Professional Documents

Culture Documents

Welcome in Any Port

Uploaded by

mattiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welcome in Any Port

Uploaded by

mattiaCopyright:

Available Formats

Welcome In Any Port

RELIABLE, LONG LASTING

ENVIRONMENTALLY FRIENDLY

MARINE BEARING SYSTEMS

Reliability, long wear life and superior customer

service have made Thordon the first choice for

pollution free propeller shaft, rudder, deck

equipment, and offshore bearing solutions in

repair, conversion and new build projects.

Today, with over 25 years of marine

installations documented, Thordon marine

bearing systems are the proven,

reliable, pollution free solution for

ship owners, managers and yards

who demand the best.

PIONEERS IN

WATER LUBRICATED

BEARING TECHNOLOGY

Thordon Bearings, a pioneer in the development of grease and

oil free elastomeric polymer bearing systems, offers a choice of

environmentally friendly journal bearing solutions for propeller shaft,

rudder, pump, offshore oil, dredge and other deck equipment

applications. Our applications engineering and global technical support

work closely with you to provide innovative bearing solutions that meet or

exceed the technical requirements of the application.

With Thordon bearings specified all around the world, an extensive

distribution network has been established in over 70 countries. Thordon

Technical Services department and factory trained distributors can provide you

with assistance, product and installation support.

SHIP OWNER BENEFITS

ZERO POLLUTION RISK: PROVEN LONG

Eliminate grease or oil BEARING WEAR LIFE:

Lower life cycle costs

HIGH ABRASION RESISTANCE:

Operate in dirty abrasive SURVIVABILITY:

environments Non-catastrophic failure mode

ELASTOMERIC BEARING: GLOBAL AVAILABILITY:

Withstands shock loads Technical support and inventory

and edge loading

Rudder Bearing Water Lubricated Sealed Stern Tube

Systems Propellor Shaft Bearings Bearings

After 25 years of ongoing product Open, water lubricated The Thor-Lube stern tube bearing system

improvements and over 4,000 rudder bearing choices include features Thordon XL bearings, TL3G

bearings installed worldwide, Thordon is Thordon COMPAC, SXL, biodegradable lubricant and 5000 Series

boldly re-confirming the confidence in the XL and Composite; lubricant circulation and monitoring system.

performance of SXL rudder bearings by each offering specific Water-based TL3G lubricant is highly soluble

increasing the wear life guarantee from 10 advantages in different in water and conforms to the United States

to 15 years for newbuilds. Thordon SXL self water environments and Clean Water Act under these parameters: i) it

lubricating rudder bearings offer total operating conditions. is readily biodegradable to a level greater

freedom from grease for all rudder bearing From cruise ships to than 70% after 28 days; ii) it exhibits water

applications above and below the bulkers to workboats, a solubility at all compositions, so it will not

waterline. In addition to SXL pintle, stock long list of propeller accumulate on the shoreline or settle in

and carrier disc bearings, SXL TRAXL or shaft bearing references continue to prove clumps; iii) it does not form a surface sheen

Thordon’s new thermoplastic product that Thordon bearings provide the lowest and iv) it is “relatively harmless” and

ThorPlas® can be specified grease free in overall life cycle operating costs and “practically non-toxic” in two U.S.

steering and linkage applications, as well increased propulsion system reliability. Environmental Protection Agency (EPA)

as fin stabilizers. Completing the rudder marine toxicity tests as certified by

bearing package, self lubricating Thorseals Water Lubricated Environment Canada’s Environmental

provide positive sealing and exceptional Bearing Benefits: Technology Verification (ETV) program.

wear life as a rudder stock seal. • Zero pollution risk

• Proven long

Thor-Lube Benefits:

SXL Rudder Bearing Benefits: bearing wear life • TL3G water-based lubricant

• Industry leading wear life guarantee • Survivability –

■ Leaves no sheen

■ Newbuild: 15 years ■ “Readily biodegradable”

non-catastrophic

■ Conversion: twice the life of replaced ■ “Practically non-toxic”

failure mode

bearing (max. 10 years) per EPA marine toxicity test

• High natural ■ Viscosity similar to SAE30 oil

• Dry or water lubrication eliminates wear resistance

greasing systems • Proven bearing wear life

• Easily maintained and fitted

• Ability to withstand shock • Emergency operation on seawater

loading and vibration • Survivability – non-catastrophic

failure mode

Dredge Bearing Offshore Oil Deck Equipment

Applications Applications

Thordon Composite Thordon bearing system solutions are There are a number

has been consistently being designed into oil platform and FPSO of deck equipment

outperforming rubber vessel applications applications where

in dredge cutterhead where reliability, long outstanding wear life

bearing applications life, low friction and and machinability of

since it was first non-polluting grease Thordon or ThorPlas®

introduced in the free operation are of provide significant

1970’s. Composite key importance. Some advantages to the

bearing wear rates in dirty abrasive typical applications ship owner. Fairlead bushings, sheave

conditions are typically half that of rubber where Thordon has bushings, pivot bushings and davit bearings

bearings reducing maintenance downtime become the bearing of choice include are deck equipment applications where

over the life of the vessel. Thordon also FPSO mooring and rotation equipment, Thordon has developed solutions to replace

supplies grease free ladder trunnion turret and slewing systems, AHTS stern bronze bearings and eliminate grease.

and water lubricated roller bearings and seals, riser tubes, net

drive shaft bearings catchers and fire pumps. Thor-Coat Shaft Coating:

for dredge vessels.

Offshore Oil Benefits:

Composite • Proven bearing wear life

Benefits: • Dry or water lubricated – no grease

• Proven bearing wear • Low friction

life – at least twice the life

• Ability to withstand shock loading

of rubber

and vibration

• Reduced maintenance down time

• Easy installation

• Water lubricated – no grease

• Easy installation

Thor-Coat was specifically developed to

complement Thordon’s COMPAC water

lubricated propeller shaft bearing system by

providing shaft corrosion protection for a ten

year period in service. A toughened, 2-part

epoxy coating, Thor-Coat is three to nine

times more flexible than existing products

currently in use as propeller shaft coatings.

Customer Focused To Support

Your Immediate And Future Needs

Supply and Service: Geared to provide quick Manufacturing: Thordon’s modern Quality: Thordon Bearings Inc. is a

response to customer needs, Thordon polymer processing facility is staffed with Canadian company manufacturing to ISO

Bearings understands the importance of fast experienced and dedicated employees. 9001:2000 Quality System requirements.

delivery and reduced down time. Thordon Bearings up to 2.2 m (86") in diameter have With over 35 years experience in

marine bearing systems can be designed, been supplied and bearings up to 1.5 m elastomeric bearing design, application

produced to the exact requirements of the (60") O.D. can be machined in-house. engineering and manufacturing, Thordon

customer and shipped quickly. marine bearing systems are recognized

Distribution: With Thordon bearings worldwide for both quality and performance.

specified all around the world, an extensive Research and Development: Thordon

distribution network has been established in bearings are being continuously tested by our

over 70 countries. Inventories of common Bearing Test Facility. The Facility evaluates

bearing sizes are stocked by local Thordon new designs and applications before they are

Distributors and are backed up by large put into service. Ongoing testing not only

regional and head office Thordon stocks. allows for design refinements, but ensures

Application Engineering: Thordon quality and performance after installation.

Bearing’s engineers work closely with Our polymer laboratory evaluates new and

customers to provide innovative bearing modified polymers in a continuing quest to

system designs that meet or exceed the improve Thordon bearing performance and

technical requirements of the application. searches for new polymer bearing solutions.

Your local Thordon Distributor

3225 Mainway, Burlington, Ontario L7M 1A6 Canada

Tel: (905) 335-1440 Fax: (905) 335-4033

E-mail info@thordonbearings.com ISO 9001:2000

TMA4 12/04/6000 BC

CGSB

PRINTED IN CANADA www.thordonbearings.com Registration #93649

You might also like

- Sandvik SAF 2507: Duplex Stainless SteelDocument8 pagesSandvik SAF 2507: Duplex Stainless SteelmattiaNo ratings yet

- Sym-Metric Actuators: Cubic Worm Gear Actuators UK Designed and ManufacturedDocument6 pagesSym-Metric Actuators: Cubic Worm Gear Actuators UK Designed and ManufacturedmattiaNo ratings yet

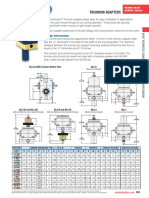

- Trunnion Adapters: Design InformationDocument1 pageTrunnion Adapters: Design InformationmattiaNo ratings yet

- Europe Germany France Italy Belgium Sweden U.K. Canada India Japan International USADocument1 pageEurope Germany France Italy Belgium Sweden U.K. Canada India Japan International USAmattiaNo ratings yet

- Sandvik SAF 2304: Duplex Stainless SteelDocument8 pagesSandvik SAF 2304: Duplex Stainless SteelmattiaNo ratings yet

- Aisi 316 L and Aluminium: Gas Springs Molle A GasDocument32 pagesAisi 316 L and Aluminium: Gas Springs Molle A GasmattiaNo ratings yet

- Process Pumps: Typical Fluids Pump UnitsDocument4 pagesProcess Pumps: Typical Fluids Pump UnitsmattiaNo ratings yet

- Self Blocking Rail ClampsDocument17 pagesSelf Blocking Rail ClampsmattiaNo ratings yet

- BallScrews and BallSplinesDocument160 pagesBallScrews and BallSplinesmattiaNo ratings yet

- Proven Water Lubricated Propeller Shaft Bearing Solutions: V IronDocument8 pagesProven Water Lubricated Propeller Shaft Bearing Solutions: V IronmattiaNo ratings yet

- Pluto Safety PLCDocument42 pagesPluto Safety PLCmattiaNo ratings yet

- Aisi 316 L: Operating Valves - Evax SerieDocument59 pagesAisi 316 L: Operating Valves - Evax SeriemattiaNo ratings yet

- Thordon Rudder BrochureDocument8 pagesThordon Rudder BrochuremattiaNo ratings yet

- Carcoseal AP/WT/RR. The Lip Is Designed So ThatDocument2 pagesCarcoseal AP/WT/RR. The Lip Is Designed So ThatmattiaNo ratings yet

- Thomson Precision Linear Actuators Sep06Document8 pagesThomson Precision Linear Actuators Sep06mattiaNo ratings yet

- Catene Rigide SerapidDocument19 pagesCatene Rigide SerapidmattiaNo ratings yet

- CarcosealunsfDocument2 pagesCarcosealunsfmattiaNo ratings yet

- Carcoseal AP / WT. The Lip Is Designed So That TheDocument2 pagesCarcoseal AP / WT. The Lip Is Designed So That ThemattiaNo ratings yet

- Carcoseal / UNDocument2 pagesCarcoseal / UNmattiaNo ratings yet

- Structural Analysis Using NX Nastran 9.0Document9 pagesStructural Analysis Using NX Nastran 9.0mattiaNo ratings yet

- Materials: Bending and Buckling of Circular Sandwich Plates With A Hardened CoreDocument14 pagesMaterials: Bending and Buckling of Circular Sandwich Plates With A Hardened CoremattiaNo ratings yet

- Ramnäs Quality Chains and AccessoriesDocument13 pagesRamnäs Quality Chains and AccessoriesmattiaNo ratings yet

- 74 25 Stress NEWDocument9 pages74 25 Stress NEWmattiaNo ratings yet

- The Iraqi Journal For Mechanical and Material Engineering, Vol.12, No.2, 2012Document18 pagesThe Iraqi Journal For Mechanical and Material Engineering, Vol.12, No.2, 2012mattiaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Benefits of The Multiple Echo Technique For Ultrasonic Thickness TestingDocument10 pagesBenefits of The Multiple Echo Technique For Ultrasonic Thickness TestingMahdi HocineNo ratings yet

- Slewing Bearing Installation and Maintenance Manual: Yantai Haoyang Machinery Co.,LtdDocument22 pagesSlewing Bearing Installation and Maintenance Manual: Yantai Haoyang Machinery Co.,Ltddony ramdhaniNo ratings yet

- Catalog - Oilfield Bits - EN - 170124 PDFDocument48 pagesCatalog - Oilfield Bits - EN - 170124 PDFaznilNo ratings yet

- Mir Azhar Fayaz Pre ThesisDocument22 pagesMir Azhar Fayaz Pre Thesismirazhar7006No ratings yet

- Positive Displacement Pumps - 10 Steps To SelectDocument8 pagesPositive Displacement Pumps - 10 Steps To SelectNilesh GohelNo ratings yet

- UTP CementDocument56 pagesUTP CementbrayanNo ratings yet

- KOWA Basics of Oil Analysis Booklet 2020Document32 pagesKOWA Basics of Oil Analysis Booklet 2020AbdoNo ratings yet

- Surfacing Caster RollersDocument3 pagesSurfacing Caster Rollersdneprmt1No ratings yet

- Cylinder Lubrication UpdateDocument9 pagesCylinder Lubrication UpdatetuyenhienchilinhNo ratings yet

- Industrial TribologyDocument2 pagesIndustrial Tribologygurudev001No ratings yet

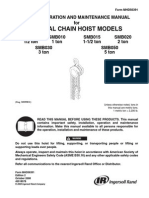

- Chain Pulley-Manual PDFDocument20 pagesChain Pulley-Manual PDFChristina ParkerNo ratings yet

- Advanced Manufacturing Techniques PDFDocument306 pagesAdvanced Manufacturing Techniques PDFLEAR to lear IndustriesNo ratings yet

- Mqa CepDocument8 pagesMqa Cepfaryad artist100% (1)

- PDC Bits CourseDocument76 pagesPDC Bits CourseRobert Koch100% (1)

- Mechanical Seal TroubleshootingDocument38 pagesMechanical Seal TroubleshootingKasih Azalia TeknindoNo ratings yet

- GL XX Mobil Jet Oil IIDocument3 pagesGL XX Mobil Jet Oil IIamirsoheilgooyavarNo ratings yet

- Pipeline Pigging (Visit http://Piping-Info - Blogspot.com)Document33 pagesPipeline Pigging (Visit http://Piping-Info - Blogspot.com)Antoshal100% (7)

- Bio Mechanics of The Articular CartilageDocument64 pagesBio Mechanics of The Articular CartilagedrhemangNo ratings yet

- JPS Reliability Bearing FailuresDocument14 pagesJPS Reliability Bearing FailuresAnonymous Bdt0OGh100% (1)

- D 968 - 93 - Rdk2oc05mwDocument4 pagesD 968 - 93 - Rdk2oc05mwuocmogiandi_aNo ratings yet

- 01-B - Centrifugal PumpsDocument44 pages01-B - Centrifugal Pumps81q1iyNo ratings yet

- Aggregate Impact Test, Ten Percent Fines TestDocument6 pagesAggregate Impact Test, Ten Percent Fines TestEmrePınarcı75% (4)

- Lubrication Solutions Mining and Heavy IndustryDocument40 pagesLubrication Solutions Mining and Heavy IndustryJako MishyNo ratings yet

- Mobil GreaseDocument2 pagesMobil Greasejohn doeNo ratings yet

- Vylon Plus Brochure PDFDocument4 pagesVylon Plus Brochure PDFFloorkitNo ratings yet

- Afton Industrial Overview Booklet 2019Document11 pagesAfton Industrial Overview Booklet 2019Clairin LohNo ratings yet

- Vol2Document508 pagesVol2red100% (2)

- Kiln LiningDocument39 pagesKiln LiningMUNNALURU UMAKANTHA RAO100% (1)

- 002 DEW Warmarbeitsstahl GB PDFDocument76 pages002 DEW Warmarbeitsstahl GB PDFSinan Yıldız100% (1)

- DSMTS-0072.5 Cr2O3Document4 pagesDSMTS-0072.5 Cr2O3Remco van den BergNo ratings yet