1.5.7 Retain and maintain mockups during construction to serve as a standard for judging work

incorporated into the Project. Do not alter, or remove.

MOCKUP ROOM S2 Part 16 - 2

HOSPITAL IN TENBAK AREA

2 PRODUCTS

2.1 MATERIALS AND COMPONENTS

2.1.1 Materials and finishes shall comply with the requirements specified in the various applicable

Sections of the Specifications, and shall match previously submitted and approved samples.

2.1.2 Mockups shall incorporate all related construction materials and finishes having a visual or

technical effect upon the completed work.

2.2 MOCKUPS

2.2.1 Mockups: Full-size physical assemblies that are constructed on-site. Mockups are

constructed to verify selections made under Sample submittals; to demonstrate aesthetic

effects and, where indicated, qualities of materials and execution; to review coordination,

testing, or operation; to show interface between dissimilar materials; and to demonstrate

compliance with specified installation tolerances. Mockups are not Samples. Unless

otherwise indicated, approved mockups establish the standard by which the Work will be

judged.

2.2.2.1 Room Mockups: Mockups of typical interior spaces complete with wall, floor, and ceiling

finishes, doors, windows, millwork, casework, specialties, furnishings and equipment, and

lighting.

2.2.2.2 Prior to installation in or on building, construct mockups for each system and finish required

to verify selections made under sample submittals and to demonstrate aesthetic effects as

well as qualities of materials and execution. Building mockups shall comply with the

following requirements, using materials indicated for final unit of work.

2.2.2.3 Place mockups on site in the location directed by Engineer. Provide mockups consisting of

constructions referred to in the various applicable sections of the specifications. Components

shall be full height and can be incorporated into the final work.

2.2.2.4 Notify Engineer one week in advance of the dates and times when mockups will be

constructed.

Demonstrate the proposed range of aesthetic effects and workmanship.

Obtain Engineer's acceptance of mockups before start of final unit of work.

Retain and maintain mockups during construction in an undisturbed condition as a standard

for judging the completed work.

Demolish and remove mockups when directed unless otherwise indicated.

Accepted mockups in an undisturbed condition at the time of Substantial Completion may

become part of the completed work.

2.3 MATERIALSPECIFICATIONS:

Item/Material Section Reference

Porcelain tile Section 24 Finishes to Buildings

Porcelain floor tile Section 24 Finishes to Buildings

Gypsum board with moisture resistance Section 24 Finishes to Buildings

CMU masonry, Section 13 Masonry

MOCKUP ROOM S2 Part 16 - 3

HOSPITAL IN TENBAK AREA

IP 006 25 mm wall Section 24 Finishes to Buildings

Paint to follow adjacent wall paint finish Section 26 Painting and Decorating

Vinyl flooring, slip resistance R9, 2 mm Section 24 Finishes to Buildings

thickness

Vinyl roll slip resistance: R9 Integral coved Section 24 Finishes to Buildings

Gypsum board, painted Regular Section 24 Finishes to Buildings

Exterior Window. 2400 x 1500 mm Section 25 Glass and Glazing

Uneven Double Door, 1100+400 mm Section 18 Carpentry, Joinery and

Ironmongery

Clinical Area Back Splash Section 18 Carpentry, Joinery and

Ironmongery

Wardrobe Section 18 Carpentry, Joinery And

Ironmongery

Bed Head Unit, Wall Section 31 Furniture

Nurse Workstation Section 18 Carpentry, Joinery And

Ironmongery

TV panel, wall Section 31 Furniture

Dispenser, Soap, wall mounted section 30 toilet and bath accessories

Dispenser, paper towel, wall mounted section 30 toilet and bath accessories

Drop down grab rail section 30 toilet and bath accessories

Grab rail horizontal section 30 toilet and bath accessories

Asymmetrical basin with overflow hole section 30 toilet and bath accessories

Dispenser, Barrier cream, wall mounted section 30 toilet and bath accessories

Television,42”-50”, flat panel Section 31 Furniture

Magnetic Glass Board Section 31 Furniture

Clinical Hand Wash Basin Section 31 Furniture

Sleeper Sofa patient room Section 31 Furniture

Side table 27”H patient room Section 31 Furniture

Chair, Patient room Section 31 Furniture

tiles for the en-suite bathroom Section 24 Finishes to Buildings

floor thresholds Section 24 Finishes to Buildings

Sanitary ware Section 20 Drainage Works For Build-

ing

Electrical fittings Section 21 Electrical Works

3 EXECUTION

3.1 INSTALLATION

3.1.1 Install materials in a manner that will duplicate the appearance in the completed building.

3.1.2 In constructing mockups, take measures to ensure the safety of Project personnel and the

public.

3.1.3 Construct mockups using same construction personnel, means, and methods as intended for

use on actual project.

3.1.4 Mockups shall be constructed in accordance with details indicated on the drawings and

approved Shop Drawings.

MOCKUP ROOM S2 Part 16 - 4

You might also like

- Annexure F Bill of Quantities (BOQ)Document31 pagesAnnexure F Bill of Quantities (BOQ)Motlatsi Anthony MoalosiNo ratings yet

- Refurbishment /re-Construction Works For Azaiba CPS Operators Room and ToiletDocument4 pagesRefurbishment /re-Construction Works For Azaiba CPS Operators Room and ToiletJosen JoseNo ratings yet

- KON-8.2-QA-PRO-0022 C1 Prefabricated Building Erection ProcedureDocument4 pagesKON-8.2-QA-PRO-0022 C1 Prefabricated Building Erection ProcedureAlizamin SalmanovNo ratings yet

- 2013 12 09 NIH - 12 Div FurnishingsDocument69 pages2013 12 09 NIH - 12 Div FurnishingsCharmierae SantosNo ratings yet

- A M 15 Mechanical Installation July 09Document109 pagesA M 15 Mechanical Installation July 09suneethmohanNo ratings yet

- Installation Method StatementDocument56 pagesInstallation Method StatementBindanna JoshiNo ratings yet

- Arch Spec Part 2Document4 pagesArch Spec Part 2شاهنوازحيدرNo ratings yet

- 531-Sweater - BOQ V.01 - 09-09-2022Document56 pages531-Sweater - BOQ V.01 - 09-09-2022AHMAD SHNo ratings yet

- CONQUAS 8th Edition Manual PDFDocument68 pagesCONQUAS 8th Edition Manual PDFladhytiaputraNo ratings yet

- CONQUASDocument50 pagesCONQUASFrankie Chan100% (2)

- Division 11 Equipment Section 11A Trash Chute 1. General: 1.1. DescriptionDocument3 pagesDivision 11 Equipment Section 11A Trash Chute 1. General: 1.1. DescriptionPatrick MutieNo ratings yet

- SOW - Improvement of Twelve (12) Units StaffhousesDocument14 pagesSOW - Improvement of Twelve (12) Units StaffhousesKathleen A. PascualNo ratings yet

- CONQUAS9Document72 pagesCONQUAS9stevenNo ratings yet

- Drainage Works For BuildingsDocument38 pagesDrainage Works For BuildingsenviroashNo ratings yet

- Bill of Quantity Rehabilitation of The Artificial Limbs Center in Falluja Falluja City - Anbar GovernorateDocument36 pagesBill of Quantity Rehabilitation of The Artificial Limbs Center in Falluja Falluja City - Anbar GovernorateALI ALTAIENo ratings yet

- Dubai Hills Villa - Phe Boq - 20210713Document32 pagesDubai Hills Villa - Phe Boq - 20210713Mohammed AzharNo ratings yet

- Demountable PartitionsDocument10 pagesDemountable PartitionsMuhammad IhsanNo ratings yet

- SECTION 03 45 00 Precast Architectural ConcreteDocument30 pagesSECTION 03 45 00 Precast Architectural ConcreteJuanPaoloYbañezNo ratings yet

- Cat. Porcelanosa Offsite - EngDocument39 pagesCat. Porcelanosa Offsite - Engjp.rochinha2000No ratings yet

- Conquas: The Bca Construction Quality Assessment SystemDocument67 pagesConquas: The Bca Construction Quality Assessment SystemalfieNo ratings yet

- BP 08 - Aluminum Curtain Wall, Storefronts, Glass & GlazingDocument3 pagesBP 08 - Aluminum Curtain Wall, Storefronts, Glass & GlazingjacksondcplNo ratings yet

- 040120.63 FL - Brick Masonry RepairDocument15 pages040120.63 FL - Brick Masonry RepairmelvinkorahNo ratings yet

- Akzonobel Uae Paints LLC': Item Description QtyDocument8 pagesAkzonobel Uae Paints LLC': Item Description Qtyimtz2013No ratings yet

- Addis Ababa Tender PDFDocument20 pagesAddis Ababa Tender PDFAsnake TegenawNo ratings yet

- Specification For Building-Works-New Build West Green RoadDocument99 pagesSpecification For Building-Works-New Build West Green RoadMaria100% (1)

- Boq Format For Residential BuildingDocument45 pagesBoq Format For Residential BuildingitsmimigamingNo ratings yet

- Conquas 2005Document65 pagesConquas 2005Anonymous p2cFoXbjDNo ratings yet

- 09 0700 Interior Fit OutDocument5 pages09 0700 Interior Fit OutTarek Tarek100% (1)

- Design StandardsDocument164 pagesDesign StandardsVikas PatelNo ratings yet

- CONST Method BuildingDocument2 pagesCONST Method BuildingAlmher RemolloNo ratings yet

- Atm 050422-q00248 Ms. Apple JacobeDocument3 pagesAtm 050422-q00248 Ms. Apple JacobeAbbeygale Tolosa MoyaNo ratings yet

- AWMAC NAAWS CSC Section 06 41 00 - Architectural Wood Casework - May2018Document11 pagesAWMAC NAAWS CSC Section 06 41 00 - Architectural Wood Casework - May2018Gilang PratamaNo ratings yet

- 18TH Flr-Architectural SpecificationDocument4 pages18TH Flr-Architectural SpecificationEllie LozaresNo ratings yet

- 0310 Concrete Works en Rev ADocument17 pages0310 Concrete Works en Rev AJaime LandinginNo ratings yet

- A M 06 Ironmongery July 09Document13 pagesA M 06 Ironmongery July 09suneethmohanNo ratings yet

- KON 8.2 QA PRO 0023 C1 Building Systems ProcedureDocument5 pagesKON 8.2 QA PRO 0023 C1 Building Systems ProcedureAlizamin SalmanovNo ratings yet

- A M 09 Metalwork July 09Document21 pagesA M 09 Metalwork July 09suneethmohanNo ratings yet

- BT4 SpecsDocument65 pagesBT4 SpecsDiether MiclaNo ratings yet

- Symfoni Kamias 1 Architectural SpecificationsDocument160 pagesSymfoni Kamias 1 Architectural SpecificationsAristeo GarzonNo ratings yet

- Work Method Statement PranavDocument8 pagesWork Method Statement PranavpranavdoorsNo ratings yet

- Sanitary SpecificationDocument15 pagesSanitary Specificationanup thapaNo ratings yet

- SECTION 08 44 13 Glazed Aluminum Curtain WallsDocument26 pagesSECTION 08 44 13 Glazed Aluminum Curtain WallsJuanPaoloYbañezNo ratings yet

- Technical Specifications FOR Plumbing Works (Internal & External)Document40 pagesTechnical Specifications FOR Plumbing Works (Internal & External)Mac ShaikNo ratings yet

- SpecphDocument98 pagesSpecphhelloitskalaiNo ratings yet

- BT4 FinalsDocument80 pagesBT4 Finalsamsdeleon.12No ratings yet

- Sistem Bekalan Air Sejuk Dalaman Dan Perpaipan SanitariDocument65 pagesSistem Bekalan Air Sejuk Dalaman Dan Perpaipan SanitariShudhan Nambiar100% (1)

- Mmc-Gamuda Conquas Road ShowDocument86 pagesMmc-Gamuda Conquas Road ShowAlsonChinNo ratings yet

- Qcs 2010 Section 10 Part 5 Control Panels and Control PDFDocument6 pagesQcs 2010 Section 10 Part 5 Control Panels and Control PDFbryanpastor106No ratings yet

- Parapet Construction Method StatementDocument6 pagesParapet Construction Method Statementnextleve.test1No ratings yet

- Section 1456t Chute: LinenDocument4 pagesSection 1456t Chute: LinenMoath AlhajiriNo ratings yet

- SPECIFICATIONSDocument5 pagesSPECIFICATIONSRenvil PedernalNo ratings yet

- Inspection (Singapore)Document54 pagesInspection (Singapore)TAMILNo ratings yet

- Building Specification BookDocument192 pagesBuilding Specification BookkaushiknashitNo ratings yet

- Plumbing SpecsDocument3 pagesPlumbing SpecsAngel NuevoNo ratings yet

- 08 70 00 Aluminium WindowsDocument19 pages08 70 00 Aluminium WindowsKiran D AnvekarNo ratings yet

- Element CDocument4 pagesElement CJm E. EsperidaNo ratings yet

- Introducing Revit Architecture 2009: BIM for BeginnersFrom EverandIntroducing Revit Architecture 2009: BIM for BeginnersRating: 3 out of 5 stars3/5 (1)

- Nonlinear Traction Control Design for Parallel Hybrid VehiclesFrom EverandNonlinear Traction Control Design for Parallel Hybrid VehiclesNo ratings yet

- Green Plus TDSDocument1 pageGreen Plus TDSشاهنوازحيدرNo ratings yet

- Rockfon Stone-Wool Sonar DatasheetDocument4 pagesRockfon Stone-Wool Sonar DatasheetشاهنوازحيدرNo ratings yet

- Anti Microbial Fabric CleaningDocument27 pagesAnti Microbial Fabric CleaningشاهنوازحيدرNo ratings yet

- AccessoriesDocument5 pagesAccessoriesشاهنوازحيدرNo ratings yet

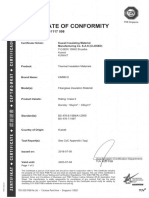

- Certificate of Conformity - Pipe Insulation - PSB Singapore Rigid Pipe-2018 - 2023Document4 pagesCertificate of Conformity - Pipe Insulation - PSB Singapore Rigid Pipe-2018 - 2023شاهنوازحيدرNo ratings yet

- BlankaDocument4 pagesBlankaشاهنوازحيدرNo ratings yet

- Unit Masonry 4.1 General 4.1.1 ScopeDocument5 pagesUnit Masonry 4.1 General 4.1.1 ScopeشاهنوازحيدرNo ratings yet

- Arch Spec Part 3Document3 pagesArch Spec Part 3شاهنوازحيدرNo ratings yet

- Arch and Id Specification 2020.12.29.-WlwDocument367 pagesArch and Id Specification 2020.12.29.-WlwشاهنوازحيدرNo ratings yet

- Arch Spec Part 2Document4 pagesArch Spec Part 2شاهنوازحيدرNo ratings yet

- Visvesvaraya Technological University Application For Issue of Consolidated Statement of Marks (Only For Non CBCS)Document1 pageVisvesvaraya Technological University Application For Issue of Consolidated Statement of Marks (Only For Non CBCS)شاهنوازحيدرNo ratings yet

- Australian Standard: Acoustics-Rating of Sound Absorption-Materials and SystemsDocument8 pagesAustralian Standard: Acoustics-Rating of Sound Absorption-Materials and SystemsشاهنوازحيدرNo ratings yet

- Sound Absorption ClassesDocument1 pageSound Absorption ClassesشاهنوازحيدرNo ratings yet

- 42-16-16 NRC 0.85 - Community College - Girls - 2020-02-08 - 13-04Document9 pages42-16-16 NRC 0.85 - Community College - Girls - 2020-02-08 - 13-04شاهنوازحيدرNo ratings yet

- Product Sustainability Declaration-Rockfon TropicDocument3 pagesProduct Sustainability Declaration-Rockfon TropicشاهنوازحيدرNo ratings yet

- BB93 February 2015Document43 pagesBB93 February 2015pero_peric4No ratings yet

- 2 - Data Sheet Wooden Acoustic PanelDocument3 pages2 - Data Sheet Wooden Acoustic PanelشاهنوازحيدرNo ratings yet

- Sound Absorption ClassesDocument1 pageSound Absorption ClassesشاهنوازحيدرNo ratings yet

- Kumara SwamiyamDocument21 pagesKumara SwamiyamVijey KumarNo ratings yet

- Job Search & Interview Skills: or Some Real-World Advice That May Prove Useful To YouDocument97 pagesJob Search & Interview Skills: or Some Real-World Advice That May Prove Useful To YouShah NawazNo ratings yet

- December + Yearly ReviewDocument2 pagesDecember + Yearly ReviewNick FabrioNo ratings yet

- Sweet Delight Co.,Ltd.Document159 pagesSweet Delight Co.,Ltd.Alice Kwon100% (1)

- The Ganga Pollution Cases: Mehta I (M.C. Mehta v. Union of India, (1987) 4 SCC 463)Document4 pagesThe Ganga Pollution Cases: Mehta I (M.C. Mehta v. Union of India, (1987) 4 SCC 463)SrivastavaNo ratings yet

- ForecastingDocument16 pagesForecastingSadain Bin MahboobNo ratings yet

- The Casbah 29 (1986) - 01 September 2015Document13 pagesThe Casbah 29 (1986) - 01 September 2015Ishaan BlundenNo ratings yet

- Ex Covid Shift ADocument1 pageEx Covid Shift ADetri Yoga AdhiNo ratings yet

- 03 CTAL TM Sample ISTQB Questions - v2.04Document35 pages03 CTAL TM Sample ISTQB Questions - v2.04CorniciucOanaNo ratings yet

- 12 C AdminstrationDocument2 pages12 C AdminstrationMuditNo ratings yet

- Shell Answer Book 07 The Driving Emergency BookDocument8 pagesShell Answer Book 07 The Driving Emergency BookKenneth100% (2)

- Enterprise Management System: Reference W.S.JawadekarDocument34 pagesEnterprise Management System: Reference W.S.JawadekarPolice stationNo ratings yet

- 2022 Significant FEHB Plan ChangesDocument12 pages2022 Significant FEHB Plan ChangesFedSmith Inc.No ratings yet

- Icd-10 CM Step by Step Guide SheetDocument12 pagesIcd-10 CM Step by Step Guide SheetEdel DurdallerNo ratings yet

- HboDocument126 pagesHboKunal ChaudhryNo ratings yet

- Euroleague Basketball: Change Pays Off ForDocument36 pagesEuroleague Basketball: Change Pays Off ForNikos TagalnikNo ratings yet

- Topic: Matrix Addition and SubtractionDocument6 pagesTopic: Matrix Addition and SubtractionAnonyNo ratings yet

- C&DS Lab Manual UpdatedDocument182 pagesC&DS Lab Manual UpdatedJesmin MostafaNo ratings yet

- RTP Cap III GR I June 2022Document92 pagesRTP Cap III GR I June 2022मदन कुमार बिस्टNo ratings yet

- Soal PAS-UAS Bahasa Inggris Kelas 11 SMADocument10 pagesSoal PAS-UAS Bahasa Inggris Kelas 11 SMAAlexander TristanNo ratings yet

- Application Form ICDFDocument2 pagesApplication Form ICDFmelanie100% (1)

- AWS Solution Architect SampleDocument3 pagesAWS Solution Architect SamplepandiecNo ratings yet

- Transport ADRDocument3 pagesTransport ADRZbinca CristianNo ratings yet

- Full Download Test Bank For Accounting Information Systems Hall 8th Edition PDF Full ChapterDocument36 pagesFull Download Test Bank For Accounting Information Systems Hall 8th Edition PDF Full Chapterfluiditytrenail7c8j100% (16)

- Kesehatan Dan Keadilan Sosial inDocument20 pagesKesehatan Dan Keadilan Sosial inBobbyGunarsoNo ratings yet

- Cbi LNG Storage US Rev8 LoresDocument4 pagesCbi LNG Storage US Rev8 LoresVilas AndhaleNo ratings yet

- Safurex - Sandvik Materials TechnologyDocument14 pagesSafurex - Sandvik Materials TechnologyGhulam AhmadNo ratings yet

- Indiabulls PILDocument64 pagesIndiabulls PILPGurus100% (1)

- April 24, 2008Document80 pagesApril 24, 2008Reynaldo EstomataNo ratings yet

- El Condor1 Reporte ECP 070506Document2 pagesEl Condor1 Reporte ECP 070506pechan07No ratings yet