Professional Documents

Culture Documents

Z-Carb JetStream SpeedFeed

Uploaded by

alphatoolsOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Z-Carb JetStream SpeedFeed

Uploaded by

alphatoolsCopyright:

Available Formats

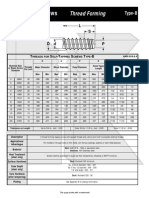

Fractional

Z-Carb with JetStream Speed and Feed Recommendations

™

Cutting Diameter

Bhn 1/2 9/16 5/8 3/4 1

Material Type

rpm in/min rpm in/min rpm in/min rpm in/min rpm in/min

Low Carbon Steels ~175 3,895 37 3,465 35 3,115 33 2,600 31 1,950 25

Low Carbon Steels ~275 3,210 30 2,850 29 2,565 27 2,140 25 1,605 21

Med Alloy Steels ~275 2,675 25 2,375 24 2,140 23 1,785 21 1,335 17

Mold And Die Steels ~275 1,375 13 1,220 12 1,100 11 915 11 690 9

Cast Iron - Gray ~200 3,630 34 3,225 32 2,905 31 2,420 29 1,815 24

Cast Iron - Ductile ~300 1,835 17 1,630 16 1,465 15 1,220 14 915 12

Cast Iron - Malleable ~300 1,145 11 1,020 10 915 9 765 9 575 7

Stainless 300 Series ~275 2,290 16 2,035 20 1,835 16 1,530 15 1,145 15

Stainless 400 Series ~185 3,210 25 2,850 29 2,565 25 2,140 22 1,605 22

Stainless PH Series ~325 1,910 14 1,700 17 1,530 14 1,275 12 955 12

Titanium Alloys ~295 2,290 18 2,035 20 1,835 18 1,530 16 1,145 16

High Temp. Alloys ~300 610 4 545 6 490 4 410 4 305 3

Profiling: Radial Width .5 x Diameter (max.) Profiling: Axial Depth 1.5 x Diameter (max.) Slotting: Axial Depth 1 x Diameter (max.)

Avoid re-milling chips

Tool holders with adequate gripping pressure are required

Stub length solid holders are recommended for heavy stock removal

Ramping or spiral plunging are the preferred entry methods into pockets (approximately 6 degrees @ 50% normal feed)

Radial Width of Cut (Rw)

Axial Depth of Cut (Ad)

Tool Diameter (D)

22 JetStream Z-Carb Solid Carbide End Mills

Metric

Z-Carb with JetStream Speed and Feed Recommendations

™

Cutting Diameter

Bhn 14 16 18 20

Material Type

rpm mm/min rpm mm/min rpm mm/min rpm mm/min

Low Carbon Steels ~175 3,535 890 3,095 817 2,750 809 2,475 804

Low Carbon Steels ~275 2,910 733 2,545 672 2,265 667 2,040 662

Med Alloy Steels ~275 2,425 592 2,125 561 1,885 556 1,700 552

Mold And Die Steels ~275 1,250 314 1,090 288 970 285 875 283

Cast Iron - Gray ~200 3,290 829 2,880 761 2,560 754 2,305 749

Cast Iron - Ductile ~300 1,665 419 1,455 384 1,295 381 1,165 378

Cast Iron - Malleable ~300 1,040 262 910 240 810 238 730 236

Stainless 300 Series ~275 2,080 405 1,820 405 1,615 380 1,455 380

Stainless 400 Series ~185 2,910 635 2,545 635 2,265 560 2,040 560

Stainless PH Series ~325 1,735 355 1,515 355 1,350 300 1,215 300

Titanium Alloys ~295 2,080 455 1,820 455 1,615 405 1,455 405

High Temp Alloys ~300 555 100 485 100 430 100 390 100

Profiling: Radial Width .5 x Diameter (max.) Profiling: Axial Depth 1.5 x Diameter (max.) Slotting: Axial Depth 1 x Diameter (max.)

Avoid re-milling chips

Tool holders with adequate gripping pressure are required

Stub length solid holders are recommended for heavy stock removal

Ramping or spiral plunging are the preferred entry methods into pockets (approximately 6 degrees @ 50% normal feed)

Radial Width of Cut (Rw)

Axial Depth of Cut (Ad)

Tool Diameter (D)

WWW.SGSTOOL.COM 23

You might also like

- SRJ Rubber Track & Pad CatalogDocument39 pagesSRJ Rubber Track & Pad CatalogeduardoNo ratings yet

- 01 - WELDING DEFECTS (Surface) - May 2021Document28 pages01 - WELDING DEFECTS (Surface) - May 2021Gerry Dan ChanliongcoNo ratings yet

- R1-Ff-Bhadra Dam-30mt Hoist - Under Sluice Gate - r1Document15 pagesR1-Ff-Bhadra Dam-30mt Hoist - Under Sluice Gate - r1ajwalNo ratings yet

- HSK DIN 69893 enDocument29 pagesHSK DIN 69893 enalphatoolsNo ratings yet

- Hob Seminar (English)Document26 pagesHob Seminar (English)RizwanAliNo ratings yet

- Casting Material Austenitic Ductile Iron in ASTM A439Document3 pagesCasting Material Austenitic Ductile Iron in ASTM A439Alex007No ratings yet

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersFrom EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersRating: 3.5 out of 5 stars3.5/5 (2)

- JIS Steel Wires StandardDocument7 pagesJIS Steel Wires StandardPS NguyễnNo ratings yet

- A Complete Guide to Watch Repair - Barrels, Fuses, Mainsprings, Balance Springs, Pivots, Depths, Train Wheels and Common Stoppages of WatchesFrom EverandA Complete Guide to Watch Repair - Barrels, Fuses, Mainsprings, Balance Springs, Pivots, Depths, Train Wheels and Common Stoppages of WatchesRating: 4 out of 5 stars4/5 (1)

- HSS CatalogueDocument56 pagesHSS CataloguenenmilNo ratings yet

- Catalogue GUNUNG GARUDADocument40 pagesCatalogue GUNUNG GARUDAhendrobama50% (2)

- Spodumene Pegmatites PDFDocument53 pagesSpodumene Pegmatites PDFcrazybearNo ratings yet

- Astm A354Document1 pageAstm A354Jemimah Joy Inguito GuarinNo ratings yet

- Z-Carb Corner Radius SpeedFeedDocument2 pagesZ-Carb Corner Radius SpeedFeedalphatoolsNo ratings yet

- Machining Duplex Stainless Steels: Shop Sheet 103Document4 pagesMachining Duplex Stainless Steels: Shop Sheet 103Adrian CeplinschiNo ratings yet

- Rule No. 1Document64 pagesRule No. 1Albert AliminNo ratings yet

- WWW - Toptech.tw: Metallographic Sample Preparation Equipment Cutting/ Mounting/ Grinding & PolishingDocument44 pagesWWW - Toptech.tw: Metallographic Sample Preparation Equipment Cutting/ Mounting/ Grinding & Polishingtien thanh doNo ratings yet

- High Speed Steel Round BarDocument4 pagesHigh Speed Steel Round BarMANJEET KUMARNo ratings yet

- Calculo Maquinado CuñeroDocument3 pagesCalculo Maquinado Cuñeroluigiv67No ratings yet

- Bigboss Cement Mill DataDocument4 pagesBigboss Cement Mill DataherwinNo ratings yet

- Torneamento Hardox 400 PDFDocument2 pagesTorneamento Hardox 400 PDFJosue OliveiraNo ratings yet

- SFM Formulae Chart 2Document2 pagesSFM Formulae Chart 2Carlos Gabriel PensamientoNo ratings yet

- Saw Blades and Bevel Cutters For GF and RA MachinesDocument5 pagesSaw Blades and Bevel Cutters For GF and RA MachinesVan DantNo ratings yet

- ChapitreGrinding GBDocument4 pagesChapitreGrinding GBLLNo ratings yet

- ASTM Rebars Properties PDFDocument4 pagesASTM Rebars Properties PDFDAN ANDNo ratings yet

- Cutter Blade Reference GuideDocument12 pagesCutter Blade Reference GuideThePrintManNo ratings yet

- Grinding English 9804Document16 pagesGrinding English 9804Subodh RanjanNo ratings yet

- SPCCDocument10 pagesSPCCDeepak JainNo ratings yet

- Metric Sizes Rock Reamer SpecificationsDocument4 pagesMetric Sizes Rock Reamer SpecificationsYusuf BagewadiNo ratings yet

- MAI R32N&S 9851 2230 01cDocument2 pagesMAI R32N&S 9851 2230 01cesteban muñozNo ratings yet

- FT Cn1293smef590Document2 pagesFT Cn1293smef590Yuseth Patio AvilesNo ratings yet

- 05 StrippersDocument10 pages05 Stripperspavel10082020No ratings yet

- Uapro Dig13 PDFDocument32 pagesUapro Dig13 PDFG-SamNo ratings yet

- RB Ca Brochure Ver2 WEBDocument11 pagesRB Ca Brochure Ver2 WEBIori YagamiNo ratings yet

- Consteel Catalogue PURLINS CPurlinDocument3 pagesConsteel Catalogue PURLINS CPurlinAnsaf AskyNo ratings yet

- Combinations Update 21-06-07Document23 pagesCombinations Update 21-06-07Burcea FlorinNo ratings yet

- VSL SlabDocument12 pagesVSL SlabhazemNo ratings yet

- Basalt Catalogue-CDocument4 pagesBasalt Catalogue-Cdanny buiNo ratings yet

- Features: Finishing-Purpose of Negative Chip Breaker For Steel TurningDocument4 pagesFeatures: Finishing-Purpose of Negative Chip Breaker For Steel TurningArdeleana TisaNo ratings yet

- Air Texturing NozzleDocument17 pagesAir Texturing Nozzleanil kapadiaNo ratings yet

- MaxWell 4.5in Casing CuttingtoolDocument3 pagesMaxWell 4.5in Casing Cuttingtooljunbo duNo ratings yet

- 140 Sheree Blvd. PO Box 566, Exton, PA 19341-0566 US - Web SiteDocument3 pages140 Sheree Blvd. PO Box 566, Exton, PA 19341-0566 US - Web SitegeorgyNo ratings yet

- PC5300NC5330 MetricDocument20 pagesPC5300NC5330 MetricSakthi VelNo ratings yet

- GF 4, GF 6 (Avm/Mvm) : Pipe Cutting MachinesDocument2 pagesGF 4, GF 6 (Avm/Mvm) : Pipe Cutting MachinesksracingNo ratings yet

- Sttype ABDocument1 pageSttype ABSean YangNo ratings yet

- Analisis Penggunaan Bit For ChevronDocument15 pagesAnalisis Penggunaan Bit For Chevronfaishal hafizhNo ratings yet

- Drill BitDocument36 pagesDrill Bitmukesh ojhaNo ratings yet

- Disc Ridger: Features & BenefitsDocument1 pageDisc Ridger: Features & BenefitsANDRE AURELLIONo ratings yet

- Selfeeder ElectricDocument32 pagesSelfeeder Electricasta seikiNo ratings yet

- S&T - Design 2013 - 2 PDFDocument40 pagesS&T - Design 2013 - 2 PDFSalmanNo ratings yet

- Steel Grades According To Japanese Standards: Mechanical PropertiesDocument2 pagesSteel Grades According To Japanese Standards: Mechanical PropertiesGANESHNo ratings yet

- Sttype BDocument1 pageSttype BSean YangNo ratings yet

- Self Tapping ScrewsDocument1 pageSelf Tapping ScrewsGulfstream Data, IncNo ratings yet

- 14 Spline NutDocument24 pages14 Spline NutCAT MINING SHOVELNo ratings yet

- Turning Handbook: General Turning - Parting and Grooving - ThreadingDocument53 pagesTurning Handbook: General Turning - Parting and Grooving - ThreadingMindrila BogdanNo ratings yet

- Recommended Rotational Speed Range RPM - TC Burrs For High-Performance ApplicationsDocument1 pageRecommended Rotational Speed Range RPM - TC Burrs For High-Performance ApplicationsLeandro BatistaNo ratings yet

- News Room Services Products Sales Network Manufacturing Units Corporate Profile Financial DataDocument1 pageNews Room Services Products Sales Network Manufacturing Units Corporate Profile Financial DataVarun PatelNo ratings yet

- ZPP z22 Doublesuctionaxiallysplitpumps E00502Document6 pagesZPP z22 Doublesuctionaxiallysplitpumps E00502Fernando Rodríguez HNo ratings yet

- Composition % Combination of Properties: The Benefits of Cal Wrought CNCDocument6 pagesComposition % Combination of Properties: The Benefits of Cal Wrought CNCAshesh MokidiNo ratings yet

- Worm Gear Sets enDocument29 pagesWorm Gear Sets enmohammad khoraminiaNo ratings yet

- Catalogue Worm Gear Sets and Customised Worm Gear SetsDocument30 pagesCatalogue Worm Gear Sets and Customised Worm Gear Setsfog900No ratings yet

- Milling Parameters: N (RPM) (VC (M/min) 1000) / 3.14 Ø d1 (MM) )Document4 pagesMilling Parameters: N (RPM) (VC (M/min) 1000) / 3.14 Ø d1 (MM) )Damir PrstenkovNo ratings yet

- Ffe Brtpctbends 210407Document2 pagesFfe Brtpctbends 210407api-3725163No ratings yet

- DELFERDocument81 pagesDELFERalphatoolsNo ratings yet

- Z-CARB MD SpeedFeedDocument1 pageZ-CARB MD SpeedFeedalphatoolsNo ratings yet

- SAITDocument166 pagesSAITalphatoolsNo ratings yet

- The Finishing Touch: Expect More From A Finishing MillDocument4 pagesThe Finishing Touch: Expect More From A Finishing MillalphatoolsNo ratings yet

- Ti NAMITEDocument2 pagesTi NAMITEalphatoolsNo ratings yet

- Z-Carb Original End Mills: Revolutionizes MillingDocument4 pagesZ-Carb Original End Mills: Revolutionizes MillingalphatoolsNo ratings yet

- Osborn Novoflex-B CatalogueDocument1 pageOsborn Novoflex-B CataloguealphatoolsNo ratings yet

- HPC Flyer UnzippedDocument8 pagesHPC Flyer UnzippedalphatoolsNo ratings yet

- Turbo CarbDocument2 pagesTurbo CarbalphatoolsNo ratings yet

- Ice-Carb High Performance Internal Coolant Drills For Drilling Depths Up To 7XdDocument4 pagesIce-Carb High Performance Internal Coolant Drills For Drilling Depths Up To 7XdalphatoolsNo ratings yet

- Osborn EZ-Flex CatalogueDocument1 pageOsborn EZ-Flex CataloguealphatoolsNo ratings yet

- Threading ToolsDocument9 pagesThreading ToolsalphatoolsNo ratings yet

- MAS-BT enDocument62 pagesMAS-BT enalphatoolsNo ratings yet

- VDI enDocument110 pagesVDI enalphatoolsNo ratings yet

- S20x2 Deckel enDocument9 pagesS20x2 Deckel enalphatools100% (1)

- Pull Studs enDocument8 pagesPull Studs enLLNo ratings yet

- DIN 69871 enDocument69 pagesDIN 69871 enalphatoolsNo ratings yet

- DIN 2080 enDocument45 pagesDIN 2080 enalphatoolsNo ratings yet

- Powerbor DrillsDocument6 pagesPowerbor DrillsalphatoolsNo ratings yet

- Cambridge IGCSE: CHEMISTRY 0620/31Document16 pagesCambridge IGCSE: CHEMISTRY 0620/31Caoling HuangNo ratings yet

- Niels Schrodinger: Curso: Química Profesor (A) :gleddy Diaz Toro Alumno (A) :manuel Omar H.PDocument39 pagesNiels Schrodinger: Curso: Química Profesor (A) :gleddy Diaz Toro Alumno (A) :manuel Omar H.Pomar PeñaNo ratings yet

- Lecture 1 Ultrasonic Welding DoneDocument42 pagesLecture 1 Ultrasonic Welding DoneFaiz IshakNo ratings yet

- Metallurgy in Ancient India and JharkhandDocument5 pagesMetallurgy in Ancient India and JharkhandInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- FinalDocument36 pagesFinalSnehal AdkeNo ratings yet

- Material Metallurgy - Descriptive TypesDocument53 pagesMaterial Metallurgy - Descriptive TypesSushant GhurupNo ratings yet

- Astm A264 (1999)Document8 pagesAstm A264 (1999)Vo Trong ThaiNo ratings yet

- Introduction To F-Block ElementsDocument12 pagesIntroduction To F-Block ElementsÑäñdäñëë ÑäyäkNo ratings yet

- Ions ChargeDocument1 pageIons Chargeshashankshukla676100% (1)

- ReportDocument31 pagesReporttehsmaNo ratings yet

- R9 MTSR Mar 2021Document47 pagesR9 MTSR Mar 2021BJ AbelaNo ratings yet

- 008a.rtfi - AbbrevationsDocument2 pages008a.rtfi - AbbrevationsVivekanandan JNo ratings yet

- Msds LimestoneDocument7 pagesMsds LimestoneFAREEDNo ratings yet

- KME PowderDocument4 pagesKME Powderfrankypanky123No ratings yet

- Brazilian Ceramic and Refractory Industry in The Last DecadeDocument7 pagesBrazilian Ceramic and Refractory Industry in The Last DecadestargmstarNo ratings yet

- 6 - Materials - Metals and Non-Metals - Book Back AnswersDocument7 pages6 - Materials - Metals and Non-Metals - Book Back AnswersSOULSNIPER 15No ratings yet

- Single Replacement ReactionDocument12 pagesSingle Replacement Reactionapi-480822405No ratings yet

- Heat Treatment Methods Applied To AISI 431 Martensitic Stainless SteelsDocument7 pagesHeat Treatment Methods Applied To AISI 431 Martensitic Stainless Steelslir mNo ratings yet

- Aggregate 20mmDocument6 pagesAggregate 20mmTapan MohapatraNo ratings yet

- 9.2 Steel GradesDocument2 pages9.2 Steel GradesĐinh Như ThànhNo ratings yet

- American Ceramic Society: Moisture Expansion of ProductsDocument11 pagesAmerican Ceramic Society: Moisture Expansion of ProductsMaulanaDPRNo ratings yet

- Calcia Stabilized ZirconiaDocument3 pagesCalcia Stabilized Zirconiaedwardbloomcer06No ratings yet

- Burning The Mix 1Document11 pagesBurning The Mix 1John GiannakopoulosNo ratings yet

- Comparative Chemistry of B, Al, Ga, In, TLDocument13 pagesComparative Chemistry of B, Al, Ga, In, TLMmadu CcyNo ratings yet

- Laton Ms58 - CuZn39Pb3 - Original FusiblesDocument4 pagesLaton Ms58 - CuZn39Pb3 - Original FusiblesLuis CeronNo ratings yet

- Gold Extraction ProcessDocument1 pageGold Extraction ProcessBintang Mas SelulerNo ratings yet

- Monobond Plus Sell SheetDocument2 pagesMonobond Plus Sell SheetIvoclar VivadentNo ratings yet

- Ffi 'W: Zffip' N.-FRDocument2 pagesFfi 'W: Zffip' N.-FRraviraj londheNo ratings yet