Professional Documents

Culture Documents

Pelj2300-00 - d10-d11 - HDXL - HD & GD New Uc Components - July18

Pelj2300-00 - d10-d11 - HDXL - HD & GD New Uc Components - July18

Uploaded by

malik rashidovOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pelj2300-00 - d10-d11 - HDXL - HD & GD New Uc Components - July18

Pelj2300-00 - d10-d11 - HDXL - HD & GD New Uc Components - July18

Uploaded by

malik rashidovCopyright:

Available Formats

MONTH 2009 DEALER INTERNAL USE ONLY

D9N/R/T, D10N/R/T & D11N/R/T New Product Portfolio

Caterpillar introduces a new product portfolio for D10N/R/T and D11N/R/T Track Type

Tractors. A new tiered offering on Large Track Type machines provides multiple

solutions for customers in any application. Our new General Duty track offers industry

standard performance and price, as well as HD XL with Dura Link track providing the

longest life and lowest operating costs in the industry.

The improvement in performance now delivers an unmatched cost per hour in either a

4,000-hour or 8,000-hour application. See below for additional detail on each new

offering.

Future State Product Portfolio

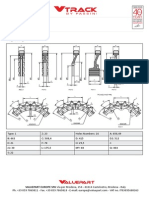

• Heavy Duty Extended Life (HD XL) with Dura Link – specifically designed to

reduce scalloping in high abrasion conditions. Users can expect a link wear life

increase of up to 30%, along with a bushing wear life increase of up to 40%.

This technology is part of a complete package of components aimed at

increasing the entire Undercarriage life. This offering provides the longest life

and lowest operating costs in the industry.

o Other Features: SRL steel with profiled link, new bushing end coatings

that increases seal life up to 8,000 hours, single tooth master link.

INFORMATION RELEASE MEMO | PAGE 2

• Heavy Duty – Specifically designed for Hard Rock applications with greater

than 5,000 hours wear life. End coated bushings provide longer seal life, coated

track pins provide exceptional performance – the only coated components in the

industry. This offering provides industry leading performance.

o Other Features: Guaranteed wet bushing turns, increased link weight to

resist cracking in even the toughest conditions, single tooth master link.

• General Duty – Specifically designed for applications with less than 5,000 hours

wear life. This offering has no end coated bushing and includes standard track

pins. Bushings can be turned.

o Other Features: General Duty wear life vs. Standard is at minimum 80%

in same application, five tooth master link, industry standard performance

and price.

o D10 and D11 General Duty will be link assemblies and track groups

only.

In addition to introduction of the new product portfolio, an eventual discontinuation of

High Abrasion (D11), PPR (D10 & D11), and Non-PPR (D10) offerings is in process.

In conjunction with the product introduction, price adjustments will be made to a number

of Undercarriage components. These changes will be made available for download on

July 4, 2018. Dealers can access part number level detail via their price files on this

date. If further assistance is needed, please send a request to

mining_pricing@cat.com.

PELJ2300 ©2018 Caterpillar

INFORMATION RELEASE MEMO | PAGE 3

D9N/R/T HEAVY DUTY EXTENDED LIFE TRACK

9.45" (240.0 mm) PITCH

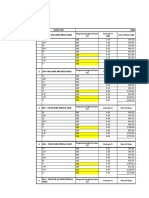

QUANTITY PART

Link Assembly – 43 Section 2 509-9144

Track Groups 2 512-0736

Super Extreme Service Shoe – 24” (610mm)

Super Extreme Service (Trapezoidal Hole) – 24” (610mm) 2 512-0738

Super Extreme Service – 27” (685mm) 2 512-0740

Track Hardware

Bolt 168 6T-2638

Nut 168 7G-0343

Master Bolt (Long) 2 6V-1728

Master Bolt (Short) 2 7T-2283

D9N/R/T HEAVY DUTY TRACK

9.45" (240.0 mm) PITCH

QUANTITY PART

Link Assembly – 43 Section 2 199-5525

Track Groups

Extreme Service Shoe – 22” (560mm) 2 379-4042

Extreme Service Shoe – 24” (610mm) 2 379-4044

Extreme Service Shoe – 27” (685mm) 2 379-4054

Extreme Service (Round Center Hole) – 27” (685mm) 2 379-4058

Super Extreme Service Shoe – 24” (610mm) 2 379-4048

Super Extreme Service Shoe – 27” (685mm) 2 379-4060

Track Hardware

Bolt 168 6T-2638

Nut 168 7G-0343

Master Bolt (Long) 2 6V-1728

Master Bolt (Short) 2 7T-2283

D9 GENERAL DUTY TRACK

9.45” (240.0 mm) PITCH

QUANTITY PART

Link Assembly – 43 Section 2 458-7787

Track Groups

Extreme Service Shoe – 24” (610mm) 2 458-7790

Extreme Service Shoe – 27” (685mm) 2 458-7804

Track Hardware

Bolt 168 6T-2638

Nut 168 7G-0343

Master Bolt (Long) 2 6V-1728

Master Bolt (Short) 2 7T-2283

PELJ2300 ©2018 Caterpillar

INFORMATION RELEASE MEMO | PAGE 4

D9N/R/T SPROCKETS

QUANTITY PART

Standard Sprocket Segment 5 499-2970

Sound Suppressed Sprocket Segment 5 258-9816

General Duty Sprocket Segment 5 458-7784

Sprocket Hardware

Bolt 30 7T-1248

Nut 30 7H-3609

Washer 30 5P-8249

D9N/R/T IDLERS

QUANTITY PART

Standard Forged 4 125-4655

Standard Forged – Arctic 4 245-9942

Heavy Duty Fabricated 4 477-2653

General Duty Fabricated 4 458-7869

D9N/R/T ROLLERS

QUANTITY PART

Standard – Single Flange 8 196-9955

Standard – Dual Flange 8 196-9954

Arctic – Single Flange 8 245-9943

Arctic – Dual Flange 8 245-9944

High Temp – Single Flange 8 245-9945

High Temp – Dual Flange 8 245-9946

General Duty – Single Flange (Bolted) 8 458-7791

General Duty – Single Flange (Boltless) 8 466-3290

Note:

The 509-9144 Heavy Duty Extended Life Undercarriage System must be installed with

499-2970 Segment. The 499-2970 Segment is designed to fit the larger diameter

bushing.

The use of double flange rollers is not recommended with the Heavy Duty Extended Life

Undercarriage System.

Custom Track Service (CTS)

Refer to CTS Pro for Custom Track Service wear information.

PELJ2300 ©2018 Caterpillar

INFORMATION RELEASE MEMO | PAGE 5

D10N/R/T HEAVY DUTY EXTENDED LIFE TRACK

10.25" (260.4 mm) PITCH

QUANTITY PART

Link Assembly – 44 Section 2 463-9336

Track Groups

Super Extreme Service Shoe – 24” (610mm) 2 495-3882

Super Extreme Service (ARM) – 24” (610mm) 2 495-3884

Super Extreme Service (Round Center Hole) – 24” (610mm) 2 495-3886

Super Extreme Service Shoe– 28” (710mm) 2 495-3888

Super Extreme Service (ARM) – 28” (710mm) 2 542-5232

Super Extreme Service (Round Center Hole) – 28” (710mm) 2 495-3890

Extreme Service Shoe – 31” (786mm) 2 542-5233

Track Hardware

Bolt 172 7T-1000

Nut 172 5P-8221

Master Bolt (Long) 2 372-3874

Master Bolt (Short) 2 372-3875

D10N/R/T HEAVY DUTY TRACK

10.25" (260.4 mm) PITCH

QUANTITY PART

Link Assembly – 44 Section 2 380-5946

Track Groups

Extreme Service Shoe – 24” (610mm) 2 380-5938

Extreme Service (ARM) – 24” (610mm) 2 380-5942

Extreme Service (Round Center Hole) – 28” (710mm) 2 398-5248

Extreme Service Shoe – 31” (786mm) 2 398-5254

Super Extreme Service Shoe – 28” (710mm) 2 380-5940

Super Extreme Service Shoe – 28” (710mm) 2 380-5944

Track Hardware

Bolt 172 7T-1000

Nut 172 5P-8221

Master Bolt (Long) 2 372-3874

Master Bolt (Short) 2 372-3875

D10 GENERAL DUTY TRACK

10.25" (260.4 mm) PITCH

QUANTITY PART

Link Assembly – 44 Section 2 458-7813

Track Group

Extreme Service Shoe – 24” (610mm) 2 485-9784

Track Hardware

Bolt 172 7T-1000

Nut 172 5P-8221

Master Bolt (Long) 2 372-3874

Master Bolt (Short) 2 372-3875

PELJ2300 ©2018 Caterpillar

INFORMATION RELEASE MEMO | PAGE 6

D10N/R/T SPROCKETS

QUANTITY PART

Standard Sprocket Segment 5 433-6739

Sound Suppressed Sprocket Segment 5 278-2352

Sprocket Hardware

Bolt 30 5P-5422

Nut 30 2M-5656

Washer 30 5P-8250

D10N/R/T IDLERS

QUANTITY PART

Standard Forged 4 125-3537

Standard Forged – Arctic 4 245-9947

D10N/R/T ROLLERS

QUANTITY PART

Standard – Single Flange 8 309-7679

Standard – Dual Flange 8 309-7678

High Abrasion – Single Flange 8 421-8434

Arctic – Single Flange 8 332-6423

Arctic – Dual Flange 8 332-6424

Note:

The 463-9336 Heavy Duty Extended Life Undercarriage System must be installed with

433-6739 Segment. The 433-6739 Segment is designed to fit the larger diameter

bushing. The new Segment must be used with the Heavy Duty Extended Life

Undercarriage System to prevent possible bushing damage and to ensure proper

engagement.

The new 421-8434 Track Roller Group has 9.0 mm (0.35 inch) increased tread diameter

for additional wear life.

In some cases where increased roller wear life is not necessary at all eight roller

locations, standard single flange rollers may be used in 3. 4. 5, and 6, track roller

locations to maximize roller wear balance. The use of double flange rollers is not

recommended with the Heavy Duty Extended Life Undercarriage System.

Custom Track Service (CTS)

Refer to CTS Pro for Custom Track Service wear information.

PELJ2300 ©2018 Caterpillar

INFORMATION RELEASE MEMO | PAGE 7

D11N/R/T HEAVY DUTY EXTENDED LIFE TRACK

12.50" (317.5 mm) PITCH

QUANTITY PART

Link Assembly – 41 Section 2 563-8476

Track Groups

Extreme Service Shoe – 32” (810mm) 2 563-8470

Extreme Service Shoe (ARM) – 32” (810mm) 2 563-8471

Extreme Service Shoe – 36” (915mm) 2 563-8472

Track Hardware

Bolt 160 6T-8853

Nut 160 3T-6292

Master Bolt (Long) 2 360-2472

Master Bolt (Short) 2 360-2473

D11N/R/T HEAVY DUTY TRACK

12.50" (317.5 mm) PITCH

QUANTITY PART

Link Assembly – 41 Section 2 361-6776

Track Groups

Extreme Service Shoe – 32” (810mm) 2 399-7408

Extreme Service Shoe (ARM) – 32” (810mm) 2 399-7414

Extreme Service (Trapezoidal Hole) – 32” (810mm) 2 399-7412

Extreme Service Shoe – 36” (915mm) 2 399-7410

Track Hardware

Bolt 160 6T-8853

Nut 160 3T-6292

Master Bolt (Long) 2 360-2472

Master Bolt (Short) 2 360-2473

D11N/R/T GENERAL DUTY TRACK

12.50" (317.5 mm) PITCH

QUANTITY PART

Link Assembly – 41 Section 2 563-8476

Track Group

Extreme Service Shoe – 32” (810mm) 2 563-8477

Track Hardware

Bolt 160 6T-8853

Nut 160 3T-6292

Master Bolt (Long) 2 360-2472

Master Bolt (Short) 2 360-2473

PELJ2300 ©2018 Caterpillar

INFORMATION RELEASE MEMO | PAGE 8

D11N/R/T SPROCKETS

QUANTITY PART

Standard Sprocket Segment (5-Tooth) 2 499-2979

Standard Sprocket Segment (6-Tooth) 6 499-2980

Sound Suppressed Sprocket Segment (5-Tooth) 2 278-2365

Sound Suppressed Sprocket Segment (6-Tooth) 6 278-2366

Sprocket Hardware

Bolt 32 7T-1243

Nut 32 3S-1356

Washer 32 3S-1349

D11N/R/T IDLERS

QUANTITY PART

Standard Forged 4 187-1484

Standard Forged – Arctic 4 245-9950

D11N/R/T ROLLERS

QUANTITY PART

Standard – Single Flange 8 184-6305

Standard – Dual Flange 8 184-6306

High Abrasion – Single Flange 8 200-5701

Arctic – Single Flange 8 245-9951

Arctic – Dual Flange 8 245-9952

Note:

The 563-8476 Heavy Duty Extended Life Undercarriage System must be installed with

499-2979 & 499-2980 Segments. The Segments are designed to fit the larger diameter

bushing. The 499-2979 & 499-2980 Segments must be used with the Heavy Duty

Extended Life Undercarriage System to prevent possible bushing damage and to

ensure proper engagement.

The use of double flange rollers is not recommended with the Heavy Duty Extended Life

Undercarriage System.

Custom Track Service (CTS)

Refer to CTS Pro for Custom Track Service wear information.

PELJ2300 ©2018 Caterpillar

INFORMATION RELEASE MEMO | PAGE 9

CAT, CATERPILLAR, their respective logos, “Caterpillar Yellow” and the ”Power Edge” trade dress, as well as corporate and product identity used herein, are

trademarks of Caterpillar and may not be used without permission.

The information contained herein is intended for circulation only to Caterpillar and dealer employees whose duties require knowledge of such reports and is

intended exclusively for their information and training. Any reproduction of this release without the foregoing explanation is prohibited.

This IRM can be viewed and downloaded electronically from the Internet. Please refer to your marketing organization specific site for access to the Global

Sales Library which contains all of the active IRMs and product support communication materials.

© 2018 Caterpillar Inc. All Rights Reserved

PELJ2300 ©2018 Caterpillar

You might also like

- определиние РВД по кат номеруDocument9 pagesопределиние РВД по кат номеруdvmashNo ratings yet

- CAT KATALOG Sempre2023 1 1Document95 pagesCAT KATALOG Sempre2023 1 1moath kareemNo ratings yet

- RODILLODocument35 pagesRODILLOfran100% (1)

- Forecast Hose Komatsu 2020-UpdateDocument1,692 pagesForecast Hose Komatsu 2020-UpdateInsannulNo ratings yet

- Screws, Fittings, Seals BucyrusDocument16 pagesScrews, Fittings, Seals BucyrusJhonny ManjarrezNo ratings yet

- At P InventoryDocument16 pagesAt P InventoryJas SumNo ratings yet

- RH 120 eDocument8 pagesRH 120 eIvanNo ratings yet

- Copy of 8.6船EPA申請リスト-2Document58 pagesCopy of 8.6船EPA申請リスト-2RiotaNo ratings yet

- Battery Service EquipmentDocument11 pagesBattery Service EquipmentMary CastilloNo ratings yet

- Wr430gb00b BMP Cat Discl EngDocument12 pagesWr430gb00b BMP Cat Discl EngY.EbadiNo ratings yet

- Component Current Last Changeout Details HM Unit Life Used HM Date Life UsedDocument8 pagesComponent Current Last Changeout Details HM Unit Life Used HM Date Life Usedmahmuda levianiNo ratings yet

- Drill Jig BushingsDocument74 pagesDrill Jig BushingsMEHABOOBBEPARINo ratings yet

- BRECO ComponentsDocument43 pagesBRECO ComponentsDobrica PetrovicNo ratings yet

- Carriage Hose KitDocument1 pageCarriage Hose Kitcmrig74No ratings yet

- UntitledDocument326 pagesUntitledANGELA ARACELLY PAREDES PEREZNo ratings yet

- Dic Trading Company: #104-1004,65-14 Shinhyon-Ro, Gwangju City, Kyunggido, KoreaDocument1 pageDic Trading Company: #104-1004,65-14 Shinhyon-Ro, Gwangju City, Kyunggido, KoreaRidha AbbassiNo ratings yet

- Berco BROCHURE PDFDocument3 pagesBerco BROCHURE PDFJohn Gonzalez100% (1)

- All Weather Dozer Track RollersDocument2 pagesAll Weather Dozer Track RollersAhmed El-sheshtawy100% (1)

- New Bom Hose 2010Document478 pagesNew Bom Hose 2010Ardian SanjayaNo ratings yet

- QRF D375a-5Document2 pagesQRF D375a-5Ralf MaurerNo ratings yet

- Pm-Clinic: Hydraulic Mining ExcavatorDocument34 pagesPm-Clinic: Hydraulic Mining ExcavatorGustavoSilvaNo ratings yet

- Kuc A34041 - 700JBDocument2 pagesKuc A34041 - 700JBMichael Percy Curasi ParedesNo ratings yet

- Hoses - Fitting - Hose Guard FinalDocument33 pagesHoses - Fitting - Hose Guard Finaladeola AdetoyiNo ratings yet

- Cat 785DDocument24 pagesCat 785DDavyda VedaNo ratings yet

- Report P2u XCMG 800D #Exxc051 - PT - Kai-Tabang - HM3076Document9 pagesReport P2u XCMG 800D #Exxc051 - PT - Kai-Tabang - HM3076Dedy DarmansyahNo ratings yet

- Ground Engaging Tools For Contruction PEBJ0078Document66 pagesGround Engaging Tools For Contruction PEBJ0078Jorge Aguado100% (2)

- HO 03 03 KTPK EvaluationDocument15 pagesHO 03 03 KTPK EvaluationMARIO DEL PINO MUÑOZNo ratings yet

- HO 02 01 KTPK Components OverviewDocument39 pagesHO 02 01 KTPK Components OverviewMARIO DEL PINO MUÑOZNo ratings yet

- VR 762000Document1 pageVR 762000aleruhoNo ratings yet

- Introduction and General Servicing Machine SafetyDocument17 pagesIntroduction and General Servicing Machine SafetyMARIO DEL PINO MUÑOZNo ratings yet

- Sprocket KOB SK200 Mark VI SI881 - GeometriaDocument1 pageSprocket KOB SK200 Mark VI SI881 - GeometriaaleruhoNo ratings yet

- Hydraulic Filter - Wheel Loader Komatsu Wa20-1 - Work Equipment Control System 777partsDocument2 pagesHydraulic Filter - Wheel Loader Komatsu Wa20-1 - Work Equipment Control System 777partsashraf elsayedNo ratings yet

- QRF HB205+HB215Document2 pagesQRF HB205+HB215Ralf MaurerNo ratings yet

- NO Brand Description Part No QTY 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30Document6 pagesNO Brand Description Part No QTY 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30BARIŞNo ratings yet

- HO 02 02 KTPK Wear Mechanism OkDocument31 pagesHO 02 02 KTPK Wear Mechanism OkMARIO DEL PINO MUÑOZ100% (1)

- Undergraund MiningDocument60 pagesUndergraund MiningVictor SagredoNo ratings yet

- BYG Teeth Cat Side Pin TeethDocument12 pagesBYG Teeth Cat Side Pin TeethteicooyNo ratings yet

- P 16 SeriesDocument17 pagesP 16 SeriesJas SumNo ratings yet

- 61 PDF FR PDFDocument4 pages61 PDF FR PDFRyan Abubakar Obili PakayaNo ratings yet

- A Es CatalogDocument17 pagesA Es CatalogAten HarisNo ratings yet

- 22-Stu-0039-Pt - Ppa Site Banjar-Modifikasi Bucket Pc2000 Kap 12ton Jadi 14tonDocument2 pages22-Stu-0039-Pt - Ppa Site Banjar-Modifikasi Bucket Pc2000 Kap 12ton Jadi 14tonVenk KisaragiNo ratings yet

- Generator FiltratDocument2 pagesGenerator FiltratArtin HykoNo ratings yet

- Maxon GP 42 CDocument2 pagesMaxon GP 42 CElectromateNo ratings yet

- Hce - hx210hd & Hx220hdDocument11 pagesHce - hx210hd & Hx220hdRivandho AnangNo ratings yet

- Calenturitas Mining Equipment Population - February 2019Document11 pagesCalenturitas Mining Equipment Population - February 2019Jose luis ConsuegraNo ratings yet

- Bottom Price Uc Genuine Q3 2014Document3 pagesBottom Price Uc Genuine Q3 2014elmanNo ratings yet

- Lista PerkinsDocument21 pagesLista PerkinsandrelovisiNo ratings yet

- No. Tolse Type Description Location Model: Skid BacketsDocument2 pagesNo. Tolse Type Description Location Model: Skid Backetsحاتم الصادقNo ratings yet

- Copy of 9.22船 EPA申請リストDocument140 pagesCopy of 9.22船 EPA申請リストRiotaNo ratings yet

- 31.2003 Cat Replacement Catalog MergedDocument4 pages31.2003 Cat Replacement Catalog MergedHerlan GarciaNo ratings yet

- CTHP763304: Idler 1 Weight: 164 KGDocument2 pagesCTHP763304: Idler 1 Weight: 164 KGchinhNo ratings yet

- CTP Water PumpsDocument4 pagesCTP Water PumpsMert KaygusuzNo ratings yet

- Hydraulics IOEDocument169 pagesHydraulics IOEEr. Satya Narayan ShahNo ratings yet

- Tiger 690 Conversion PDFDocument8 pagesTiger 690 Conversion PDFGerardo Esteban Lagos RojasNo ratings yet

- CM20190228 43314 16908 PDFDocument325 pagesCM20190228 43314 16908 PDFEduardo Ariel Bernal100% (1)